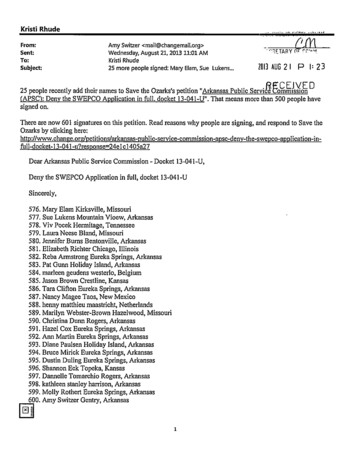

Transcription

2022Concrete FieldTesting TechnicianCourse OverviewARDOT SpecificationsSamplingTemperatureSlumpDensityAir Content (Pressure)Test Specimens Cylinders & BeamsAir Content (Volumetric)Introduction41

2022Exam Requirements5 Year Certification Written Exam Performance ExamFailure of Either Exam Requires retake of failed exam within 1 year Entire written exam Entire performance exam If date is missed, student must retake both exams Student is responsible for rescheduling of retakeIntroduction5Written ExamQuestionsLimitations Standard Specifications Special Applications55 Questions Multiple Choice True / False 5 to 10 questions on each of 3 Exam Stations 1 Hour Exam Closed BookMinimum Passing Requirements 70 % Overall 60 % Each Standardthe seven ASTM standardsIntroduction62

2022Performance ExamPassing Requirements Successfully perform all seven standards in the laboratory Two trials are allowed per standard One additional retrial allowed per standard Student must request retrial Proctor may not stop you Student retrial starts over at beginning of testFailure to pass any standard within the allowable trials requiresretaking of the entire performance examIntroduction7Test ResultsACI test results are usually received within 1 month of testingACI test results will be sent by email Overall written exam score Individual section scoresCTTP only receives a pass/fail score for each studentIntroduction83

2022Recertification5 Year Certification Time starts from thecompletion date of allrequirementsRepeat Testing Written Exam Performance ExamIntroduction9Help?If you need help withmathematical calculations,just ask. Your instructorwill be happy to assist you.If you need further practiceor assistance, please seeour website www.cttp.orgfor online training.MobileAccessibleIntroduction104

2022Why certify?Would we all test the sameway without thespecifications to guideus?Do specificationsguarantee that we will allget the same result?How does time affect ourtest results?IntroductionAggregates11ConcreteWhat is it?CoarseFinePastePortland CementWaterEntrapped AirEntrained AirThe paste hardens due to a chemical reactiontaking place between the cement and water(hydration), binding the aggregates into a hardsolid massIntroductionAir - Entrained Concrete125

2022Temperature Effects on ConcreteCold WeatherHot Weather If concrete freezes while still Potential strength reductionfresh, the cement paste matrixis disrupted causing up to a50% loss in ultimate strength Increased set timesdue to high water demand Decreased set times Increased risk of shrinkagecracking Increased possibility of thermalcracking due to rapid cooling Difficulty in controlling aircontentIntroduction13ARDOT SpecificationsARDOT specification limits areconsidered absolute limits ! Observed or calculated values are not rounded for determination ofcompliance Compared directly with the limit Average values are rounded to the same # of significant digits Any deviation outside limits is non-compliance Failing testARDOT Specifications146

2022ARDOT SpecificationsRigid Concrete PavementAcceptance – Section 501.04 Lot - 4000 yd³Sublot – 1000 yd³ Gradation (fine & coarse aggregate) 1 ½” - # 8 Sieves 7 % from JMF # 16 - # 100 Sieves 4 % from JMF Aggregate Moisture Content Slump ( 2”) Sampled after placement on grade but before consolidationARDOT Specifications15ARDOT SpecificationsRigid Concrete PavementAcceptance – Section 501.04 Air Content (Pressure) (4 % - 8 %) Sampled after placement on grade but before consolidation Compressive Strength (f’c @ 28 days) ( 4000 psi) Cored Specimens (AASHTO T 24) (28 – 90 days) 3.70 inches in diameter Thickness Cored Specimen (AASHTO T 24)ARDOT Specifications167

2022ARDOT SpecificationsStructuresARDOT Specifications17ARDOT SpecificationsStructuresAcceptance – Section 802.06 Lot - 400 yd³Sublot – 100 yd³ Class SAE – minimum 1 per structure/deck pour Gradation (fine & coarse aggregate) (500 yd³) Fineness modulus of coarse aggregate ( 20 points) If outside tolerance a new mix design is required Aggregate Moisture Content Slump 1” - 4” for Classes A, B, S, and SAE 4” – 8” for Class SealARDOT Specifications188

