Transcription

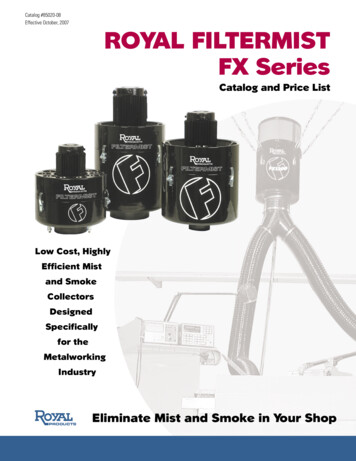

Catalog #85020-08Effective October, 2007ROYAL FILTERMISTFX SeriesCatalog and Price ListLow Cost, HighlyEfficient Mistand SmokeCollectorsDesignedSpecificallyfor theMetalworkingIndustryEliminate Mist and Smoke in Your Shop

CONTENTSWhy Control Oil Mist and Smoke in Your Shop?3Common Mist Collection Methods4–5How Does the Royal Filtermist Work?6FX Series Design Enhancements7Why is the Royal Filtermist the Best Choice for the Metalworking Industry?8Risk-Free Performance Guarantee9Filtermist Performance Accessories10 – 11Mounting12 –13Choosing the Correct Filtermist Unit14 –15Efficiency16Commonly Asked Filtermist Questions17Model FX-27518 –19Model FX-55020 – 21Model FX-90022 – 23Model FX-120024 – 25Filtermist Maintenance26Replacement Parts27– 28Filtermist Ordering Sheet29Division of Curran Manufacturing Corporation200 Oser AvenueHauppauge, New York 11788Tel: 1-631-273-1010Fax: 1-631-273-1066Toll-Free USA and CanadaTel: 1-800-645-4174Fax: 1-800-424-2082Email: info@royalprod.comwww.royalprod.comINDUSTRIAL SUPPLY ASSOCIATIONLinking Channel Partners Copyright 2007 Royal Products, Div. of Curran Mfg. Corp.Printed in U.S.A. Prices and specifications subject to change without notice.

FILTERMIST— THE WORD’S LEADING MIST COLLECTORFor over 30 years, the Royal Filtermist has beeneffectively collecting mist and smoke generated byall types of metalworking machinery.There are currently more than 125,000 unitsoperating in over 40 countries worldwide, makingFiltermist the world leader in metalworking pollutioncontrol equipment.Throughout its history, the Royal Filtermist has undergonecontinuous design advances. The Filtermist FX representsthe ninth generation of Royal Filtermist, and is the result ofextensive computer-aided modeling and testing. Based uponthe well-established principle of centrifugal impaction, theFiltermist FX incorporates a series of improvements thathave resulted in the most advanced and effective systemavailable for the removal of mist and smoke created bymetalworking machinery.This catalog will help you learn how the Royal Filtermist can make yourshop a cleaner, safer, and healthier place to work. It contains all of theinformation you will need to make an educated purchasing decision —including prices.We have also produced a nine-minute video to further explain the manyadvantages offered by the Royal Filtermist. If you didn’t receive a copyof the video with this catalog, you may view it on our website atwww.mistcollectors.com, or you can contact our customer servicedepartment at 1-800-645-4174 for a free copy.Thank you for considering Royal Filtermist for your shop. We look forward to working with you.TEL: 1-800-645-4174 FAX: 1-800-424-2082 www.mistcollectors.com1

A ROYAL FILTERMIST FOR EVERY APPLICATIONThe low-cost, highly efficient Royal Filtermist effectively collectsmist and smoke generated by all types of machines, including: 2CNC LathesMachining CentersGrindersSwiss-Style CNC’sScrew MachinesEDM MachinesTEL: 1-800-645-4174 Manual LathesMilling MachinesInjection Molding MachinesRotary Transfer MachinesGear HobbersCold Heading Machines FAX: 1-800-424-2082 Aqueous Parts WashersVacuum PumpsPrinting PressesBaking LinesSome Heat Treating Processeswww.mistcollectors.com

