Transcription

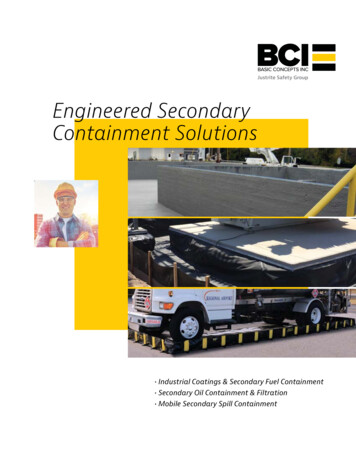

Engineered SecondaryContainment Solutions Industrial Coatings & Secondary Fuel Containment Secondary Oil Containment & Filtration Mobile Secondary Spill Containment

2

3A GrowingEnvironmental PortfolioJustrite’s leadingenvironmental solutionsportfolio now includesBasic Concepts, Inc.,C.I.Agent Solutionsand IndustrialMaintenance Group.Basic Concepts (BCI) is partof Justrite Safety Group For over a century, Justrite Safety Grouphas helped protect where the worldworks. Our mission is to identifyworkplace vulnerabilities and guidecustomers in creating an ecosystemof safety—so your team can workwith confidence.

4Making Confident Choices for the EnvironmentClean air and clean water touch everyone worldwide.They are essential to everyday life. That’s why regulationshave been enacted to protect our environment. AtBasic Concepts (BCI), our experts collaborate with youto understand your unique needs, helping you to selectappropriate solutions or designing custom systems to meetyour requirements. Our job is to help you make confident,compliant choices when it comes to secondary containment.A Wide Range of EngineeredSecondary Containment SolutionsAt BCI, we protect where the world works. We offer acomprehensive range of secondary containment solutionsacross applications, tailored to meet your specificrequirements and industry needs. The regulationssurrounding environmental containment can be complex. Wewill guide you into compliance—and help keep you there.Make BCI part of your Spill Prevention, Control andCountermeasure (SPCC*) Plan.*See page 19 for a detailed description of SPCC

5Table of ContentsSecondary Containment Solutions by Industry6SPCC Compliant Solutions for Oil, Fuel, Chemical Containment8Safe and Compliant Dewatering and Filtration Solutions12Compliant Containment Coating Solutions14

6Secondary ContainmentSolutions by IndustryBasic Concepts (BCI) offers high-quality,engineered solutions to meet the needs ofnearly any application across industries.Petroleum Storage & RefiningAs a leader in the coatings and secondary containmentmarket, we provide exclusive, innovative options tomeet your fuel containment requirements. Our patentedcontainment system (T.R.A.P.S.) and patented liner seamingsystem (PolySeam ) provide cost-effective methods to meetfuel containment regulations. Our patented Rigid-LockQuickBerm offers flexible, portable spill containment withthe added benefit of drive-in, drive-out conveniencefor vehicles. Hydrocarbon filtration products mitigateoil contamination for SPCC compliance.Electric PowerA variety of coating and liner options are availablefor the power industry. Utilizing high temperature, fast-setstructural coatings, epoxies and synthetic liners, wehelp meet your needs for secondary fuel containment,pond liners, waterproofing and pipeline repair. We increasethe life expectancy of key operating equipment such asprecipitators, pumps and more. Below-ground orabove-ground liners fitted with hydrocarbon filtrationproducts help utility companies comply with EPAand SPCC requirements. Containment systems arecustom-designed based on site-specific variables.Water/WastewaterMeeting the needs of the water/wastewater industryis our priority. We supply cost-effective solutions toconcrete degradation, restoration, corrosion prevention,water proofing, and rehabilitation of manholes and holdingpond liners. Use our coating systems to restore andmaintain sand filters, clarifying tanks, holding tanks andmany other steel, concrete or operational equipment.Complies with NSF/ANSI standard 61, section 5.

