Transcription

BRANCH FITTINGSAND SPECIALTYFORGED PRODUCTS

Table Of ContentsHow to Order . 4-5Quality Control. 5Pipets . 6-19Bossets . 20-22Vesselets . 23-25Special Tees. 26Wyes and Laterals. 27WFI INTERNATIONALA BONNEY FORGE COMPANY4407 HAYGOOD STREETHOUSTON, TX 77022(713) 695-3633 (800) 231-0430FAX (713) 695-3528www.wfi-intl.come-mail: customerservice@wfi-intl.comSALES CENTER/WAREHOUSE14496 CROGHAN PIKEP.O. BOX 330MT. UNION, PA 17066(814) 542-2545 (800) 231-0655(800) 345-7546 FAX (814) 542-9977www.bonneyforge.come-mail: bfsales@bonneyforge.comSpecialty Products. 28-29Flanges. 30Consolidation Charts . 31-33Pipet , Vesselet and Bosset are trademarks registered for the exclusive use of WFI International.

Expertise, capability and desire.These are the cornerstones forsuccess. They are also the samethree reasons why WFI has becomea world leader in the design andmanufacture of high quality forgings,fittings, flanges, and a wide variety ofspecialty items.Founded in 1972, WFI has grownfrom a few employees and 2,800square feet of office and productionspace to 150 employees and morethan 120,000 square feet of spacelocated on 13 acres.Excellence inQuality is theStandard at WFIExcellence in Quality is the standardat WFI. We are recognized in theindustry for our superior NuclearQuality Assurance Program. Originallyawarded in 1977, WFI currentlyholds a Quality System Certificate(QSC 425) issued by ASME as aMaterial Organization manufacturingand supplying both ferrous andnon-ferrous materials. WFI’s QualityAssurance Program is written to meetthe most stringent requirements ofASME Section III, NCA3800, 10CFR50Appendix B, 10CFR21, and ANSIN45.2. In addition to these nuclearstandards, our quality program meetsthe ever increasing demands of thepiping and pressure vessels codesincluding ASME Section I and VIII,B31.1, B31.3, B31.4, B31.8, API6APED Annex I Paragraph 4.3, TuV ADWO and the requirements of MIL-I45208A and MIL-STD-6875F.All of WFI products arecompetitively priced and we are atyour service 24-hours-a-day,7-days-a-week. We maintain oneof the highest levels of on timedeliveries in our industry and ourprofessional sales and engineeringstaff can always be reached toassist you.2Our MissionTo be, today and in the future, therecognized leader in our industry,marketing and manufacturingforged fittings, branch connectionsand other related productsto satisfy our customer’sexpectations.To be cost effective through TotalQuality performance of theseoperations, and thus provide theresources required to supportour commitment to improve ourproducts, processes andcustomer service.To be a law abiding corporatecitizen respecting the rightsof individuals, contributing tothe needs of the communityand conserving the stateof the environment.3

How To Order Branch Connections/WFI PipetsHow To Order Branch Connections/WFI Pipets (Continued)1. Specify Run or Header Size (For Consolidated Run Sizes see pages 30-32)6. Specify Piping Code (if available):2. Specify Branch/Outlet SizeExamples: ASME B31.1, B31.3, B31.4, B31.8, ASME See VIII & ASME Sec I3. Specify Class, Schedule or Thickness:Branch Connection fittings are engineered fittings. Stock fittings are designed using "proof of design" BurstTests. ASME B31.1 and ASME B31.3 codes accept Burst Test Design fittings. ASME Section III also acceptsBurst Test Design fittings. Socket-weld & Threaded Branches: Specify Header Size, Branch Size and Class(3000, 6000 & 9000) Buttweld Branches: Specify Schedule or Thickness for both header and branch pipes:Std, XS, S160 etc.4. Specify Branch StyleASME Sec VIII, Sec I, B31.4 and B31.8 require additional design considerations and Burst Test design stockfittings may not meet specific code requirements in certain applications. They, as well as some specifications,require area replacement calculations as proof of adequacy. The requirements are project specific and WFI mustbe consulted and provided with the following additional ordering information:Design Code & Edition/AddendaDesign TemperatureDesign PressureCorrosion Allowance (if applicable)Design/Location Factor (if applicable)Pipet Buttweld Pipet (BWP)Threaded Pipet (THP)Socketweld Pipet (SWP)BW/SW/THD Elbo Pipet (BEP, SEP, TEP)BW/SW/THD Lateral Pipet (BLP, SLP, TLP)Quality ControlWFI International craftsmanship is combined with rigid quality control systems to provide complete assurance ofthe highest manufacturing standards and compliance with applicable ASME and ASTM specifications. Every fittingmanufactured is subjected to three separate quality control systems: one for material control, one for manufacturingcontrol, and one for design control.5. Select Material Specification Carbon Steel - SA/A105, SA/A105N, SA/A350-LF2 Class , etc. Stainless Steels: SA/A 182 F304L, F316L, F347, F321, F317/L, etc. Chrome Moly: SA/A182 F11 Class , F22 Class , F5, F9, F91, etc. Other: High Yield, Nickel/Nickel Alloys, Copper Nickel, Nickel Copper, Duplex, 6 Moly,Super Duplex, Titanium, etc.4All forgings are inspected before being passed to the shipping room. Frequent analyses are made to check againstmill documents. Accurate records are kept of every fitting, from initial forging bar through forging, heat treatment,machining, storage and shipment. Every single fitting is traceable to the exact material and process used in itsmanufacture.In-house testing capabilities include:Mechanical Testing: Tensile/Yield, Hardness and CharpyChemical Product AnalysisPositive Material Identification (PMI)Utrasonic ExaminationLiquid Penetrant Examination5Magnetic Particle ExaminationCorrosion TestingMacrostructure ExaminationMicrostructure ExaminationFerrite Examination

