Transcription

CONTENTSProduct Features and Specifications .3Installation Requirement . 5Steps of Installation .6Exploded View . 37Test Run . 41Operation Instruction . 43Maintenance . 44Troubleshooting . 45Parts List . 461

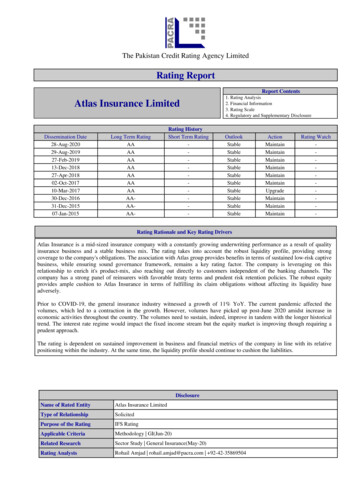

I. PRODUCT FEATURES AND SPECIFICATIONSCLEAR-FLOOR DIRECT-DRIVE MODEL FEATURESModel PV-10P & PV-10HP (See Fig. 1)· Direct drive hydraulic cylinder design, minimizes the lift wear parts and breakdown ratio· Dual hydraulic cylinders, designed and made on ANSI standards, utilizing NOK oil seal incylinder· Self- lubricating UHMW Polyethylene sliders and bronze bush· Single-point safety release with dual safety design. Clear-floor design, provides non-obstructed floor use. Overhead safety shut-off device prevents vehicle damage. Standard adjustable heights accommodates variety of ceiling heightsFig. 1MODEL PV-10P/ PV-10HP SPECIFICATIONSModelStyleClear-floorPV-10PDirect driveClear-floorPV-10HPDirect driveLiftingCapacity4.5 T10,000 lbs4.5 T10,000 lbsLiftingLifting HeightTime55S55SOverall ght 0mm115 mm72 1/2”–83 1/8”143 1/8”/ 147”137 1/2”110 1/4”4 72 1/2”–83 1/8”150”/167 1/8”/171”137 1/2”110 1/4”4 1/2”2Motor3.0HP3.0 HP

Arm Swings ViewFor Model PV-10P & PV-10HP39.5 in58 in40.5 in96.25 in28 in137.5 inFig. 23

. INSTALLATION REQUIREMENTA. TOOLS REQUIRED9 Rotary Hammer Drill (3/4in)9Carpenter’s Chalk9 Hammer9Screw Drivers9 4 Foot Level9Tape Measure (7.5m)9 Crescent Wrench (12")9Pliers9 Ratchet With Socket (28#)9Socket Head Wrench (3#, 5#, 8#)33Wrench Set(10#, 13#, 14#, 15#, 17#, 19#, 24# ,27#, 30#,)Fig. 34Vise Grips

B. CONCRETE SPECIFICATIONS (See Fig. 4)Specifications of concrete must be adhered to the specification as following.Failure to do so may result in lift and or vehicle falling.1. Concrete must have 4 inches minimum and must be totally cured before lift installation.2. Concrete must be in good condition and must have a test strength 3,000psi minimum.3. Floors must be level with no cracks or holes.Fig. 4Concrete intensity must be3,000 psi minimum.4”C. POWER SUPPLY220 volt single phase 30 amp breaker with minimum of 10 gauge wireIII.INSTALLATION STEPSA. Location of installationCheck and ensure the installation location (concrete, layout, space size etc.) is suitable for liftinstallation.B. Use a carpenter’s chalk line to establish installation layout (See Fig. 5).Model PV-10P PV-10HPChalk Line137 1/2”Fig. 5

C. Check the parts before assembly.1. Packaged lift and hydraulic power unit (See Fig. 6).Fig. 62. Move the lift aside with a fork lift or hoist, and open the outer packing carefully(See Fig. 7).Top Connecting Assy.Shipment Parts listParts boxSerial No.Fig. 73. Remove the top connecting assembly and parts box (See Fig. 8).Fig. 8

4. Lift the upper column with a fork lift or hoist and loosen the bolts on the upper package stand.Remove the upper column and take out the parts in the bottom column (See Fig. 9).Fig. 95. Lift the lower column with a fork lift or hoist, remove the package stand. Remove the lowercolumn and remove the parts in the inner column (See Fig. 10).Fig. 10

6. Move aside the parts and check the parts according to the shipment parts list(See Fig. 11).Fig. 117. Open the parts box and check the parts according to parts box list (See Fig. 12).Fig. 12

