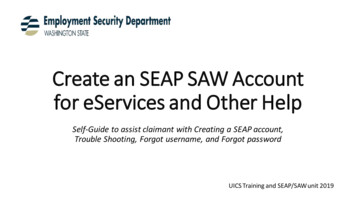

Transcription

BAND SAW BLADESNEWBlades&SolutionsTriple ChipCarbide Set Tooth20 Negative RakeX-51tmBroadBand BlockBuster SiClone IC EndurotmDieBand Plus PalletBuster Red StreakHardBackFlexBackWoodMaxFrictionSimoGritPower HacksawsTriplCarb20 NX-51BroaBlocSiCloIC EnDieBPalleRedHardFlexBWooFrictSimoPowThe Professionals’ EdgeTMThe Professionals’ Edge The Professionals’ Edge SIMONDS INTERNATIONAL135 Intervale Road, P.O. Box 500, Fitchburg,(978) 424-0100 (800) 343-1616 fax (800) 541www.simondsinternational.comNALBox 500, Fitchburg, MA 014203-1616 fax (800) 541-6224onal.com Simonds International 5/10 3M #304R Simonds International 5/10 3M #304R

What do we mean by“The Professionals’ Edge ”?TMIt all comes down to confidence inquality products. With Simondsproducts you have the peace of mindof knowing that the designs andinnovations present in every SimondsBlade and cutting tool have stoodthe test of time in the harshestenvironments under the scrutiny ofsome very tough customers. And thatquality comes at a fair price. We offertremendous value for products madeto exacting standards from thelongest-lasting alloys and other stateof-the-art materials, resulting fromtime-tested research and design.“The Professionals’ EdgeTM” alsomeans you have access to Simonds’superior product support. We offercomprehensive customer servicebacked up by our highly skilled andtrained field technicians. We offertraining, partnerships to increasebusiness productivity, and money-backguarantees. You can also look to usfor other product lines including filesand other industrial products.“The Professionals’ EdgeTM” simplydelivers our promise — the best bladesand the best people to back them up.Guaranteed Trial OfferIf the blade Simonds recommendsdoesn't outperform your current blade,it's yours FREE!4Simonds– in operation since 18321-800-343-1616

Table of ContentsINTRODUCTIONINTRODUCTIONSimondsEdgeSimonds —— TheThe Professionals’Competitive ION MADEEASYChoosethe Correct BladeCutting Considerations2-33Choose SAWthe CorrectBladeBANDPRODUCTS TechnologySineWaveBANDSAW PRODUCTSSineWave TechnologyCARBIDE4-54-5BAND APPLICATIONS CROSS-REFERENCE CHARTTriple ChipCARBIDECWT Carbide NEW!Triple ChipQuad 7 Carbide NEW!Carbide Set ToothNegative Rake20 Negative RakeCarbide Set ToothTMTMBI-METALBI-METALX-51X-51BroadBand SiCloneBlockBuster BlockBusterSiClone BroadBandIC Enduro ICEnduroPlus DieBandDieBandPlus PalletBusterPalletBuster CARBONRed FlexBackFrictionTMTMOTHER SIMONDS PRODUCTSGRIT-EDGEBladeTerminologyIMOGRITSTooth Pitch PrimerBreak-in ProceduresPOWER HACKSAWSSpeed and Feed ChartsTroubleshootingBlade TerminologyTooth Pitch PrimerBreak-in ProcedureSpeed and Feed ChartsTroubleshootingSimondspremiumquality band saw bladesOTHER SIMONDSPRODUCTSare made in the USA and .com6787981091920172118221923TMBANDSAW INFORMATIONAL PAGES6-7111012-131114121513161417151816TMTMBAND SAW INFORMATIONAL PAGESinside front cover21120-212422232524-252626-2728inside back cover2930-3132

PalletBusterBandApplicationsCross-Reference ChartApplicationsDismantling/recycling pallets usingbandsaw blades.MaterialsTriple ChipTriple ChipBI-METALCARBIDECARBIDECarbideCWTTMSet Tooth20 NegativeQuad 7TMRakeNegativeRake X-51pagepage107pagepage 118Recycled pallets constructedwithpagepage68 nails pagepage 79or staples.WoodWoodCarbonCarbonGraphiteGraphite alsMaterialsNon-FerrousNon-FerrousMetalsMetals BrassBrass BronzeBronze AluminumFeaturesand BenefitsAluminum Carbon CUTS SHAPEMATERIALMATERIAL Specialwood ingdesignresultsinlongerblade usageCutting Oversized blade width improves ghter cuts Plastic capping on bi-metal bladesCarbonCarbonSteelsSteelsminimizestooth damage in transitand handlingBi-Metal eelsSteels6X-51TMBlockBuster SiClone SiClone BlockBuster IC Enduro pagepage12-139page14page 10pagepage 1511page16page 12 1-1/4” x .04234 x 1.1250’ 60331250 64371520 40540020 40840020O VSSESCoils shown as 250' lengths. May also be shipped in random lengths. Also available in welded-to-length.500' coils are available.LE rRodRod Carbon TPI65-8 TPI GTitaniumTitaniumAlloysAlloys Set ToothBroadBand TPI5-8 TPILANickelNickelBaseBaseAlloysAlloys GStainlessStainlessSteelsSteels BI-METAL PalletBuster Bi-Metal BI-METALPalletBuster is manufactured specifically for recycling used wood ls/Steels/Mold SteelsMold BANDSAWBLADESBLADES CATEGORIESCATEGORIES ANDS A F E T Y24181-800-343-16161-800-343-1616

