Transcription

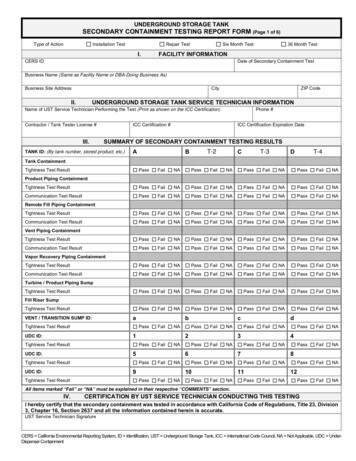

UNDERGROUND STORAGE TANKSECONDARY CONTAINMENT TESTING REPORT FORM (Page 1 of 6)Type of ActionInstallation TestRepair TestI.Six Month Test36 Month TestFACILITY INFORMATIONCERS IDDate of Secondary Containment TestBusiness Name (Same as Facility Name or DBA-Doing Business As)Business Site AddressCityII.ZIP CodeUNDERGROUND STORAGE TANK SERVICE TECHNICIAN INFORMATIONName of UST Service Technician Performing the Test (Print as shown on the ICC Certification)Contractor / Tank Tester License #III.Phone #ICC Certification Expiration DateICC Certification #SUMMARY OF SECONDARY CONTAINMENT TESTING RESULTSTANK ID: (By tank number, stored product, etc.)ABCT-2DT-3T-4Tank ContainmentTightness Test tness Test unication Test tness Test unication Test tness Test unication Test tness Test unication Test FailNAPassFailNAPassFailNAProduct Piping ContainmentRemote Fill Piping ContainmentVent Piping ContainmentVapor Recovery Piping ContainmentTurbine / Product Piping SumpTightness Test ResultFill Riser SumpTightness Test ResultVENT / TRANSITION SUMP ID:aTightness Test Resultb1UDC ID:Tightness Test Result25UDC ID:Tightness Test ResultFailNA9Tightness Test ResultFailNA47PassFailNA10Passd36PassUDC ID:cPass8PassFailNA11FailNAPass12FailNAAll items marked “Fail” or “NA” must be explained in their respective “COMMENTS” section.IV.CERTIFICATION BY UST SERVICE TECHNICIAN CONDUCTING THIS TESTINGI hereby certify that the secondary containment was tested in accordance with California Code of Regulations, Title 23, Division3, Chapter 16, Section 2637 and all the information contained herein is accurate.UST Service Technician SignatureCERS California Environmental Reporting System, ID Identification, UST Underground Storage Tank, ICC International Code Council, NA Not Applicable, UDC UnderDispenser Containment

UNDERGROUND STORAGE TANKSECONDARY CONTAINMENT TESTING REPORT FORM (Page 2 of 6)V.ManufacturerTANK SECONDARY CONTAINMENT INFORMATIONIdentify Tank ID from Section III for each ManufacturerAATest Method Used:BBCCDDManufacturer Guidelines (Specify):Industry Code or Engineering Standard (Specify):Engineered Method (Specify):# of Attached PagesAttach the testing procedures and all documentation required to determine the results.Tank Containment Testing Training and Certifications (List applicable certifications.)VI.Expiration DateCOMMENTSProvide any additional comments here.VII.ManufacturerPRODUCT PIPING CONTAINMENT TESTING INFORMATIONIdentify Tank ID from Section III for each ManufacturerAATest Method Used:BBCCDDManufacturer Guidelines (Specify):Industry Code or Engineering Standard (Specify):Engineered Method (Specify):# of Attached PagesAttach the testing procedures and all documentation required to determine the results.Product Piping Containment Testing Training and Certifications (List applicable certifications.)Interstitial Communication Verification Method Used:VIII.Provide any additional comments here.ID IdentificationCOMMENTSExpiration Date

