Transcription

Important User InformationBecause of the variety of uses for the products described in thispublication, those responsible for the application and use of this controlequipment must satisfy themselves that all necessary steps have been takento assure that each application and use meets all performance and safetyrequirements, including any applicable laws, regulations, codesand standards.The illustrations, charts, sample programs and layout examples shown inthis guide are intended solely for example. Since there are many variablesand requirements associated with any particular installation, Allen-Bradleydoes not assume responsibility or liability (to include intellectual propertyliability) for actual use based upon the examples shown in this publication.Allen-Bradley publication SGI-1.1, “Safety Guidelines For TheApplication, Installation and Maintenance of Solid State Control”(available from your local Allen-Bradley office) describes some importantdifferences between solid-state equipment and electromechanical deviceswhich should be taken into consideration when applying products such asthose described in this publication.Reproduction of the contents of this copyrighted publication, in whole orin part, without written permission of Allen-Bradley Company, Inc.is prohibited.Throughout this manual we make notes to alert you to possible injury topeople or damage to equipment under specific circumstances.ATTENTION: Identifies information about practices orcircumstances that can lead to personal injury or death, propertydamage or economic loss.Attention helps you:Identify a hazard.Avoid the hazard.Recognize the consequences.Important: Identifies information that is especially important forsuccessful application and understanding of the product.Important: We recommend you frequently backup your applicationprograms on appropriate storage medium to avoid possible data loss.

Summary of Changes This release of the publication contains updated information from thelast release.Updated InformationThis publication covers the Series B version of the Analog Outputmodule.In addition, this version of the manual contains informationformally included in publication 1771-6.5.30–RN1, dated December1995.A revised circuit board layout has the configuration jumpersrelocated from previous versions. Access holes are included in theside cover so that covers no longer have to be removed to adjust thejumpers or potentiometers.The module also contains information on “Compliance to EuropeanUnion Directives.”Change BarsTo help you find new and updated information in this release of thepublication, we have included change bars as shown to the right ofthis paragraph.

SOC-2Summary of Changes

Manual's PurposeThis manual shows you how to use the analog output module with anAllen-Bradley programmable controller. It describes methods forinstalling, programming, calibrating, and troubleshooting yourmodule.AudienceTo make efficient use of your module, you must be able to programand operate an Allen-Bradley programmable controller. Inparticular, you must be able to program block transfer instructions.In this manual we assume that you know how to do this. If you donot, refer to the appropriate programming and operations manual forthe processor that you are using.VocabularyIn this manual we refer to the: Analog Output Module (cat. no. 1771-OFE) as the “outputmodule” Programmable Controller as the “processor” or “controller.”Manual OrganizationThe manual is divided into seven chapters. The following chartshows each chapter with its corresponding title and a brief overviewof the topics covered in that chapter.ChapterTitleTopics Covered1Overview of the Analog OutputModuleDescription of the module, including general andhardware features. How modules communicate withprogrammable controllers2Module InstallationPower requirements, keying, module location and hardĆware configuration3Module ConfigurationSoftware configurations, output range selection, dataformat and data scaling4Module ProgrammingWriting data to the module, and other programmingconsiderations (default block length, block transferboundary word, and watchdog timer)5Module Status and Input DataReading data from the module6Calibrating Your Output ModuleCalibration procedures7Diagnostics and TroubleshootingTroubleshooting Guide for problem diagnosisPublication 1771Ć6.5.30 - November 1998

