Transcription

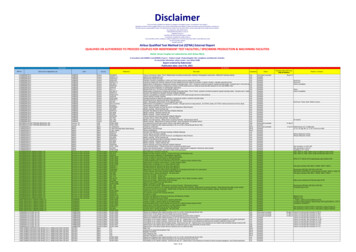

DisclaimerThis is the Airbus Qualified Test Method List (Register of Qualified Couples Test Method / Test Facility )Publication of this list neither engages Airbus in any contract relationship/responsibility nor allows automatic contract authorization, ordering, etc.All subcontractors using qualified couples 'Test Method & Test Facility' from the Airbus QTML remain responsible of the quality of their products.As consequence, they shall conduct:* Alerting/informing Airbus in case of:- significant events or- identified risks with potential impact on Airbus- consistently unsatisfactory quality results or- the test facility is either unwilling or unable to implement a corrective action plan within a reasonable time-scaleThe list it monthly updatedAll rights reservedAirbus Qualified Test Method List (QTML) External ReportQUALIFIED OR AUTHORISED TO PROCEED COUPLES FOR INDEPENDENT TEST FACILITIES / SPECIMENS PRODUCTION & MACHINING FACILITIESNote2: Green Couples are Laboratories with Airbus MeritIn Accordance with M20691.2 and M20691.3 Issue A - Perform Couple Product/Supplier Site Compliance and Maturity’s ActivitiesFor any further information, please contact : your Airbus SCQMReport ordered by ReferentialPublication date: June 4 th, 2021Test 6561146561146561146561146561Name of the Independent T TESTING SERVICES, INC.ACCUFLEET TESTING SERVICES, .L.ACEM.S.L.ACEM.S.L.ACEM.S.L.AEROFIN LABORATORIES LTD.AEROFIN LABORATORIES LTD.AEROFIN LABORATORIES LTD.AEROFIN LABORATORIES LTD.AEROFIN LABORATORIES LTD.AEROFIN LABORATORIES LTD.AEROFIN LABORATORIES LTD.AEROFIN LABORATORIES LTD.AEROFIN LABORATORIES LTD.AEROFIN LABORATORIES LTD.AEROFIN LABORATORIES LTD.AEROFIN LABORATORIES LTD.AEROFIN LABORATORIES LTD.AEROFIN LABORATORIES LTD.AEROFIN LABORATORIES LTD.AEROFIN LABORATORIES LTD.AEROFIN LABORATORIES LTD.AEROFIN LABORATORIES LTD.AEROFIN LABORATORIES LTD.AEROFIN LABORATORIES LTD.AEROFIN LABORATORIES LTD.AEROFIN LABORATORIES LTD.AEROFIN LABORATORIES LTD.AEROFIN LABORATORIES LTD.AEROFIN LABORATORIES LTD.AEROFIN LABORATORIES LTD.AEROFIN LABORATORIES LTD.AEROTECH LABORATORIES LtdAEROTECH LABORATORIES LtdAEROTECH LABORATORIES LtdAEROTECH LABORATORIES LtdAEROTECH LABORATORIES LtdAEROTECH LABORATORIES LtdAEROTECH LABORATORIES LtdAIM ALTITUDE UK LTDAIM ALTITUDE UK LTDAIM ALTITUDE UK LTDAIM ALTITUDE UK LTDAIM ALTITUDE UK LTDAIM ALTITUDE UK LTDAIM ALTITUDE UK LTDAIM ALTITUDE UK LTDAIM ALTITUDE UK LTDAIRBUS DEFENCE AND SPACE S.A.U. AIRBUS MILITARY GETAFEAIRBUS DEFENCE AND SPACE S.A.U. AIRBUS MILITARY GETAFEAIRBUS DEFENCE AND SPACE S.A.U. AIRBUS MILITARY GETAFEAIRBUS DEFENCE AND SPACE S.A.U. AIRBUS MILITARY GETAFEAIRBUS DEFENCE AND SPACE S.A.U. AIRBUS MILITARY GETAFEAIRBUS DEFENCE AND SPACE S.A.U. AIRBUS MILITARY GETAFEAIRBUS DEFENCE AND SPACE S.A.U. AIRBUS MILITARY GETAFEAIRBUS DEFENCE AND SPACE S.A.U. AIRBUS MILITARY GETAFETest