Transcription

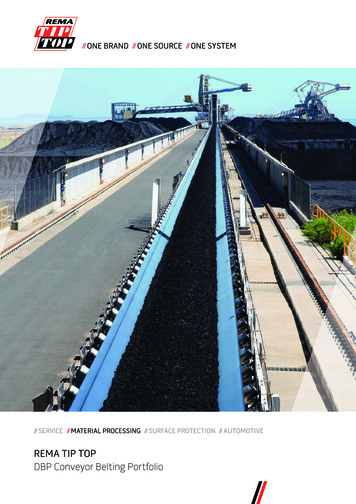

ENSynthetic Conveyor BeltsGeneral BrochureInnovation andService in Belting

1. Company profileAmmeraal Beltech is a global market leader in the design,manufacturing, fabrication and servicing of high-quality,high-performance process and conveyor belts.Ammeraal Beltech products are at homein nearly every industry, often in criticalapplications:We employ over 3,000 of the best people in the business– people who love belting and are passionate about whatthey do best – helping our customers with their beltingchallenges, so they can achieve more production up-time,higher product quality and lower total cost of ownership(TCO). Our products are available in 150 countries around theworld; our network is vast, which means it’s also local, andon-site service is often 24/7.In addition to our Synthetic Belt range, we offer: Modular Belts Homogeneous Belts Plastic and Steel Chains Engineered Belts High Performance Flat Belts Endless Woven Belts Round & V-beltsAirportsAutomotiveCarton, Paper, Packaging materialsCoating & LaminationFoodLogisticsMarble and CeramicMetalTextileTobaccoTreadmillsTyreWoodlocal stockquick belt replacementshort delivery time24/7 service

2. Features & StandardsAmmeraal Beltech Synthetic Belts are designed to meet the specific needs of the industries in which they areused. We offer a broad array of materials, constructions, colours and unique features of design created throughcollaboration with industry leaders in the segments we service.Some of our features & standards are: Food gradeWe manufacture belts for use in high or low temperatures,with excellent resistance to oils and fats and superb releasecharacteristics. To ensure food safety and to avoid any foodcontamination, a complete range of belts is available incompliance with: the latest EU regulation EC 1935/2004, EU 10/2011 andamendments food contact surface FDA standards AntiMicrobialAmmeraal Beltech developed belts with antimicrobialadditives to assist in reducing the number of microbes onfood contact surfaces. This also reduces the risk of foodcontamination - insuring optimum adherence to your foodsafety standards and supports the implementation of yourISO 22000 (ex HACCP) programs. Non-frayOur non-fray belts run and remain intact longer anddeliver even better food hygiene by reducing fabric fraycontamination. Our KleenEdge and AmSeal Belts tacklecontamination risks that may occur from belt edge wear.The belt construction is designed in such a way thatthe high strength reinforcement fabric is held securelytogether with a tough non-cracking thermoplasticpolyurethane seal. Knife-edge transferParticularly when conveying small goods, the transferbetween 2 belts must be as short as possible. In this caseit is common to use knife-edges. More tension is neededto flex the belt over a knife-edge which causes more wear.This calls for premium quality belts.

Low noise, Flame-retardant, Impact ResistantWe offer low noise belts, flame retardant belts and beltsdesigned to handle impact and abrasion; all of whichis required in todays high speed logistics and airportenvironments. High gripOur high grip belts are specifically designed to increase thefriction between the belt and the products being carried.This is often needed for inclined transport or in slipperyconditions. High grip characteristics can be obtained byusing cover surface profiles (embossing). Wear-resistantWe offer a range of wear-resistant belts that are specificallydesigned to handle even the toughest conditions you canthink of. Wear-resistance is one of the most importantproperties that determine the life expectancy of a process& conveyor belt. Energy savingBelt selection is a very important factor in saving energy,but not the only one. Ammeraal Beltech’s ‘Energy SavingConcept’ is based on 3 pillars that influence the powerdemands of a conveyor: Conveyor design, in order to get the basics right Belt selection, a fit for purpose belt Drum motor sizing, not too big (waste of energy) andnot too small (will be overworked)

3. Indication of useThere are more usages forSynthetic Belts besides the normalA-to-B (horizontal) conveying ofgoods, where a specific belt isneeded to get the job done. Troughed (roller support)Process- and Conveyor typeexamples: Troughed conveyors Curved conveying Inclined or declined conveying AccumulationCurved belts are used to change the direction of travelof goods (between 30 and 180 degrees), for sortingpurposes or when saving floor space is crucial.Used to convey bulk materials such as sand, grain,sugar, etc. The belts need to have good lateral flexibility. Curved conveying Inclined/declined conveyingFor inclined conveying measures must be taken toprevent goods from sliding down or falling: cover profileproviding high friction between goods and belts oraccessories (like cleats) for larger angles of inclinationor for bulk products. AccumulationTo interrupt the flow of goods temporarily, the simplestsolution is to stop the belt, but often this is neitherpossible nor desirable. In this case, the flow of goods isstopped, while the belt continues to run.This is called accumulation or buffering.

