Transcription

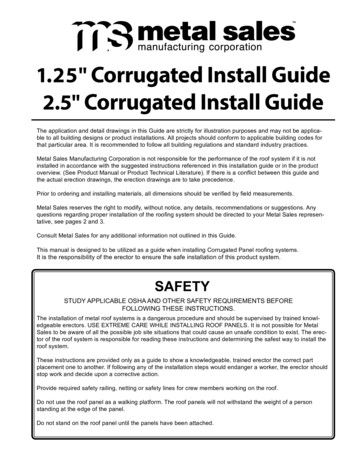

1.25" Corrugated Install Guide2.5" Corrugated Install GuideThe application and detail drawings in this Guide are strictly for illustration purposes and may not be applicable to all building designs or product installations. All projects should conform to applicable building codes forthat particular area. It is recommended to follow all building regulations and standard industry practices.Metal Sales Manufacturing Corporation is not responsible for the performance of the roof system if it is notinstalled in accordance with the suggested instructions referenced in this installation guide or in the productoverview. (See Product Manual or Product Technical Literature). If there is a conflict between this guide andthe actual erection drawings, the erection drawings are to take precedence.Prior to ordering and installing materials, all dimensions should be verified by field measurements.Metal Sales reserves the right to modify, without notice, any details, recommendations or suggestions. Anyquestions regarding proper installation of the roofing system should be directed to your Metal Sales representative, see pages 2 and 3.Consult Metal Sales for any additional information not outlined in this Guide.This manual is designed to be utilized as a guide when installing Corrugated Panel roofing systems.It is the responsibility of the erector to ensure the safe installation of this product system.SAFETYSTUDY APPLICABLE OSHA AND OTHER SAFETY REQUIREMENTS BEFOREFOLLOWING THESE INSTRUCTIONS.The installation of metal roof systems is a dangerous procedure and should be supervised by trained knowledgeable erectors. USE EXTREME CARE WHILE INSTALLING ROOF PANELS. It is not possible for MetalSales to be aware of all the possible job site situations that could cause an unsafe condition to exist. The erector of the roof system is responsible for reading these instructions and determining the safest way to install theroof system.These instructions are provided only as a guide to show a knowledgeable, trained erector the correct partplacement one to another. If following any of the installation steps would endanger a worker, the erector shouldstop work and decide upon a corrective action.Provide required safety railing, netting or safety lines for crew members working on the roof.Do not use the roof panel as a walking platform. The roof panels will not withstand the weight of a personstanding at the edge of the panel.Do not stand on the roof panel until the panels have been attached.

1.25" Corrugated2.50" Corrugated9Branch Territory Map818617213111414125,10719201513216NOTE: Shaded areas represent regions served by each location.For more than 50 years, Metal Sales Manufacturing Corporation has earned a reputationas the premier provider of innovative metal building components and accessories.We’ve backed this reputation with the industry’s largest professional sales andservices team. We offer a full line of exceptional quality metal roof and wall panelsfor agricultural, commercial, architectural, industrial, and residential projects ofevery shape and size, new construction or retro-fit.2 Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/16

