Transcription

Housing andEquipment forSheepUNITED 5T An sDEPARTMENT OfAGRICUll UREFARMERS'BULLETINNUMBER 2242PRfPAR[O BYSCIENCE ANDEDUCATIONADMINISTRATION

CONTENTSPageShelters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Conventional shelters . .Slatted floor housing . .Feeding equipment . .Feed racks . . .Feed troughs .Self-feeders . . .Mineral feeders . . .Water troughs . .Feedlots . . .Panels . . .Fences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Chutes . . .Cutting chutes . .Loading chutes . .Squeezes . . .Scales .Corrals . . .Dipping vats . . .Shipping crates . . .Shearing equipment .Tools.Plans for sheep facilities .334555667788888899910101213Revised July 1978For sale by the Superintendent of Documents, U,S, Government PrintingW.oshington, nc. 20402Stock No. 001-000-(13816-82om

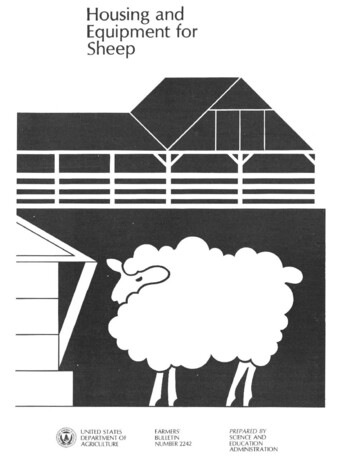

HOUSING AND EQUIPMENTFOR SHEEPYou can build most of the housingand equipment illustrated ordescribed in this bulletin with readilyavailable tools and materials. Beforeyou build your own equipment, compare the cost of the materials you willneed with the cost of buying readymade equipment. Even if the originalcost of readymade equipment ishigher, it may be cheaper to use if itis more durable and has built-in conventences.Your county agricultural agent orState extensio o specialist can giveyou additional information about thetools and materials you will need formaking your own equipment. If necessary, he can also help you modifyure I. In mild climates, shelters needto do little more than provide shadefor the animals (fig. 2). Even in placeswhere winters are severe, sheepshould not be shut in, except duringstorms and when they are lambing.The complete unit in figure I canhouse 30 to 36 ewes. It can be closed induring storms. The pen panels, feedracks, creep, and trough can berearranged for lambing, shearing, fattening lambs, and other operations. Ifthere is electricity at the barn, you canequip the lambing pens ("jugs") withheat lamps to warm newborn lambs incold weather.Directions for building the housingin figure 1 are in USDA Plan 5919, andthe plans to suit your climate andsoil. Consult local sheep raisers, too,for figure 2, in USDA Plan 5926. Youbefore you buy or build shelters andequipment. They may be able to offerhelpful suggestions.sheep shed in USDA Plan 5874.SHELTERSConventional SheltersA small flock of sheep can behoused in a barn with other stock. Aflock of 100 or more ewes needs separate housing, however, such as theall-purpose unit illustrated in fig-will find plans for another permanentHere are some points to keep inmind when you are planning a shelter: Allow 8 square feet of floorspacefor each lamb; 14 square feet for asmall ewe; and 20 square feet for alarge ewe. Build the shelter or barn on welldrained land. It should face awayfrom the wind. Locate windows and doorswhere they will let in plenty of light3

and air and make the shelter cool insummer. Be sure that windows anddoors fit tight to prevent drafts. Clay noors should slope towardthe front of the building. Roofing should be sound andresistant to wind damage. Place troughs on eaves for rainrunoff. Pole-type sheds are generallycheaper to build than those on concrete or masonry foundations. Polesand lumber that are in contact withthe ground should be pressure-treatedwith a preservative. It is best to use anonstaining preservative.Slatted Floor HousingYou may want to use slatted floorhousing if you are going to practiceintensive sheep raising.Use expanded metal or 2- by 2-inchlumber to build a slatted floor. If youHEQSTOR.fEED RACKLAMBFEEDING Figure I.-Above, complete unit fo r a small fl ock of sheep; below, dimensions and interiorarrangement. ( USDA Plan 5919)4