WHY CONTROL OIL MIST & SMOKE IN YOUR SHOP? Reduced Health RisksAny form of pollution is potentially dangerous to the lungs, larynx, and skin. Reduced Accident RisksOil mist creates slippery surfaces which increase accident rates. Reduced Fire HazardsOil deposits create a serious fire risk by allowing fires to spread quickly. Coolant Cost SavingsThe Royal Filtermist recycles coolant and returns it to your machine rather than ventingit to the atmosphere. Heating and Cooling Cost SavingsThe Royal Filtermist returns clean air to the shop instead of exhausting it outdoors. Cleaning and Maintenance Cost SavingsUncontrolled airborne mist and smoke deposits result in more frequent cleaning ofexposed surfaces.CostSavings Fewer A/C Service CallsThe Royal Filtermist helps reduce breakdowns of shop air conditioning equipment bypreventing mist from contaminating the intake filters. Improved Employee AttendanceA contaminated shop environment often results in higher worker absenteeism andlower morale. Less Machine DowntimeFouled contacts in electronic equipment cause expensive downtime. Higher Speeds and FeedsMachining operations can run at higher speeds and feeds without the negative effectsof increased mist and smoke production. Better LightingHaze from mist and smoke and grimy buildup on shop lighting fixtures cause even themost well-lit shops to take on a dingy appearance. Bright, cheerful environmentsimprove employee morale and performance.INCREASEDPRODUCTIVITY Fewer Workmen’s Compensation ClaimsThe increase in workmen’s compensation rates from one large claim can cost more thanan air cleaning system for an entire factory. Government RegulationsThe current OSHA and NIOSH limits on airborne oil mist are 5 mg/cubic meter, and thisrequirement is expected to become even stricter in the future. The Royal Filtermistexceeds both the current and new proposed limits. Moral Concerns — You Owe It To Your EmployeesThey deserve a workplace that is as hazard-free as you can make it. One customer,when asked why he wanted to control the oil mist and smoke in his plant, responded,“I wouldn't expect my office people to work with smoke pouring out of their computers,and I sure don’t expect my shop workers to work on machines with oil mist pouring outof them!”TEL: 1-800-645-4174 FAX: 1-800-424-2082 www.mistcollectors.com3

COMMON MIST COLLECTION METHODSCOMMON MIST COLLECTION METHODSIn order to fully understand why the Royal Filtermist is the best choice for handling oil mist and smoke produced by themetalworking industry, it is important to have some general knowledge of how other types of collection systems work. Thissection contains an overview of the most common methods for controlling mist and smoke. While these systems all have somepositive features, their drawbacks make them unsuitable for use in most metalworking applications.External VentingAt one time, the only method for controlling oil mist and smoke in a shop was to vent it out of the building. This was done eitherby opening the doors and windows or installing a ventilation system. While this method may look like an attractive low-costsolution, the potential dangers should be enough to make any shop owner reconsider this practice.Environmental Hazards Today, it is illegal in many states toexhaust pollutants to the atmosphere. Offending companies run therisk of large fines and lawsuits.Fire Hazards Over time, oil deposits collect in the ductwork ofventilation systems, making them prime targets for flash fires andproviding pathways for fires to spread quickly.Cleanliness Problems As mist and smoke travels through a shopto the exhaust points, it collects on exposed surfaces. Over time, agrimy buildup occurs on machines, lights, floors, and walls,resulting in dirty, unsafe conditions.Media-Type Filtration SystemsMedia-type filtration systems typically consist of a blower and several filters of varying efficiencies. The contaminated air firstpasses through a coarse pre-filter where the largest particles are filtered out. It then moves through one or two medium-rangefilters before reaching the final filter, which is usually made from a high-efficiency HEPA material. Media-type systems are goodat collecting dry contaminants such as welding smoke and graphite dust. However, they are often not suitable for metalworkingapplications where coolant mist is the primary contaminant.High Operating Costs The biggest drawback of media-typeDirty AirFilter (Fine)Clean Airfiltration systems is the high operating cost associated withreplacement filters. Because these filters are designed to retaincontaminants, they will become clogged with use. Usually they aremade from media that cannot be cleaned, so the only alternative isreplacement. Depending upon the cost of the filters and thereplacement frequency, this type of system can be quite expensiveto operate over the long term.Decreased Throughput Another problem with multi-stage filterEnclosureFilter (Coarse)Blowerunits is that the throughput of the system, measured in cfm,decreases as contaminants become trapped in the pores of thefilters. It is important to maintain the correct throughput of anycollection system. Reduced throughput means reduced collection,allowing contaminants to escape into the shop air.Not for Mist Most media filters are designed to collect drypollutants such as smoke and dust. Exposure to coolant and oilmist may damage certain types of filter media.4TEL: 1-800-645-4174 FAX: 1-800-424-2082 www.mistcollectors.com