1.25" Corrugated2.50" CorrugatedBranch Locations1.) DENVER BRANCH7990 E. I-25 Frontage RoadLongmont, CO 80504303.702.5440 Phone800.289.7663 Toll Free800.289.1617 Toll Free Fax8.) SPOKANE BRANCHEast 2727 Trent AvenueSpokane, WA 99202509.536.6000 Phone800.572.6565 Toll Free509.534.4427 Fax15.) FONTANA BRANCH14213 Whittram AvenueFontana, CA 92335909.829.8618 Phone800.782.7953 Toll Free909.829.9083 Fax2.) JACKSONVILLE BRANCH7110 Stuart AvenueJacksonville, FL 32254904.783.3660 Phone800.394.4419 Toll Free904.783.9175 Fax800.413.3292 Toll Free Fax9.) SEATTLE BRANCH20213 84th Avenue, SouthKent, WA 98032253.872.5750 Phone800.431.3470 Toll Free (Outside WA)800.742.7900 Toll Free (Inside WA)253.872.2008 Fax16.) ANCHORAGE BRANCH4637 Old Seward HighwayAnchorage, AK 99503907.646.7663 Phone866.640.7663 Toll Free907.646.7664 Fax3.) JEFFERSON BRANCH352 East Erie StreetJefferson, OH 44047440.319.3779 Phone800.321.5833 Toll Free440.576.9242 Fax800.233.5719 Toll Free Fax10.) NEW ALBANY BRANCH999 Park PlaceNew Albany, IN 47150812.944.2733 Phone812.944.1418 Fax4.) INDEPENDENCE BRANCH1306 South Powell RoadIndependence, MO 64057816.796.0900 Phone800.747.0012 Toll Free816.796.0906 Fax5.) SELLERSBURG BRANCH7800 State Road 60Sellersburg, IN 47172812.246.1866 Phone800.999.7777 Toll Free812.246.0893 Fax800.477.9318 Toll Free Fax6.) ROGERS BRANCH22651 Industrial BoulevardRogers, MN 55374763.428.8080 Phone800.328.9316 Toll Free763.428.8525 Fax800.938.9119 Toll Free Fax7.) NASHVILLE BRANCH4314 Hurricane Creek BoulevardAntioch, TN 37013615.229.6570 Phone800.251.8508 Toll Free615.283.4283 Fax800.419.4372 Toll Free Fax11.) ROCK ISLAND BRANCH8111 West 29th StreetRock Island, IL 61201309.787.1200 Phone800.747.1206 Toll Free309.787.1833 Fax12.) DEER LAKE BRANCH29 Pinedale Industrial RoadOrwigsburg, PA 17961570.366.2020 Phone800.544.2577 Toll Free570.366.1648 Fax800.544.2574 Toll Free Fax13.) TEMPLE BRANCH3838 North General Bruce DriveTemple, TX 76501254.791.6650 Phone800.543.4415 Toll Free254.791.6655 Fax800.543.4473 Toll Free Fax14.) WOODLAND BRANCH1326 Paddock PlaceWoodland, CA 95776530.668.5690 Phone800.759.6019 Toll Free530.668.0901 Fax17.) BAY CITY BRANCH5209 Mackinaw RoadBay City, MI 48706989.686.5879 Phone888.777.7640 Toll Free989.686.5870 Fax888.777.0112 Toll Free Fax18.) DETROIT LAKES BRANCH1435 Egret AvenueDetroit Lakes, MN 56501218.847.2988 Phone888.594.1394 Toll Free218.847.4835 Fax888.594.1454 Toll Free Fax19.) MOCKSVILLE BRANCH188 Quality DriveMocksville, NC 27028704.859.0550 Phone800.228.6119 Toll Free704.859.0157 Fax800.228.7916 Toll Free Fax20.) FORT SMITH BRANCH7510 Ball RoadFort Smith, AR 72908479.646.1176 Phone877.452.3915 Toll Free479.646.5204 Fax21.) SIOUX FALLS BRANCH2700 West 3rd Street, Suite 4Sioux Falls, SD 57104605.335.2745 Phone888.299.0024 Toll FreeTECHNICAL SUPPORTTECHNICAL SERVICES545 South 3rd Street, Suite 200Louisville, KY 40202502.855.4300 Phone800.406.7387 Toll Free502.855.4290 Fax Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/163

1.25" Corrugated2.50" CorrugatedTABLE OF CONTENTSPAGE NO.General InformationImportant Information & Safety .1Branch Territory Map .2Branch Locations.31.25" Corrugated Panel Information .61.25" Corrugated Section Properties and Fastening Patterns .72.5" Corrugated Panel Information .82.5" Corrugated Section Properties and Fastening Patterns .9Flashing Profiles .10Accessories . 11Fastener Selection Guide .12Fastener Installation Technique.12Design / Installation ConsiderationsGeneral.13Condition of Substructure.13Handling MaterialReceiving Material.14General Handling.14Mechanical Handling.14Manual Handling.15StorageGeneral .16Foot Traffic .16Required Tools.16Field Cutting and Touch-UpField Cutting.17Touch-Up Paint.17Ventilation.174 Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/16