ouston, TXHouston, , SomersetBurnham-on-Sea, SomersetBurnham-on-Sea, SomersetBurnham-on-Sea, SomersetBurnham-on-Sea, SomersetBurnham-on-Sea, SomersetBurnham-on-Sea, SomersetBurnham-on-Sea, SomersetBurnham-on-Sea, SomersetBurnham-on-Sea, SomersetBurnham-on-Sea, SomersetBurnham-on-Sea, SomersetBurnham-on-Sea, SomersetBurnham-on-Sea, SomersetBurnham-on-Sea, SomersetBurnham-on-Sea, SomersetBurnham-on-Sea, SomersetBurnham-on-Sea, SomersetBurnham-on-Sea, SomersetBurnham-on-Sea, SomersetBurnham-on-Sea, SomersetBurnham-on-Sea, SomersetBurnham-on-Sea, SomersetBurnham-on-Sea, SomersetBurnham-on-Sea, SomersetBurnham-on-Sea, SomersetBurnham-on-Sea, ainSpainSpainSpainSpainSpainSpainSpainUnited KingdomUnited KingdomUnited KingdomUnited KingdomUnited KingdomUnited KingdomUnited KingdomUnited KingdomUnited KingdomUnited KingdomUnited KingdomUnited KingdomUnited KingdomUnited KingdomUnited KingdomUnited KingdomUnited KingdomUnited KingdomUnited KingdomUnited KingdomUnited KingdomUnited KingdomUnited KingdomUnited KingdomUnited KingdomUnited KingdomUnited KingdomUnited KingdomUnited KingdomUnited KingdomUnited KingdomUnited KingdomUnited KingdomUnited KingdomUnited KingdomUnited KingdomUnited KingdomUnited KingdomUnited KingdomUnited KingdomUnited KingdomUnited KingdomUnited erentialEN 2003-9ASTM E112ASTM E407ASTM G34ASTM G110ISO 3651-1ASTM G67ASTM E3EN 3114ISO 3651-2ASTM E18AITM 3-0013ASTM E8ASTM A262ASTM B117ISO 643EN 2716 (Pren)EN 2002-1ASTM B557ISO 6506ASTM E10ISO 6508ISO 6507ASTM E92ISO 9227ISO 1463ISO 9220AITM 2-0009AITM 2-0002Z CombustionZ Glow Discharge Mass SpectroscopyZ Opt. metallo.ASTM E18ASTM E8ASTM B557ISO 6506ASTM E10ISO 6508ISO 6507ASTM E92AITM 1-0025EN 2563AITM 4-0005ASTM E384ISO 4516ASTM E3AITM 3-0030AITM 3-0032AITM 3-0034AITM 3-0035AITM 3-0036ASTM B117ASTM B117ASTM B487ASTM E92ISO 9227ISO 2409ISO 1518ISO 2812-2ISO 2808AITM 2-0024ASTM D3359ISO 1463ISO 2360ISO 2106AITM 3-0038ASTM E70ASTM D512ASTM D1125ASTM D1293AITM 3-0030AITM 3-0032AITM 3-0034AITM 3-0035ASTM B117ISO 9227AITM 3-0038AITM 2-0002AITM 2-0006AITM 3-0005AITM 2-0003AITM 2-0004AITM 2-0005AITM 2-0038AITM 2-0007AITM 2-0008TT1TT2TT4TT6TT8AITM 2-0002AITM 2-0003AITM 2-0004Test LabelComplexityStatusExpiration Date (ATP only)END OF MONTHTitanium and titanium alloys - Part 9: Determination of surface contamination (method A: Micrographic examination / Method B: Hardness testing)LowAuthorised to proceedDetermining average grain sizeLowQualifiedMicroetching metals and alloysLowQualifiedExfoliation corrosion susceptibility in 2XXX and 7XXX series aluminum alloys (EXCO Test)LowQualifiedEvaluating intergranular corrosion resistance of heat treatable aluminium alloys by immersion in sodium chloride hydrogen peroxide solutionLowQualifiedDetermination of resistance to intergranular corrosion of stainless steels - Part 1: Austenitic and ferritic-austenitic (duplex) stainless steels - Corrosion test in nitric acid mediumLow by measurementQualified of loss in mass (Huey test)Determining the susceptibility to intergranular corrosion of 5XXX series aluminium alloys by mass loss after exposure to nitric acid (NAMLT test)LowQualifiedStandard guide for preparation of metallographic specimensLowQualifiedMicrostructure of (a ß) titanium alloy wrought productsLowQualifiedDetermination of resistance to intergranular corrosion of stainless steels - Part 2: Ferritic, austenitic and ferritic-austenitic (duplex) stainless steels - Corrosion test in mediaLowcontaining