COMMON MIST COLLECTION METHODSElectrostatic PrecipitatorsElectrostatic preciptitators use a blower to draw mist and smoke particles past an ionizer, which imparts a positive charge tothem. They then pass across a series of alternately like-charged and grounded collection plates. The particles are repelled by thelike-charged plates and forced towards the grounded plates where they collect. The filtered air is returned to the shop.Variable Efficiency Although electrostatic systems arevery efficient when the collection plates are clean, theefficiency drops off drastically as the plates becomecovered with particles. Each time a particle deposits on aplate, it eliminates a spot for other particles to adhere to.Dirty AirCharged ParticlesBlowerMaintenance Costs To maintain high efficiency, thecollection plates must be cleaned often. This can beexpensive because the residue is considered to behazardous waste and must be disposed of by a certifiedwaste handling company. Many electrostatic systems aresold with costly maintenance contracts, resulting inoperating costs that greatly exceed the original unitpurchase price.Pre-filterIonizerEnclosureCollector Plates(Charged particles adhere togrounded plates)Health Hazards As the collection plates become full, aphenomenon known as arcing can occur. This arcingresults in the production of ozone, which has been foundto cause a variety of health problems. This potentialdanger (and the fear of lawsuits) has caused many U.S.companies to remove electrostatic units from their factories.The Dangers of OzoneOzone produced by electrostatic precipitators presents a significant health risk to humans. Here’s what OSHA and the EPA haveto say about ozone on their websites:OSHAOzone is highly injurious and potentially lethal to experimental animals at concentrations as low as a few parts per million(ppm). A study in which young mice were exposed to 1 ppm ozone for 1 or 2 days reported damage to alveolar tissue. Humanpopulations chronically exposed to lower concentrations of ozone were observed to have adverse changes in lung function.Human volunteers exposed to 0.5 ppm ozone for 3 hours per day, 6 days per week, for 12 weeks showed significant adversechanges in lung function. Another report showed a 20 percent reduction in timed vital lung capacity in persons exposed toaverage concentrations of ozone of 1.5 ppm for 2 hours. 14/id214.htmlEPABreathing ozone can trigger a variety of health problems including chest pain, coughing, throat irritation, and congestion. It canworsen bronchitis, emphysema, and asthma. "Bad" ozone also can reduce lung function and inflame the linings of the lungs.Repeated exposure may permanently scar lung tissue. http://www.epa.gov/oar/oaqps/gooduphigh/With these health (and potential lawsuit) risks, many companies have establishedpolicies that ban the use of electrostatic mist collectors in their facilities.TEL: 1-800-645-4174 FAX: 1-800-424-2082 www.mistcollectors.com5

