Transcription

http://en.pisco.co.jp/Best suited for chemical liquid piping in semi-conductor manufacturing processNewFluororesin equipmentProductCharacteristicsHigh pull-out strength and sealability are realized. An impact-ring holds the tube firmly.Impact-ringEasy control of union nut tightening.(mm-type:Green,Inch-type:Blue) A click gauge is incorporated for making an easy check that the union nut isfirmly tightened.Union nutClick gaugeTightening completion can be checked visually and by click sound when thegauge convex part and nut concave part touches.Main body Applicable for most of fluid medium or gaseous atmosphere.Straight Through type, in which the liquid touches only with the tube, is also available. The body has a through hole equals to the tube O.D. (See page 70 and 71 for details.) Tube can be fixed at any length through fitting body.Clean washing clean packaging. ISOclass 6 cleanliness Clean and SanitaryLower tightening torque Little body deformationNeedle valve, best suited for applications thatrequire flow rate adjustment, is also available. 2 types are provided.Union Straight type:F-JHAWUnion Elbow type:F-JHAPlarailchain SDLittle liquid stagnationFluororesin equipment SUS Ball ValveMade of PFA and PTFE with high chemical and heat resistance.57

2017 New ProductsFluororesin equipmentModel designation of fittings (Example)FMC①M12R4②③③. Connection type and size Compression fittingCodeTube O.D.Tube I.D.M3ø3ø2mm size( )(Impact-ring color:Green)M4M6M8 M10 M12 M19 M25ø4ø6ø8ø10ø12ø19ø25ø3ø4ø6ø8ø10 ø15.8 ø22Inch size(inch( ))(Impact-ring color:Blue)CodeH1H2H3H4H6H8Tube O.D. ø1/8(ø3.2) ø1/4(ø6.35) ø3/8(ø9.35) ø1/2(ø12.7) ø3/4(ø19.05) ø1(ø25.4)ø3.95ø6.35ø9.53ø15.8ø22.2Tube I.D.( ) ø2.18 Taper threadCodeMale threadFemale threadR2R1/4Rc1/4Taper pipe T1/4NPT threadN3N4NPT3/8 NPT1/2N6NPT3/4N8NPT1R1R1/8Rc1/8CodeN1Thread size NPT1/8②. Tube sizeCodeTube O.D.Tube I.D.M3ø3ø2mm size( )(Impact-ring color:Green)M4M6M8 M10 M12 M19 M25 *M19 (Tube O.D.:ø19mm) and H6 (TubeO.D.:ø 3/4in.) are common. Order mmø4ø6ø8ø10ø12ø19ø25size (Code: M19) for Tube O.D. ø3/4in.ø3ø4ø6ø8ø10 ø15.8 ø22Inch size(inch( ))(Impact-ring color:Blue)CodeH1H2H3H4H6H8Tube O.D. ø1/8(ø3.2) ø1/4(ø6.35) ø3/8(ø9.35) ø1/2(ø12.7) ø3/4(ø19.05) ø1(ø25.4)ø3.95ø6.35ø9.53ø15.8ø22.2Tube I.D.( ) ø2.18①. Fitting typeCodeUUTRUTMCMETypeUnion StraightUnion TeeUnequal Union TeeStraightElbowCodeRURUECPMCTFETypeUnequal Union StraightUnequal Union ElbowCapStraight ThroughFemale ElbowCodeUEPMUUEAFCMBTFluororesin equipmentModel designation of needle valve (Example)FJHAW①H2②②. Tube size記 号Tube O.D.Tube I.D.①. Needle valve type記 号JHAWJHAFluororesin equipment58TypeUnion StraightUnion Elbowmm size( )M3M6ø3ø6ø2ø4Inch sizeH1H2ø1/8(ø3.2) ø1/4(ø6.35)ø2.18ø3.95TypeUnion ElbowBulkhead UnionUnion Elbow AdapterFemale StraightRun Tee