Figure 2.- Lightweight, temporary sheep shed. (USDA Plan 5926)use expanded metal, use l/8-inchsheets, rolled flat, with 9/ 16-inch by 15/8-inch diamond-shaped holes.Fasten the metal to treated, 2- by 6inch wooden frames with cross supports every 4 feet.If you use lumber, trim the loweredges of the 2- by 2-inch pieces so thatthere is 518 inch between the upperedges and 314 inch between the loweredges of each pair of slats. Support theslats every 18 inches.The floor should be 2 to 3 feetabove ground. This allows for ayear's accumulation of manure. Thefloor can be removed for cleaning oncea year. Provide 10 to 14 sq uare feet offloorspace for each ewe. Bedding is notnecessary.To use slatted floor housing, movelambs and ewes from the lambingarea to the slatted floor 4 or 5 daysafter lambing. Wean lambs at about 60days and finish them by themselves onthe slatted floor. These lambs usuallygain weight at a very good rate. Inaddition , lambs raised on a slattedOoor will be practically free ofparasites. 'FEEDING EQUIPMENTBuild and locate feeders where youcan fill them easily. Keep them clean;sheep may refuse to eat from a dirtyfeeder. Keep feed dry and free frominsects.Feed RacksCombination hay and grain racksare best for small flocks. Whenweather permits, feed hay outdoors inportable racks. You will find rackssuitable for outdoor use in USDAPlans 5910 and 5913. If the racks areinside the shelter (figs. 3 and 4), besure that you can fill them withoutentering the pen. USDA Plan 5913also shows another indoor feed rack.Feed TroughsFeed troughs are generally made ofwood. Although troughs may be Vshaped, Oat-bottomed troughs aremore stable and easier to keep clean,especially if they can be reversed.For small farms, portable feedtroughs are more practical than stationary ones. They can be used in the5

-.-tt:J:- o· . ---.--0,-.--'.-. .Jo .-Figure 3.- Combinalion hay and grain rack.field, as well as near the barn. Bracethem on the ends with metal straps andbuild them at least 8 inches wide.Instructions for making portable feedtroughs are in USDA Plan 5918.Use heavy, seasoned lumber. If youcannot get well-cured lumber for thebottom, line the trough with tempered hardboard to help preventcracks and make the trough moredurable.In a combination hay and graintrough, provide 10 to 12 inches oftrough space for each lamb and asmuch as 18 inches for each eweweighing 140 pounds or more.Self-FeedersSelf-feeders can save you time andlabor in feeding young sheep. Theygenerally hold 6 to 10 days' supply or6pelleted feed or grain. Do not selffeed pellets or grain to mature sheep.The self-feeder shown on the frontcover is weatherproof. It is 15 feetlong (30 reet or trough space), but itcan be built in other lengths. It has acapacity of 3,000 pounds (50 bushels)and will feed pellets to 100 lambs forabout JO days. You. will find directions ror building it in USDA Plan5861.Mineral FeedersMake sa lt and other mineral supplements available to the flock at alltimes. Set a block of salt on a post or inan open box. If you use granulatedsalt, put it in a small feeder to keep itdry and clean.If internal parasites are a pro blem,you can parti.ally control them bymixing phenothiazine with the salt.

Here is a good phenothiazine mixlure: 6 parts salt with trace minerals, 3parts dicalcium phosphate, and I partphenothiazine.USDA Plan 5916 tells how to builda se lf-feeding, weather-tight saltfeeder for 50 to 100 ewes.Water TroughsWater trough s may be made of galvanized iron or concrete. Iron is usually cheaper, but concrete is moredurable. Round troughs require lessmaterial than sq uare or rectangulartroughs. Make su re that the troughsare easy to clean.Allow I foot of trough space forevery 10 sheep. One sheep will drinkabout 2-1 / 2 gallons of water per day.Use a float valve connected to areservoir or water hydrant to controlthe water level in the trough.For good drainage be sure that theground slopes away from the tank. Apaved surface that extends g to IO feetaround the tank prevents mud holesfrom forming.In cold regions, locate the tank s inprotected places, such as behind awindbreak or in a shed. to reduce thedanger of freezing.A single tank in a fence line or in acorner can serve two or more lots.If you use galvanized tanks withoutbottoms. seal the earth inside thetank wall with bentonite.If you use an automatic waterer. youwill not have to haul water, and thesheep will ha ve a constant supply offresh water.FeedlotsMany sheep raisers, especiallythose who fatten sheep for market,confine their flocks in feedlots.Locate lots in well-drained areas,close to feed storage facilities. Allowabout 30 square feet per head. Theshortest part of the lot should rundownhill.Figure 4.- Combination hay and grain rack.7