1.25" Corrugated2.50" CorrugatedTABLE OF CONTENTS (cont.)PAGE NO.Corrugated Panel InstallationInstalling Closures (Step 1).18Installing First Panel (Step 2).18Eave Detail.19Box Gutter Detail.19Installing Second Panel (Step 3).20Installing Sidelap Panel (Step 4).20Endlap Detail.21Valley Detail.21Rake Detail.22Rakewall Detail.22Endwall Detail.23Peak Detail.23Hip Detail.24Ridge Detail.24Additional DetailsChimney/Cricket Detail.25Roof Penetration Detail.25Care and Maintenance .26Notes .27 Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/165

1.25" Corrugated2.50" Corrugated1.25" CORRUGATED PANEL INFORMATIONPANEL PROFILE24" CoverageColor ATIONPERFORMANCE TESTFASTENING SYSTEMFASTENERSMATERIALSFINISH511/4"12"1/4"The minimum recommended slope for any 1.25" Corrugated roof panel is 3:12.The recommended substrates are 5/8" plywood with a 30 pound felt moisture barrier or open framing. Toavoid panel distortion, use a properly aligned and uniform substructure.1.25" Corrugated is available in 24" width with a 1/2" rib height.Lengths under 5'-0" are available with some cutting restrictions. Maximum recommended panel length is45'-0". Longer panels require additional consideration in packaging, shipping and erection. Please consultyour Metal Sales branch for recommendations (see pages 2-3 for branch locations).26 Gauge standard. (Optional 29 Ga. Contact your local Metal Sales branch for availability)Architectural and Residential panelUL 790, UL 263, UL 2218Direct fastened (exposed)The fastener selection guide should be consulted for choosing proper fasteners for specific applications.Quantity and type of fastener must meet necessary loading and code requirements (see page 12).Steel grade 50, per ASTM A 792 *Acrylic Coated Galvalume (ACG) / ASTM A 792 - AZ55 Pre-painted Galvalume, MS Colorfast45 / ASTM A 792 - AZ50 **PVDF***6/8"Differential appearance of Acrylic Coated Galvalume roofing materials is not a cause for rejection.Meets both Kynar 500 and Hylar 5000 specifications. Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/16

1.25" Corrugated2.50" Corrugated1.25" SECTION PROPERTIES & FASTENING PATTERNROOF & WALL FASTENING PATTERNEnds and Field of PanelSide Lap 1/4-14 x 7/8" Stitch Fastener (1'-0" o.c.)Panel FastenerTape SealantALLOWABLE UNIFORM LOADS, psfFor various fastener spacingsSECTION PROPERTIESGaWidth Yield WeightinksipsfInwardLoadTop In Compression Bottom In wardLoad1' 1.25' 1.5' 1.75' 2'2.5'1' 1.25' 1.5' 1.75' 196 12673463116202 127734631161. Theoretical section properties have been calculated per AISI 2007 'North American Specification for the Design of Cold-Formed Steel Structural Members'. Ixx and Sxx areeffective section properties for deflection and bending.2. Allowable load is calculated in accordance with AISI 2007 specifications considering bending, shear, combined bending and shear and deflection. Allowable load considers the3 or more equal spans condition. Allowable load does not address web crippling, fasteners, support material or load testing. Panel weight is not considered.3. Deflection consideration is limited by a maximum deflection ratio of L/180 of span.4. Allowable loads do not include a 1/3 stress increase for wind. Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/167