2022ARDOT SpecificationsStructuresAcceptance – Section 802.06 Air Content (Pressure) 4% - 8 % for Class SAE only Compressive Strength (f’c @ 28 days) ( 4000 psi) Cylinders Minimum of 2 cylinders 4 x 8 or 6 x 12ARDOT Specifications19ARDOT SpecificationsStructuresTemperature (802.16) Bridge Decks Concrete batches withtemperatures in excess of 90 Fwill be rejected Temperature of all concrete Protection Maintain the temperatureadjacent to the concrete atminimum of 50 F for at least 7daysmust be more than 50 F whenplaced Bridges Box Culverts Retaining WallsConcrete that has been frozen shall be removed and replacedARDOT Specifications209

2022ARDOT SpecificationsStructuresPumping (802.10) Samples for slumpand air content arecollected at thedischarge end of thepipe0.5% to 1.0% loss of air contentis typical but may be up to 50%of the air content going inARDOT Specifications21ACI Concrete Field Testing TechnicianGrade 12210

2022Sampling FreshlyMixed ConcreteASTM C 172AASHTO R 60Sampling23ScopeCovers the procedures for obtaining representative samples of freshconcrete delivered to the jobsite Samples may be used to determine compliance with specificationrequirementsCovers the procedures to be used in wet-sieving Removal of aggregates larger than a designated sizeSampling2411

2022SamplingDampen containerObtain composite samples unless otherwise noted Maximum time allowed between obtaining first and final portions ofthe composite sample is 15 minutes Wet – sieve if requiredSample 1Sample 2Sample X15minutesSamplingPass the concrete over thedesignated sieve to removeoversized aggregate25Wet - SievingDiscard aggregate retained on thesieveScrape any paste left on sieveback into the batch (remainingsample)Remix with a shovel to ensureuniformity before testingSampling2612

2022SamplingTransport samples to place of testing Combine all samples Remix with a shovel to ensure uniformitySampling27SamplingWithin 5 minutes of obtaining the final portion of the compositesample, start tests for :TemperatureSlumpSamplingAir Content2813

2022SamplingStart molding strength test specimens within 15 minutes afterfabricating the composite sampleCylindersBeamsSampling29SamplingProtect the sample from :SunWindOtherSources ofRapidEvaporationContaminationSampling3014

2022ProcedureSample Sizes Strength Test Specimens 1 cubic foot (ft³) minimum Temperature, Slump, & Air Tests Smaller sample sizes are permitted Size of sample is dictated by the maximum size of the aggregateSampling31ProcedureSampling should normally be performed as the concrete is deliveredfrom the mixer to the conveying vehicle used to transport theconcrete to the forms Specifications may require other points of sampling Discharge end of concrete pump (ARDOT)Sampling3215

2022Collect SampleProcedureStationary MixersStationary Batch Plant Collect two or more portions At regularly spaced intervals From the middle of the batchObtain Portions Pass a receptacle through the entiredischarge stream Divert the entire discharge streaminto a receptacleCombine portions into onecomposite sampleSamplingProcedureAdd all water and admixtures to mixerbefore samplingRevolving DrumTruck MixersCollect SampleTruck Mixer33 Collect two or more portions At regularly spaced intervals From the middle of the batchObtain Portions Pass a receptacle through the entiredischarge stream Divert the entire discharge stream into areceptacleCombine portions into one compositesampleTo slow rate of discharge, slowthe rate of drum revolutionSampling3416

2022Make all adjustments to the mixProcedureContinuous MixersContinuous Mix Truck Obtain sample after 5 ft³ or more ofconcrete has been dischargedCollect Sample Collect two or more portions At regularly spaced intervals From the middle of the batchObtain Portions Pass a receptacle through the entiredischarge stream Divert the entire discharge stream into areceptacleCombine portions into one compositesample Wait 2 – 5 minutes before testingSamplingProcedurePaving MixersConcrete Paver35Discharge the contents of thepaving mixer to gradeObtain 5 or more sample portionsfrom different areas of the pile Avoid contamination Avoid prolonged contact with anabsorptive subgradeCombine portions into onecomposite sample for testingSampling3617

