Transcription

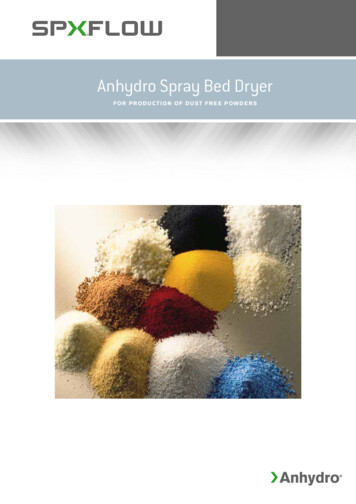

Anhydro Spray Bed DryerF OR PR OD U CTI ON OF D U ST FR E E P OWD E R S

SPX Flow Danmark A/S is an internationalengineering company with a consistent goalto provide our customers with the optimalprocessing technology and the highest plantCustomized Drying Systems forMaking Dust Free Powdersperformance standards. We have specialized insupplying the optimal design and engineeringwith respect to production performance,flexibility, energy efficiency and environmentalprotection.The Anhydro spray bed dryer (SBD) is designed to combine spray dryingand fluid bed agglomeration in one process in order to meet our customersdemands of being able to produce uniform non-dusty powders withconsistent powder quality.SPX FLOW offers a wide range of Anhydrospray bed dryer technologies for handlingnumerous applications that give high-qualityend products in the most efficient andeconomical way.The system combines a conventional conical spray drying plant with fluid bedtechnology.Improvements of powder quality as well as reduction in operating costscompared to Anhydro standard spray drying plants are the most importantbenefits of the spray bed technology.The Anhydro spray bed dryer is widely used in the food, dairy, pharmaceutical,and chemical industries.SPX FLOW, Inc. (NYSE:FLOW) is a leadingmanufacturer of innovative flow technologies, Food ingredientsmany of which help define the industry standard Yeast productsin the market segments they serve. From its Plant extractsheadquarters in Charlotte, North Carolina, itoperates a sales and support network, centers Flavours and fragrancesof manufacturing excellence, and advanced Agro chemicalsengineering facilities, throughout the world. Itscutting-edge flow components and process Tanning agentsequipment portfolio includes a wide range Dyestuffsof pumps, valves, heat exchangers, mixers, Fertilizershomogenisers, separators, filters, UHT, and dryingtechnology that meet many application needs.Its expert engineering capability also makes it apremium supplier of customized solutions andcomplete, turn-key packages to meet the mostexacting of installation demands.Incorporating many leading brands, SPX FLOWhas a long history of serving the food andbeverage, power and energy, and industrial marketsectors. Its designs and engineered solutionshelp customers drive efficiency and productivity,increase quality and reliability, and meet the latestregulatory demands. In-depth understandingof applications and processes, state-of-the-artInnovation Centers, and advanced pilot/testingtechnology further assist in optimizing processesand reducing timescales to reliably meetproduction targets.To learn more about SPX FLOW capabilities,its latest technology innovations and completeservice offerings, please visit www.spxflow.com.2Typical applications are: Detergent ingredients

A N H Y D R O S P R AY B E D D RY E RAnhydro fluidisation chamber is provided with an integrated fluid bed.Typical Product ApplicationsThe feed is sprayed co-current into the drying air towards the fluidbed, where an adjustment of the fluidisation rate enables full controlof the fines fraction to be removed from the product.With the Anhydro spray bed dryers, you canThe fines are conveyed with the drying air to the wet zone in theproduce a wide range of powders for variousdrying chamber top, where the fines agglomerate with the wetindustries.droplets. Fines carried out together with the air are separated fromthe air in a cyclone system or a bag filter, and the fines are recirculated to the atomizer zone for agglomeration.The powder is further dried and cooled in an external fluid bed beforedischarge. The agglomerated powder produced is dust free with anDairy Industryaverage particle size of 100-350 microns, and the agglomerateshave a high mechanical strength. The external fluid bed is often builttogether with the integrated fluid bed, saving building height andductwork. This is an option for small and medium size plants.Food & Beverage IndustryBag houseHeaterAi rPharmaceutical IndustryHomogeniserExternal fluidbedPo w d e rAi rChemical IndustryZ I G - Z AG PA R T I C L E S I Z E C L A S S I F I E RThe external fluid bed can be replaced by a zig-zag particle sizeclassifier in cases where de-dusting and only moderate cooling of theagglomerated powder are required. The zig-zag particle size classifierprovides particle size classification using very small air volumescompared to those of a fluid bed.3

Customized TechnologiesATO M I Z AT I O NProper atomization is the key to the spray drying process. Thespray is created by either a nozzle system or a centrifugalatomizer.Particle formation and particle size distribution, and therebythe final powder specifications, can be controlled withincertain limits through selection of the atomizer principle and byadjusting the atomization parameters, such as the feed pressureto the nozzles, or the atomizer wheel velocity in the centrifugalatomizer.Normally, nozzle atomization is preferred in spray bedapplications, as the average particle size which can be achievedis generally larger than that from a centrifugal atomizer.Furthermore, the agglomerated particles are more uniform. Theplant can, however, be designed for an optional choice betweenthe two systems, if required.Nozzle atomizer4An An h y d r o s p r a y b e d d r y e rNozzle atomizer