1.25" Corrugated2.50" Corrugated2.5" CORRUGATED PANEL INFORMATIONPANEL PROFILE211/3" Roof Coverage11/3"Color Side22/3"12"1/2"24" Wall CoverageColor PPLICATIONPERFORMANCE TESTFASTENING SYSTEMFASTENERSMATERIALSFINISH22/3"1/2"The minimum recommended slope for any 2.5" Corrugated roof panel is 3:12.The recommended substrates are 5/8" plywood with a 30 pound felt moisture barrier or open framing. Toavoid panel distortion, use a properly aligned and uniform substructure.2.5" Corrugated roof coverage is 21-1/3" wide with a 1/2" rib height.2.5" Corrugated wall coverage is 24" wide with a 1/2" rib height.Lengths under 5'-0" are available with some cutting restrictions. Maximum recommended panel length is45'-0". Longer panels require additional consideration in packaging, shipping and erection. Please consultyour Metal Sales branch for recommendations (see pages 2-3 for branch locations).26 gauge standard. (Optional 24 ga. and 29 ga. Contact your local Metal Sales branch for availability)Architectural and Residential panelUL 790, UL 263, UL 2218, Texas Windstorm Evaluation RC-159, 2010 FBC Approval FL14645.1,ICC Evaluation Report ESR-2385Direct fastened (exposed)The fastener selection guide should be consulted for choosing proper fasteners for specific applications.Quantity and type of fastener must meet necessary loading and code requirements (see page 12).Steel grade 50, per ASTM A 792 *Acrylic Coated Galvalume (ACG) / ASTM A 792 - AZ55 Pre-painted Galvalume, MS Colorfast45 / ASTM A 792 - AZ50 **PVDF***812"Differential appearance of Acrylic Coated Galvalume roofing materials is not a cause for rejection.Meets both Kynar 500 and Hylar 5000 specifications. Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/16

1.25" Corrugated2.50" Corrugated2.5" SECTION PROPERTIES & FASTENING PATTERNSROOF FASTENING PATTERNEnds of PanelSide Lap 1/4-14 x 7/8" Stitch Fastener (1'-0" o.c.)Panel FastenerTape SealantSide Lap 1/4-14 x 7/8" Stitch Fastener (1'-0" o.c.)Field of PanelPanel FastenerTape SealantALLOWABLE UNIFORM LOADS, psfFor various fastener spacingsSECTION 3321.338080500.700.901.17Top In CompressionBottom In CompressionInward LoadOutward 71013445582228371419251013171. Theoretical section properties have been calculated per AISI 2007 'North American Specification for the Design of Cold-Formed Steel Structural Members'. Ixx and Sxx areeffective section properties for deflection and bending.2. Allowable load is calculated in accordance with AISI 2007 specifications considering bending, shear, combined bending and shear and deflection. Allowable load considers the3 or more equal spans condition. Allowable load does not address web crippling, fasteners, support material or load testing. Panel weight is not considered.3. Deflection consideration is limited by a maximum deflection ratio of L/180 of span.4. Allowable loads do not include a 1/3 stress increase for wind.WALL FASTENING PATTERNPanel FastenerALLOWABLE UNIFORM LOADS, psfFor various fastener spacingsSECTION PROPERTIESGa292624Width Yield Weightinksipsf2424248080500.620.801.04Top In Compression Bottom In 50.01850.02440.0315Inward Load2' 2.5'103 53134 69175 903'3140523.5'1925334'131722Outward Load4.5' 2' 2.5'9 103 5312 134 6915 175 903'3140523.5'1925334'1317224.5'912151. Theoretical section properties have been calculated per AISI 2007 'North American Specification for the Design of Cold-Formed Steel Structural Members'. Ixx and Sxx areeffective section properties for deflection and bending.2. Allowable load is calculated in accordance with AISI 2007 specifications considering bending, shear, combined bending and shear and deflection. Allowable load considers the3 or more equal spans condition. Allowable load does not address web crippling, fasteners, support material or load testing. Panel weight is not considered.3. Deflection consideration is limited by a maximum deflection ratio of L/180 of span.4. Allowable loads do not include a 1/3 stress increase for wind. Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/169

1.25" Corrugated2.50" CorrugatedFLASHING PROFILES320126423101622181311. BASE MOLDING82141771. ANGLE BASE2. J-CHANNELC1"1 1/2"7/8"2"1"45 1"C1 1/2"71"3. 14" UNIVERSAL RIDGE/8"4. 12" SOFFIT4. SOFFIT1 3/4"C321159C1"5115 1/2"4"/8"3143 12"5 1/2"1 3/4"/8"3 1/2"C1C5 1/8"/2"12"4. 24" SOFFIT5. UNIVERSAL ENDWALL6. UNIVERSAL SIDEWALLC5 1/2"C105 1/8"1 /4"3124"/2"5"C143 3 /2"4"1"13 /2"173/4"/8"1" Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/16