Pave the feedlot to prevent mudholes. If you do not want to pave anentire feedlot, pave only aroundfeeders and waterers.Make sure that runoff from thefeedlot does nol pollute streams.Consult your local county agent orSoil Conservalion Service office foradvice as to the need for pollutioncontrol facilities.PANELSUse panels to separate fatteninglambs by age, to control sheep atshearing time, and to form temporaryfeeding fences and lambing pens forewes and newborn lambs.Build 10-foot panels of 1- by 8-inchboards. You can stack hinged orsingle panels for storage. USDA Plan5917 gives instructions for buildingfencing, feeding, and creep panels.CHUTESCutting ChutesA cutting chute can help separatethe flock into smaller groups forbreeding, lambing , shearing , orCUlling. To keep sheep from turningaround. make the chutes about 18inches wide.USDA Plan 5859 gives directionsfor building a portable chute. It hasremovable hinge pins that allow thegates to open from either side. Withthis chute, you can separate sheepmoving in either direction into threegroups. To separate the flock intomore than three groups, install morethan one chute, and build small pensopposite each gate.Loading ChutesLocate a loading chute in or nearthe corral. Leave enough roomFENCESaround it for a truck . Build the chuteat least 18 feet long and 1-1 / 2 feetBuild outside fences 5 feet high wide.7-1 / 2-foot posts driven 2-1 / 2 feetYou will find directions forinto the ground. Stretch one strandbuilding a variable·height loadingof barbed wire close to the ground.chute in USDA Plan 5924. This chuteRun 4-foot rectangular-mesh wirepermits easy loading into any type offencing above it. Run two strands oftruck body. It has a concrete ounter barbed wire above the mesh.weight to counterbalance part of theBuild cross fences at least 40 incheschute, so that one man can raise andhigh. They need not be equipped withlower it. There is a 3·foot-Iongbarbed wire.entrance fence that is taller than theIf you use homemade gates, makechute walls, to keep sheep fromsure they are strong. They should bejumping out. A permanent fence canas high as the fence.be attached to it.Fence in enough pastures to allowsheep to move frequently to freshSqueezesground. This is necessary to preserveA sheep squeeze is convenient forthe pastures and to control internalparasites.examining or treating an animal, butElectric fences are showing promise a sheep may be held by hand easily, ifof being effective for protecting sheep necessary. Consult local sheep raisersagainst predators and dogs.for easy ways to handle and hold8

CORRALSFigure 5. - Tilting squeeze for sheep. (US DAPlan 6006)sheep. Figure 5 shows a tiltingsqueeze that keeps the sheep in aprone position and permits regularinspection and trimming of the feet.Directions for building the squeezeare in USDA Plan 6006.SCALESYou should weigh sheep andfleeces to keep your productionrecords accurate and to form a basisfor selecting breeding stock.Use a small milk scale to weighfleeces and newborn lambs. Forlarger sheep, on a small farm wheresheep can be weighed one at a time,use portable scales with a 5OG-poundcapacity.On a large farm you may need apermanent scale that can weighseveral sheep at a time. Locate it nearfeeding pens or corrals. Place thescales on a platform with sides. Thiskeeps the sheep from crowdingagainst the sides of the pen andcausing errors in the readings.A well-built and well-locatedsystem of corrals can save you a lotof wo rk . USDA Plan 6019 shows Ihedetails of three basic corral designs.Equip your corral system with asqueeze chute, a cutting chute,holding pens, a water trough, scales,spray area, and loading facilities .Locate it on well-drained ground .The cutting area should formenough pens that lead to the cuttinggate for all the culs you need tomake.A shallow trough in the cuttingchute can be used for a footbath.Sheep can walk through it for treatment of foot ailments.DIPPING VATSDipping is the most effective way totreat shee p for control of lice, ticks.and mites. Vats for dipping areusually made of concrete o r galvanized iron.The permanent vat in figure 6 ismade of concrete, which is m oredurable than iron. It rests o n welltamped earth. The bottom and sidesare 4 to 6 inches thick. The low roofover Ihe front keeps Ihe sheep fromjumping into the vat and splashing theliquid. The rear of the vat slopes 20 to25 degrees and is fitted with slats tohelp the sheep climb out. For mo redelails, see USDA Plan 5390.NOT E: You can u se a hi g hpressure sprayer (at least 25 pound spressure per square inch) instead of avat. If yo u use a sprayer, be sure tospray the entire surface of each animal.9