2022ProcedureOpen-Top ContainersDump TruckTake samples by the previousmethod that is most applicableunder the given conditionsSampling37Temperature51Temperature ofFreshly MixedConcreteASTM C 1064AASHTO T 30918

2022IntroductionConcrete temperature influences: QualityTime of setStrength of concretePerformance of additives and admixturesScope Covers how to determine the temperature of freshly mixed hydraulic-cement concrete Does not give specificationsTemperature52Significance and UseTypically used to verify conformance with temperaturespecifications Concrete containing aggregate of a nominal maximum size greaterthan 3” may require up to 20 minutes for the transfer of heat fromaggregate to mortar Time from batching to delivery usually exceeds this time and thereforeadditional wait time is rarely neededTemperature5319

2022ApparatusTemperature Measuring Device (TMD) Capable of measuring to 1 F Temperature range of 30 – 120 F Allow 3 inches or more of immersionVerify Accuracy: Annually Question of accuracyTemperature54Verification EquipmentReference Measuring Device Readable and Accurate to 0.5 F Liquid in Glass Thermometers Verify Once Direct Reading Resistance Thermometers Verify Yearly Maintain records of accuracy in lab Document NIST traceable reference standard used in verificationTemperature5520

2022Verification EquipmentSuitable Bath Liquid ofUniform Density Maintain ConstantTemperature 0.5 F Continuously 6Immerse both thermometers in bath forat least 5 minutes Suspend thermometers so that neitherare touching the sides or bottom ofbathRecord temperature readings of boththermometers Thermometer must check within 1 Fof reference thermometerCheck @ 2 temperatures 30 F apartTemperature5721

2022ProcedureCoverComposite samples are not required ifthe only purpose is to determinetemperatureAcceptable Locations Transportation Equipment Forms Containers 3” 3” 3”Cover Transport Equip. & Forms 3” min. cover in all directions Containers : 3” min. or 3 x NMAS (whichever is greater)TemperatureProcedureInsertion 3”58If using a container, dampen thecontainer prior to obtaining the samplePlace the TMD in the concrete so that theend of the temperature sensor issubmerged a minimum of 3 inchesClose the void by gently pressing theconcrete around the stem at the surfaceof the concrete Prevents the ambient air temperaturefrom affecting the readingTemperature5922

2022ProcedureReadingWait 2 - 5 minutesRead TMD Leave TMD device in concrete to readRecord temperature Nearest 1 F (0.5 C)68 FTemperature60Slump62Slump ofHydraulic-CementConcreteASTM C 143AASHTO T 11923

2022IntroductionSlump test measures the consistency of fresh concrete Consistency – A measure of the relative fluidity of the concretemixture Lab conditions: an increase in water content increases slump Field conditions: an increase in slump does not mean water content hasincreasedTerminology : Subsidence – to sink to a lower level (slump)Slump63Significance and UseApplicable to concrete having coarse aggregate up to 1½” If aggregate is retained on 1½” sieve, wet sieve over 1½” sieveTest not applicable for: Non-plastic concrete Slumps ½” Non-cohesive concrete Slumps 9”Slump6424

2022ApparatusBase Plate Non-absorbent, rigid, flat, level Must release mold without movement of the mold Must contain all slumped concreteTamping Rod Round, smooth, straight steel5/8” 1/16” diameterAt least 4” mold depth but 24” in lengthHemispherical tip(s)Slump65ApparatusSeamless & RigidMoldFrustum of a cone 12” 1/8” High 4” 1/8” Dia. Top 8” 1/8” Dia. BaseMold shall be free from dents,deformation, or adhered mortarSlump6625

2022ApparatusMoldVerification Check mold condition and alldimensions before 1st use and annuallythereafter Metal Molds Average Thickness 0.060 in. Individual Thickness 0.045 in. ABS Plastic Molds Average Thickness 0.125 in. Individual Thickness 0.100 in.Slump67ApparatusMeasuring DeviceRuler or tape 12” Length ¼” Divisions or smallerSlump6826

2022ProcedureDampen the mold and base Place mold on a flat, level, non-absorbent, rigid surface free ofvibrationStand on the two foot pieces, or use a clamping arrangement duringthe filling of the mold Prevent any movement of the mold during filling and prior to lifting ofthe moldSlump69ProcedureFill the mold in three layers ofequal volume Lift 1 Lift 2 Lift 32-5/8”6-1/8”TopLift 3Move scoop around perimeteropening when filling to ensurean even distribution of concreteLift 2Lift 1Slump7027