1.25" Corrugated2.50" CorrugatedFLASHING PROFILES7. MINI ANGLE8. INSIDE CORNERC9. POST TRIMC11/2"11/2"4"C1"4"11/2"10. TOP MOUNT TRACK COVER10. NATIONAL TRACK COVER3 /2"1 /4"C35/8"17/8"523/8"4"1"CC5 /4"54"23/4"1/2"/8"5314. OVERHEAD DOOR TRIMC/4"13. OUTSIDE CORNER1/4"15/16"3C11/16"367/8"13/8"/8"12. RAKE TRIM4"7147 /2"11. GABLE TRIM/8"C1 /8"147 21/4"5111/16"341/2"21/2"110. CANNONBALL TRACK COVERC1391/4"/8"15. DOOR JAMB11/2"/8"16. DRIP CAPC1 /8"715/8"17/8"21/2"7C/8"9 /4" or 7 /4"11/8"1/2"7 /8"7 Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/1611

1.25" Corrugated2.50" CorrugatedPOST FRAME FLASHING PROFILES17 - DOOR POST TRIM18 - FRAMING CLOSURE20 - TRANSLUCENT PANELC11/4"55/8"31/4"ilerofl P ionsean nse P meSe r DiFo2"1 /2"1C35/8"21 - EAVE MOLDING3LENGTHS: 8'-0",10'-0",12'-0"/4"22 - DOUBLE ANGLE23 - WIDE Z-METAL31/2"CC1 /4"1105 711/8"/8"C41/8"11/2"5130 313/16"/4"124 - UNIVERSAL GAMBREL31/2"25 - RAKE / EAVE TRIM11/4"341/4"120 /4"26 - 3/8" F & J-CHANNEL15/8"C23/4"/8"/8"1"23/4"23/4"1/4"1/2"3/8" Hem26 - 3/4" F & J-CHANNEL11/4"3/4"1"21/4"C12 Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/16C

1.25" Corrugated2.50" CorrugatedRESIDENTIAL FLASHING PROFILES1511 - RIDGE / HIP COVER64231 - 13" STEP RIDGE / HIPCOVER2 - GABLE TRIM510"C5 1/2"C1 1/2"4"/8"C11/16"51/4"1"53 - EAVE4 - UNIVERSAL ENDWALL/8"4 - PITCH BREAK3 7/8"C4"4"3"51"3 1/2"C7Specify Angle/8"C6"/8"5 - UNIVERSAL SIDEWALL6 - VALLEYCC4"1"31/2"79 1/2"/8"1" Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/1613

1.25" Corrugated2.50" CorrugatedFLASHING h 10'-2" - *Specify Slope AngleBOX GUTTER END/2"Length 10'-2", 20'-3"*Specify Slope AngleLength 10'-2"BOX GUTTER ENDUNIVERSAL GUTTER/DOWNSPOUT STRAPHem31/2"1"1"X*5"4"5"1"4"Hem1"CCC5"10"135 CHemC1"16"5"11/2"Length 10'-2", 20'-3" *Specify Slope Angle950 ELBOW 4" x 31/2"DOWNSPOUT 4" x 31/2"4"4"31/2"DOWNSPOUT BRACKET31/2"CCC4"Length 10'-2", 20'-3"(Also available 6" x 4")RAKE(Also available 6" x 4")RAKEWALL(Also available 6")PEAKC6"X*5"3Length 10'-2", 20'-3"Length 10'-2"FORMED RIDGEFORMED RIDGE1.25" CORRUGATED2.5" CORRUGATEDLength 10'-2"/8"11" RIDGE/HIP COVERC51/2"X*Hem14Length 10'-2", 20'-3" - *Specify Slope Angle Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/16