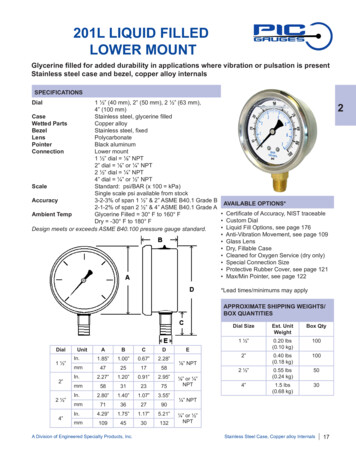

http://en.pisco.co.jp/Specifications (Fitting)Construction (Fitting)LiquidFluid medium0.7MPa(at 0 60 C)*1Max. operating pressureOperating temp.0 200 C(Depending on Impact-ring material. See the chart below.)*2range0.80.70.6③②④PartsFitting bodyUnion nutImpact-ringClick EP0.50.4Table. Tube dimensions0.30.2Tube /8"ø1/2"ø3/4"ø1"020406080 100 120 140Fluid medium temp.(ºC)160180200PVDF impact-ring (Standard):PVDFPPS impact-ring (For high temp.):PPSRelation of Operating Temp. & Max. Operating PressurePiscoʼs Fluororesin PFA (New) tube “SFTN series” is recommended.All sizes for Fluororesin equipment are available (ø3 ø25mm, ø1/8 ø1inch). In case of using non-PISCO brand tubes, make sure thetolerance of the outer tube diameter and tube hardness are within thelimits of Table. Tube dimensions.inch sizei Applicable .822.2ThicknessTolerance(mm) O.D.(ømm)Thickness(ømm) 0.1 0.050.5 0.1 0.050.5 0.1 0.061 0.12 0.061 0.12 0.061 0.12 0.061 0.12 0.11.6 0.2 0.11.5 0.1 0.050.5 0.1 0.11.2 0.12 0.11.6 0.12 0.11.6 0.12 0.11.6 0.2 0.11.6Construction (Needle valve)Specifications (Needle valve)F-JHAW (Union Straight)LiquidFluid medium0.7MPaMax. operating pressure0 100 COperating temp.(Must be within the range of the chart below.)*range⑥* When operating temp. exceeds 60 C, refer to the following chart "Relation ofOperating Temp. & Max. Operating .40.30.20.1020406080Fluid medium temp.(ºC)100120Relation of Operating Temp. & Max. Operating PressureFlow characteristics (Needle valve)【Conditions】1000 Fluid medium:WaterTemp.:25ºC800 Primary pressure:0.15MPa6004006A-MJHF2,A-HHJM6FAWF- JH,2HAWF- JHHA-M31, F- J-HF- JHA-M3F-JHAWW-H1,F- JHA2000011.522.53Needle rotations (times)3.54PartsFitting bodyNeedleFerruleOuter nutStopperLock nutUnion nutImpact-ringClick TFE/FEPPlarailchain SDFlow ⑨⑩Fluororesin equipment SUS Ball ValveFluid medium pressure(MPa)⑤①No,①②③④⑤mm sizeFluid medium pressure(MPa)*1. When operating temp. exceeds 60 C, refer to the following chart "Relationof Operating Temp. & Max. Operating Pressure"*2. Impact-ring made of PVDF (Max. operating temp. : 150 C) is equipped withfitting as standard. PPS impact-ring (Max. operating temp. : 200 C ) isrequired when using fittings in high temp. exceeding 150 C).Check the tube dia. and order applicable impact-ring as well.F-UT (Union Tee)59

2017 New ProductsFluororesin equipmentHow to install (by hot flaring)1:Insert a tube into a union nut and an impact-ring.TubeImpact-ringUnion nut2:Heat the edge of the tube evenly.Heat gunAbout 15 30sec.withair temperature 450 C at outlet.3:Insert the heated tube edge onto a flaring tool immediately and hold it until the tube cools down.Flaring tool4:Insert the flared PFA or PTFE tube edge onto the fitting body. With a special wrench, tighten a union nutuntil projections on the union nut touch with a click gauge.Special wrenchFitting body*For fluororesin fittings with tube O.D.:ø1/8inch, ø3mm or ø4mm, install them by cold flaring.Cold flaring: flaring without heating. For details, please contact us.60