P–2PrefaceAppendicesRelated ProductsTitleASpecificationsBBlock Transfer with MiniĆPLCĆ2 and PLCĆ2/20 ProcessorsCData Table FormatsYou can install your output module in any system that usesAllen-Bradley programmable controllers that have block transfercapabilities and the 1771 I/O structure.For more information on your programmable controllers, contactyour nearest Allen-Bradley office.Product CompatibilityThe 1771-OFE module can be used with any 1771 I/O chassis.Communication between the discrete analog module and theprocessor is bidirectional; the processor block-transfers output datathrough the output image table to the module and block-transfersinput data from the module through the input image table. Themodule also requires an area in the data table to store the read blocktransfer data and write block transfer data. I/O image table use is animportant factor in module placement and addressing selection.Compatibility and data table use is listed in the following table.Table P.ACompatibility and Use of Data TableUse of Data esA, BA Compatible with 1771ĆA1, ĆA2, ĆA4B Compatible with 1771ĆA1B, ĆA2B, ĆA3B, ĆA3B1, ĆA4BY Compatible without restriction. You can place your module in any I/O module slot of the I/Ochassis. You can put two output modules in the same module group. Do not put the module in the same module group as a discretehigh density module. Avoid placing output modules close to ac modules or high voltagedc modules.Related PublicationsPublication 1771Ć6.5.30 - November 1998For a list of publications with information on Allen-Bradleyprogrammable controller products, consult our publication index(SD499).

Overview of the AnalogOutput ModuleChapter 1Module InstallationChapter 2 Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Module Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Module Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Output Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .How Analog Modules Communicate with Programmable ControllersAccuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Chapter Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Compliance toEuropean Union Directives . . . . . . . . . . . . . . . . . . . . . . . . . . .EMC Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Low Voltage Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Before You Install Your Analog Module . . . . . . . . . . . . . . . . . . . . .Calculating Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . .Determine Module Location in the I/O Chassis . . . . . . . . . . . . . . . .Setting Module Configuration Jumpers . . . . . . . . . . . . . . . . . . . . .Current Output Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Voltage Output Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Last State Configuration Jumpers . . . . . . . . . . . . . . . . . . . . . . .Setting Voltage Range Configuration Jumpers (1771ĆOFE1 only) .Installing the Analog Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Connecting Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Interpreting the Indicator Lights . . . . . . . . . . . . . . . . . . . . . . . . . . .Chapter Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Module -22-32-32-32-32-32-62-82-102-122-12Chapter 3Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Configuring Your Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Configuration Word . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Default Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Data Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Scaling Value Polarity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Maximum and Minimum Scaling Values . . . . . . . . . . . . . . . . . . .Procedure for Configuring Your Module . . . . . . . . . . . . . . . . . . . . .Chapter Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13-13-33-43-43-63-63-63-93-9Publication 1771Ć6.5.30 - November 1998

iiTable of ContentsModule ProgrammingChapter 4Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Block Transfer with the Analog Output Module . . . . . . . . . . . . . . . .Block Transfer Programming Formats . . . . . . . . . . . . . . . . . . . . . .Block Transfer Programming Ć PLCĆ2 Family Processors Only . . . . .Block Transfer Programming Ć PLCĆ3 Family Processors Only . . . . .Block Transfer Programming Ć PLCĆ5 Family Processors Only . . . . .Other Programming Considerations . . . . . . . . . . . . . . . . . . . . . . . .Block Length and Scaling Considerations . . . . . . . . . . . . . . . . .Block Transfer Boundary Word Ć PLCĆ2 Family Processors Only .Module Update Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .System Expansion Recommendations Ć PLCĆ2 Processors Only . . .Chapter Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Module Status and InputDataChapter 5Calibrating Your OutputModuleChapter 6Diagnostics andTroubleshootingPublication 1771Ć6.5.30 - November 1998Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Reading Data from the Module . . . . . . . . . . . . . . . . . . . . . . . . . . .Chapter Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Tools and Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Calibrating Your Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Voltage Output Version (1771ĆOFE1) . . . . . . . . . . . . . . . . . . . . . . .Calibration Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Current Output Version (1771ĆOFE2) . . . . . . . . . . . . . . . . . . . . . . .Channel Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Current Output Version(1771ĆOFE3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Channel Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Chapter Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -26-16-16-16-16-26-56-66-96-96-11Chapter 7Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Interpreting the Indicator Lights . . . . . . . . . . . . . . . . . . . . . . . . . . .Read Block Transfer Status Words . . . . . . . . . . . . . . . . . . . . . . . .Chapter Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-17-17-27-3

iiiTable of ContentsSpecificationsAppendix ASpecifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Block Transfer withMiniĆPLCĆ2 and PLCĆ2/20ProcessorsAppendix BData Table FormatsAppendix CMultiple GET Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Rung 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Rungs 2 and 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Rung Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Setting the Block Length (Multiple GET Instructions Only) . . . . . . . .4ĆDigit Binary Coded Decimal (BCD) . . . . . . . . . . . . . . . . . . . . . . .SignedĆmagnitude Binary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Two's Complement Binary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1B-1B-1B-2B-2B-3C-1C-2C-3Publication 1771Ć6.5.30 - November 1998