2022ProcedureFill the mold to a depth of 2-5/8” with concreteRod the bottom layer using 25strokes Penetrate rod to the bottom Incline rod slightly for strokesaround perimeter Spiral inward and use verticalstrokes in center portionSlump71ProcedureFill the mold to a depth of 6-1/8” with concreteRod the 2nd layer using 25strokes Penetrate rod through 2nd liftand 1 inch into the 1st liftSlump7228

2022ProcedureAdd concrete until the level isabove the rim of the moldRod the 3rd layer using 25strokes Penetrate rod through 3rd liftand 1 inch into the 2nd lift Stop rodding and add concreteto keep mold full at all timesSlump73Slump74Procedure Strike off top of moldusing the tamping rod Apply a rolling andscreeding motion29

2022Procedure Remove concretefrom base of mold toprevent interference Do not allow mold tomove during thisprocessSlump75ProcedureHold mold down firmly withhandlesStep off foot pieces or releaseclamps Accidental raising of mold priorto lifting is cause to start thetest overSlump7630

2022ProcedureRemove the mold Steady, upward lift to a heightof 12” Avoid lateral or twisting motions Complete the raise in5 2 secondsComplete the test in 2½ minutesor less Filling to mold removalSlump77ProcedureMeasure slump Vertical distance from the topof the mold to the displacedoriginal center If a decided falling away orshearing occurs disregard thetest and test another portionNormalShearSlump7831

2022ReportReport slump to the nearest ¼ inch¼” ½” ¾”Slump79Report4¾”3½”Slump8032

2022Density(Unit Weight)of ConcreteASTM C 138AASHTO T 121Density83IntroductionA change in density may indicate: Change in air content Change in water content Change in cement contentA change in density may affect: Strength Resistance to chemicalsDensity8433

2022ScopeCovers the determination of the density of freshly mixed concrete Excludes non-plastic concreteGives formulas for calculating: YieldRelative YieldCement ContentGravimetric Air ContentDensityApparatus85Balance Accurate to 0.1 lb (45 g) 0.3 % of test loadMeasureMeasure Steel or suitable metal Capacity of measure is based on NMAS(Table 1 – ASTM C 138) Minimum size 0.2 ft³ May use pressure meter bowl if NMAS 1” Rim of air meter bowls must be planewithin 0.01” (0.3mm)Density8634

2022VolumeMeasureVolume of Measure Determine using ASTM C 29 Annually Reason to question accuracy Record volume of measure to 0.001 ft ³Density87Consolidation Equipment Tamping Rod 5/8 1/16” steel Hemispherical tip At least 4” mold depth but 24” in length Internal Vibrator 9000 vpm Element ¾” – 1½” dia. Length of shaft and elementmust exceed depth of sectionby 3”Density8835

2022Strike-OffEquipmentFlat Strike-Off PlateSize Length & width at least 2” greater thanthe diameter of the measureMetal, Glass or Acrylic Metal ¼” thick Glass or Acrylic ½” thickEdges straight and smooth within 1/16”Density89ApparatusMalletScoop Size 1.25 0.50 lb Large enough to obtainrepresentative scoops ofconcrete Measures 0.5 ft³ 2.25 0.50 lb Measures 0.5 ft³ Small enough so concrete isnot spilled during placementinto mold Head Rubber or RawhideDensity9036

2022ProcedureConsolidation method is based on slump unless the jobrequirements specify a specific methodDensity91ProcedureRodding 3 lifts Strokes based on the size of the measure 10 – 15 Taps / Lift Use enough force to close voids left by the tamping rod and release trappedair bubblesDensity9237

2022ProcedureVibration 2 lifts 3 Insertions per layer Apply vibration only until surface becomes smooth Over vibration may cause segregation and loss of entrained air No taps with malletDensity93ProcedureDampen the measure Remove excess waterRecord the empty weight of themeasureDensity9438

2022ProcedureNote : The steps shown for filling and compactionassume a slump greater than 3 inches and a 0.250cubic foot measure is being usedFillingFill the measure in 3 equal layers Move the scoop around the perimeterwhile filling to limit segregation andobtain an even distribution of concreteDensity95ProcedureConsolidate each layer of concrete byrodding 25 times per liftRodding Penetrate each previous lift by about 1”Tap each layer 10 – 15 times using therubber mallet Use enough force to close holes left byroddingDensity9639