sulfuricQualifiedacidStandard Test Methods for Rockwell Hardness of Metallic MaterialsLowQualifiedTesting of susceptibility to exfolation corrosion in 2XXX and 7XXX series wrought aluminium alloy productsLowQualifiedTension testing of metallic materialsLowQualifiedStandard practices for detecting susceptibility to intergranular attack in austenitic stainless steelsLowQualifiedStandard practice for operating salt spray (Fog) apparatusLowQualifiedSteels - Micrographic determination of the apparent grain sizeLowQualifiedDetermination of susceptibility to intergranular corrosion - Wrought aluminium alloy products - AL-P2XXX- series, AL-P7XXX- series and aluminium-lithium alloysLowQualifiedTensile testing at ambient temperatureLowQualifiedTension Testing Wrought and Cast Aluminum- and Magnesium-Alloy ProductsLowQualifiedMetallic materials - Brinell hardness testLowQualifiedStandard Test Method for Brinell Hardness of Metallic MaterialsLowQualifiedMetallic materials - Rockwell hardness testLowQualifiedMetallic materials - Vickers hardness testLowQualifiedVickers Hardness and Knoop Hardness of Metallic MaterialsLowQualifiedCorrosion tests in artificial atmospheres - Salt spray testsLowQualifiedMetallic and oxide coatings - Measurement of coating thickness - Microscopical methodLowQualifiedMetallic coatings - Measurement of coating thickness - Scanning electron microscope methodLowQualifiedFire resistance of aircraft seat cushion utilizing a high density open flameHighAuthorised to proceedResistance of Materials when tested according to the 12 s or 60 s Vertical Bunsen Burner TestLowQualifiedAnalysis by combustionNoneAuthorised to proceedSpectrometry: glow dischargeNoneQualifiedOptical metallographyNoneQualifiedStandard Test Methods for Rockwell Hardness of Metallic MaterialsLowQualifiedTension testing of metallic materialsLowQualifiedTension Testing Wrought and Cast Aluminum- and Magnesium-Alloy ProductsLowQualifiedMetallic materials - Brinell hardness testLowQualifiedStandard Test Method for Brinell Hardness of Metallic MaterialsLowQualifiedMetallic materials - Rockwell hardness testLowQualifiedMetallic materials - Vickers hardness testLowQualifiedVickers Hardness and Knoop Hardness of Metallic MaterialsLowQualifiedFiber reinforced plastics - Flatwise tensile test of composite sandwich panelLowQualifiedCarbon fibre reinforced plastics - Unidirectional laminates - determination of apparent interlaminar shear strengthLowQualifiedMacroscopic and microscopic examination of fiber reinforced plasticsLowQualifiedMicroindentation hardness of materialsLowQualifiedMetallic and other inorganic coatings - Vickers and Knoop microhardness testsLowQualifiedStandard guide for preparation of metallographic specimensLowQualifiedTitration of sulphuric and tartaric acid in anodizing electrolytesLowQualifiedAnalysis of metals in galvanic bathes by ICP-spectroscopyLowQualifiedCombined determination of free hydroxide and aluminium in alkaline surface treatment bathsLowQualifiedDetermination of chloride contaminations in surface treatment bathsLowQualifiedDetermination of hydrogen ions in surface treatment bathsLowQualifiedStandard practice for operating