Transcription

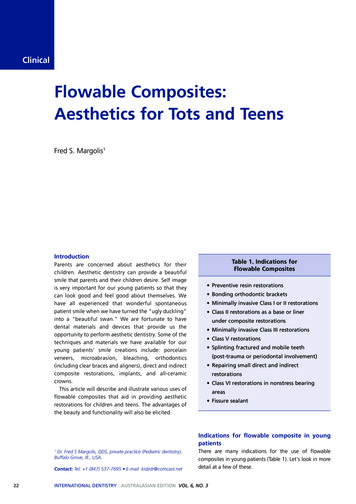

Composite Materials Handbook Volume 1CMH-17Polymer Matrix Composites: Guidelines forCharacterization of Structural MaterialsThe Composite Materials Handbook, referred to by industry groups as CMH-17, is a sixvolume engineering reference tool that contains over 1,000 records of the latest test datafor polymer matrix, metal matrix, ceramic matrix, and structural sandwich composites.CMH-17 provides information and guidance necessary to design and fabricate enditems from composite materials. It includes properties of composite materials that meetspecific data requirements as well as guidelines for design, analysis, material selection,manufacturing, quality control, and repair.The primary purpose of the handbook is to standardize engineering methodologiesrelated to testing, data reduction, and reporting of property data for current and emergingcomposite materials. It is used by engineers worldwide in designing and fabricatingproducts made from composite materials.R-422Volume1Polymer Matrix Composites: Guidelines for Characterization of Structural MaterialsThe first volume of this six-volume compendium contains guidelines for determiningthe properties of polymer matrix composite material systems and their constituents,as well as the properties of generic structural elements, including test planning, testmatrices, sampling, conditioning, test procedure selection, data reporting, data reduction,statistical analysis, and other related topics. Special attention is given to the statisticaltreatment and analysis of data. Volume 1 contains guidelines for general development ofmaterial characterization data as well as specific requirements for publication of materialdata in CMH-17.COMPOSITE MATERIALS HANDBOOKPolymer MatrixComposites: Guidelinesfor Characterization ofStructural MaterialsVolume1

CMH-17-1GVolume 1, Foreword / Table of ContentsTABLE OF CONTENTSPageFOREWORD . iiSUMMARY OF CHANGES . xxiCHAPTER 1GENERAL INFORMATION .11.11.21.31.4INTRODUCTION TO THE HANDBOOK .1OVERVIEW OF HANDBOOK CONTENT .1PURPOSE AND SCOPE OF VOLUME 1.2USE OF THE DOCUMENT AND LIMITATIONS .41.4.1 Roadmaps for use of Volumes 1 - 3.41.4.2 Source of information .161.4.3 Use of data and guidelines in applications .161.4.4 Strength properties and allowables terminology .161.4.5 Use of references .161.4.6 Use of tradenames and product names .171.4.7 Toxicity, health hazards, and safety .171.4.8 Ozone depleting chemicals .171.5APPROVAL PROCEDURES .171.6MATERIAL ORIENTATION CODES .181.6.1 Laminate orientation codes .181.6.1.1 Stacking sequence notation .181.6.1.2 Ply percentage notation.201.6.2 Braiding orientation codes .211.7SYMBOLS, ABBREVIATIONS, AND SYSTEMS OF UNITS.211.7.1 Symbols and abbreviations .211.7.1.1 Constituent properties .261.7.1.2 Laminae and laminates .271.7.1.3 Subscripts.281.7.1.4 Superscripts.291.7.1.5 Acronyms.291.7.2 System of units .311.8DEFINITIONS .32REFERENCES .56CHAPTER 2GUIDELINES FOR PROPERTY TESTING OF COMPOSITES .12.1INTRODUCTION .12.1.1 Building-block approach to substantiation of composite structures .12.1.2 Test levels and data uses.22.1.2.1 Structural complexity levels.22.1.2.2 Data application categories .32.1.2.3 Test program definition.42.2TEST PROGRAM PLANNING.52.2.1 Overview.52.2.2 Baseline and alternate approaches for statistically-based properties .62.2.3 Issues of data equivalence .62.2.4 Test method selection .72.2.5 Population sampling and sizing.112.2.5.1 Sample size selection.112.2.5.2 Batch quantity effects on ANOVA .122.2.6 Material and processing variation, specimen preparation and NDE .132.2.6.1 Materials and material processing.13iv

CMH-17-1GVolume 1, Foreword / Table of ContentsTABLE OF CONTENTSPage2.2.6.2 Specimen preparation and NDE.16Moisture absorption and conditioning factors.162.2.7.1 Moisture diffusivity .182.2.7.2 Moisture equilibrium content .182.2.7.3 Conditioning and test environment.202.2.8 Material operational limit (MOL) .202.2.8.1 Steam pressure delamination.242.2.8.2 MOL considerations for high temperature composite systems .242.2.8.3 Hot wet testing - report moisture content at failure .272.2.9 Nonambient testing.292.2.10 Space environmental effects on material properties .292.2.10.1 Introduction.292.2.10.2 Atomic oxygen .292.2.10.3 Micrometeoroid debris .302.2.10.4 Ultraviolet radiation.302.2.10.5 Charged particles .302.2.11 Unidirectional lamina properties from laminates .312.2.12 Data normalization.312.2.13 Data documentation .312.2.14 Application specific testing needs .322.3RECOMMENDED TEST MATRICES .332.3.1 Material screening test matrices.332.3.1.1 Mechanical property screening .332.3.1.2 Mechanical property screening for high-temperature material systems .342.3.1.3 Fluid sensitivity screening .352.3.2 Material qualification and lamina basis values test matrices.402.3.2.1 Constituent test matrix.402.3.2.2 Prepreg test matrix .402.3.2.3 Lamina test matrices .412.3.2.4 Alternate approaches for lamina basis values .422.3.2.5 Filament-wound materials test matrix.472.3.3 Material acceptance test matrices.482.3.4 Alternate material equivalence test matrices .492.3.4.1 Qualification of alternate source composite materials.492.3.4.1.1 Introduction .492.3.4.1.2 Goal and approach .492.3.4.1.3 Material compatibility .502.3.4.1.4 Key material or structural performance parameters .502.3.4.1.5 Success criteria.502.3.4.1.6 Lamina-level test matrices for alternate material assessment.522.3.4.1.7 Laminate-level test matrices for alternate material assessment.552.3.4.2 Evaluation of changes made to previously qualified materials .552.3.4.2.1 Modification categories .572.3.4.2.2 Actions required for each modification category.572.3.4.2.3 Implementation.582.3.4.2.4 Validation test matrices .582.3.5 Generic laminate/structural element test matrices .632.3.5.1 Introduction.632.3.5.2 Suggested unnotched laminate strength test matrix .652.3.5.3 Suggested open-hole laminate strength test matrix.672.3.5.4 Suggested filled-hole laminate strength test matrix .672.3.5.5 Overview of mechanically-fastened joint testing .722.3.5.5.1 Failure modes .722.3.5.5.2 Bearing/bypass interaction effects .722.3.5.5.3 Effects of thickness/gaps/shimming.732.2.

The primary purpose of the handbook is to standardize engineering methodologies related to testing, data reduction, and reporting of property data for current and emerging composite materials. It is used by engineers worldwide in designing and fabricating products made from composite materials. Polymer Matrix Composites: Guidelines for