HOW DOES THE ROYAL FILTERMIST WORK?MotorOil ReturnChannelPolyetherFoamSilencerClean owerHousingPolyetherDrumPadThe principle of impaction can beeasily understood by considering a carpassing through a fog bank. As the foghits the windshield, tiny mist particlesbegin to grow into water dropletswhich are then shed off.Dirty Air InThe Royal Filtermist uses the principle of centrifugal impaction to eliminate mist. With onlythree main components: a drum, a motor, and the housing, its operation is quite simple.1. A three-phase motor rotates the internal drum at high speed,creating a vacuum which draws mist particles into the centerof the drum.2. The mist particles then collide with the rotating drum’s vanesand are forced together with other particles, causing them tocoalesce and form larger, droplet-sized particles.3. As the particles grow into droplets, they pass throughthe perforations in the rotating drum and centrifugal forcecauses them to be thrown onto the inner wall of the housing.4. The particles are then forced, under pressure, up the wallsof the housing to the oil return channel, where they aresubsequently drained back to the machine’s coolant tank.6TEL: 1-800-645-4174 5. Clean, oil-free air blows past the motor and is returned tothe shop.6. Since this process relies on the mechanical principle ofcentrifugal impaction and the rotational speed remainsconstant, the Royal Filtermist maintains a continuoushigh efficiency.7. For certain applications that produce smoke and/or very finemist particles, an after filter may be required. This filtereasily mounts to the top of the Filtermist unit by slippingover the motor and it is secured in place with twotoggle clips. An after filter mounted to a Royal Filtermisttypically enjoys a comparably long service life because mostcontaminants are removed by the impaction process prior toreaching the filter.FAX: 1-800-424-2082 www.mistcollectors.com

FX SERIES DESIGN ENHANCEMENTSThe Royal Filtermist FX Series is the ninth generation of Filtermist. FX Models incorporatea number of design improvements over previous versions to provide the most advancedand effective system available for the removal of mist and smoke.Compact designand reduced weightprovide greatermounting flexibility.Heavy-duty 3-phasemotor meets all federal,state, and local electricaland safety codes.Oil return channelhas been enlarged,enabling unit toprocess a greatervolume of liquid.Curved drum vanesimprove airflow.Gap betweendrum and housinghas been optimizedfor maximumfiltration efficiency.Conical air deflectorpositioned at intakeaccurately controlsairflow within unit.Air flow is automaticallyregulated as machinedoors close to keep thecorrect negative pressureinside the enclosure. Noneed to adjust drum speed.TEL: 1-800-645-4174 FAX: 1-800-424-2082 www.mistcollectors.com7

WHY IS THE ROYAL FILTERMIST THE BEST CHOICEFOR THE METALWORKING INDUSTRY?High EfficiencyNo Heat/AC WasteThe Royal Filtermist maintains a continuous high efficiencythrough constant drum speed. Performance does notdecrease with use. See page 16 for efficiency information.Processed air is returned to the shop, reducing heatingand cooling costs. A/C service calls are also reduced byprotecting intake filters from contaminants.FlexibilityLow MaintenanceBecause the unit works on a mechanical principle instead ofelectrostatics or multi-stage filters, the Royal Filtermistrequires significantly less maintenance than most otherfiltration systems on the market. The small amount of regularmaintenance that is required can be easily performed by thecustomer. See page 26 for maintenance information.High QualityWhen you purchase a Royal Filtermist, you receive a qualityproduct. Features found on all units include: Heavy-duty 3-phase motors that meet all federal, state andlocal electrical and safety codes. All exposed surfaces on the drum and housing arepowder coated for wear resistance and long life. Very tight manufacturing tolerances provide precise fitsbetween mating parts and ensure that the unit willprovide years of trouble-free service.Units are portable and typically service individual machines,allowing machines to be easily moved or replaced. Largecentral systems are connected to multiple machines bycostly and non-flexible ductwork, making relocation difficult.Modular DesignThe Royal Filtermist is a modular system. Accessories suchas after filters, dust cyclones, noise attenuators, etc. can beeasily added as applications require. See pages 10 –11 forinformation on performance accessories.Easy To InstallMultiple installation configurations allow the Filtermist toovercome almost any mounting obstacle. See pages 12 –13for mounting details.Wide Range of SizesVibration ControlFour sizes ranging from 275 –1200 cfm are available to suitall applications.The Royal Filtermist incorporates unique features to help itovercome vibration-related problems that are sometimesassociated with other centrifugal impaction type systems: All drums are dynamically balanced at the factory andtested before shipping.Strong Technical Support Vertical drum arrangement provides even massdistribution.A large network of local distributors and factory-trainedrepresentatives are strategically located throughoutthe country to provide quick and accurate on-sitetechnical support. Motor is connected to housing with four neoprenemounts, effectively isolating vibration and controllingstartup torque.5-Year WarrantyLow Operating CostsThe Royal Filtermist is cost-effective to own and operate.Other types of systems (media, electrostatic, etc.) requirefrequent maintenance and costly filter replacement.Companies that sell these units often push expensivemaintenance contracts that can far exceed the initialpurchase price.Every Royal Filtermist unit carries a 5-year warranty againstfailure due to manufacturing defects. Other brands are onlyprotected for 1– 2 years. Please note that our warrantydoes not include normal wear and tear items such asdrum pads, silencers, ductwork, etc. The motor carries aone-year warranty.Proven WorldwideThere are over 125,000 units currently operating in over40 countries worldwide, making Filtermist the world leaderin metalworking pollution control equipment.8TEL: 1-800-645-4174 FAX: 1-800-424-2082 www.mistcollectors.com