Table of Contents

Overview of the Analog OutputModuleWhat This ChapterContainsAbout the Analog OutputModuleRead this chapter to familiarize yourself with the analog outputmodule.For information onSee page !&% % ! & ! & %&# &%"&% !( ! ! & ! & % ( % #! # ! %#! # The Analog Output Module (cat. no. 1771-OFE) is an intelligentblock transfer module that converts binary or four-digit BCD values(supplied by your processor) to analog signals at its four moduleoutputs. The module accomplishes the data transfer with blocktransfer programming.Block transfer write (BTW) programming moves up to 13 words ofdata from the processor to the module for digital to analog (D/A)conversion in one program scan. This information is converted toanalog signals and is sent to the appropriate output channels.A block transfer read (BTR) moves five words of data from themodule to the processor data table, if desired, for diagnosticpurposes. The BTR is discussed in Chapter 7, “Diagnostics andTroubleshooting.”The module has a scaling feature that converts data sent to themodule in engineering units to the proper analog signals.You may connect up to four analog output devices--such as valvepositioners, motor speed controllers, signal converters orrecorders--to the analog output module’s four channels. All analogoutput device inputs should conform to the voltage or current ratingsof each module output channel. & % ! ) !' #

1-2Module FeaturesIn the programmable controller system, the analog output moduleprovides the following functions: four individually isolated differential outputsselectable scaling to engineering unitsselectable data formatselectable voltage ranges (1771-OFE1 only)no external power required--power is drawn from the 1771 I/Ochassis backplane. requires only one I/O slotOutput RangesThere are three versions of the analog output module:Catalog NumberModule OutputOutput Range1771ĆOFE1Voltage1Ć5V dc0Ć10V dc 10V dcSelected ory set1771ĆOFE3Current0Ć50mAFactory setThe voltage version (1771-OFE1) voltage output range is selectedwith configuration jumpers in the module:Note: The 1771-OFE1 is shipped with the selection jumpers inthe 10V position.The current output versions (1771-OFE2 and -OFE3) are factory set.Publication 1771Ć6.5.30 - November 1998

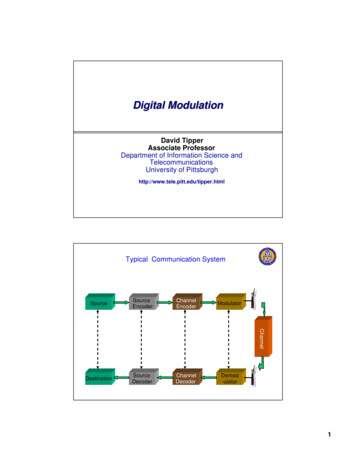

1-3How Analog ModulesCommunicate withProgrammable ControllersThe processor transfers data to the module (block transfer write) andfrom the module (block transfer read) using BTW and BTRinstructions in your ladder diagram program. These instructions letthe processor send output values to the module, establish themodule’s mode of operation (see illustration below) and receivestatus information from the module.Communication Between Processor and Module251 3 – # " # #(' (' ) & 4 %# % !! #"'%# % " # (' (' # ( ' # * 1. The processor transfers your configuration and output data to themodule via a block transfer write instruction.2. The module converts the data into proportional voltage or currentoutputs.3. These module outputs drive external analog devices.4. When instructed by your ladder program, the processor performsa read block transfer of output values and module status.5. The processor and module determine that the transfer was madewithout error.6. Your ladder program can use and/or move the data (if valid)before it is written over by the transfer of new data in asubsequent transfer.AccuracyChapter SummaryThe accuracy of your output module is described in Appendix A.In this chapter you read about the functional aspects of the outputmodule and how the module communicates with the programmablecontroller. ( ' #" * #) ! %