4. MaterialsOur comprehensive range of Synthetic Belts is able to fulfil the application needs for light to heavy processing andconveying applications.Synthetic conveyor belts are made of fabrics with a coating on the top and/or bottom side. A belt consists ofone or more fabric plies to give features such as strength, stability and impact resistance. The coatings usedon Synthetic Belts are called polymers and can be made of various materials which can be of influence on thesuitability of the belt in a certain application.Main used compounds for coatings are: PVC: Flexam, NonexPolyurethane: Ropanyl, Ropanol, Ropan, Ultraclean, UltranylPolyolefin: Peflex, Poliflex, PolikleenPolyester: AmtelSilicone: SilamSpecial Blends: Pletex, Elastoflex, ElastonylBy mixing polymers together, Ammeraal Beltechproduces variations on PVC or PU called “SpecialBlends”.The Synthetic Belts range also includes Fabricand Felt belts, used in a wide variety of materialtransport applications such as car manufacturing,food processing and heavy industry.Felt is a non-woven fabric. The most importantraw material for belting fabrics is polyester.Main fabrics used are: Cotton (natural) Flax(natural) Polyamide (synthetic) Polyester(synthetic).

PVC BELTSPOLYURETHANE BELTSFlexam Good chemical resistance (including chlorine) Hydrolysis resistance (hot water and steam) Flame-retardant types available (ISO 340)Nonex Good resistance to oil and fat Food compliance for all foodstuff Available in white and light blue, and withvarious profilesRopanyl Belts with thermoplastic polyurethane coating Very flexible even at low temperatures Very good resistance to oil and fatRopanol Belts with polyurethane impregnation (zerothickness) Low friction top side for accumulation Very flexible even at low temperaturesRopan Belts with unique heavy duty polyurethane coating Extremely good abrasion and cut resistance Thermoplastic inner layer, suitable for hotsplicingUltranyl Very good hydrolysis resistance Belts with thermoplastic polyurethane coating Flexible, suitable for high temperatureUltraclean Excellent release properties Very good oil and fat resistance High chemical resistanceDraft

POLYOLEFIN & POLYESTER BELTSSPECIAL BLENDS BELTSPeflex Flexible at low temperatures Chemically inert material, good chemical resistance Pyrolysis resistance non-toxic when burning(tobacco approved)Poliflex Excellent chemical resistance Pyrolysis resistance (non-toxic when burning,tobacco approved) Food compliance for all foodstuffPolikleen Excellent chemical resistance Pyrolysis resistance (non-toxic when burning,tobacco approved) Good wear resistanceAmtel Polyester Mechanically very strong Flexible at low temperaturesPletex High grip Good chemical resistance Available in red colourSilam Good release of sticky products High temperature resistance Chemical resistanceElastoflex Very good wear resistance and good grip Good oil resistance Available in green and beige colourElastonyl Excellent wear-resistance and good grip Very good oil resistance Available in green colour

5. Fabrication & AccessoriesSynthetic Belts can also be fitted with accessories such as cleats (also called carriers), ropes and bordoflex.Fitting of accessories is only possible on thermoplastic belts using a material that is similar to the belt cover.Rubber accessories are always glued.icrseCourseFabric FabricBased BasedBeltingBeltingMain STANDARD fabrication and accessoriessibleMaterialMaterialtypesPVCPURPVCPUR PE SIy belts- y belts y belts- CleatsTopTopBottomPE SI Rubber CoverImpregnationRubber CoverImpregnationCover BordoflexRopes & Strips (V Guide)BottomCoverImpregnatioImpregnationFabr - -AmsealCleats (also called ‘carriers’) Bordoflex is used toRopes and strips can be used: Belt with Amseal closedadhesionon fabricis insufficient,thereforeAmsealis not advised.Amsealon fabricthereforeisnot ofadvised.Amsealisnot is nare usedison insufficient,the topside of increaseconveying Amseal on thetopsidethe beltedgesare used material.beltforinclinedandcapacitybulkgoodsandas innerlayerspill material.edges, in particularmarket segments to d conveying as well are transported.where bulk goods arebacteria growth, frayingproductseparationtoinThereare two oftypesofconveyed to maintainoredges, conveyorfabric particles inbelting,ealweldedis ,edgetheofthermoplasticandbelting,usingmany industries:Bordoflex:solid and fabric processincrease capacityandconveyoralso the products(usually eprovidedwithAmseal.agriculture, Thermosetreinforced. Thefabric cannotas cleatsdivide the flow withand idedAmseal.chemical, packaging, andreinforced type is moreof goods.automotive.rigid and tear resistant on the bottom side of thethan the solid one.belt to assist and improvetrackingOther SPECIAL fabrication and accessoriesDepannersdepannerspannersFinger cleatsFinger cleatser cleatsFlower cleatsFlower cleatsFlower cleatsBrush beltsBrush beltsBrush beltsPillows PillowsPillowsHarvest beltsGrapebeltsharvesGrape harves

