Transcription

TIMING IS EVERYTHINGWarehouse management and theimportance of timing 2017 FourKites 1

INTRODUCTIONA bit about me: Ran an outbound shipping dockLed receiving operations for warehouse consolidation projectsImplemented a variety of technology focused process improvements for highvalue inbound goodsStood up a transportation account for a large oil and gas account utilizingOTMLed FourKites carrier onboarding teamCurrently a Senior Manager for Strategic Accounts at FourKites 2017 FourKites 2

RIGHT PLACE RIGHT QTY RIGHT PRICE RIGHT TIME Visibility trends in the industry: “The Amazon Effect” “63% of drivers are detained more than 3 hours per stop”- DAT Shippers focused on driving costs down TCO(total cost of ownership) models being adopted bycompanies No one wants to own inventory JIT principles being applied beyond manufacturing 2017 FourKites 3

HOW DO YOU GET VISIBILITY TODAY? 2017 FourKites 4

CONSTRAINTS Dock space Have you ever had a fully staged shipment on the dock for 5 hours, 5 days? Material handlers, operators, and clerks Thinking you have too many people at the beginning of the day and not enoughat the end- vis versa? Yard space Ever had an accident in the yard from too many trucks jockeying? Rack space If you knew that shipment was arriving tomorrow would you have put that skidin that location? Driver’s time Can you say you’ve never had a driver leave without getting loaded? 2017 FourKites 5

WASTE FROM POOR TIMING Waiting Receiving/shipping teams waiting to unload/load trucks Defects When people rush; wrong labels end up on the wrong skid etc Overproduction Using hot-shots and expedites when standard shipments would work if the customer had visibility Transportation Moving material to over-flow space Over processing Lack of space can lead to duplicate QA checks Inventory Keeping extra inventory because team doesn’t know when next shipment will arrive Motion Moving material around the dock because it was staged too early 2017 FourKites 6

PLANNING CASE STUDYInbound 4 LTL 14 TL 1 floor stack 6 hourly material handlers tounload and put-awayBryce 4 LTL 9 TL 6 hourly material handlers to pick,stage, and in 2017 FourKites 7

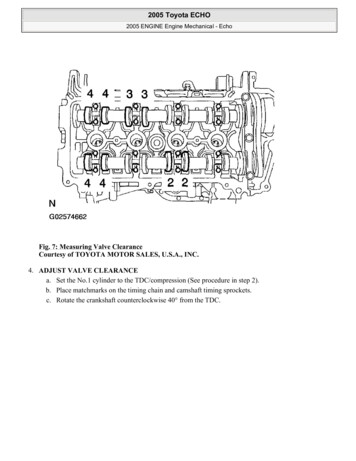

HIJUNKA BOX/BOARD PLANIB: :00-18:001YRC LTL (Anna)PITT OHIO LTL (Anna)Flex (Anna)Leonard’s Express TL (Anna)Dock Clean (Charlie)2XPO LTL (Bryce)ESTES LTL (Bryce)Marten TL (Bryce)Stevens TL (Bryce)Dock Clean (Charlie)3CR England TL(Steve)Maersk : Floor Stack (Steve)Maersk : Floor Stack(Steve/Charlie)CH Robinson TL (Charlie)Dock Clean (Charlie)4Coyote TL (Eric)Echo TL (Eric)Swift TL (Eric)Covenant TL (Eric)Dock Clean (Charlie)5Transforce TL (Matt)JB Hunt TL (Matt)Carrol Fulmer TL (Matt)Crete (Matt)Dock Clean (Charlie)OB: :00-18:001Prep work (Shannon)LTL (Ryan)LTL (Ryan)Dock Clean (Ryan)2Prep work (Shannon)LTL (Veronica)LTL (Veronica)XPO TL(Veronica)3Prep work (Shannon)CH Robinson (Adam)CR England (Adam)Prime(Adam)4Prep work (Shannon)TQL (Collin)USA Truck (Collin)Swift(Collin)5Prep work (Shannon)Carrol Fulmer (Shannon)JB Hunt (Shannon) 2017 FourKites 8CRST (Shannon)

HIJUNKA BOX/BOARD AFTERWaitingIB: DOOR08:00-10:00Over 6:0016:00-18:0018:00-20:001 YRC LTL (Anna)PITT OHIO LTL (Anna)Leonard’s Express LTL (Anna)Carrol Fulmer TL (Matt)2 XPO LTL (Bryce)ESTES LTL (Bryce)Transforce TL (Charlie)Marten TL (Bryce)3 (Steve)Maersk : Floor Stack (Steve)Maersk : Floor Stack (Steve)CH Robinson TL (Charlie)4 (Eric)Echo TL (Eric)CH Robinson TL & Swift TL(Eric)Coyote TL (Eric)5 (Matt)(Matt)Covenant TL & Crete (Bryce)CR England TL (Steve)Stevens (Charlie)JB Hunt TL :0018:00-20:001LTL (Ryan)LTL (Ryan)Dock Clean (Ryan)2(Veronica)LTL (Veronica) LTL (Adam)XPO TL(Veronica)OB: DOOR08:00-10:003CH Robinson (Shannon)(Adam)CR England Ref (Adam)Prime (Adam)4TQL Ref #3 (Shannon(Collin)USA Truck (Collin)Swift (Collin)CRST (Veronica) 2017 FourKites 95JB Hunt (Shannon)(Shannon)Carrol Fulmer (Shannon)Dock Clean (Ryan)

CHANGES WITH VISIBLITYInbound 2 start at 8:00Outbound 3 start at 10AM 2 start at 10:00 1 start at 14:00 2 start at 14:00 2 OT hours reduced 10 hours reduced8AM-4:00PMAnnaBryceMatt Reduction in errors at 10AM10AM-6PM10AM-6PMEric Same amount of coverage andcan reduce working hours by AdamCollin 2017 FourKites 10

DO YOU THINK VISIBILITY IS ANISSUE ON YOUR DOCKS? 2017 FourKites 11

CASE STUDY: DO WE NEED TO CHANGE THE LINE?BACKGROUND Large automotivemanufacturer JIT operation Milk runs to multipledelivery pointsWITHOUT VISIBILITY Line-side teams relied onmanual check-calls toknow if material wouldarrive on time Check-points were madeat points like bridgecrossings and otherpointsWITH VISBILITY Team was able to reduceworkload on carriers byautomating these checkcalls Alerts for materialsarriving allow for priorityshipments get unloadedquicker; 1M an hour 15,000 a minute 2017 FourKites 12

CASE STUDY: HARDWARE STORE PREVENTS STOCK-OUTSBACKGROUND Large nationalhardware retailer Small docks in the backof stores to receivegoods Moving towards holdingless inventory of slowmoving itemsWITHOUT VISIBILITY People managementand work-flow issueswith only one or twodock workers on asmall dock Stock-outsunacceptable for theretailerWITH VISBILITY Now able to tell theirdedicated fleet todeliver somewhere elseif the store can’t unloadin time Store managers usingmobile apps to find outwhere near stock-outsSKUs are 2017 FourKites 13

2017 FourKites 14

1 YRC LTL (Anna) PITT OHIO LTL (Anna) Leonard's Express LTL (Anna) Carrol Fulmer TL (Matt) 2 XPO LTL (Bryce) ESTES LTL (Bryce) Transforce TL (Charlie) Marten TL (Bryce) 3 (Steve) Maersk : Floor Stack (Steve) Maersk : Floor Stack (Steve) CH Robinson TL (Charlie) 4 (Eric) Echo TL (Eric)