What This ChapterContains In this chapter, you will read about:For information onSee page ,*-)& " 1, 2/,-" &, '" 1&3"0 ) 2) 1" 1%" ,4"/ ".2&/"*" 10 "1 ,!2)" , #& 2/ 1&, 2*-"/0 "5 1%" (-) " , " 1,/0 01 )) 1%" *,!2)" ! &")! &/& /* , " 1 1%" &/& /,2 ! 1%" % 00&0 ! ,!2)" Read this installation chapter completely before you install yourmodule. Double check all connections and option selections beforeyou begin programming your module.!Compliance toEuropean Union DirectivesATTENTION: To avoid injury to personnel anddamage to equipment, disconnect and lockout all acpower supplies before installing and wiring the outputmodule.If this product has the CE mark, it is approved for installation withinthe European Union and EEA regions. It has been designed andtested to meet the following directives.EMC DirectiveThis product is tested to meet Council Directive 89/336/EECElectromagnetic Compatibility (EMC) and the following standards,in whole or in part, documented in a technical construction file: EN 50081-2EMC – Generic Emission Standard, Part 2 –Industrial Environment EN 50082-2EMC – Generic Immunity Standard, Part 2 –Industrial EnvironmentThis product is intended for use in an industrial environment.Low Voltage DirectiveThis product is tested to meet Council Directive 73/23/EECLow Voltage, by applying the safety requirements of EN 61131–2Programmable Controllers, Part 2 – Equipment Requirements andTests. 2 )& 1&, 6 ,3"* "/

2-2For specific information required by EN 61131-2, see the appropriatesections in this publication, as well as the following Allen-Bradleypublications: Industrial Automation Wiring and Grounding Guidelines ForNoise Immunity, publication 1770-4.1 Guidelines for Handling Lithium Batteries, publication AG-5.4 Automation Systems Catalog, publication B111This equipment is classified as open equipment and must be mountedin an enclosure during operation to provide safety protection.Calculating PowerRequirementsThe analog output module receives its power through the 1771 I/Ochassis backplane from the chassis power supply. It does not requireany other external power supply. When planning your system, youmust consider the power usage of all modules in the I/O chassis toprevent overloading the I/O chassis backplane and/or power supply.Add this to the requirements of all other modules in the I/O chassis.Analog Module # # # ! ! # " Power Requirement ATTENTION: Do not insert or remove modulesfrom the I/O chassis while system power is ON.Failure to observe this rule could result in damage tomodule circuitry.

2-3Determine ModuleLocation in the I/O ChassisYou can place your module in any I/O module slot of the I/O chassiswith the following guidelines: Do not put the module in the same module group as a discretehigh-density module. Avoid placing output modules close to ac modules orhigh-voltage dc modules. Group output modules together within an I/O chassis wheneverpossible to minimize noise interference from other modules. You can put two output modules in the same module group.Setting ModuleConfiguration JumpersThe module configuration jumpers consist of: the last state configuration jumper (all versions) the voltage range configuration jumpers (1771-OFE1 only).Current Output VersionCurrent version modules (1771-OFE2 and -OFE3) have allconfiguration jumpers installed and require no additionalconfiguration. The configuration jumper for the Last State modeoutput level is in the default position (MID). See “Last StateConfiguration Jumpers” below.Voltage Output VersionIf you are using the voltage output version, you need to set severalconfiguration jumpers on the module’s circuit board. You must setthese jumpers before you can proceed with configuring the module.When you set these jumpers, you configure each channel for one ofthe three voltage ranges listed above. The module is shipped withthe plugs in the 10V position.Important:You do not have to remove the module cover to set theconfiguration jumpersLast State Configuration JumpersThe LAST STATE configuration jumpers determine the value of allthe module’s outputs whenever communication between the moduleand the processor is lost. This condition occurs when a processor oradapter faults, or the processor is placed in the PROG or TESTmode, or if the remote I/O cable breaks.

