Transcription

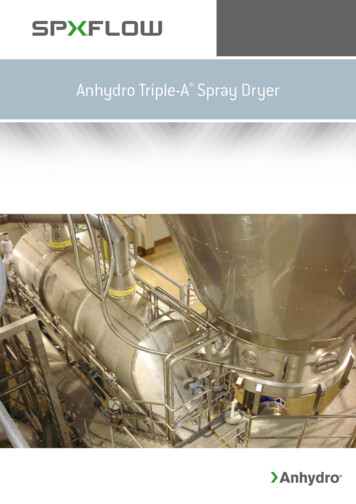

Anhydro Triple-A Spray Dryer

SPX Flow Technology Danmark A/S is aninternational engineering company with aconsistent goal to provide our customers withthe optimal processing technology and theCustomised Drying for IndividualNeedshighest plant performance standards. We havespecialized in supplying the optimal designand engineering with respect to productionperformance, flexibility, energy efficiency andenvironmental protection.SPX FLOW offers a wide range of AnhydroThe Anhydro Triple-A spray dryer enables SPX FLOW to dimension andcustomize a com plete drying solution for the production of free-flowingdust less powders and agglomerates according to customer specifications.Based on a platform of innovative and advanced technologies, the AnhydroTriple-A spray dryer technologies for handlingTriple-A spray dryer combines a new spray dryer design with an integratednumerous applications that give high-quality endfluid bed and an external fluid bed to give our customers total control overproducts in the most efficient and economicalway.product quality and process economy.SPX FLOW, Inc. (NYSE:FLOW) is a leadingmanufacturer of innovative flow technologies,many of which help define the industry standardin the market segments they serve. From itsheadquarters in Charlotte, North Carolina, itoperates a sales and support network, centersof manufacturing excellence, and advancedengineering facilities, throughout the world. Itscutting-edge flow components and processequipment portfolio includes a wide rangeof pumps, valves, heat exchangers, mixers,homogenizers, separators, filters, UHT, and dryingtechnology that meet many application needs.Its expert engineering capability also makes it apremium supplier of customized solutions andcomplete, turn-key packages to meet the mostexacting of installation demands.Incorporating many leading brands, SPX FLOWhas a long history of serving the food andbeverage, power and energy, and industrial marketsectors. Its designs and engineered solutionshelp customers drive efficiency and productivity,increase quality and reliability, and meet the latestregulatory demands. In-depth understandingof applications and processes, state-of-the-artInnovation Centers, and advanced pilot/testingtechnology further assist in optimizing processesand reducing timescales to reliably meetproduction targets.To learn more about SPX FLOW capabilities,its latest technology innovations and completeservice offerings, please visit www.spxflow.com.2A Tr i p l e - A s p r a y d r y e r w i t h a s i f t e r

F O C U S O N E N D - P R O D U CT Q UA L I T YPowder manufacturers are facing increasingly rigid qualitydemands requiring full control over powder structures andTypical Product Applicationsfunctional properties.The Anhydro Triple-A spray dryer enables you to customizea plant which ensures competitive and consistent end-productquality, while providing complete control over your productionrun-time, yield, and operating costs: Innovative drying chamber design for efficient drying and longThe Anhydro Triple-A spray dryer offers plantcustomisation options enabling you to take full controlof particle size and structure in your production offree-flowing dustless powders and agglomerates, forexample:production time between CIP (Cleaning-In-Place) Nozzle atomization for optimum spray of feed material Selection of integrated second-stage fluid bed drying Third-stage external fluid bed option for final drying and/orWhole Milk and InstantSkim-Milk Powderscooling Selection of exhaust systems and fines recirculation options toensure maximum product quality and yieldHigh-Fat Dairy BlendsInfant FormulasNon-Dairy CreamerAn h y d r o e x t e r n a l f l u i d b e d3

The Anhydro Triple-A Spray DryerD r y i n g ch a m b e rBag filterHeaterCycloneAi rHomogenizerIntegrated fluid bedExternal fluid bedAi rPo w d e rAn An h y d r o f l u i d b e d i n c o m b i n a t i o n w i t h a s p r a y d r y i n g p l a n t4