7MilitaryServing different branches of the U.S. Military,our battle- and field-tested technologies aresuitable for secondary fuel spills containmentfrom HEMTT trucks, pillow tanks, fuel bladders,and generators. Fail-Safe MilBerms , All-TerrainBerms , Modular Channel MilBerms and more aredesigned for efficient transport and quickdeployment in the field. All meet SPCCrequirements.RailroadFlexible in design, use our rail containment systems for newor existing rail loading and unloading areas. We design yourrail containment system to meet capacity requirementswhile using existing grades and structures. Our internalhigh-performance coating system provides uniform thicknessto meet your pressure rating needs. External coatings canbe applied with or without a high-tensile strength steelmesh to provide extremely high pressure ratings.Chemical, Pulp/Paper & Specialty PlantsA wide range of chemical resistant productsmeet specialty chemical needs and requirements.Regardless of your containment needs, whetherover concrete, steel or many other substrates,we offer a solution for aggressive chemicalenvironments. Both full immersion and secondarycontainment products available.*See page 19 for a detailed description of SPCC

8SPCC Compliant Solutions for Oil, Fuel, Chemical ContainmentSPCC Compliant Solutions forOil, Fuel, Chemical ContainmentGeomembrane Liner with Barrier Boom Self-activating, passive transformer oil containment Suitable for below—and above—ground applications Meets and exceeds SPCC and IEEE 980 requirementsSuitable for all soil types, the Geomembrane Liner withBarrier Boom system offers compliant secondary oilcontainment for substation transformers. Water flowsunimpeded through the panels, but in the event ofan oil release, the proprietary polymers in the panels willcompletely solidify, preventing any hydrocarbons fromleaving the site. Systems are custom designed basedon site-specific variables. Typically installs in two days orless. No downtime necessary—equipment can remainenergized during installation.Geomembrane Liner with Barrier Boom oil containment system during installation.Barrier Boom—Secondary Oil Containment F lows a minimum of 4.5 GPM per ft2(with 1-foot head pressure) Solidifies approximately ½ gallon of oil per ft2(depending on type, viscosity and temperature) N o need for concrete walls, sump pumps,oil-water separators, pits, manual valves,and hydrocarbon detectors Requires little to no maintenance—“bury and forget” application Install vertically in a to-grade or dike applicationA simple, passive secondary oil containment solutionsuitable for impervious subsurfaces such as clay. Walls arecomposed of non-woven geotextile materials and apatented filtration media that prevents the penetration ofoil and petroleum products, while allowing water to flowat a high rate. It is typically installed around the perimeterof the substation.

SPCC Compliant Solutions for Oil, Fuel, Chemical ContainmentEthylene Polymer PVC withElvaloy Technology Geomembrane G reater durability and longer-life protectionthan batten barB EFOR E T he strongest geomembrane for use in theworld’s harshest conditions Custom configurationsUse geomembranes for secondary containmentfor fuel storage tanks, pond and tank liners.High performance features: E xcellent stability, with low thermalexpansion-contraction properties High-strength, chemical-resistant grade for maximumprotection to high temperatures and a broad range ofchemicals including acids, oils, and methaneGeomembrane shown with PolySeam Formulated for long-term outdoor exposure to UV rays Florida Department of Environmental Protection Agencyapproved for secondary containmentCASE ST U DYInstallation of Approximately 215,000 Square Feet of Ethylene PolymerPVC Membrane Material at a Gas Power Plant in FloridaTwo tanks holding a total of 3 million gallons of diesel fuel required reliable containment. The firstphase of the project involved removal of approximately one foot of dirt in the containment area.Elevation was then established for storm water drainage. Thousands of rolls of liner were broughtto cover the 215,000 total square foot area. Each roll took approximately a half-hour to install.The installation was completed within a scheduled timeframe of four weeks.Workers unrolling liners.Elvaloy is a registered trademark of DuPontCompleted installation providing reliable, safe secondary containment for 3-milliongallons of diesel fuel.9