RISK-FREE PERFORMANCE GUARANTEEDesigned specifically to collectoil mist and smoke produced bymetalworkingmachinery,theRoyal Filtermist simply does thebest job, over a longer period oftime, for the lowest cost.Still Not Convinced? Try a Unit Risk-Free!We’re so confident that the Royal Filtermist is the best solution for mist and smoke generated by metalworkingmachinery, we are willing to guarantee its performance. Our guarantee is simple:Risk-Free Performance GuaranteeRoyal Products will issue full credit on any Royal Filtermist unit returned within 45 daysof the purchase date if the customer is not completely satisfied with its performance. Thefollowing conditions apply:1. The unit must be sized and installedaccording to the recommendations of ourlocal factory representative and/or authorizedFiltermist distributor.3. The customer must contact Royal Productsfor a return goods number (RGA #). Thisnumber must appear on all paperwork andpackaging of the unit being returned.2. Credit will be issued for the unit, but may notbe issued for ductwork, oil return hoses, etc.,if they are not in resalable condition.4. The returned unit must be securely packagedand arrive at Royal Products in good condition.So give us a call today at 1-800-645-4174 and let us help solve your mist andsmoke problems. You’ll be glad you did.TEL: 1-800-645-4174 FAX: 1-800-424-2082 www.mistcollectors.com9

FILTERMIST PERFORMANCE ACCESSORIESRoyal Products offers a number of optional accessories designed to enhance Filtermist performance, particularly in verydemanding applications. Please contact one of our engineers at 1-800-645-4174 if you have any questions regarding the use ofthese performance accessories.After FilterAfter filters are available for all Royal Filtermist models. They can beused in any application where extreme high efficiency is required,and are especially useful for dealing with the following conditions: Applications where heavy, dry smoke is generated along withthe mist. Applications that produce very fine mist particles which maysometimes bypass the impaction process, (jobs that run at veryhigh spindle speeds, high-pressure coolant, etc.).Important — An after filter should not be used to compensate forblow-thru that could result from improper installation. If you havequestions or concerns about your installation, please contact one ofour engineers at 1-800-645-4174.After Filter AdvantagesEasy InstallationThe Royal after filter simply slides over the Filtermist motorand is secured in place with two toggle clips.High EfficiencyAdding an after filter to a Royal Filtermist unit will greatlyincrease efficiency in the sub-micron range. See page 16 foradditional information on efficiency.Noise ReductionAn after filter reduces the noise level of a Filtermist unit byapproximately 3 dB.Long LifeRoyal after filters have extended service lives due to their largesurface area. They also last longer because the centrifugalimpaction process of the Filtermist removes most of thepollutants before they ever reach the filter. Systems that relyentirely on media filters for the filtering process tend to havemuch shorter service lives.Full RangeAfter filters are available for all size Filtermist units. Models arealso available for older series units.Stainless Steel Filtermist Units In addition to our standard line of powder-coated units,Royal Products also offers all Filtermist FX Series units instainless steel versions for special applications. Drum, housing, internal hardware, and motor shaft are allmanufactured from stainless steel. Great for aqueous parts washers where caustic soap couldpenetrate the paint and erode the steel components. Also popular for use in food processing applications such asthe collection of oil spray from baking lines.10TEL: 1-800-645-4174 FAX: 1-800-424-2082 www.mistcollectors.com