T R I P L E - A - C U S T O M I S AT I O N O P T IA. Air distribution and nozzle atomization systemsC. Exhaust and fines recirculation systems Air flow at controlled conditions into the spray dryer, inte- Cyclones or bag filters, or a combi nation of bothgrated fluid bed, and optional external fluid bed Nozzle atomization Recirculation of fines to the spray drying chamber, theintegrated fluid bed, or the external fluid bed Total control over air distribution within the drying chamber Precise control of powder particle, agglomerate, andgranule sizesD. Second-stage integrated fluid bed Integrated, second-stage fluid bed for final, low-impactdryingB. Innovative drying chamber design Drying of a wide range of dustless products from low-fat Configuration based on required capacity, residence time,tem pe rature constraints, etc.to hygro scopic and “sticky” Minimum of product residue in the chamberE. Third-stage external fluid bed options Significantly longer production time between CIP External third-stage fluid bed, including vibratory options, Low exit temperature to conserve energycon nected to the integrated fluid bed outlet for additionaldrying and/or coolingC h a m b e r w i t h a n An h y d r o i n t e g r a t e d f l u i d b e dI n s i d e v i e w o f a n An h y d r o e x t e r n a l f l u i d b e d5

Triple-A - Synonymous withSound Business SenseSynonymous with solidity, reliability and performance, theAnhydro Triple-A spray dryer combines the best of SPXFLOW Advanced Applications engineering and expertiseto offer you a long line of compelling business benefits.PROCE SS Individually customized plant delivers the optimumsolution for specific process and productionrequirements. Complete process control together withuncompromising technology and engineering ensuresproduction of consistent end-product in accordance withpredefined customer specifications.P R O D U CT I O N Equipment options are available for all capacityrequirements from small-scale plant to full industrialproduction. Innovative drying system design together withstraightforward service and maintenance accessensures maximum production run-time.P R O F I TA B I L I T Y Consistently high yield, energy-efficiency, and lowoperating costs mean rapid payback and low total costof ownership. Components and equipment designed and engineeredfor reliability and performance ensure long service lifewith modest service and maintenance requirements.M a ke p o w d e r f r o m l i q u i d6

Global Services for Individual NeedsOur aim is to help you find the best solution for your long-E N G I N E E R I N G S TA N D A R D Sterm needs. We offer a close partnership based on personalEnvironment protection is incorporated in accordance withcommitment and documented Best Practice from the initiallocal rules and regulation and is a key point in the plantneeds analysis and planning stage until the end of thedesign. We are ISO 9001:2008 certified. All our plants meetservice life of your Anhydro Triple-A spray dryer many yearsthe CE marking and ATEX requirements where applicable. later.Together with you we analyse the available options basedLI FE LON G S E RVI CE AN D S U PP ORTon your product and through put requirements. If necessary,SPX FLOW worldwide service organization is ready, at allwe can run a pilot test at our test facility to ensure that thetimes, to provide any necessary spare parts at short notice.process will meet your expectations on a production scale.We can also dispatch service technicians to help you rectifyany problems, thus reducing unscheduled downtime to aI N N OVAT I O N C E N T R Eminimum.SPX FLOW Anhydro offers an advanced test centre forSPX FLOW offers a number of service agreement options,testing new products and evaluation of process conditionsdepending on your individual needs, and our serviceto secure precise synergy between optimization of the plantengineers are always available to provide applications andconcept and reproducible product quality.development support.Alternatively, we can install small scale test plants at yoursite for a limited period for demonstration purposes or pilotscale pro duction.S PX F LOW i n n o v a t i o n c e n t r e i n S o e b o r g , D e n m a r k7

Anhydro Triple-A Spray DryerGlobal locationsUSAA PACS PX F LOWS PX F LOW C H I N AGetzville, NY 14068Shanghai 2000052USAPeoples Republic of ChinaP: 1 716 692 3000 or 800 828 7391P: 86 21 2208 5888F: 1 716 692 6416E: anhydro.china@spxflow.comE: anhydro.americas@spxflow.comBased in Charlotte, North Carolina, SPX FLOW, Inc. (NYSE: FLOW) is a multi-industry manufacturing leader. For more information, pleasevisit www.spxflow.comS P X F LOW T E C H N O LO GY DA N M A R K A / SOestmarken 72860 SoeborgDenmarkP: 45 7027 8222F: 45 7027 8223E: ft.dk.soeborg@spxflow.comSPX FLOW, Inc. reserves the right to incorporate our latest design and material changes without notice or obligation.Design features, materials of construction and dimensional data, as described in this bulletin, are provided for your information only and should not be relied upon unless confirmedin writing. Please contact your local sales representative for product availability in your region. For more information visit www.spxflow.com.The green “ ” and “ ” are trademarks of SPX FLOW, Inc.ANH-119-GBVERSION 02/2017ISSUED 1/2018COPYRIGHT 2018 SPX FLOW, Inc.

The Anhydro Triple-A spray dryer enables you to customize a plant which ensures competitive and consistent end-product quality, while providing complete control over your production run-time, yield, and operating costs: Innovative drying chamber design for efficient drying and long