6. Endlessing methodsTo make belts endless, Ammeraal Beltech offers several options with the choice of type dependent on theapplication itself. Multiple in-house developed splice tools are available.Standard splicing methodsFinger SpliceFinger-overlap-finger Splice Stepped SpliceSkived Splice 40 - 50% strength of beltbreaking strength Consistent thickness Flexible 2 running directions 70 - 80% strength of beltbreaking strength Consistent Thickness Strong and reliable in dirtycircumstances Combination of a finger anda stepped splice 75 - 85% strength of beltbreaking strength Increased thickness Very strong and reliable Easy to prepare One running direction 65 - 75% strength of beltbreaking strength More ‘stiff’ than the belt Easy to prepare One running directionSteel lacingStaple laceFastener methodsWire hooksSpiral laceMaestro Splicing Equipmentfor Fast and High Quality SplicingZipLockZipLock is ideal for applications wherebelt replacement time is an issue, forexample on airports and in distributioncentres. Especially designed forapplication in inaccessible locations, suchas conveyors at ceiling height, very shortconveyors, built-in conveyors etc.

Local Contacts. and 150 more service contact pointsat ammeraalbeltech.comAustriaT 43 171728 133info-de@ammeraalbeltech.comIndiaT 91 44 265 34 244info-in@ammeraalbeltech.comSlovakiaT 421 255648542info-sk@ammeraalbeltech.comBelgiumT 32 2 466 03 00info-be@ammeraalbeltech.comIsraelT 972 4 6371485info-il@ammeraalbeltech.comSouth KoreaT 82 31 448 3613-7info-kr@ammeraalbeltech.comCanadaT 1 905 890 1311info-ca@ammeraalbeltech.comItalyT 39 051 660 60 06info-it@ammeraalbeltech.comSpainT 34 93 718 3054info-es@ammeraalbeltech.comChileT 56 2 233 12900info-cl@ammeraalbeltech.comJapanT 81 52 433 7400info-jp@ammeraalbeltech.comSwedenT 46 (0) 10 130 96 00info-se@ammeraalbeltech.comChinaT 86 512 8287 2709info-cn@ammeraalbeltech.comLuxembourgT 352 26 48 38 56info-lu@ammeraalbeltech.comSwitzerlandT 41 55 2253 535info-ch@ammeraalbeltech.comColombiaT 57 1 893 9890info-co@ammeraalbeltech.comMalaysiaT 60 3 806 188 49info-my@ammeraalbeltech.comThailandT 66 2 902 2604-13info-th@ammeraalbeltech.comCzech RepublicT 420 567 117 211info-cz@ammeraalbeltech.comMexicoT 52 55 5341 8131info-mx@ammeraalbeltech.comTurkeyT 90 232 877 0700info-tr@ammeraalbeltech.comDenmarkT 45 7572 3100info-dk@ammeraalbeltech.comNetherlandsT 31 72 57 51212info-nl@ammeraalbeltech.comUnited KingdomT 44 1992 500550info-uk@ammeraalbeltech.comFinlandT 358 207 911 400info-fi@ammeraalbeltech.comPeruT 51 1 713 0069info-pe@ammeraalbeltech.comUnited StatesT 1 847 673 6720info-us@ammeraalbeltech.comFranceT 33 3 20 90 36 00info-fr@ammeraalbeltech.comPolandT 48 32 44 77 179info-pl@ammeraalbeltech.comVietnamT 84 8 376 562 05info-vn@ammeraalbeltech.comEngineered BeltsSingaporeT 65 62739767info-sg@ammeraalbeltech.comHomogeneous BeltsHungaryT 36 30 311 6099info-hu@ammeraalbeltech.comFabrication & ServiceAustraliaT 61 3 8780 6000info-au@ammeraalbeltech.comExpert advice, quality solutionsand local servicefor all your belting needsSynthetic BeltsPortugalT 351 22 947 94 40info-pt@ammeraalbeltech.comEndless Woven BeltsGermanyT 49 4152 937-0info-de@ammeraalbeltech.comModular BeltsArgentinaT 54 11 4218 2906info-ar@ammeraalbeltech.comGeneral contact information:Ammeraal BeltechP.O. Box 381700 AA HeerhugowaardThe NetherlandsT 31 (0)72 575 1212info@ammeraalbeltech.comMember of Ammega Group.Date: 05.2021ammega.com

for all your belting needs. Fabrication & Service Endless Woven Belts Synthetic Belts Engineered Belts Modular Belts. General contact information: Ammeraal Beltech . P.O. Box 38 1700 AA Heerhugowaard The Netherlands T 31 (0)72 575 1212 info@ammeraalbeltech.com. ammega.com. Member of Ammega Group. Argentina. T 54 11 4218 2906 info-ar .