2022ProcedureAfter consolidation, there should be about 1/8” (3mm) excessconcrete above the top of the mold Adjust top level if needed by adding or removing a representativeportion of concrete Do not consolidate any additions Adjustments may only be made prior to strike-offDensityProcedure97Strike - Off Use only the strike-off plate Cover 2/3 of surface with the plate andpull back with a sawing motionStrike - Off Keep plate horizontal and in contact withthe rim of the moldDensity9840

2022ProcedureStrike - Off Cover the same 2/3 area and pushforward with a sawing motion Keep plate in a horizontal position and inStrike - Offcontact with the mold rim until plate slidescompletely off the measure Do not lift plateDensityProcedureStrike - Off99Strike Off Incline the plate slightly to finishthe concrete and produce asmooth surface Pull back in a smooth motion If low spots are visible, pullconcrete toward low areasDensity10041

2022ProcedureProper Strike - OffDensity101ProcedureClean Mold Exterior Clean exterior completely Remember to look at all sidesand under handlesDensity10242

2022ProcedureRecord the weight of the fullmeasureCalculate densityD WcVmReport density to nearest0.1 lb/ft³Density103CalculationDensity(Unit Weight)The weight of concreteper unit volume ofconcretelb/ft³kg/m³WcD VmMass of Empty MeasureMass of Full MeasureNet Mass of ConcreteWcVm Volume of MoldReported DensityD DensityReportDensity tothe nearest0.1 lb/ft³8.50 lb47.84 lb39.34 lb0.250 ft³157.4 lb/ft³39.34 157.360.25010443

2022Density CalculationVolume of Measure 0.249 ft³D Mass of Empty MeasureWcVm8.42 lbMass of Full Measure45.19 lbNet Mass of ConcretelbReported Density (unit weight)lb/ft³Density105Questions ?cttpDensity10844

2022CalculationY YieldM(D x 27)Report Yieldto the nearest0.1 y³M Mass of Batched MaterialsD Density of ConcreteThe volume of concreteproduced from aconcrete batchy³m³Y 40,160 lb146.3 lb/ft³27 ft³ 1 yd³40,16040,160 10.166.(146.3 x 27) 3,950.1Density10.2 yd³110Yield CalculationY M(D x 27)Mass of Batched MaterialsDensity of Concrete38,651 lb144.1 lb/ft³Density11145

2022CalculationRy Relative YieldYYdReportRelative Yieldto the nearest0.01Y Yield of ConcreteYd Designed YieldA ratio of concrete yieldto the designed yield10.2Ry 1.0210.010.2 yd³10.0 yd³1.02Density113Relative Yield CalculationRy YYdYield of Concrete9.9 yd³Designed Yield10.1 yd³Density11446

2022CalculationC Cement ContentCbYReport CementContent to thenearest 1 lb/yd³Cb Weight of Cement in BatchY Yield of ConcreteThe weight of cement percubic yard or cubic meterof concrete producedC 5,753 564.01 10.25,753 lb10.2 yd³564 lb/yd³Density116Cement Content CalculationC CbYWeight of Cement in BatchYield of Concrete5,211 lb9.9 yd³Density11747

2022CalculationA Air Content(Gravimetric)(T D)x 100TT Theoretical DensityD Density of ConcreteCalculated air contentbased on the theoreticaldensity of the concretebatchA (168.0 157.4)x 100168.0A 10.6x 100 6.309 168.0T 0 % air basisReport AirContent to thenearest 0.1 %168.0 lb/ft³157.4 lb/ft³6.3 %Density119Air Content (Gravimetric) CalculationA (T D)x 100TTheoretical Density153.2 lb/ft³Density of Concrete144.1 lb/ft³Density12048

2022Theoretical Density CalculationBased on the total absolute volume (Vft³) and total mass (Mlb) of allingredientsT MV V M / (G x 62.4 lb/ft³) G - Specific gravity Use saturated surface dry (SSD) specific gravities and masses for all aggregatesReport theoretical density to nearest 0.1 lb/ft³Density122Air Content - Pressure128Air Content ofFreshly MixedConcrete by thePressure MethodASTM C 231AASHTO T 15249