1.25" Corrugated2.50" CorrugatedFLASHING PROFILESREGLET FLASHINGPITCH BREAKCOUNTER FLASHING1C/2"4"X*51"1"C2"6"HemLength 10'-2" - *Specify Slope Angle1.25" Corrugated2.50" CorrugatedLength 10'-2"3/8"/4"3C/4"Length 10'-2"ACCESSORIESCORRUGATED CLOSURESTUBE SEALANTTAPE SEALANT1 1/4" CORRUGATED2 1/2" CORRUGATED1" x 2'-0"Polyethylene Foam10.3 oz. Cartridge UrethaneRUBBER ROOF JACKTOUCH-UP PAINTSingle Bead Sealant3 8/ " Bead x 50' Butyl - GreyUNIVERSAL CLOSURERound or SquareMini (1/4" to 11/8" O.D. Pipe)#2 (13/4" to 3" O.D. Pipe)#4 (3" to 6" O.D. Pipe)#6 (6" to 9" O.D. Pipe)#8 (7" to 13" O.D. Pipe)Available in pintsMS Colorfast45 or PVDF1" x 1-1/2" x 50'-0"1" x 1-1/2" x 10'-0"ms-HT UNDERLAYMENTHigh-Temperature UnderlaymentC- Indicates color side of flashing. Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/1615

1.25" Corrugated2.50" CorrugatedPOP RIVETFASTENER SELECTION GUIDESIZETYPEFINISHAPPLICATION/"x / "AUnpaintedFlashing to Panel,Flashing to Flashing/ " x 3/16"APaintedFlashing to Panel,Flashing to FlashingSIZETYPEFINISHAPPLICATION#10-12 x 1"APlatedPanel or Flashing towood substructureSIZETYPEFINISHAPPLICATION#10-14 x 1"#10-14 x 11/2"#10-14 x 2"AAAPaintedPaintedPaintedPanel or Flashingto wood substructureSIZETYPEFINISHAPPLICATION/ - 14 x 7/8"StitchPaintedFlashing to Panel,Flashing to Flashing,Panel Sidelap1 83 161 8PANCAKE HEAD WOODSCREWWOODSCREWSTITCH SCREW1 4FASTENER INSTALLATION TECHNIQUERecommended Tool Type - Use depth locating nose or adjustable clutch on screw gun to prevent overdrilling and strip out.Do not use impact tools or runners.Seating the washer - Apply sufficient torque to seat the washer - do not overdrive the fastener.CORRECTWOODSCREWSealing material slightly visible at edge of metal washer.Assembly is watertight.TOO LOOSESealing material is not visible;not enough compression toseal properly.TOO TIGHTMetal washer deformed;sealing material pressedbeyond washer edge.To prevent wobbling - Make sure fastener head iscompletely engaged in the socket. If the head does notgo all the way in the socket - tap the magnet deeper intothe socket to allow full head engagement. Metal chipswill build up from drilling and should be removed fromtime to time.Protect drill point - Push only hard enough on thescrew gun to engage clutch. This prevents excess friction and burn out of the drill point. Correct pressurewill allow screw to drill and tap without binding.Drilling through sheet and insulation - Ease up onpressure when drilling through insulation to avoidstriking the purlin or girt with the point - apply morepressure after drill point contacts purlin or girt.Drilling through purlin overlaps - Drilling through lapped purlins requires extra care. Excessive voids between purlinssometimes damages drill points and two self-drillers might be necessary to complete the operation. It is sometimes advantageous to predrill.16 Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/16

1.25" Corrugated2.50" CorrugatedDESIGN / INSTALLATION CONSIDERATIONSGENERALMetal Sales’ panels are designed to be installed over open framing and/or directly over a wood substrate (minimum 5/8”)with 30# felt moisture barrier (or an Ice and Water Shield when required by Local Building Codes).Always check with local building codes prior to all installations for any additional requirements that may be specific to yourarea.Galvanized and Galvalume panels should not be in contact with, or subject to, water runoff from copper, lead, or uncoatedsteel materials.Condensate water from air conditioning units typically contains dissolved copper. This condensate should be dischargedthrough a plastic pipe extended beyond the edge of the roof.CONDITION OF SUBSTRUCTUREThe roof should be inspected for any trapped moisture or structural damage such as bowing or sagging rafters and warped orloose roof purlins or solid decking. These areas should be repaired prior to installing new metal panels.Prior to installation, make sure there are no nails or fasteners protruding from the roof framing or wood substrate which coulddamage the panels and impede the installation process.When installed, panel distortion may occur if not applied over properly aligned and uniform substructure.Whether installing over new or existing roof, the installer should check the roof deck for squareness before installing panels.Several methods can be used to verify squareness of the structure for proper installation of the panels.METHOD “A” - One method for checking the roof for squareness is to measure diagonally across one slope of the roof fromsimilar points at the ridge and eave and obtain the same dimension.METHOD “B” - The 3-4-5 triangle system may also be used. To use this system, measure a point from the corner along theedge of the roof at a module of three (3). Measure a point from the same corner along another edge at a module of four (4).By measuring diagonally between the two points established, the dimension should be exactly a module of five (5) to have asquare corner. Multiple uses of this system may be required to determine building squareness. If the endwall cannot be madesquare, the roof system cannot be installed as shown in these instructions.METHOD A5050METHOD B543 Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/1617