8. Check the parts in the parts bag 1 according to parts bag list (See Fig. 13).Fig. 139. Check the parts in the parts bag 2 according to parts bag list(See Fig. 14).Fig. 14D. Install the hydraulic hose and lock release cable brackets on the extension columns(See Fig. 15).Use M6 x 20 Hex Bolts withM6 Nylock Nut & M6 WasherFig. 15

E. Install hydraulic cylinderConnect the extended straight fitting and 90 fitting. Install the cylinders inside the carriages(See Fig. 16).Offside columnPower side columnUse Teflon tape to seal pipe threads. Do notuse Teflon tape on hydraulic hose ends.Fig. 16

F. Install columnsLay down the two columns on the installation site parallel of each other. Position the power sidecolumn according to the actual installation site. This lift is designed with 2 sectional columns.Adjust the height according to your ceiling height.For model PV-10P1. When the ceiling height is over 3750mm (147 5/8”), connect the sectional columns with thelower holes (See Fig. 17).Fig. 17 High Setting

2. When the ceiling height is less than 3750mm (147 5/8”), connect the sectional columns with theupper holes (See Fig.18).Fig. 18 Low Setting

For model PV-10HP1. When the ceiling height is over 4350mm (171 1/4”), connect the sectional columns with thelower holes (See Fig. 19).Fig. 19 High Setting

2. When the ceiling height is over 4250mm (167 3/8”) but less than 4350mm (171 1/4”), connectthe sectional columns with the middle holes (See Fig.20).Fig. 20 Low Setting

G. Position postsPosition the columns on the installation layout.?WANT TO WORK SMART NOT HARD?MAKE THE INSTALLATION EASY. DO IT LIKE A PROFFESSIONAL LIFTINSTALLERPosition the columns upright on the installation layout. Position the offside column parallel tothe power side column at the approximate overall width (1371/2”). Install the overhead crossbeam. Do not drill holes for anchor bolts until overhead cross beam has been installed.See Figure 23Use M12 x 30 Hex Boltwith M12 Nylock NutFig. 22Fig. 21Drill the anchor holes to the depthof the length of the anchor boltsInstall the anchor bolts. Check the posts for plumb with level bar, and adjust with the horseshoe shims if thecolumns are not plumb. Do not tighten the anchor bolts.

H. Install overhead top beam1. With help of the hook of top beam, put one side of top beam on top of the extension column andconnect the top beam to extension column by bolts, tighten the bolts. Then assemble theconnecting bracket (See Fig. 23).Hook on to theextension columnsUse M12 x 30 Hex Boltswith M12 Nylock NutFig. 23Tighten the bolts

2. Assemble overhead top beam and tighten the anchor bolts between 60 and 86 foot pounds.(See Fig. 24).Use M12 x 30 Hex Boltswith M12 Nylock NutTightenFig. 24

I. Installing the limit switch control bar and limit switch (See Fig. 25).Use M12 x 30 Hex Boltwith M12 Nylock NutLoosen Screw on Drive Rod toadjustment. Tighten the screwafter adjustment.Adjust Drive Rod onLimit SwitchLimit Switch connectedwith Cable NC: Normal contactFig. 25

J. Install safety device (See Fig. 26 & Fig. 27).145 SpringUse M10 x 10 Allen Head Set ScrewFig. 26 Power side safety deviceUse M10 x 10 Allen Head Set Screw145 SpringUse M10 x 10 Hex Head Bolts tosecure the pulley bracket120 SpringFig. 27 Offside safety device

K. Lift the carriages up manually and lock them on the 1st set of locks (See Fig. 28).Fig. 28

L. Install cablesFor model PV-10P1. High setting cable connection. For a ceiling height over 3750mm (147 5/8”)1.1 Remove the carriages’ plastic covers, the cable passes through from the bottom of thecarriages and is pulled out from the opening of carriages, then install the two cable nuts (SeeFig. 29).Screw the twocable nutsCableconnectingdirectionCableFig. 29connectingdirection

1.2 Connecting the cable for the high setting (See Fig. 30)High settingCable 2Cable 1959694Cable 2Fig. 30

2. Low setting cable connection. For a ceiling height less than 3750mm (147 5/8”)(See Fig.31)Low SettingCable 1Cable 2Cable 2Fig. 31

For model PV-10HP1. High setting cable connection. For a ceiling height over 4350mm (171 1/4”)1.1 Remove the carriages’ plastic covers, the cable passes through from the bottom of the carriageand is pull out from the opening of the carriages, then install the two cable nuts (See Fig. 32).Screw the twocable nutsCable ConnectingdirectionFig. 32Cable Connectingdirection