2022IntroductionSpallingWithout enough air in themortar fraction of concrete,normal concrete that isexposed to cycles offreezing and thawing mayscale and/or spall, resultingin a durability failure of theconcreteToo much entrained air maycause a reduction inconcrete strengthScalingAir Content - Pressure129ScopeDetermines the air content of freshly mixed concrete Based on the change in volume of the concrete due to a change inpressureFor use with relatively dense aggregates and mortars only Requires an aggregate correction factorNot applicable to: Non-plastic concrete, or concretes containing lightweight aggregates,air-cooled blast furnace slag, or high porosity aggregatesAir Content - Pressure13050

2022ApparatusType A MeterType B Meter Calibration affected bychanges in barometricpressure or elevationAir Content - Pressure131ApparatusBowlCalibration Vessel 5 % of bowl volume Metal Diameter must be at least 0.75to 1.25 times the height Minimum capacity is 0.20 ft³ Typical volume is 0.250 ft³ for aType B meterAir Content - Pressure13251

2022ApparatusTamping RodInternal Vibrator 5/8 1/16” steel Hemispherical tip 4” mold depth but 24” in 9000 vpm ASTM C 192lengthAir Content - Pressure133ApparatusMallet Size 1.25 0.50 lbs Measures 0.5 ft³ 2.25 0.50 lbs Measures 0.5 ft³ Head Rubber or RawhideScoop Large enough to obtainrepresentative scoops ofconcrete Small enough so concrete isnot spilled during placementinto moldAir Content - Pressure13452

2022ApparatusStrike-Off Bar Metal 1/8” thick, ¾” wide, & 12” longStrike Off Plate Metal ¼” thick Glass or Acrylic ½” thick Length & Width at least 2” greater thanthe diameter of the measure Edges smooth within 1/16”Air Content - Pressure135CalibrationAnnex 1.2 to 1.5 – Once or to check A1.2 – Wt. of water to fill calib. vessel (ω) A1.3 – Weight of water to fill bowl (W) A1.4 – Calib. vessel % of bowl volume (R)R ωൗW x 100 (type B meter) A1.5 - Check of expansion factor (IP)Annex 1.9 – Not to exceed 3 months A1.9 : Check of air pressure dial gaugeAir Content - Pressure13653

2022CalibrationCalibration Records Determination of expansion factor Size of calibration vessel used Reading of the gauge at the calibration test point(s)Air Content - Pressure137Aggregate Correction FactorAccounts for the surface porosity of the aggregateDetermined from a combined aggregate sample Typical values range from 0.2% to 0.5%Air is forcedfrom poresunderpressureEntrappedairAir Content - Pressure13854

2022ProcedureIf aggregate is retained on the 2”sieve, wet-sieve the concrete overan 1-1/2” sieveDetermine the consolidation method based on the slump of theconcrete unless otherwise stipulatedAir Content - Pressure139ProcedureDampen bowl and fill with concrete according the requirements forthe consolidation method :Rodding3 layers25 strokes / layer10 – 15 taps / layerVibration2 layers3 insertions / layerNo taps / layer Penetrate previous layers by 1” during consolidation Never continue vibration long enough to cause the escape of froth from thesample Over vibration may cause segregation and the loss of entrained airAir Content - Pressure14055

2022ProcedureAdjust level of concrete afterconsolidation of final layerStrike-off Bar 1/8” of excess concrete is optimal Adjust concrete level prior to strike offStrike-off the concrete surface Strike-off Bar – use sawing motion Strike-off Plate – use same technique asin density testAir Content - Pressure141ProcedureClean the rim of bowlAir Content - Pressure14256

2022Type B Air Pressure Meter1.2.3.4.5.6.7.8.9.Fill petcock with waterClose air bleeder valve (top nut)Pump up to initial pressureClose both petcocksOpen main air valve (lever)Tap the bowl with malletRead dial to nearest 0.1%Close main air valve (lever)Open both petcocks (cover)Air Content - Pressure143ProcedureDampen the cover and clean the rubbergasketRelease any residual pressure shown ondial gauge Accidently bumping the main air valvemay cause failure during testingOpen both petcocks and check for anyblockageAir Content - Pressure14457