http://en.pisco.co.jp/Safety instruction manualWarnings【For all fluororesin equipment】1.Make sure to follow the instructions in this catalog (or instructions manual) for the installation, retorquing and reinstallation of the products.Improper installation or tightening may cause accidents like a fluid leakage or a piping coming off.2.Do not retorque the products while pressure is supplied or under high temperature. It may cause damage or deformation of the products,leading to a fluid spouting. Make sure to lower the temperature to normal, and set the pressure to “0” before retorquing.3.Make sure to use the fitting within the range of the specifications. Otherwise accidents like a fluid leakage or a piping coming-off may becaused.4.Max. operating pressure of this products varies depending on the operating temperature. Make sure to check the “Relation of OperatingTemp. & Max. Operating Pressure” in the specifications before the usage and follow it.5.Since the fitting is made of resin, avoid any tensile force and bending force in / after installing it. Otherwise, there is a risk of causingdamage or deformation of the product, resulting a fluid leakage.6.Check chemical resistance before using the products, when the fluid medium is chemicals or solvent. Depending on the conditions, it maycause damage to the products, the detaching of tubes, and a fluid leakage.7.Do not use the products under the condition with vibration or physical impact. These may cause damage to the products, the escape oftubes and a fluid leakage.【For fluororesin needle valve】1.Since this product is made of resin, do not tighten the nut or turn the knob excessively.2.Loosened outer nut causes a fluid leakage, which is very dangerous. Make sure to retorque it, stopping the operation immediately whenlooseness occurs.CautionsFluororesin equipment SUS Ball Valve1.Do not use Pisco’s fluororesin equipment, combined with any other parts than this series. Otherwise accidents like a fluid leakage or apiping coming off may be caused.2. Take safety measures such as providing a protection cover on piping and fitting to avoid burn when the liquid in piping exceeds 70 C.3. Make sure to use Pisco’s flaring tool to flare tubes. Otherwise accidents like a fluid leakage may be caused.4. Pay attention not to get burned when flaring tubes. The parts get hot.5. Make sure the room is well ventilated when flaring tubes. Toxic gas may be generated if excessively heated.6. Make sure to dispose liquid in a fitting and wash it before discarding the fitting. Unwashed fitting waste with toxic, flammable or corrosiveliquid can be dangerous.7. Toxic gas is generated when burning fluororesin. Dispose the fitting according to the regulations in your area.8. Contact us when using gas as fluid medium. Basically Pisco’s fluororesin equipment is designated for liquid.9. Make sure that the impact-ring is in the right position after piping. Piping without impact-ring is dangerous, causing accidents like a fluidleakage or a piping coming off.10. Make sure to use impact-ring for high temperature when the liquid in piping exceeds 150 C. The impact-ring equipped with a fitting asstandard will cause a fluid leakage or a piping coming off on 150 C or higher.11. When retorquing is necessary, due to a leakage from tube inserting parts, make sure the liquid temperature is normal, and make thepressure “0” before retorquing. Tighten the union nut with a special wrench by 1/4 turns and observe the progress. Be noted that theliquid still may ooze out after retorquing (even after the leakage stops) for a while, since some liquid remains inside the union nut.12. A leakage from taper pipe thread parts due to “creep phenomenon” which is particular to resin may occur. Check the tighteningcondition periodically and re-torque the thread in case of leaks.13. After the initial tightening of the union nut and taper pipe thread, the torque is reduced, normally within 24hours, due to thecharacteristics of the resin. Therefore, retorquing after 24hours is effective to ensure the long-term stable sealability. When a heat cycleis applied to the fitting, retorquing at low temperature after the first heat cycle is recommended.14. Taper thread is not coated with Sealock. When coating the thread with seal tape, do not coat 1.5 to 2 screw ridges from the tip of thethread.15. Tighten taper thread by hand until it stops, then use a wrench to tighten it about 1.5 to 2.5 more turns. Excessive tightening may breakthe thread part. Inadequate tightening may cause a loosened thread or a fluid leakage.16. Take safety measures such as providing a protection cover if there is a risk of causing damages or fire on machine / facilities by a fluidleakage.17. Corrosiveness of a fitting and its ion elution to fluid medium depend on the operating environment. If they might adversely affect themachine and equipment, evaluate and examine the product based on the actual usage condition prior to the product adoption.Plarailchain SD61

2017 New ProductsFluororesin equipmentAppearance drawingF-U Union Straight2-øDødBModel codeF-U-H1F-U-H2F-U-H3F-U-H4F-U-H8H22-H1Tube size : inchTube O.D. x I.D.øD3.18 2.186.35 3.959.53 6.3512.7 9.5325.4 40.064.0247.0Tube size : mmModel -U-M25Unit:mmTube O.D. x I.D.øD3 24 36 48 610 812 1019 15.825 773.388.3102.311111619192432411313202323293849F-RU Unequal Union H8-H6Tube O.D. x I.D.øD16.35 3.959.53 6.3512.7 9.5319 15.825.4 22.2Tube O.D. x I.D.øD23.18 2.186.35 3.956.35 3.959.53 6.359.53 6.3512.7 9.5312.7 9.5319.05 .180.887.895.3101622H2H3H1Tube size : inchModel 23243241293849Tube size : mmModel e O.D. x I.D.øD16 48 610 812 1019 15.825 22Tube O.D. x I.D.øD23 24 36 46 48 66 48 610 810 812 1012 1019 70.0190.0

http://en.pisco.co.jp/2-H2-EF-UE Union Elbow2-øDødTube size : inchModel be O.D. x I.D.øD3.18 2.186.35 3.959.53 6.3512.7 9.5325.4 Weight(g)10.426.140.068.0278.0Tube size : mmModel UE-M19F-UE-M25Unit:mmTube O.D. x I.D.øD3 24 36 48 610 812 1019 15.825 731111161919243241F-UT Union 68.0150.0259.0Tube size : inchModel Tube size : mmModel codeUnit:mmTube O.D. x I.D.øD3 24 36 48 610 812 1019 15.825 0105.0214.0396.0Plarailchain roresin equipment SUS Ball ValveF-UT-H1F-UT-H2F-UT-H3F-UT-H4F-UT-H8Tube O.D. x I.D.øD3.18 2.186.35 3.959.53 6.3512.7 9.5325.4 22.2Unit:mm63

2017 New ProductsFluororesin equipmentøD1ød1H1E1F-RUE Unequal Union ElbowøD2ød2H2E2Tube size : inchModel RUE-H6-H3F-RUE-H6-H4F-RUE-H8-H4F-RUE-H8-H6Tube O.D. x I.D. Tube O.D

Inch-type:Blue) Union nut . Piping without impact-ring is dangerous, causing accidents like a fluid leakage or a piping coming off. 10. Make sure to use impact-ring for high temperature when the liquid in piping exceeds 150 C. The impact-ring equipped with a fitting as standard will cause a fluid leakage or a piping coming off on 150 C or higher. leakage. Union Straight Unequal Union .