Transcription

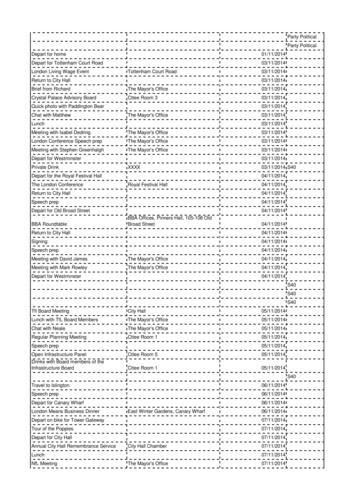

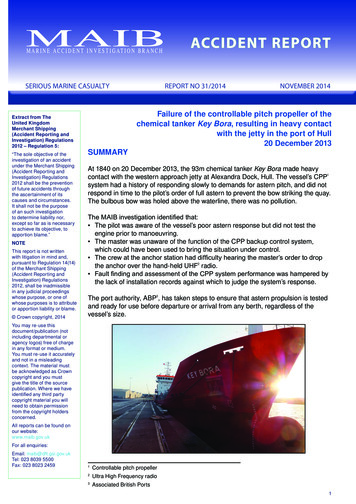

M A R I N E A C C I D E N T I N V E S T I G AT I O N B R A N C HSERIOUS MARINE CASUALTYNOTEThis report is not writtenwith litigation in mind and,pursuant to Regulation 14(14)of the Merchant Shipping(Accident Reporting andInvestigation) Regulations2012, shall be inadmissiblein any judicial proceedingswhose purpose, or one ofwhose purposes is to attributeor apportion liability or blame. Crown copyright, 2014REPORT NO 31/2014NOVEMBER 2014Failure of the controllable pitch propeller of thechemical tanker Key Bora, resulting in heavy contactwith the jetty in the port of Hull20 December 2013Extract from TheUnited KingdomMerchant Shipping(Accident Reporting andInvestigation) Regulations2012 – Regulation 5:“The sole objective of theinvestigation of an accidentunder the Merchant Shipping(Accident Reporting andInvestigation) Regulations2012 shall be the preventionof future accidents throughthe ascertainment of itscauses and circumstances.It shall not be the purposeof an such investigationto determine liability nor,except so far as is necessaryto achieve its objective, toapportion blame.”ACCIDENT REPORTSUMMARYAt 1840 on 20 December 2013, the 93m chemical tanker Key Bora made heavycontact with the western approach jetty at Alexandra Dock, Hull. The vessel’s CPP1system had a history of responding slowly to demands for astern pitch, and did notrespond in time to the pilot’s order of full astern to prevent the bow striking the quay.The bulbous bow was holed above the waterline, there was no pollution.The MAIB investigation identified that: The pilot was aware of the vessel’s poor astern response but did not test theengine prior to manoeuvring. The master was unaware of the function of the CPP backup control system,which could have been used to bring the situation under control. The crew at the anchor station had difficulty hearing the master’s order to dropthe anchor over the hand-held UHF2 radio. Fault finding and assessment of the CPP system performance was hampered bythe lack of installation records against which to judge the system’s response.The port authority, ABP3, has taken steps to ensure that astern propulsion is testedand ready for use before departure or arrival from any berth, regardless of thevessel’s size.You may re-use thisdocument/publication (notincluding departmental oragency logos) free of chargein any format or medium.You must re-use it accuratelyand not in a misleadingcontext. The material mustbe acknowledged as Crowncopyright and you mustgive the title of the sourcepublication. Where we haveidentified any third partycopyright material you willneed to obtain permissionfrom the copyright holdersconcerned.All reports can be found onour website:www.maib.gov.ukFor all enquiries:Email: maib@dft.gsi.gov.ukTel: 023 8039 5500Fax: 023 8023 24591Controllable pitch propeller2Ultra High Frequency radio3Associated British Ports1

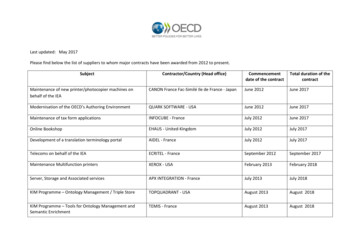

The vessel’s manager, V.Ships, has been recommended to investigate and rectify the anomaly withthe CPP system on Key Bora and to include in its safety management system a requirement for bridgewatchkeeping officers to familiarise themselves with the emergency backup control of their CPP system.Following a recommendation from the chief inspector, BV4 has requested IACS5 to include responsetimes in its forthcoming unified requirement for commissioning trials on CPP systems.FACTUAL INFORMATIONBackgroundKey Bora had visited the Humber on many occasions and, following a call at Hull in November 2010, thepilot had made an entry on the port’s Pilot and Vessel Information System (PAVIS) stating that the vesselhad very slow astern power. The vessel was in Rotterdam in December 2013 when Key Bora’s masterwas replaced by a new master who had not worked on the vessel before. During the handover from hispredecessor, the new master was informed that the astern response of the CPP was very slow, and whilestill in Rotterdam he experienced a near collision due to hat performance standards are available totechnical staff responsible for monitoring the systems.2014/152Improve the effectiveness of the safety management systems on board the vessels underits management by: Requiring ships’ crews to carry out periodic drills to practise the correct responseto propulsion system failures and regularly test the associated backup controlsystems. Ensuring that all communication systems are functioning and used appropriately.Safety recommendations shall in no case create a presumption of blame or liability11

SHIP PARTICULARSVessel’s nameKey BoraFlagGibraltarClassification societyBureau VeritasIMO number/fishing numbers9216024TypeChemical tankerRegistered ownerKey Shipping AS, NorwayManager(s)V.Ships UK LtdYear of build2006ConstructionSteelLength overall86.9mGross tonnage2627Minimum safe manning10Authorised cargoType 2 chemicalsVOYAGE PARTICULARSPort of departureRotterdamPort of arrivalHullType of voyageShort InternationalCargo informationBallastManning12MARINE CASUALTY INFORMATION12Date and time20 December 2014, 1840Type of marine casualty or incidentSerious Marine CasualtyLocation of incidentWest Approach jetty: Alexander dock, HullInjuries/fatalitiesNoneDamage/environmental impactBulbous bow breached above waterline, damage tojetty fenders and piling / noneShip operationManoeuvringVoyage segmentArrivalExternal & internal environmentSoutherly force 5, visibility good, tidal stream 2.2ktsflood, high tide 1952Persons on board12

The master was unaware of the function of the CPP backup control system, which could have been used to bring the situation under control. . Propulsion system Key Bora had an MaK 6 M 25 main propulsion engine and a KH 960 CPP system manufactured by ZF Marine7. The propeller shaft and shaft generator were driven through a common gear train .