UNDERGROUND STORAGE TANKSECONDARY CONTAINMENT TESTING REPORT FORM (Page 3 of 6)IX.REMOTE FILL PIPING CONTAINMENT TESTING INFORMATIONManufacturerIdentify Tank ID from Section III for each ManufacturerAATest Method Used:BBCCDDManufacturer Guidelines (Specify):Industry Code or Engineering Standard (Specify):Engineered Method (Specify):# of Attached PagesAttach the testing procedures and all documentation required to determine the results.Remote Fill Piping Containment Testing Training and Certifications (List applicable certifications.)Expiration DateInterstitial Communication Verification Method Used:X.COMMENTSProvide any additional comments here.XI.ManufacturerVENT PIPING CONTAINMENT TESTING INFORMATIONIdentify Tank ID from Section III for each ManufacturerAATest Method Used:BBCCDDManufacturer Guidelines (Specify):Industry Code or Engineering Standard (Specify):Engineered Method (Specify):Attach the testing procedures and all documentation required to determine the results.Vent Piping Containment Testing Training and Certifications (List applicable certifications.)Interstitial Communication Verification Method Used:XII.Provide any additional comments here.ID IdentificationCOMMENTS# of Attached PagesExpiration Date

UNDERGROUND STORAGE TANKSECONDARY CONTAINMENT TESTING REPORT FORM (Page 4 of 6)XIII.VAPOR RECOVERY PIPING CONTAINMENT TESTING INFORMATIONManufacturerIdentify Tank ID from Section III for each ManufacturerAATest Method Used:BBCCDDManufacturer Guidelines (Specify):Industry Code or Engineering Standard (Specify):Engineered Method (Specify):# of Attached PagesAttach the testing procedures and all documentation required to determine the results.Vapor Recovery Piping Containment Testing Training and Certifications (List applicable certifications.)Expiration DateInterstitial Communication Verification Method Used:XIV.COMMENTSProvide any additional comments here.XV.ManufacturerTURBINE / PRODUCT PIPING SUMP TESTING INFORMATIONIdentify Tank ID from Section III for each ManufacturerAATest Method Used:BBCCDDManufacturer Guidelines (Specify):Industry Code or Engineering Standard (Specify):Engineered Method (Specify):Attach the testing procedures and all documentation required to determine the results.Turbine / Product Piping Sump Testing Training and Certifications (List applicable certifications.)XVI.Provide any additional comments here.ID IdentificationCOMMENTS# of Attached PagesExpiration Date

UNDERGROUND STORAGE TANKSECONDARY CONTAINMENT TESTING REPORT FORM (Page 5 of 6)XVII.ManufacturerFILL RISER SUMP TESTING INFORMATIONIdentify Tank ID from Section III for each ManufacturerAATest Method Used:BBCCDDManufacturer Guidelines (Specify):Industry Code or Engineering Standard (Specify):Engineered Method (Specify):# of Attached PagesAttach the testing procedures and all documentation required to determine the results.Fill Riser Sump Testing Training and Certifications (List applicable certifications.)XVIII.Expiration DateCOMMENTSProvide any additional comments here.XIX.ManufacturerVENT / TRANSITION SUMP TESTING INFORMATIONIdentify Vent / Transition Sump ID from Section III for each ManufactureraaTest Method Used:bbccddManufacturer Guidelines (Specify):Industry Code or Engineering Standard (Specify):Engineered Method (Specify):Attach the testing procedures and all documentation required to determine the results.Vent / Transition Sump Testing Training and Certifications (List applicable certifications.)XX.Provide any additional comments here.ID IdentificationCOMMENTS# of Attached PagesExpiration Date

UNDERGROUND STORAGE TANKSECONDARY CONTAINMENT TESTING REPORT FORM (Page 6 of 6)XXI.UNDER-DISPENSER CONTAINMENT TESTING INFORMATIONManufacturer(s)Identify UDC ID from Section III for each Manufacturer1717Test Method Used:28283939410410511511612612Manufacturer Guidelines (Specify):Industry Code or Engineering Standard (Specify):Engineered Method (Specify):Attach the testing procedures and all documentation required to determine the results.UDC Testing Training and Certifications (List applicable certifications.)XXII.Expiration DateCOMMENTSProvide any additional comments here.If the facility has more components than this form accommodates, additional copies of these pages may be attached.UDC Under-Dispenser Containment; ID Identification# of Attached Pages

SECONDARY CONTAINMENT TESTING REPORT FORM (Page 1 of 6) Type of Action Installation Test Repair Test Six Month Test 36 Month Test I. FACILITY INFORMATION CERS ID Date of Secondary Containment Test Business Name (Same as Facility Name or DBA-Doing Business As) Business Site Address City ZIP Code .