Figure 6.-Permanent concrete dipping vat . (USDA Plan 5390)SHIPPING CRATESsheared and facilities for keeping thewool clean afterward.Strong crates help prevent acciIf a shearing room with sackingdents when sheep are shipped toracks(fig. 7) is not practical for you,exhibitions or to breeders. Use wellseasoned pine boards I inch thick. use 200-pound-capacity paper orFasten troughs for water and feed to . plastic-lined wool bags in a packingrack. USDA Plan 59 I I givesone end of each crate.Collapsible crates cost more to instructions for building a hingedconstruct than noncollapsible crates, rack that folds flat for easy moving andbut they can be folded for easy return storage. It also has a ring-type bagclamp on a removable top.to the shipper.USDA Plan 5867 tells howto buildA rack without hinges or a specialboth collapsible and noncollapsible clamp is shown in the same set ofcrates. These crates weigh 50 to 75 plans. This type of rack is lesspounds and will hold a sheep expensive to build. It can be takenweighing up to 300 pounds. Crates apart and reassembled.should be about I foot longer andTie fleeces into compact bundlesI foot wider than the animals. with paper twine. If you have only aIncrease these clearances by about 50 few sheep you may want to use apercent for ewes in advanced stages of hinged tying box. Directions forpregnancy.making a box are in USDA Plan5805. If you have a larger flock , however, you should learn to tie fleecesSHEARING EQUIPMENTwithout using the box. After youA shearing room should include practice a little, you.will find that this isroom for holding sheep while they are faster than using a box.10

11

TOOLSHere are some small tools neededfor raising sheep: Docking stool; and dockingchisel, sharp knife, e1astrator. or allin-one tool for severing tails and castrating the male lambs. Pruning knife, pruning shears, orcommercial foot-rot shears for trimming feet.12 Punch, dies, and metal tags fornumberi'ng sheep. Graduated nursing bottle withnipple for measuring medicines andraising orphaned and disownedlambs. Hand shears for trimming fleecesand removing tags . One power-operated shearingmachine for a small flock is adequate.

PLANS FOR SHEEP FACILITIESTitlePlan 759055910591159125913Sheep shed - 16' x 24'Sheep shed - 30' x 60'Self feeder for sheep - 2'8" W, 8' L, 4' HParting chutes for sheep - IS" x 24' and 16" x 36'Sheep shed - 20' x 72'Sheep shed - 24' x 92'Three-way cutting gates - 2'4" x 5'7"Self feeder for sheep - IS' long, 30' troughCombination lamb brooder and ewe feeder - 2' x 8'Shipping crates for sheep - 1'9" W, 4' L. 3' HSheep shed - 26' x 120'Weighing crate for sheep - 27" W, 42" L, 34" HSheep equipment - feeder 16' L, lamb shelter 16' LHay and grain feeder - for to sheepWool packing racksEwe stanchion - 2'10" x 3'Sheep feeders - 3' W, 6' L, 2'6" Hand1'6" W, 8' L, 3'4" 04760966142Portable self-feeder for sheep - 8' L, 16' troughLamb feeder - 1'6" W, 8' L, and mineral box at each endMineral feeder for sheep - 1'4" W, 5'5" LFencing and feeding panels for sheep - 3' x 10' sectionsSheep equipment - grain troughs - 10' longSheep and lambing shed - 20' x 32'Variable height loading chute for sheep - 1'6" x 18'Shelter for sheep - 28' x 48'Portable dipping vat for sheep - trailer unitTilting squeeze for sheepCorrals for sheepSheep corralSheep chairShearing shed and corral for sheepPortable foot bath for sheep13

HOW TO ORDER WORKING DRAWINGSComplete working drawings may request to Agricultural Engineer, Scibe obtained from the extension agri- ence and Education Administrationcultural engineer at your State uni- Extension, U.S. Department of Agriversity. There may be a small charge culture. Washington. D.C. 20250. Hewill forward your request to the corto cover cost of printing.If you do not know the locati'o n of rect university.your State university. send yourPRECAUTIONDo not use paint containing leadon 'sheep equipment or on parts ofbuilding accessible to sheep. Poisoning may result when anima1s lick orchew objects covered with paintcontaining lead.14

Slatted Floor Housing You may want to use slatted floor housing if you are going to practice intensive sheep raising. Use expanded metal or 2- by 2-inch lumber to build a slatted floor. If you fEED RACK Figure I.-Above, complete unit fo r a small fl ock of sheep; below, dimensions and interior arrangement. (USDA Plan 5919) 4