2-4This is a significant safety feature. You can choose to have themodule’s outputs go to the maximum, minimum, or middle of theirrespective ranges or hold their last state if a module or system faultoccurs or if the system processor changes from RUN to PROGmode.You do this by placing the LAST STATE configuration jumpers oneight (four jumpers on sets of pins) of the stake pins marked MAX,MIN, MID on the module’s circuit board (Figure 2.1). If you do notplace configuration jumpers in one of these positions, the moduledefaults to the HOLD LAST VALUE setting.Figure 2.1 shows jumper positions for the 1771-OFE, Series B,Analog Output Module LAST STATE Configuration Jumpers.Important:Ignore the MAX, MIN, MID markings on the printedcircuit board.Important:On power-up, the module’s output is disabled until themodule receives the first block transfer write. Theoutput then enables with the value that you send it inthe block transfer write block.Important:We ship 1771-OFE modules with the LAST STATEconfiguration jumpers in the MID position.ATTENTION: Switch 1 of the I/O rack affects thefunction of the configuration settings as indicated inthe table below.!Configuration Jumper SettingRack Switch 1Setting " MINMIDMAXHOLD LAST STATE !

2-5Figure 2.1LAST STATE Configuration JumperLast State Output LevelConfiguration JumpersFront of Circuit BoardHOLD LAST STATEMINMIDMAXTable 2.A lists the output ranges and their minimum, maximum, andmiddle values.Table 2.AOutput Last State Configuration ValuesOutput RangeSelectionMinimumValueMiddle 0mA1Ć5V1V3V5V0Ć10V0V5V10V 10VĆ10V0V 10VThese output conditions are active only if the following conditionsexist: the module faults the processor is in the PROGRAM or TEST mode rack switch 1 is in the reset positionPublication 1771Ć6.5.30 - November 1998

2-6Rack switch 1 determines what output conditions occur during a rackfault.Configuration Jumper SettingRack Switch 1S ttiSetting %& & & % &MINMIDMAXHOLD LAST STATE %& & & %& & & %& & & %& & & ! ) %& & & To set the last state configuration jumpers, proceed as follows.!ATTENTION: Do not insert modules into or removemodules from the I/O chassis while system power isON. Failure to observe this rule could result in damageto module circuitry and unexpected machine operation.1. Locate the jumpers as shown in Figure 2.1.2. Carefully pull up on the jumpers to remove from the pins.3. Reposition as necessary to provide the value selected inTable 2.A.Setting Voltage Range Configuration Jumpers (1771ĆOFE1 only)If you ordered the voltage output version, you must set severalconfiguration jumpers located inside the module on the circuit board.To do this, follow these steps:2. Locate the configuration jumpers and set them according to youroutput voltage requirements (Figure 2.3). %& & & '&#'& ( "! ' & "! ' # % %% " % " "! ' & "! ' # %5. Position the jumpers as indicated in Figure 2.3. ' & "! * "(

2-7Figure 2.3Configuration Jumper LocationsLAST STATEInOut(side viewof jumper)ConfigurationJumperLocationDesired Voltage RangeOutputChannelP3, Jumper 5678910InInOutOutOutOut 10VOutOutInInOutOutP5, Jumper tInIn2P7, Jumper tInIn3P9, Jumper tInIn40-10V1-5VOutOutOutOutInIn1Install the Keying Bands!ATTENTION: Observe the followingprecautions when inserting orremoving keys: Insert or remove keys with yourPosition the keying bands in the backplane connectors tocorrespond to the key slots on the module.Place the keying bands:between 10 and 12between 26 and 28fingers. Make sure the key placement iscorrectIncorrect keying or the use of a tool canresult in damage to the backplaneconnector and possible system faults.UpperConnectorI/O chassisYou can change the position of these bands ifsubsequent system design and rewiring makesinsertion of a different type of module necessary.Publication 1771Ć6.5.30 - November 1998