FILTERMIST PERFORMANCE ACCESSORIESCyclonic Swarf Separator Recommended for applications that generate solid particles, suchas wet grinding dust, cast iron fines, etc. Also good for high-speed aluminum milling that produces lightfly-away chips. Cyclonic action removes solid particles, ensuring that only mist is6"drawn into the Filtermist unit. Acts as a great pre-filter for high pressure coolant applications.23.6" Reduces maintenance in difficult applications such as heavy grinding. Easily attaches to the bottom of the Filtermist unit. Note — theseparator cannot be used in direct-mount applications. 6" diameter intake port is located on the side of the unit. A 2" ball-valve is located on the bottom of the unit for draining. Two-piece design allows for easy cleaning. Not for use in purely dry applications. For models FX-900 and FX-1200 only. Reduces throughput of Filtermist unit by approximately 300 cfm.Chip Deflector Protects the Filtermist intake from chips and direct coolant splash. Opening is large enough to ensure that airflow and intake velocity6"are not negatively affected. Powder coated finish protects against rust.10" Can be used with all size Filtermist models.10" See page 13 for additional information on correct intake positioning.Noise Attenuator Reduces noise level by 5 dB. Easy installation — slips over motor and is secured withtoggle clips.13.6" Cannot be used in conjunction with after filters. Excellent for shops with low ceilings. Fits models FX-900 and FX-1200.TEL: 1-800-645-4174 FAX: 1-800-424-2082 www.mistcollectors.com11

MOUNTING OPTIONSA wide variety of mounting optionsmakes the Royal Filtermist very easyto install. If you have any questionsregarding mounting, please contactone of our applications engineers at1-800-645-4174.FX-275FX-550FX-900FX-1200Direct Mount Suspended–– Floor Stand Machine Top Stand–– Wall Mount Machine Side Mount * ** Can be accomplished using either wall bracket or modified floor stand.Direct MountTypically used on enclosed machinessuch as CNC lathes. All Filtermistmodels can be mounted this way,but it is important to make surethat the mounting location is wellsuited to the application and doesnot interfere with any machinecomponents.Suspended MountEyebolts included with the FX-900and FX-1200 enable these units tobe suspended from the factoryceiling. Suspension is a low-costmounting option and is often thebest choice for tall machines likelarge machining centers. Suspensionis also a popular choice when aFiltermist unit will be servicingmore than one machine.Floor StandFloor stands are available for allmodels. The stand for modelsFX-275 and FX-550 is fixed at aheight of 6 ft., while the stand formodels FX-900 and FX-1200 can beadjusted from 6 ft. – 9 ft. Note thatstands must be bolted to the factoryfloor to prevent tipping.Machine Top StandThis 3 ft. high stand enables modelsFX-900 and FX-1200 to be mountedto the top of a machine, but offersadvantages over direct mountingwith its small footprint and flexibleintake positioning.Wall MountWall mount brackets are availablefor all models. Depending uponthe machine, it may be possible touse the wall mount bracket tomount a Filtermist to the side of amachine tool.Machine Side MountWe offer a special side mountbracket for models FX-275 andFX-550 that enables a Filtermist unitto be mounted to the outside wallof a machine tool without the needfor any ducting. A built-in deflectorprotects against chips and coolantsplash.12TEL: 1-800-645-4174 FAX: 1-800-424-2082 www.mistcollectors.com

