Transcription

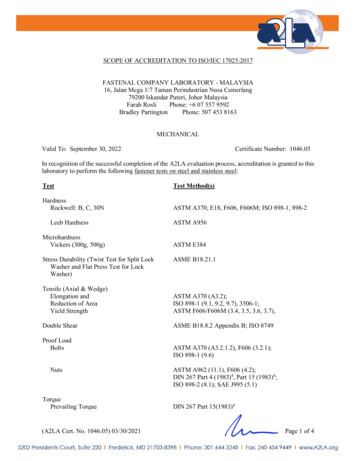

SCOPE OF ACCREDITATION TO ISO/IEC 17025:2017FASTENAL COMPANY LABORATORY - MALAYSIA16, Jalan Mega 1/7 Taman Perindustrian Nusa Cemerlang79200 Iskandar Puteri, Johor MalaysiaFarah RosliPhone: 6 07 557 9592Bradley PartingtonPhone: 507 453 8163MECHANICALValid To: September 30, 2022Certificate Number: 1046.05In recognition of the successful completion of the A2LA evaluation process, accreditation is granted to thislaboratory to perform the following fastener tests on steel and stainless steel:TestTest Method(s)HardnessRockwell: B, C, 30NASTM A370, E18, F606, F606M; ISO 898-1, 898-2Leeb HardnessMicrohardnessVickers (300g, 500g)Stress Durability (Twist Test for Split LockWasher and Flat Press Test for LockWasher)ASTM A956ASTM E384ASME B18.21.1Tensile (Axial & Wedge)Elongation andReduction of AreaYield StrengthASTM A370 (A3.2);ISO 898-1 (9.1, 9.2, 9.7), 3506-1;ASTM F606/F606M (3.4, 3.5, 3.6, 3.7),Double ShearASME B18.8.2 Appendix B; ISO 8749Proof LoadBoltsNutsTorquePrevailing Torque(A2LA Cert. No. 1046.05) 03/30/2021ASTM A370 (A3.2.1.2), F606 (3.2.1);ISO 898-1 (9.6)ASTM A962 (11.1), F606 (4.2);DIN 267 Part 4 (1983)4, Part 15 (1983)4;ISO 898-2 (8.1); SAE J995 (5.1)DIN 267 Part 15(1983)4Page 1 of 4

TestTest Method(s)DuctilityASME B18.6.3, IFI Evaluating Stainless Screw onTapping ScrewTorsional StrengthSAE J78, J933Charpy Impact StrengthASTM A370, E23; ISO 148-1DecarburizationASTM F835, F912, F2328; ISO 898-1, 898-5;SAE J121 (1997)4, J419Case DepthSAE J423Discontinuity (External Thread Acceptance)ASTM F788(2008)4, F788MSalt SprayASTM B117; ISO 9227Plating ThicknessASTM B499XRF PMI AnalyzerNiton Alloy Analyzer User’s GuideSurface RoughnessASME Y14.5(A2LA Cert. No. 1046.05) 03/30/2021Page 2 of 4

Dimensional Testing1:ParameterThreads3RangeCMC2 ( )Technique / Method#3 to 2 inM2.5 to M27N/ARings /System 21 ASME B1.3M,ASME B1.16MUp to 2 in0.00083 inPitch micrometer/System 22 ASME B1.3M#4 to 1-1/2 inM3 to M27N/APlug gages / System 21 ASME B1.3M,ASME B1.16M1/2 in to 2 in ACMERing Gages, 2G / ASME B1.51/4 in to 3/4 in NPT L1Ring Gages, Class 1 / ASME B1.20.5Up to 2 in.0035 inThree-Wires / ASME B1.5Up to 3 in0.00016 inOutside micrometers / MIL-STD-120(1950)4Up to 6 in0.0015 inCalipers / MIL-STD-120 (1950)4Up to 2 in0.00065 inDigital indicator / ASME B18.2.1Up to 12 in0.0014 inLength gage / MIL-STD-120 (1950)4Up to 24 in0.0017 inHeight gage / MIL-STD-120 (1950)4Linear3 2Dx axis: Up to 11.77 iny axis: Up to 7.87 in0.00074 in0.00081 inVideo measurement / QA7M-114Angle30º to 180º0.09ºVideo measurement / QA7M-114Radii3Up to 3 in14 µmVideo measurement / QA7M-114Linear3 1D(A2LA Cert. No. 1046.05) 03/30/2021Page 3 of 4

ParameterRangeCMC2 ( )Technique / MethodRecessPenetration3Hex: 5/64 to 3/8 in2 to 10 mmPhilips: #1, #2, #3SlotPinTorx (6-lobe): T-20 – T-40Square: #00 – #40.0020 inRecess penetration gage /ASME B18.6.3, B18.6.4 (1998)4Wobble3Phillips #2, #30.58ºWobble gage / ASME B18.6.4 (1998)4Flat Head3Up to 3/8 in0.00065 inProtrusion gage / ASME B18.6.3,B18.6.4 (1998)4Runout,Concentricity& FIM testUp to 0.19”0.0013 inDial indicator and fixture, Zoomscope /ASME B18.3, 18.2.2; ISO 4759-1Commercial dimensional testing service is sometimes available for this laboratory.1Calibration and Measurement Capability Uncertainty (CMC) is the smallest uncertainty of measurementthat a laboratory can achieve within its scope of accreditation when performing more or less routinemeasurements of nearly ideal measurement standards or nearly ideal measuring equipment. CMC’srepresent expanded uncertainties expressed at approximately the 95 % level of confidence, usually using acoverage factor of k 2. The actual measurement uncertainty of a specific measurement performed bythe laboratory may be greater than the CMC due to the behavior of the customer’s device and toinfluences from the circumstances of the specific measurement.23This test is not equivalent to that of a calibrationThis laboratory’s scope contains withdrawn or superseded methods. As a clarifier, this indicates that theapplicable method itself has been withdrawn or is now considered “historical” and not that the laboratory’saccreditation for the method has been withdrawn.4(A2LA Cert. No. 1046.05) 03/30/2021Page 4 of 4

Accredited LaboratoryA2LA has accreditedFASTENAL COMPANY LABORATORY-MALAYSIAJohor, Malaysiafor technical competence in the field ofMechanical TestingThis laboratory is accredited in accordance with the recognized International Standard ISO/IEC 17025:2017General requirements for the competence of testing and calibration laboratories. This accreditation demonstratestechnical competence for a defined scope and the operation of a laboratory quality management system(refer to joint ISO-ILAC-IAF Communiqué dated April 2017).Presented this 30th day of March 2021.Vice President, Accreditation ServicesFor the Accreditation CouncilCertificate Number 1046.05Valid to September 30, 2022For the types of tests to which this accreditation applies, please refer to the laboratory’s Mechanical Scope of Accreditation.

Ring Gages, Class 1 / ASME B1.20.5 . Three-Wires / ASME B1.5 . Linear. 3. 1D . Up to 3 in . Up to 6 in . Up to 2 in . Up to 12 in . Up to 24 in . 0.00016 in . 0.0015 in . 0.00065 in . 0.0014 in . 0.0017 in . Outside micrometers / MIL-STD-120 (1950) 4 . Calipers / MIL-STD-120 (1950) 4. Digital indicator / ASME B18.2.1 . Length gage / MIL-STD-120 (1950) 4. Height gage / MIL-STD-120 (1950) 4 .