1.2 Connecting cable for high setting (See Fig. 33).High settingCable 2Cable 1959694Cable 2Fig. 33

2. Low setting cable connection. For a ceiling height between 4250mm (167 3/8”) to 4350mm(171 1/4”) (See Fig. 34)Low settingCable 2Cable 1Cable 2Fig. 34

3. Special low setting cable connection PV10P. For a ceiling height between 3820mm (1503/8”) to 4250mm (167 3/8”) (See Fig. 35) this setting requires the optional short cables.Special low settingCable 2Cable 1969994Cable 2Fig. 35

0. Install power unit (See Fig. 36)Use M8 x 25 Hex Boltwith M8 Nylock Nut201Fig. 36

1. Install oil hoseAt high setting and low setting oil hose connection (See Fig. 37).Limit switch wireOil hoseOil hose and wirepass through thesupport bracketOil hose passes through thewire tube on top beam88Oil hose connectedwith T-fittingOil hose connectedwith 90 fitting Fig. 37

2 Install safety cable.Install the safety cable from the off side safety assembly to the power side safety assembly andthrough the top beam (See Fig. 38).SafetySafety cablethroughcablesmallpassespulleybracketInstall safety cablefrom off side safetyassembly first!Safety cable connected with thepower side safety assemblyFig. 38

3. Install hose retainers on both columns (See Fig. 39).Install oil hose retainersusing M6 x 8 screwsCar in direction Fig. 39

4. Install lifting arms (See Fig. 40); Lower the carriages down to the lowest position. Use an 8mmAllen wrench to loosen the bolt (See Fig.41). Adjust arm lock in direction of arrow (See Fig.42).Adjust moon gear and arm lock until they mesh, then tighten the Allen bolts on the arm lock (SeeFig.43).Loosen the Allen BoltFig. 40Use the 8mm Allen Head Wrenchto loosen the Allen BoltFig. 41Moon GearLock the bolts after the moon gearand arm lock engaged wellTighten the boltsArm lockAdjust Gear and arm lockFig. 42Fig. 43

Install Electrical SystemConnect the power source according to the data plate on the Power Unit.Remove the short “Pig Tail” wire connected to the AC contactor terminals. This wirewas used to test the motor after production.ATLAS Single phase motorPlease Note: This motor is powered by Alternating Current and the terminals on the ACcontactor are not wire color specific. There are no positive or negative terminals.1. Connect the two power supply (incoming) wires (black & white) to terminals on the AC contactor marked L2 &L3.2. Connect the two motor wires to terminals on the AC contactor marked T2, T3. These wires are alreadyconnected from the factory.3. Connect the short wire A2 to L3 on the AC contactor. This wire is already connected from the factory.4. Remove the entire wire that connects from the “UP” button to A1 on the AC contactor.5. Connect one of the wires (does not matter which one) on the Limit Switch to the “UP” button and connectthe remaining Limit Switch wire to terminal A1 on the AC contactor.AC CONTACTORFig. 44

Remove this wireFig. 45

“UP” Button WireIncoming Power LinesLimit Switch WiresGround WireJumper WireMotor WiresFig. 46

. EXPLODED VIEWModel PV-10P & PV-10HPFig. 47

CylindersFig. 48SPX Manual power unit 220V/60HZ, Single phaseFig. 49

ATLAS Manual power unit (Fig. 50)220V/60HZ, Single PhaseFig. 50

Illustration of hydraulic valve for SPX & ATLAS hydraulic power unita. SPX manual power unit, 220V/60HZ, Single phase (See Fig. 51)CapacitorOil return portRelief valveProtective ringCheck valveAuxiliary holeAuxiliary holeRelease valveOil OutletHandle for Release valveFig. 51b. ATLAS manual power unit, 220V/60HZ, Single phase (See Fig. 52)Running capacitorStart capacitorProtective ringRelief valveOil return portCheck valveRelease valveThrottle valveOil OutletHandle for ReleasevalveFig. 52

č. TEST RUN1. Adjust the equalizing cables (See Fig. 53)Use wrench to hold the cable fitting, meanwhileCable nutUse a ratchet to tighten the cable nut.Make sure the cables have the same tensionso the two carriages lift at the same time.Replace the covers on the carriages.If the carriages do not lift at the same time,tighten the cable nut on the lower of the two carriages.Fig. 532. Adjust safety cableLift the carriages and lock at the same height, pull the safety cable and then release a little, andthen tighten the cable nuts. Make sure the safety locks click at the same time.3. Bleeding airThis hydraulic system is designed to bleed air by looseningBleeding plugthe bleeding screw. Lift the carriages to about 12 inchesand loosen the bleeding plug, lower the lift until fluid comesFig. 54out. Tighten the screws after bleeding, (See Fig. 54).4. Adjust the lowering speed (Only for ATLAS power unit) (Adjust with a load on the lift)You can adjust the lowering speed of the lift if necessary: Loosen the locking nut on the throttlevalve, and then turn the throttle valve clockwise to decrease the lowering speed, orcounterclockwise to increase the lowering speed. Do not forget to tighten the locking nut afterthe lower speed adjustment has been completed.Throttle ValveLock NutClockwise to decreasethe lowering speedFig. 55Counterclockwise to increasethe lowering speed