Band Applications Cross-Reference ChartPalletBuster ApplicationsSIMONDSBANDSAWBANDSAW BLADEBLADESCATEGORIESCATEGORIES ANDSIMONDSAND ing pallets usingBI-METAL BI-METALCARBONbandsaw blades.CARBONBroadBand IC EnduroTMDie Band Plus PalletBuster WoodMaxTMHardBackMaterials DieBand PlusPalletBusterRed age15 pagepage18 23palletsconstructed18 14 Recycledpage 1920 page 16withpagenails21 page 17page 22pagepagepageor staples. Special nail-embedded wood tooth design results in longer blade usage Oversized blade width improves beam cuts strength for straighter Plastic capping on bi-metal blades minimizes tooth damagein transitand handling Bi-Metal CarbonWoodWood CarbonGraphiteGraphiteCarbon FiberglassFiberglass ousNon-FerrousMetalsMetals CastIronIronCastBrassBrass BronzeBronze Aluminum AluminumGeneral PurposeGeneral PurposeCUTS SHAPE CuttingCuttingPalletBuster is manufactured specificallyStructuralfor recyclingSteel used wood p Structural SteelCarbonSteelsSteelsCarbon 1-1/4” xLowAlloyAlloySteelsSteelsLow 34 x 1 PalletBusterMed. Alloy Steels:Med. Alloy PISiliconSteelsSteelsSilicon6033125-8 TPIAlloy Steels/Alloy Steels/Mold SteelsMold SteelsTool Steels/Tool Steels/Die SteelsDie Steels643715408400Stainless SteelsStainless Steels405400Bi-Metal 6Carbon6TPI 5-8 TPICoils shown as 250' lengths. May also be shipped in random lengths. Also available in welded-to-length.Nickel Base Alloys500' coils are available.Nickel Base AlloysSSVELAOGS18 LS A F E T xBackSimoGritpagepage1924 Features and Benefits G GRIT-EDGEMATERIALMATERIAL ES CA53 Titanium AlloysTitanium AlloysInduction HardenedInduction HardenedCylinder RodCylinder Rod

SineWave TechnologySpecial Applications TechnologyIMPROVED!SIMONDS application engineeredSineWave technology provides enhancedcutting ability, reducing work timetime,andandincreasing blade life.d toerteine exac ds!gnreE ou ney ngticutSineWave technology features avalue-added broaching cutting action byutilizing ramps on the back edge of theblade. This technology exerts more forceinto the cut without having to increasemachine pressure.SineWave technology provides rampcustomization capabilities to optimizethe cutting performance of specificalloy cross sections.SineWave can be supplied on allM42 bi-metal and all carbide tippedbandsaw blades from 1” to 3-1/8”.SineWave is supplied only inwelded-to-length bands.CUTS SHAPESSimonds Bi-metal and Carbide Tipped bandsaw blades with SineWave technology areideal for use on difficult to cut steels such as high chrome, tool, die, stainless andnickel base. Yourfor titaniumcutting titaniumandothermetals.exotic metals.Also bestidealsolutionfor cuttingand otherexoticWith self-feeding action, the band actually grows in width (see magnified back edgeview of the SineWave blade above), forcing each tooth to penetrate the work.VSSOELALSGGESProducts displayingthis icon are available withSineWave technology.S A F E T Y461-800-343-1616