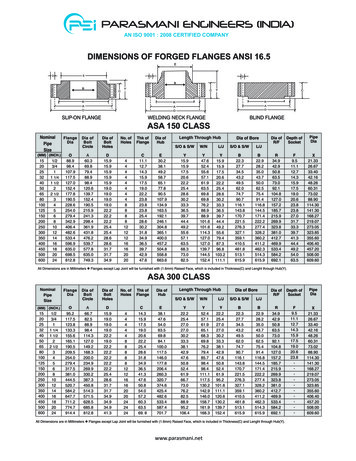

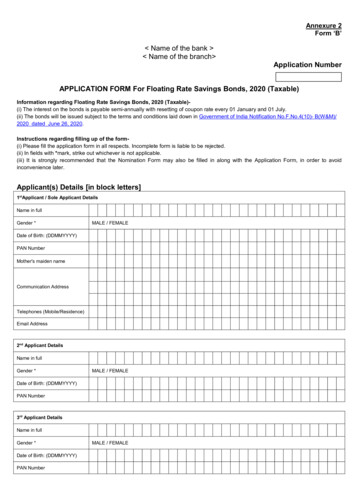

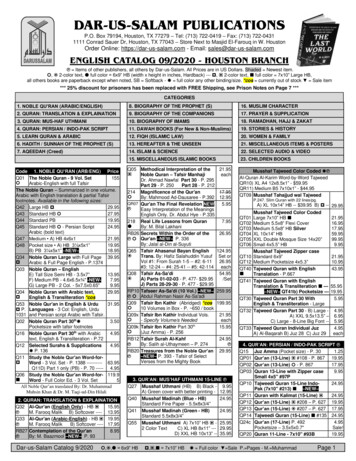

Butt-Weld PipetButt-Weld Pipet SA/A105 & SA/A350 LF2 CL1SA/A105 & SA/A350 LF2 CL1Butt-WeldStandard WeightSchedule 160Extra 00194.61230.90335.23477.50Outlet Size -1/83/47/81-1/211-1/16 1-13/161-1/4 1-1/42-1/41-1/2 1-5/16 2-9/1621-1/23-5/162-1/2 1-5/83-21/3231-3/44-9/323-1/2 1-7/85425-3/863-1/16 7-21/3283-7/89-3/4103-11/16 12124-1/16 14-1/4143-15/16 15-1/2164-3/16 17-5/8184-3/819-3/4204-11/16 000Appx. 5165.85262.10315.67Larger outlet sizes available on applicationLarger outlet sizes available on 1-3/42-1/42-3/4344-7/165 .4385.187DimensionsOutlet /42-1/42-3/4344-7/165 03.1524.897Appx. .25Appx. 2.94Each outlet size listed is available to fit any run curvature.BW Ends per B16.9 and B16.25. Design per MSS-SP-97.Each outlet size listed is available to fit any run curvature.BW Ends per B16.9 and B16.25. Design per MSS-SP-97.RUN PIPE SIZESSCHEDULESFLATSORDERINGSchedule 25017.25019.25023.25025.25029.25035.250Appx. WeightPoundsDimensionsOutlet SizeInchesXXSOutlet Size -1/83/47/81-1/211-1/16 1-13/161-1/4 1-1/42-1/41-1/2 1-5/16 2-9/1621-1/23-5/162-1/2 1-5/83-21/3231-3/44-9/323-1/2 1-7/85425 -3/862-3/87-21/3282-3/49-3/4103-1/16 12123-3/814-1/4143-1/215-1/2163-11/16 17-5/8183-13/16 19-3/420421-7/8244-9/16 26264-11/16 28-7/16305-3/832-5/8365-3/838-15/16Extra StrongStandardButt-WeldOutlet sizes 6" and less fit a number of run pipe sizes, and the fittings are markedaccordingly. See page 30 for Pipet Consolidation Chart.Standard Weight Fittings are the same as schedule 40 fittings through 10". A schedule 40 Butt-Weld Pipet forsizes 12" and larger is available. Dimensions and prices on application. Extra Strong Fittings are the same asschedule 80 fittings through 8". A schedule 80 Butt-Weld Pipet for sizes 10" and larger is available. Dimensions and priceson application. Pipe schedule numbers and weight designations are in accordance with ASME B36.10.A flat Butt-Weld Pipet fitting for use on welding caps, elliptical heads and flat surfaces is available.When ordering a fitting, see page 4.Although every attempt has been made to insure that the information contained in these tables is correct, WFI reserves the right to change the“B” and “C” dimensions as deemed necessary.*The "C" dimension represents the waterway dimension of the fitting and does not include the minimal taper and radius required formanufacturing purposes. Installation holes in header should be based on actual fittings.6RUN PIPE SIZESSCHEDULESFLATSORDERINGOutlet sizes 6" and less fit a number of run pipe sizes, and the fittings aremarked accordingly. See page 30 for Pipet Consolidation Chart.Pipe schedule numbers and weight designations arein accordance with ASME B36.10.A flat Butt-Weld Pipet fitting for use on welding caps, elliptical heads and flatsurfaces is available.When ordering a fitting, see page 4.Although every attempt has been made to insure that the information contained in these tables is correct,WFI reserves the right to change the “B” and “C” dimensions as deemed necessary.*The "C" dimension represents the waterway dimension of the fitting and does not include theminimal taper and radius required for manufacturing purposes. Installation holes in header should bebased on actual fittings.7