1.25" Corrugated2.50" CorrugatedHANDLING MATERIALRECEIVING MATERIALIt is the responsibility of the installer to unload material from the delivery truck. The installer shall be responsible forproviding suitable equipment for unloading of material from the delivery.After receiving material, check the condition of the material, and review the shipment against the shipping list to ensure allmaterials are accounted for. If damages or shortages are discovered, it should be noted on the Bill of Lading at the time ofdelivery. A claim should be made against the carrier as soon as possible. Metal Sales is not responsible for any damages orshortages unless they are documented in writing and presented to Metal Sales within 48 hours.GENERAL HANDLINGEach bundle should be handled carefully to avoid being damaged. Care should be taken to prevent bending of thepanel or abrasion to finish. Whenever possible, the bundle should remain crated until it is located in its place of storage. If bundles must be opened, we recommend you re-crate them before lifting. To avoid damage please lift thebundle at its center of gravity.CAUTIONImproper loading and unloading of bundles and crates may result in bodily harm and/ormaterial damage. Metal Sales is not responsible for bodily injuries and/or materialdamages resulting from improper loading and unloading.MECHANICAL HANDLINGForklift - A forklift may be used for panels up to 20'-0" long. Please make sure the forks are at their maximum separation.Do not transport open bundles. When transporting bundles across rough terrain, or over a longer distance, some means ofsupporting the panel load must be used.Crane - A crane should be used when lifting panels with lengths greater than 20'-0". Please be sure to utilize a spreader bar toensure the even distribution of the weight to the pick up points. As a rule when lifting panels, no more than 1/3 of the length ofthe panel should be left unsupported. Never use wire rope because this will damage the panels.18 Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/16

1.25" Corrugated2.50" CorrugatedHANDLING MATERIAL (cont.)MANUAL HANDLINGWhen handling painted steel, care should be taken to prevent scratching of material. Clean gloves should be worn at all timesto prevent a reaction with salts found on bare skin. Installers should wear rubber sole shoes to keep from scuffing materialwhile walking on the roof.Handling of individual panels should be done carefully and properly to avoid bending or damaging. Panels should be carriedby grasping the edge of the panel so that the panel is vertical to the ground. The panel should not be carried horizontal to theground as this could cause the panel to buckle or bend in the center.Normally, individual panels can be handled by people placed every 6'-0" to 8'-0" along the length of the panel.CORRECTAX'M'-86INCORRECT Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/1619

1.25" Corrugated2.50" CorrugatedSTORAGEGENERALPlease inspect panels for moisture accumulation. If moisture has formed, the panels should be unbundled, wiped dry, andallowed to dry completely. Once dry, carefully re-stack the panels and loosely recover allowing for ample air circulation.Bundled sheets should be stored high enough off of the ground to allow for air circulation and prevent contact withaccumulating water. Elevate one end of the bundle to allow any moisture to run off the panels. Metal Sales recommendscovering the bundle with a tarpaulin. Do not use tight fitting plastic-type tarpaulins as panel bundle covers. While they mayprovide protection from heavy dow

Metal Sales reserves the right to modify, without notice, any details, recommendations or suggestions. Any questions regarding proper installation of the roofing system should be directed to your Metal Sales represen-tative, see pages 2 and 3. Consult Metal Sales for any additional information not outlined in this Guide.