I N T E G R AT E D F L U I D B E DF I N E S R E C I R C U L AT I O NBy adjusting the air flow and the air temperature to the fluid bed,The fines from the product inside the drying chamber andthe size of the agglomerates and the residual moisture can bethe external fluid bed are separated from the process air in afine-tuned, as required.cyclone battery or a bag filter.As fluid beds generally provide much longer residence timesThe fines discharged from the separation system arethan single-stage spray dryers, the drying outlet air temperaturere-circulated to the atomizer zone for agglomeration with thecan be reduced in the combined system while achieving thewet droplets. Agglomeration in the wet zone results in a verysame residual powder moisture. This reduces the energystable agglomerated powder, which can be bulk handled.consumption, and thereby the drying costs.The fluid bed drying takes place at lower temperatures, providingAI R B ROOMa low heat impact on the product.Some products are thermoplastic and have a tendency ofsticking to the chamber wall. This can be prevented by applyingE XTE R NAL FLU I D B E DFinal drying and cooling can take place in the external fluidbed. Instant properties of some agglomerated products can bethe unique Anhydro rotating air broom system, sweeping andcooling the entire chamber surface by means of slightly heatedair.achieved by adding lecithin in the rewet zone of the fluid bed.Separate air inlet systems to the fluid bed provide flexibility withregard to air velocity and product temperature, ensuring removalof fines and discharge at the requested product temperature.E X PLOS I ON PR OTE CTI ONIn case of a potential risk of a dust explosion, the plant isprotected by means of a pressure relief system venting to theatmosphere, or by explosion suppression by means of injectionof an inert media suppressing the explosion.Closed circuit systems are applied where organic solvents arepresent in the feed applied. Nitrogen can be used as drying gas,which eliminates the risk of an explosion.A second benefit is that the emission to the environment isminimised, which is imperative, when handling toxic materials.C I P - C L E A N A B L E SYS T E M SThe complete plant including the bag filter can be Cleaned-InPlace (CIP). Fully automatic CIP systems designed according tothe individual customer requirements are supplied on request.An An h y d r o s p r a y b e d d r y e r5

Advantages of Anhydro Spray Bed DryingAll plants are tailor-made for each purpose with special focus onproduct quality, yield, and operating costs.The Anhydro spray bed dryer offers the followingadvantages: Ability to produce uniform, stable agglomerated powders,which have a consistent powder structure and are easilydissolvable or dispersible Cost efficient drying, as the energy consumption is reducedby 10-15% due to multi stage drying compared to traditionalsingle stage drying at low temperatures Gentle drying process, well suited for heat sensitive products,as the product temperatures generally are lower compared tostandard dryers High plant availability due to optimised process conditions High flexibilityAn An h y d r o s p r a y b e d d r y i n g p l a n t6I n s i d e v i e w o f a n An h y d r o e x t e r n a l f l u i d b e d

Global Services for Individual NeedsSPX FLOW is committed to helping our customers all over theI N N O VAT I O N C E N T R Eworld to optimise product quality and plant availability, and toSPX FLOW’s state-of-the-art test facility close to Copenhagenminimize operating costs on their Anhydro spray bed dryingin Denmark enables customers to test new products and toplants. Our solutions range from feasibility studies to full scaleevaluate process conditions to secure precise synergy betweenturnkey projects.optimization of the plant concept and reproducible productquality.P R O C E S S D E V E LO P M E N TAlternatively, we can install small scale test plants at your siteSPX FLOW helps you to find the best solution for your long-for a limited period for demonstration purposes or pilot-scaleterm needs. We offer a close partnership based on personalpro duction.commitment and documented Best Practice from the initialneeds analysis and planning stage until the end of the servicelife of your Anhydro spray bed dryer many years later.E N G I N E E R I N G S TA N D A R D SEnvironment protection is incorporated in accordance with localTogether with you we analyse the available options based onrules and regulations and is a key point in the plant design.your product and through put requirements. If required, we canWe are ISO 9001:2008 certified. All our plants meet the CErun pilot tests at our test facilities to ensure that the process willmarking and ATEX requirements where applicable.meet your expectations on a production scale.3D computer design, global sourcing of equipment, and localLI FE LON G S E RVI CE AN D S U PP ORTmanufacture, where appropriate, are part of our standardSPX FLOW worldwide service organization is ready, at allproject execution.times, to provide any necessary spare parts at short notice. Wecan also dispatch service technicians to help you rectify anyproblems, thus reducing unscheduled downtime to a minimum.SPX FLOW offers a number of service agreement options,depending on your individual needs, and our service engineersare always available to provide applications and developmentsupport.S PX F LOW i n n o v a t i o n c e n t r e i n S o e b o r g , D e n m a r k7

Anhydro SprayBed DryerGlobal locationsUSAA PACS PX F LOWS PX F LOW C H I N AGetzville, NY 14068Shanghai 2000052USAPeoples Republic of ChinaP: 1 716 692 3000 or 800 828 7391P: 86 21 2208 5888F: 1 716 692 6416E: anhydro.china@spxflow.comE: anhydro.americas@spxflow.comBased in Charlotte, North Carolina, SPX FLOW, Inc. (NYSE: FLOW) is a multi-industry manufacturing leader. For more information, pleasevisit www.spxflow.comS P X F L OW T E C H N O LO GY DA N M A R K A / SOestmarken 72860 SoeborgDenmarkP: 45 7027 8222F: 45 7027 8223E: ft.dk.soeborg@spxflow.comSPX FLOW, Inc. reserves the right to incorporate our latest design and material changes without notice or obligation.Design features, materials of construction and dimensional data, as described in this bulletin, are provided for your information only and should not be relied upon unless confirmedin writing. Please contact your local sales representative for product availability in your region. For more information visit www.spxflow.com.The green “ ” and “ ” are trademarks of SPX FLOW, Inc.ANH-118-GBVERSION 02/2017ISSUED 12/2017COPYRIGHT 2017 SPX FLOW, Inc.

The Anhydro spray bed dryer (SBD) is designed to combine spray drying and fluid bed agglomeration in one process in order to meet our customers demands of being able to produce uniform non-dusty powders with consistent powder quality. The system combines a conventional conical spray drying plant with fluid bed technology.