Threaded PipetSocket-Weld Pipet SA/A105 & SA/A350 LF2 CL1SA/A105 & SA/A350 LF2 CL1Socket WeldCL 3000CL 3000CL 6000CL 6000CL 6000Outlet Size px. WeightPoundsOutlet 6.181/43/81/23/411-1/41-1/222-1/234Appx. WeightPounds0.140.140.280.390.730.961.121.66Each outlet size listed is available to fit any run curvature.Threaded ends are in accordance with ANSI/ASME B1.20.1Design per MSS-SP-97.RUN PIPE SIZESFLATSORDERINGCL 3000Outlet Size tlet sizes noted above fit a number of run pipe sizes, and the fittings aremarked accordingly. See page 30 for Pipet Consolidation Chart.A flat Threaded Pipet for use on welding caps, elliptical heads and flatsurfaces is available.When ordering a fitting, see page 4.Although every attempt has been made to insure that the information contained in these tables iscorrect, WFI reserves the right to change the “B” and “C” dimensions as deemed necessary.Outlet SizeInchesCL 6000CL 3000Threaded1/23/411-1/41-1/22DimensionsABC*EAppx. 1.631.66Each outlet size listed is available to fit any run curvature.Socket dimensions are in accordance with ASME B16.11.Design per MSS-SP-97.RUN PIPE SIZESFLATSORDERINGOutlet sizes noted above fit a number of run pipe sizes, and the fittings aremarked accordingly. See page 30 for Pipet Consolidation Chart.A flat Socket-Weld Pipet for use on welding caps, elliptical heads and flatsurfaces is available.When ordering a fitting, see page 4.Although every attempt has been made to insure that the information contained in these tables iscorrect, WFI reserves the right to change the “B” and “C” dimensions as deemed necessary.*The "C" dimension represents the waterway dimension of the fitting and does not include theminimal taper and radius required for manufacturing purposes. Installation holes in header should bebased on actual fittings.*The "C" dimension represents the waterway dimension of the fitting and does not include theminimal taper and radius required for manufacturing purposes. Installation holes in header should bebased on actual x. WeightPounds9

Butt-Weld PipetThreaded Pipet STAINLESS & ALLOYSTAINLESS & ALLOYButt-WeldThreadedStandard WeightCL 1/41-5/161-1/21-5/81-3/422-3/8Outlet SizeInchesExtra 65DimensionsA3/81/23/4

ASME Sec VIII, Sec I, B31.4 and B31.8 require additional design considerations and Burst Test design stock fittings may not meet specific code requirements in certain applications. They, as well as some specifications, require area replacement calculations as proof of adequacy. The requirements are project specific and WFI must be consulted and provided with the following additional ordering .File Size: 2MBPage Count: 20