5. Test with loadAfter finishing the above adjustment test run the lift with a load. Run the lift in the low positionseveral times. Run the lift to the top completely.NOTE: If the lift vibrates on the way up with a load, lubricate all pulley shafts and wearblocks. If the lift vibrates on the way down, the cylinders need to be bled.Fig. 56 Hydraulic System

Ď. OPERATION INSTRUCTIONSPlease read the safety tips carefully before operating the liftTo lift vehicle1. Keep the lift area free of clutter;2. Position lift arms to the lowest position;3. Open lift arms;4. Position vehicle between columns;5. Move arms to the vehicle’s lifting points;Note: The four lift arms must make contact at the same with the vehicle’s lifting points andboth axles must rise off of the ground at the same time.6. Press the UP button until the lift pads contact underside of vehicle. Check to make sure vehicleis secure;7. Continue to raise the lift slowly to the desired working height, ensuring the balance of vehicle;8. Push lowering handle to lower lift onto the nearest locks. The vehicle is ready to repair. Note:The lift must always be on the safety locks!!!!!To lower vehicle1. Keep the lift area free of clutter;2. Press the button of UP to raise the vehicle slightly, and then release the safety device, lowervehicle by pushing lowering handle.3. Open the arms and position them to the shortest length.4. Drive away the vehicle.

. MAINTENANCE SCHEDULEMonthly:1. Re-torque the anchor bolts to 85 Ft Lbs.2. Check all connectors, bolts and pins to insure proper mounting.3. Lubricate cable with lubricant.4. Make a visual inspection of all hydraulic hoses/lines for possible wear or leakage.5. Check the condition of the safety lock device.6. Lubricate all rollers and pins with 90wt. Gear oil or equivalent.Note: All anchor bolts should take full torque. If any of the bolts do not function for any reason,DO NOT use the lift until the bolt has been replaced.Every six months:1. Make a visual inspection of all moving parts for possible wear, interference or damage.2. Check and adjust as necessary, equalizer tension of the cables to ensure level lifting.3. Check columns for plumb.4. Check rubber pads and replace as necessary.5. Check safety lock device and make sure the condition is suitable.

. TROUBLE SHOOTINGTROUBLECAUSEREMEDY1. Button does not work1. Replace button2. Wiring connections are not in good2.Repair all wiring connectionscondition3. Motor burned out3. Repair or replace motor4. Height limit switch is damaged4.Replace the limit switch5. AC contactor burned out5. Replace AC contactor1. Motor runs in reverse rotation1.Reverse two power wire2. Gear pump out of operation2.Repair or replaceMotor runs but the lift is3. Release valve in damage3. Repair or replacenot raised4. Relief valve or check valve in damage4.Repair or replace5. Low oil level5.Fill tankMotor does not run1. Release valve out of work2. Relief valve or check valve leakageLiftRepair or replacedoes not stay up3. Cylinder or fittings leaks1. Oil line is jammed1. Clean the oil line2. Motor running on low voltage2. Check electrical system3. Oil mixed with air3. Fill tank4. Gear pump leaks4. Replace pump5. Overload lifting5. Check load1. Safety device are in activated1. Release the safeties2. Release valve in damage2. Repair or replace3. Safety cable broken3. Replace4. Oil system is jammed4. Clean the oil systemLift raises slowlyLift can not lowerFor more detail on motor troubleshooting visit our web site at gregsmithequipment.com. Go to “KnowledgeBase” and click on “Troubleshooting and repair leshooting