10SPCC Compliant Solutions for Oil, Fuel, Chemical ContainmentRigid-Lock QuickBerm S econdary containment with drive-in,drive-out capability for vehicles F lexible, durable geomembrane liner sets upin minutes, no assembly needed S tainless steel brace support for strongstructural integrity, no sagging Folds down for easy portabilityRigid-Lock QuickBerm offers one-piece construction for100% leakproof protection to avoid costly fines and complywith EPA and SPCC. Reliable protection for the environmentagainst hazardous spills from: Vehicles Heavy equipment Generators Storage tanks Air compressors 55-gallon drums Tankers Intermediate bulkcontainers (IBCs) PumpsIBC containmentFuel or tanker containmentDrum containmentGenerator containment Pillow tanksCAS E ST U DYSouthwestern Utility Ensures Power Supplyto Customers During Substation RebuildUtility company needed to find a versatile, low-maintenancesecondary containment solution durable enough to last overa year while they were rebuilding a substation. They broughtin a portable transformer and regulators which arrived on amobile trailer. It required cooling oil to operate and neededto comply with SPCC regulations.A custom-designed Rigid-Lock QuickBerm was the answer.Its single-piece, durable liner construction allowed forfast, easy set-up with no tools or assembly required.The Rigid-Lock devices on the entry and exit walls enableddrive-in, drive-out access for the trailer with no need to raiseor lower the wall. To avoid manual draining following arainstorm, the utility connected an HFF Oil-Stop Valve to theberm. Not only did this provide continued unmonitoreddrainage without incurring O&M costs, it also ensured allwater draining from the containment site was free of oil.Rigid-Lock QuickBerm and HFF Oil Stop Valve provides leakproof protection andcaptures hydrocarbons for mobile transformer.

SPCC Compliant Solutions for Oil, Fuel, Chemical ContainmentRigid-Lock QuickBerm Lite Leakproof containment for smaller-scaled spills Portable, one-piece design sets up fast and easy A dd optional grates for use as a decon stationor to lift containers above liquidTough geomembrane liner provides broad UV and chemicalresistance. Patented Rigid-Lock walls with stainless steelbraces lock at 90 for structural integrity. Unobstructed100% leakproof sump offers versatile, on-the-gocontainment for: Damaged saddle tanks Leaky containers and equipment Hydraulic leaks and breaks Battery or transformer storage Refueling overfillsCapture spills from damaged saddle fuel tanks.All-Terrain Berm L eakproof containment solution for fuel bags and bladders,metal storage tanks, transformers, and waste products D eploys quickly and easily without toolsor heavy equipment Waveguard for splashout protectionDesigned for the utmost flexibility and security, the bermadapts to the contour of the ground. Features quick-setaluminum A-frame supports and 3-foot tall walls.Military field application containing a flexible fuel tank—deployed in 45 minutes byfive people.CAS E ST U DYNational Guard Training FacilityTraining facility in Virginia serves soldiers from regional National Guard, activemilitary units from other installations, and soldiers from all branches of the military.In their mission to provide realistic and challenging training in support of soldierreadiness and deployment missions, they utilized a 100 x 100-foot All-Terrain Bermcapable of containing 210,000 gallons for fuel bladder containment.All-Terrain Berm can be customizedto suit any application and size—rightmeasured 100 x 100-feet.11

12Safe and Compliant Dewatering and Filtration SolutionsSafe and Compliant Dewateringand Filtration SolutionsVIPOR-100 SOWF System H igh flow rates 100 GPM using patentedsolidifier technology 100% automatic shutoff during oil releaseVIPOR-100100 GPM flow rateVIPOR 100 Oil StopSystem, configuredoutside of concretesubstation moat. Advanced oil-water separatorThe VIPOR-100 delivers the industry’s highest flow ratesand offers low maintenance. Helps customers lower, and insome cases eliminate, the costs associated with manuallyevacuating standing water in containments.Plug and playinstallationSimply plumb units intoexisting drainage systemsor into substation yard.CAS E ST U DYNew York Utility Saves onSecondary Containment O&M CostsThe electric utility wanted a solution to prevent standingwater in the containment moats and decrease operation andmaintenance (O&M) costs. They preferred an automaticpumping system with high flow rates. It was important forthe system to be simple to maintain, able to filterhydrocarbons to a non-detectable level, and providecomplete shut off in the event of an oil release.The utility replaced many of its low-flow filtration unitswith the VIPOR-100 SOWF system, and ordered severalmore. They saved money because they achieved higher flowrates with less maintenance over their previous system.Portable and compact35-1/2-in high x 22-3/4-indiameter.