salt spray (Fog) apparatusLowQualifiedStandard practice for operating salt spray (Fog) apparatusLowQualifiedMeasurement of metal and oxide coating thicknesses by microscopical examination of a cross-sectionLowQualifiedVickers Hardness and Knoop Hardness of Metallic MaterialsLowQualifiedCorrosion tests in artificial atmospheres - Salt spray testsLowQualifiedPaints and varnishes - Cross-cut testLowQualifiedPaints and varnishes - Scratch testLowQualifiedPaints and varnishes - Determination of resistance to liquids - Part 2: Water immersion methodLowQualifiedPaints and varnishes - Determination of film thicknessLowQualifiedDetermination of adhesion by wet tape testingLowQualifiedMeasuring adhesion by tape testLowQualifiedMetallic and oxide coatings - Measurement of coating thickness - Microscopical methodLowQualifiedNon-conductive coatings on non-magnetic electrically conductive basis materials - Measurement of coating thickness - Amplitude-sensitive eddy current methodLowQualifiedAnodizing of aluminium and its alloys - Determination of mass per unit area (surface density) of anodic oxidation coatings - Gravimetric methodLowQualifiedDetermination of non-volatile-residueLowQualifiedpH of aqueous solutions with the glass electrodeLowQualifiedChloride ion in waterLowQualifiedStandard Test Methods for Electrical Conductivity and Resistivity of WaterLowQualifiedStandard Test Methods for pH of WaterLowQualifiedTitration of sulphuric and tartaric acid in anodizing electrolytesLowQualifiedAnalysis of metals in galvanic bathes by ICP-spectroscopyLowQualifiedCombined determination of free hydroxide and aluminium in alkaline surface treatment bathsLowQualifiedDetermination of chloride contaminations in surface treatment bathsLowQualifiedStandard practice for operating salt spray (Fog) apparatusLowQualifiedCorrosion tests in artificial atmospheres - Salt spray testsLowQualifiedDetermination of non-volatile-residueLowQualifiedResistance of Materials when tested according to the 12 s or 60 s Vertical Bunsen Burner TestLowAuthorised to proceedDetermination of heat release and heat release rate of aircraft materialsHighAuthorised to proceedDetermination of specific gas components of smoke generated by aircraft interior materialsHighAuthorised to proceedResistance of Materials when tested according to the 15s horizontal bunsen burner testLowQualifiedFlammability of non-metallic materials - Small burner test, 45 - Determination of the resistance of material to flame and glow propagation, and to flame penetrationLowQualifiedFlammability of non-metallic materials - Small burner test, 60 - Determination of the resistance of electrical wire insulation materials to flame at 60 LowQualifiedFlammability of non-metallic heat shrinkable tubings - Small burner test, 60 - Determination of the resistance of non-metallic heat shrinkable tubings to flame at 60 LowQualifiedDetermination

11.05.2021 · 312060 ACEM.S.L. Madrid Spain ASTM E8 Tension testing of metallic materials Low Qualified Without Reduction of Area 312060 ACEM.S.L. Madrid Spain ASTM B557 Tension Testing Wrought and Cast Aluminum- and Magnesium-Alloy Products Low Qualified Without Reduction of Area