IX. Parts list for model PV-10P and PV-10HPItemPart#1217001201DescriptionQty.Note PV-10PPV-10HPPower side column11 209002Power unit11 3209003Bolt44 4209034Lock washer44 5217002Nut44 6217003Power side lock cover11 7217004Main cam lock11 8217069Bolt3434 9206006Washer3535 10206023Self locking nut3434 11420018Self locking nut8812217013Bolt88 13420045Washer2626 14217025Protective ring22 15217015Right overhead bar11 16217016Left overhead bar11 17217017Pin stop22 18209033Washer88 19209055Bolt44 20217019Top pulley44 21217020Bronze bush for pulley66 22217021Top pulley spacer4423217022Pin2224217023Pin spacer22 25217024Hose support22 26206009Plastic small pulley3327209056Self locking nut33 28209046Bolt33 29217026Safety cable bracket2220 02 30217027A217027BExtension column31217028Offside lock cover11 32217034Offside column11 33209051Adapter 1.5”44 34209052Adapter 3”44

pter 6”44209059Anchor bolt121237620065Shim101038680030Rubber pad frame support4439217036Bottom pulley2240217037Bottom pin2241209038Bolt6642217047Arm pin4443209039Lock washer181844209022Washer181845206049Moon gear4446217041Left front arm1146A217042Right front arm11Right rear arm11Left rear arm11121246B46C47217049206048Allen bolt48206032C-clip4449217043Limit ring4450206036Roll pin4451217044Arm lock4452217045Spring4453217046ALeft arm lock bar2254217046Right arm lock bar2255209019Flat head screw121256217053Rubber pad2257209009Cup head bolt262658217054Carriage plastic cover2259217055Carriage2260209015Slider block161661217056Cylinder2262217065AWire cable1163206025AFoam Cushion1164206025Limit bar1165201005Split Pin2266206025CLimit bar link2267206013Limit switch1168206011Cup head bolt (not used)2269206042Limit bar bracket2270420026Lock washer11Note

tic ball1173217006Lock handle1174217007Large spacer2275217008Main spring2276217009Main lock2277217010Bolt1178217011Nut1179217012Small spacer2280217050Main lock pin2281217051Screw2282217066Bolt2283217030Torsion spring1184217031Cam lock1185217033Self locking nut1186217032Cable lock hold1187217029Small pulley bracket1188217057Overhead hose1189217058T-fitting for power unit 90217059Short hose 91217060Cylinder pipe 92217061A90 Fitting 93217048Hose clamp 94420029Cable nut washer 95209066Cable nut PV-10PPV-10HP96217063ACable 97217064ASafety cable Parts For Hydraulic Cylinder61-1209069O-Ring 61-2209070Bleeding Plug 61-3209071Support Ring 61-4209072Y-Ring 61-5209073O-Ring 61-6209074Piston 61-7209075O-Ring 61-8217076Piston rod2261-9209077Piston rod fitting2261-10209078Dust ring2261-11209079Head cap2261-12209080O-Ring2261-13209081ABore weldment22Note

Parts for SPX Manual Power Unit, 220V/60Hz, 1 phaseNote tor11201-2209109Protective ring11201-3209083Motor connecting shaft11201-4209084Valve body11201-5209085Relief valve11201-6209086Lock washer 44201-7209087Allen bolt44201-8209088Inlet lt22201-14209094Cover of er gasket11201-17209097Bolt11201-18209098Cover of motor terminal box11201-19209099Push button11201-20209110Oil return port11201-21209100Oil outlet11201-22209101Release valve11201-23209102Release valve 6209105Check valve11201-27209106Gear pump11201-28209107Oil return pipe11201-29209108Filler cap11

Parts For ATLAS Manual Power Unit, 220V/60Hz, 1 te PV-10PPV-10HPMotor11209109Protective ring11201A-3209112AC contactor11201A-4209083AMotor connecting shaft11201A-5209084AValve body11201A-6209085ARelief valve11201A-7209113Throttle valve11201A-8209086ALock washer 44201A-9209087AAllen bolt44201A-10209088AInlet 201A-13209091AAllen bolt44201A-14209092AReservoir11201A-15209093ACup head bolt with washer44201A-16209094ACover of capacitor22201A-17209095AStart capacitor11201A-17A209095BRun capacitor11201A-18209096ARubber gasket22201A-19209097ACup head bolt with washer22201A-20209098ACover of motor terminal box11201A-21209099APush button11201A-22209110AOil return port11201A-23209100AOil outlet11201A-24209105ACheck valve11201A-25209101ARelease valve11201A-26209102AHandle of release 1A-29209106AGear pump11201A-30209107AOil return pipe11201A-31209108AFiller cap11

2 I. PRODUCT FEATURES AND SPECIFICATIONS CLEAR-FLOOR DIRECT-DRIVE MODEL FEATURES Model PV-10P & PV-10HP (See Fig. 1) · Direct drive hydraulic cylinder design, minimizes the lift wear parts and breakdown ratio · Dual hydraulic cylinders, designed and made on ANSI standards, utilizing NOK oil seal in cylinder · Self- lubricating UHMW Polyethylene sliders and bronze bush