Safe and Compliant Dewatering and Filtration Solutions13EVAC Filtration System E asy-to-use, reusable dewatering equipment filterssediments Filters oil sheen Eliminates vac trucks and water processing Comes in storage bucketPart NoCamlockEVAC-2M2-in maleEVAC-2F2-in femaleEVAC-3M3-in maleEVAC-3F3-in femaleRemoves suspended solids and light sheen from water discharge operations. Use invaults, manholes, elevator shafts, bilges, tanks and more.HFF Oil-Stop Valve S elf-activating, passive filtration system for secondarycontainment drainage Q uickly evacuates water while safely removinghydrocarbons M ulti-directional filtration provides highest flowrates on the marketVersatile filtration device that filters and processes rainwater, reducing organic hydrocarbons to a non-detectablelevel while meeting SPCC and IEEE 980 requirements.Automatically shuts off in the event of a major oil release.Requires low maintenance when used with reusablepre-filter. Standard and custom sizes available per specifiedflow rates.Part NumberFlow Rate*HFF2x12MUp to 8 GPMHFF4x12MUp to 18 GPMHFF4x24MUp to 25 GPMHFF6x24MUp to 31 GPMHFF14x24MUp to 100 GPMHFF14x24MCUp to 100 GPM* at 12-inch head pressure; varies per vertical or horizontal mountsUse with a variety of containment systems. Standard and custom sizes available, perspecified flow rates.

14Compliant Containment Coating SolutionsCompliant ContainmentCoating SolutionsSC-3900 Coating Systems Q uick installation spray-applied coating with short curetime seals a leak rapidly and eliminates vulnerabilities toweather and moisture—offers leakproof containment 3 00% elongation allows it to remain flexible and movewith the substrateSpray-on technology coats smoothly to repair cracksand leaks—tack-free in secondsB EFOR E 3700-5500 psi tensile strength for excellent durability Resistant to abrasion, corrosion, fuels and chemicals UV and high-temperature resistantSC-3900 coatings bond to most substrates includingoverlay for earthen/soil, steel, concrete, asphalt, and severalother substrates. Application thickness ranges from 40 to1000 mils. Once solid, it is 100% free of VOCs. Complieswith NSF/ANSI Standard 61, section 5 2011, is approvedfor secondary containment by the Florida Department ofEnvironmental Protection Agency, and is accepted by theUS Army Corps of Engineers.Precipitator coatingB EFOR EStructural issuesprior to coatingVersatile applications: Fuel containment systems Extend storage tank rooflife Steel coatings Potable water systems Earthen berms PCB and asbestosencapsulation Concrete containment areas Tank linings Floating roofs Repair traditional HDPEand ethylene polymer PVCwith Elvaloy technologyliners Truck loading bays/racksUV and corrosion resistant high-strengthcoating for tanks Waterproofing FDA food contact systems NSF 61 approved systems Manhole rehabilitation andrepair Silo rehabilitationInternal tank containment coatingElvaloy is a registered trademark of DuPont

Compliant Containment Coating SolutionsConcrete containmentTruck loading rackFuel containment areaB EFOR EJFK airport jet fuel tank farm concrete containment coatingSeals old, brittle bolts to prevent leaks including sump areas that accumulate sludge15

16Compliant Containment Coating SolutionsTotal Release AnnularProtection System (T.R.A.P.S.) F or new and existing tanks—approved by the FloridaDepartment of Environmental Protection Agencyrequiring overfill protection system P rovides continuous monitoring of a containmentarea for hydrocarbons V alve closure activates at desired rate withinstantaneous closing of containment valveT.R.A.P.S. immediately notifies personnel with visual andaudio alerts should hydrocarbons be detected. Customoptions include email, cell phone or other—interfacescompatible with most PLCs. Durable containment systemprovides an impervious coating—no VOCs, rapid cure time.Applied over soil, asphalt, concrete, steel, and more.Hydrocarbon sensordetects most commonlight fuels in 3 secondswith 1-mm filmControl panel monitors up to 128 sensorcircuits simultaneouslyConcrete applicationCR-3000 Chemical Coatings F aster set times gets equipment back in service withinhours, not days Outstanding adhesion and elongation, primer not necessaryB EFOR EB EFORE S uitable for tank and pipeline repairs: stops leaks, repairscracks, bridges gaps, stops deterioration and freeze thawLeak and crack repairSpray applied elastomer system is comparable to epoxysystems—offers a cost-effective way to rehabilitateequipment and structures.Holes in tank were repaired using ourstructural coating systemBE FOREPipeline repairChemical resistant coating