MOUNTING OPTIONSExamples of Various Mounting ArrangementsDIRECT MOUNT Unit Direct Mounting Kit Oil Return HoseSTAND MOUNT Unit Floor Stand Oil Return Hose Ducting Hose Clamps (2) Flange AdapterSUSPENDED MOUNT Unit Suspension Kit Oil Return Hose Hose Clamps (4) Y-Junction Ducting FishtailsWALL MOUNT Unit Wall Bracket Oil Return Hose Hose Clamps (2) Ducting Flange AdapterIntake Position — Very ImportantWhen installing a Filtermist unit, be sure to locate the intake in a position where it willcollect mist, not splash. A common mistake is to locate the collection point too close tothe cutting action, causing raw coolant and chips to be drawn into the unit. For example,the intake on a CNC lathe should be located near the tailstock-end of the machine, notover the chuck. Whenever possible, draw the mist across the enclosure from an area ofheavy concentration to an area of lighter concentration.Intake DuctingDeflectorFor machines where the intake must be positioned near the cutting action, a deflector isoften necessary (see page 11). A deflector protects the intake from chips and coolant yetallows mist and smoke to pass around it for collection.Light Oil MistHeavy Droplets & SplashAccessoriesUnitIntake DiameterFX-2756"FX-5506"FX-9006"FX-12008"TEL: 1-800-645-4174 Royal Products offers a full array of mounting accessories to simplifyinstallation, including flange adapters, reducers, fishtails, ducting,Y-junctions, etc. Please be sure to keep the correct Filtermist intakediameter in mind when ordering accessories.FAX: 1-800-424-2082 www.mistcollectors.com13

CHOOSING THE CORRECT FILTERMIST UNITSizing UnitsThe Royal Filtermist is available in four sizes, basedon throughput capacities: 275, 550, 900, and 1200 cfm.Royal Products maintains a database with specificationsfor many different machine tools, and we recommend youcontact one of our applications engineers for your specificsizing requirements.For those who would like a general rule of thumb, werecommend using the following formula to obtain a roughidea of your requirements:Filtermist Size Internal Enclosure Volume x 5For example, suppose you have a small CNC lathe with aninternal work envelope measuring 4ft. wide x 3ft. deep x 4ft.high. Multiplying 4x3x4, we see that the machine has anenclosure volume of 48 cu. ft. Multiplying 48x5 we see that240 cfm is required, so we’d choose the model FX-275.Although this rule is very simple, it is handy for determiningthe general size requirements.If you are not sure which unit to use, please contactyour local Royal Filtermist Distributor or one of ourapplications engineers.GrindingGrinding applications can sometimes be more demanding than typicalturning and milling applications because grinding produces fine dustparticles that become entrained in the mist stream. Over time, this dustcan accumulate on the drum pads, resulting in the need for more frequentmaintenance. If regular maintenance is not performed and a significantvolume of solid matter builds up in the drum, balance and vibration issuesmay arise.A simple way to overcome the problems associated with grinding dust isto fit the Filtermist with a cyclonic swarf separator. The separator mountsbelow the Filtermist unit and uses cyclonic action to separate out the solidmatter, leaving the drum free to process the mist and preventing buildupon the pads. A valve on the bottom of the unit facilitates drainage.Royal Products recommends using a cyclonic swarf separator for all grinding applications.14TEL: 1-800-645-4174 FAX: 1-800-424-2082 www.mistcollectors.com

CHOOSING THE CORRECT FILTERMIST UNITTurningCNC lathes are relatively easy applications to tackle because themachines are usually well enclosed and direct mounting is oftenpossible. On any well enclosed machine, it is recommended that theFiltermist intake point be located as far from the machining action aspossible so that the mist is drawn from an area of heavy concentrationto an area of lighter concentration. On CNC lathes, therefore, theideal intake location is on the right side of the machine, near thetailstock. On subspindle lathes where the right-hand wall movesalong the z-axis, it might be necessary for the Filtermist to have amore central location.MillingFor enclosed machining centers, the Filtermist intake position should belocated in an upper corner of the enclosure. Installation on open-topmachines is not a

The Royal Filtermist uses the principle of centrifugal impaction to eliminate mist. With only three main components: a drum, a motor, and the housing, its operation is quite simple. Motor Polyether Foam Silencer Clean Air Out Upper Housing Rotating Drum Vane Oil Return Channel Returned Coolant Polyether Drum Pad Lower Housing Dirty Air In