SineWave TechnologyHow Does SineWave Work?SineWave AdvantagesSineWave technology from Simondsprovides providesan aggressivebroachingbroachingSimonds SawInternationalan aggressiveaction in the cut, enhancing cutting ability, reducing work time and increasing blade life.It incorporates a series of “ramps” on the back edge of bandsaw blades, which allowsbandsaw machines to exert more force into a cut without increasing machine pressure.whichThe “rocking” motion of SineWave ensures less tooth to work piece contact, whichincreases penetration for faster cutting. Cuts work hardened materials30-40% faster. Can double blade life. Makes cutting rate more consistent.How Do I Order SineWave? Determine maximum cross-sectiondimension of all materials cut. Determine your required aggressiveness of the cutting action –light, moderate or aggressive. Call your Simonds sales personfor applications assistance.Ramp depth and length can be engineered to a customer’s specific cutting applications,operating parameters and production requirements to optimize performance across awide variety of materials. SineWave technology can be applied for light, moderate oraggressive cutting action.Supplied only in welded-to-length bands, Simonds SineWave technology is ideal forblades cutting high chrome, tool, die, stainless and nickel based steels. The technologyis a proven solution for cutting titanium and other exotic metals and can be used onalmost all bandsaw machines.SineWave Engineering Rocks!SineWaveSineWave’s rocking motion ensures better toothpenetration for faster cutting rates while allowing theblade to cut with less pressure, extending blade life Lighter Machine Pressure Reduced Sawblade Strain Faster Cutting Longer LifeActual SineWave finish on high nickel om75ConventionalBlades

PalletBusterTripleChip ts usingProductioncutting operations,steel serviceservbandsawblades.icecenters,aerospaceand forging alloys,constructedtitanium, InconelandRecycledwith nailsHighnickelalloys,titanium, aluminum,otherexoticmaterials.or staples.bronze, Inconel and other exotic materials.Bi-MetalCarbonFeatures and Benefits High Carbide tipped teeth increase wearFeaturesand Benefitsresistancehigh temperatureFeaturesandcuttingBenefits alloysSpecial nail-embedded wood toothCUTS SHAPECUTS SHAPES Carbidetipped inteethincreasedesignChipresultslongerblade awearusage Triplegeometryprovidessmoothercuttingwidthhigh improvestemperature p is idealforsmoothsurfacePalletBusteris manufacturedspecificallyrequiringfor recyclingusedwoodfinishpallets.idealfor cuttingcutting shandandhighhighalloysstrengthrakefor straightercutsfaster Positiveangle allowsproduction rates. TriplegeometryprovidessmootherPlasticChipcappingon bi-metalbladespenetrationfor amageteethin transit surfacePlasticcappingagainst1/2”x3/4”x1” x1-1/4” x 1-1/2” x2” x2-5/8” x 3-1/8” xrakeangleandallowsfaster Positiveand handling1-1/4”.035.035.042.042.050.062 x .042 .062.062damagein transithandlingpenetration for high production cuttingx 1.1 67 x 1.6 80 x 1.613 x 0.9 19 x 0.9 27 x 1.1 34 x 1.1 41 x 1.3 54 34x 1.6PalletBuster250’Triple �� Plastic cappingprotects1/2”x .035 teeth3/4”againstx .0353/4” x .0501” x .0421-1/4” x .042 1-1/2” x .0502” x .0622-5/8” x .062 3-1/8” x .062Tripledamage in transit13 xand0.9 handling19 x 0.919 x 1.327 x 557990001.134 x 1.1 5580100041 x 1.367 x 1.680 x 1.63TPI5580000055801800 54 x �150’150’150’Welded SectionCarbide Tip92 Ra47 Rc to 49 Rc Backer55800508 55801108 55801208 5580450855805858558058085580700855804008 55805808 5580700855805308558080084084002055805008 55805308 5580800840540020Coils shown as 150' and 250’ lengths. May also be shipped in random lengths. Also available in welded-to-length and SineWave .Coils shown as 250' lengths. May also be shipped in random lengths. Also available in welded-to-length.500' coils are available.SESVEOVLOGLGWelded SectionCarbide Tip92 Ra2.5-3.5 TPI55800050655801000TPI558011082-3TPI5-8 TPI1.9-2.1 TPICarbon1.4-1.8 TPI6TPI.9-1.1 TPI5-8 TPIEE TPITPITPITPITPITPIGGLL AA32.5-3.52-31.9-2.11.4-1.8.9-1.1SS AA FF EE TT YY648181-800-343-16161-800-343-1616

NEW!CarbideCWT SetCarbideTooth DieBand Plus nd die makers.servicealuminumcenters, foundries,risers,automationaerospace(Mossner),and forginghouses.Inconeland DEProduction cutting operations, steelBI-METALservice centers, foundries, aerospace.Materialsand BenefitsFeaturesHigh nickelrakealloys,titanium,aluminum, herexoticmaterials.tooth geometry for faster cuttingandincreased production Three tooth pattern with Raker mimicsSet Tooth blade advantages Plastic Capping prevents tooth damageduring shipping and handlingCalifornia Wing Tip tooth /4” x .04234 x 1.1150’553344001-1/2” x .05041 x 1.3150’5534140055341500553416002”

Simonds premium quality band saw blades are made in the USA and Germany. www.simondsinternational.com 1 INTRODUCTION Simonds — The Competitive Edge 2 BAND SELECTION MADE EASY Cutting Considerations 3 BAND APPLICATIONS CROSS-REFERENCE CHART Choose the Correct Blade 4-5 BANDSAW PRODUCTS SineWave Technology 6-7