2022ProcedureAttach cover assembly to provide awater-tight seal Clamps should be adjusted if too tightor too loose Secure opposite clamps into position atthe same time Assure that clamp fingers are fully underrimAir Content - PressureProcedure145Close the main air valveNote: Main air valve is spring loaded andis closed unless held openUsing a syringe, inject water through apetcock until it emerges from theopposite petcock Jar the meter gently while water isbeing added until all trapped airbeneath the cover is expelledClose the air bleeder valve Top nutAir Content - Pressure14658

2022ProcedurePump air into the air chamberuntil the dial is on the initialpressure line IP is found written on the dialface IP marks are below 0%Allow a few seconds for thecompressed air to coolAir Content - Pressure147ProcedureTap the gage lightly with fingersuntil reading stabilizes Adjust air to initial pressureline Bleed air off by loosening the airbleeder nut Pump additional air if needed Tap gauge lightly afteradjustments to stabilize needleAir Content - Pressure14859

2022ProcedureClose both petcocksAir Content - Pressure149ProcedureOpen the main air valve betweenthe air chamber and the bowl(hold lever down) Sharply tap the measure withmallet Do not let up on leverAir Content - Pressure15060

2022ProcedureContinue holding lever down Drop mallet and lightly tap thedial gage with your fingers untilreading is stableRead the dial gageAir Content - Pressure151ProcedureAir Content 8.0 %Air Content 8.0 % Report to nearest 0.1 % Report to nearest half-scale division4.4 %10.25 %Air Content - Pressure15261

2022ProcedureClose the main air valve (release lever) Failure to close main air valve before releasing pressure from airchamber or container may result in water entering the air chamber If water enters air chamber, bleed water from air bleeder valve and thenpump up and blow out air chamberRelease pressure by opening both petcocks before removing cover Cover both petcocks with your handsRemove coverAir Content - Pressure153CalculationDetermine the reported air content Subtract the aggregate correction factor (ACF) from the reading onthe dial gageMeasured Air ContentAggregate Correction Factor5.6 %0.4 %Reported Air Content5.2 %If wet sieved, calculate adjusted air contentAir Content - Pressure15462

2022Air Content CalculationWhat is the reported air content ?ACF 0.2 %Measured air contentAggregate correction factorReported air contentAir Content - Pressure155Cylinders & Beams161Making andCuring ConcreteTest Specimens inthe FieldASTM C 31AASHTO R 10063

2022IntroductionMost concrete is bought and sold basedon the strength of the concreteConcrete strength test specimens mustbe made properly so that the: Results are reliable Tests can be reproduced Deviation from standard procedures cancause significant differences in strengthresultsCylinders & BeamsIntroduction162Concrete cylinders are made to test for: Compressive Strength Splitting Tensile StrengthConcrete beams are used to test for: Flexural StrengthCylinders & Beams16364

2022ScopeCovers the procedures for making andcuring, protecting, and transportingcylinder and beam specimens madefrom fresh concreteTesting RequirementsField Technicians making and curingspecimens for acceptance testing shallmeet qualifications of ASTM C1077 ACI Concrete Field Testing Technicians(Grade I) Or equivalentCylinders & Beams164SamplingSample according to ASTM C 172 after all on-site adjustments havebeen made Water AdmixturesRecord identification information Placement location Time of castingPerform tests for temperature, slump, and air content Do not use concrete from air tests to make cylinders or beamsCylinders & Beams16565

2022ApparatusSampling Receptacle Heavy metal pan, wheelbarrow, or a large flat, clean andnonabsorbent boardMolds Must be rigid and watertight A heavy grease or microcrystalline wax may be applied to the joints toprevent leakage May be reusable or single use Reusable molds shall be lightly coated before use with mineral oil or othernonreactive form release materialCylinders & Beams166ApparatusCylinder MoldsBeam MoldsCylinders & Beams16766

2022ApparatusTamping Rod 3/8 1/16” 6” cylinder diameter 6” beam width 5/8 1/16” steel 6” cylinder diameter 6” beam width 4” greater than the depth of mold but 24” in length Hemispherical tip(s)Cylinders & Beams168ApparatusInternal Vibrator 9000 vpm Check periodically with a vibrating – reedtachometer Vibrator element must be ¼ of thediameter of the cylinder mold or b

2022 2 5 Year Certification Written Exam Performance Exam Failure of Either Exam Requires retake of failed exam within 1 year Entire written exam Entire performance exam If date is missed, student must retake both exams Student is responsible for rescheduling of retake Exam Requirements Introduction 5 Written Exam Questions Standard Specifications