2-8Install the Module and FieldWiring Arm!ATTENTION: Remove power from the 1771 I/Ochassis backplane and field wiring arm beforeremoving or installing an I/O module. Failure to remove power from the backplane orwiring arm could cause module damage, degradationof performance, or injury. Failure to remove power from the backplane couldcause injury or equipment damage due to possibleunexpected operation.1wiring armAttach the wiring arm (1771ĆWC) to the horizontalbar at the bottom of the I/O chassis.The wiring arm pivots upward and connects withthe module so you can install or remove themodule without disconnecting the wires.1771ĆWHremovehorizontal bar21771ĆA1B, ĆA2B, ĆA3B, ĆA3B1, ĆA4B I/O chassislocking tabinstall176431771ĆA1B, ĆA2B, ĆA3B1, ĆA4B Series B I/O chassislocking bar pinlocking barcard guidescard guidesmoduleSnap the chassis latch overthe top of the module to secure it.Publication 1771Ć6.5.30 - November 1998moduleSwing the chassis locking bar down into place to securethe modules. Make sure the locking pins engage.19809

2-9Connect the WiringThe analog devices connect to the analog module through a fieldwiring arm (cat. no. 1771-WC). The field wiring arm pivots on thefront of the I/O chassis to connect with the module. You can removethe module from the chassis without disconnecting user wiringbecause wiring connections are made on the field wiring arm. Theconnection diagram (Figure 2.5) shows connections to the fieldwiring arm.!ATTENTION: To avoid injury to personnel anddamage to equipment, disconnect and lockout ac powerfrom the processor and system power supplies beforewiring the module.Figure 2.5Connection of Analog Devices to the Field Wiring Arm (cat. el 1 output ( ) lead0Channel 1 output (Ć) lead1Channel 2 output ( ) lead2Channel 2 output (Ć) lead3Channel 3 output ( ) lead4Channel 3 output (Ć) lead5Channel 4 output ( ) lead6Channel 4 output (Ć) lead7Not usedBNot usedField Wiring ArmCat. No 1771ĆWC12878The sensor cable must be shielded. The shield must: extend the length of the cable, but be connected only at the 1771I/O chassis extend up to the point of terminationImportant: The shield should extend to the termination point,exposing just enough cable to adequately terminate theinner conductors. Use heat shrink or another suitableinsulation where the wire exits the cable jacket.Publication 1771Ć6.5.30 - November 1998

2-10The module requires shielded cable for signal transmission to theanalog devices. Use Belden 8761 shielded cable, which consists of asingle insulated, twisted-pair of conductors, covered along theirentire length by a foil shield and encased in plastic. The shieldreduces the effect of induced noise at any point along the cable.Ground the Chassis andModuleYou must ground the shield at the chassis end only. We recommendconnecting each output cable’s shield to a properly groundedcommon bus. Refer to “Industrial Automation Wiring and GroundingGuidelines for Noise Immunity,” publication 1770-4.1, for additionalinformation.Figure 2.6Cable GroundingRemove a length of cablejacket from the Belden 8761cable.Pull the foil shield and baredrain wire from the insulatedwires.Bare drainwireTwist the foil shield and drainwire together to form a singlestrand.Attach a ground lug.Belden 8761 CableInsulatedwires20104FoilshieldChassis GroundSingleĆpoint GroundingWhen you connect grounding conductors to the I/O chassisgrounding stud, place a star washer under the first lug, thenplace a nut with captive lock washer on top of each ground lug.Extend shield to termination point.Expose just enough cable to adequately terminate inner conductors.Ground LugNutNut and CaptiveWasherGrounding StudI/O ChassisSide PlateStarWasherUse heat shrink tubing orother suitable insulationwhere wire exits cab

In this manual we assume that you know how to do this. If you do not, refer to the appropriate programming and operations manual for the processor that you are using. In this manual we refer to the: Analog Output Module (cat. no. 1771-OFE) as the "output module" Programmable Controller as the "processor" or "controller."