Compliant Containment Coating SolutionsPolySeam Liner Attachment SystemWhen used with our liners, the patented, cost-effectivePolySeam system replaces maintenance and repairsneeded to maintain integrity of the batten bar methodof attachment—for a virtually maintenance-free system I nstalls faster and is more durable, saving thousandsof dollars in installation costs Installs in the most extreme conditionsB EFOR EConcrete applicationSteel sheeting applicationPump pad applicationPipe support applicationDouble-bottom tank sealed withPolySeam prevents water from goingunder the tank, no corrosion.17

18Compliant Containment Coating SolutionsCAS E ST U DYHydrostatic Pressure Test Proves SecondaryContainment Solution Won’t LeakAn electric utility installed a 60-mil HDPE liner and sumppump for containment at a transformer pit. After a fewmonths, they suspected the lack of water in the sumpindicated that water was escaping through the liner itself.To mitigate any potential catastrophic leak into a localharbor, they decided to install another liner over theexisting one, with a requirement for a hydrostatic pressuretest to ensure it met their engineering standards.The solution included a switch to a 40-oz PVC liner, andusing the PolySeam spray-on coating system to seal thenumber of cable and ground grid penetrations. A hydrostaticpressure test was conducted to check for strength and leaks.To pass, the pit could lose no more than 1-inch of water in a24-hour period, after factoring in evaporation. The systempassed, surpassing the utility operator’s high standards. Forlow maintenance and 100% automatic shutoff during an oilrelease, the VIPOR-100 SOWF was recommended to filterand evacuate standing water and decrease O&M costs.

19For over a century, Justrite Safety Grouphas protected workers, workplacesand the environment with a comprehensiverange of industrial safety solutions.Worker & Workplace Safety Cable Management Emergency Showers Hazardous Storage Industrial Matting Motion SafetyEnvironmental Protection Aerosol Recycling Ground Protection Material Handling Secondary Containment Spill ContainmentTo learn more about our full portfolio ofproducts, please visit justrite.comAbout compliance with EPA and SPCCOne top priority of the Environmental Protection Agency (EPA) is to prevent, prepare for, and respond to oil spillsthat occur in and around inland waters of the United States. EPA’s oil spill prevention program includes the SpillPrevention Control and Countermeasures (SPCC) rules and is a part of the Clean Water Act found in 40 CFR part 112.Its purpose is to prevent oil and oil-related materials from reaching navigable waters and adjoining shorelines. Manyindustries require a SPCC plan that includes secondary containment for oil and fuel storage containers. Some local stateand municipal governments have separate requirements that must be adhered to in addition to the federal regulations.A facility is subject to the SPCC regulations if it has a total aboveground oil storage capacity greater than1,320 U.S. gallons or 42,000 U.S. gallons of buried storage capacity. Any container with a capacity of 55 gallons ormore should be included in the site capacity assessment. All types of hydrocarbon based oils are subject to the SPCCregulations. Common oils addressed by the SPCC regulations are: petroleum, fuel oil, sludge, oil refuse, oil mixed withwastes, fats, all animal oils, vegetable oils, synthetic oils, and mineral oils. Any site that stores, processes, refines, uses orconsumes oil and is a non-transportation-related operation is subject to the SPCC rule. Facilities that meet these criteriamust comply with the SPCC regulations.

Put Our Expertiseto Work for YouAt BCI, we are dedicated to protecting people,property and the planet. Our experts will help youselect solutions that work for your organizationand guide you into compliance with EPA and SPCC.To learn more about our customized line of secondary containment solutions, call:Portable secondaryspill drocarbon managementfor secondary el storage containmentand coating systems1-813-659-3512sales@basicconcepts.com 2019 Justrite Safety Group. All rights reserved.Code No. BC180 (1119)

Self-activating, passive transformer oil containment Suitable for below—and above—ground applications Meets and exceeds SPCC and IEEE 980 requirements Suitable for all soil types, the Geomembrane Liner with Barrier Boom system offers compliant secondary oil containment for substation transformers. Water flows