Transcription

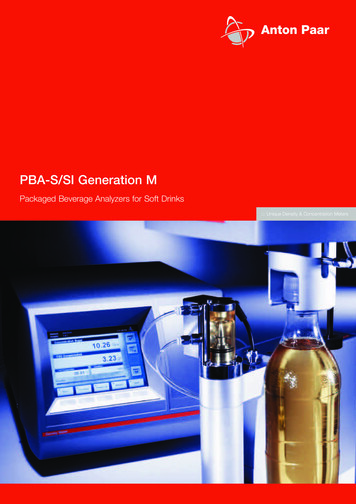

PBA-S/SI Generation MPackaged Beverage Analyzers for Soft Drinks::: Unique Density & Concentration Meters

PBA-S M and PBA-SI M:Two Strong TeamsPBA-S M and PBA-SI M are analysis systems forthe determination of Brix and CO2 in soft drinkscontaining sugar: PBA-S M applies to sampleswithout sugar inversion and PBA-SI M applies tosamples with sugar inversion. The beverage is filledinto the analysis system directly from its containerwithout any sample preparation, and is thenmeasured fast and with unprecedented precision.The Packaged Beverage Analyzer for Soft Drinks(PBA-S M) consists of the density meterDMA 4100 M, DMA 4500 M or DMA 5000 M for Brix determination, the CO2 meter CarboQC ME andthe PFD filling system. In the PBA-SI M System, theDMA M is replaced by a Soft Drink Analyzer M/P.PBA-S M: The Sum of Great ComponentsDMA 4100/4500/5000 M: The DMA M density metersmeasure density with the oscillating U-tube method.Subsequently, the Brix value is calculated with thedensity. Depending on the accuracy you need, useDMA 4100 M, DMA 4500 M or the most accuratedensity meter on the market, DMA 5000 M.The DMA M unit controls the entire measurement.Measuring data are transferred to the DMA Mdisplay, a printer or a PC, in full compliance withGLP. The data is stored in the DMA M memory.CarboQC ME: CarboQC ME precisely and reliablydetermines the dissolved CO2 content. The patentedmultiple volume expansion method (AT 409673, GB2373584, US 6,874,351) eliminates the influence of otherdissolved gases (e.g. N2 and O2) on the measuring result.PFD: The PFD filling system enables the comfortable,clean and safe filling of the PBA-S M measuring cells fromglass bottles, PET bottles or cans. Due to the appliedoverpressure, no CO2 is lost during filling and measuring.The Heart of PBA-SI M: The Soft Drink Analyzer M/PPBA-SI M externally appears as a compact team ofthree, just like PBA-S M. The difference is that insteadof the DMA M unit a Soft Drink Analyzer M/P is used incombination with CarboQC ME and PFD. The Soft DrinkAnalyzer M/P simultaneously determines both densityand sound velocity in the sample with high precision.CarboQC MEFor the determination of CO2.Optionally, a O2 sensor can bemounted on the CarboQC ME.DMA 4100/4500/5000 MFor the determinationof Brix (PBA-S M)Optional:Soft Drink Analyzer M/PFor the additionaldetermination of Brixfresh, Brix invertedand degree of inversion(PBA-SI M)

PFDFor reproducible filling directly out of thepackage.Two that Instantly DeliverOptionally, the Xsample 510 can be usedinstead for fully automated operation withup to 18 packages.PBA-S M and PBA-SI M keep the CO2 dissolvedthrough overpressure and determine the CO2 contentwhile measuring the density. From the measureddensity, the fraction that is caused by dissolved CO2is eliminated mathematically, then this CO2-correcteddensity value is converted into the Brix.In this way you receive the same Brix and CO2value as with the traditional method, yet with betterreliability and in much less time: Results are providedafter 2-3 minutes only (5 minutes with PBA-SI M).FasterWithout sugar inversionConventionalPBA-S MThermostatting5 minutesDegassing2 minutes Brix measurement3 minutesCO2 measurement2 minutesO2 measurement2 minutesTotal14 minutes3 minutesConventionalPBA-SI MInversionapprox.70 minutesNot needed Brix measurement3 minutesCO2 measurement2 minutesO2 measurement2 minutesTotal77 minutesNot needed3 minutesWith sugar inversion5 minutes5 minutesMore ReliablePBA-S M and PBA-SI M are not only much faster, butalso more reliable than previous routine analyses. Possibleerrors during sample preparation are completely avoided.PBA-S M and PBA-SI M are easy to use and guaranteeexcellent measuring results.More AutomationWith the optional Xsample 510 package sampler, 18samples can be queued to be filled and measuredautomatically.

The End of Time-consumingSample PreparationEmploying the same filling technique as Anton Paar’swell-proven PFD filling system, the Xsample 510automated package sampler simplifies and speedsup work with samples in packages.Apart from putting the package in the rotary table,no other preparation is needed. This high level ofautomation ensures highly reproducible measurementresults.18 different bottles or cans in one cycleThe Xsample 510 is designed to handle up to 18different packages in one measuring cycle, includingglass bottles, PET bottles and different sized cans.Save time and spaceXsample 510 is a benchtop sampler which is easy toclean and maintain. Cleaning is fully automatic withtwo cleaning liquids. The entire cleaning cycle takesonly a few minutes.Technical specificationsPackages perrotary table18*Package types**Can:Glass bottle:PET bottle:Filling modePressurized filling from closedpackagesCompressed gassupply6 bar (87 psi) relative pressureDimensions(L x W x H)900 mm x 750 mm x 1200 mm(35.4 x 29.5 x 47.2 inches)Interfaces1111Power supplyAC 100 to 240 V; 50/60 HzWeight75 kg (165.3 lbs)Degree ofprotectionIP 54xxxx0.25 L, 0.33 L,0.5 L0.33 L, 0.5 L0.5 L, 1 L, 1.5 L,2 L, 3 LRS-232S-BUSCANopen inCANopen out*Depending on the diameter of the package**Adapters for different package types

Additional O2 Measurementfor Longer Product Shelf LifeA high dissolved oxygen content andresulting oxidation products have anegative impact on the taste and shelflife of beverages. Continuous monitoringof the oxygen content during productionand in the final product with the option O2therefore aids the production of beverageswhich will taste good for longer. Option O2delivers highly accurate results withoutextending the analysis time.Determine carbon dioxide and oxygensimultaneouslyOption O2 is directly connected toCarboQC ME. This allows the simultaneousdetermination of the dissolved oxygen anddissolved CO2 contents.Low maintenance, high performanceThe optical oxygen sensor in option O2provides a proven and reliable way ofoxygen determination. Option O2 can alsobe easily retroffited in your CarboQC ME.Technical DataMeasuring range0 ppm O2 to 10 ppm O2Repeatability s.d.*5 ppbReproducibility s.d.*20 ppbUnits for oxygencontentppm, mg/L, ppb,% SaturationMeasuring time persampleapprox. 2 minutes.* Specifications valid for low oxygen ranges at room temperature

PBA-SI M: Perfect forSamples with Sugar InversionPBA-SI M can do just what many beverageproducers never thought possible until now:By simultaneous measurement of densityand sound velocity, PBA-SI M determines Brix fresh, Brix inverted and the degree ofinversion in sugared samples, in addition tothe current Brix content, CO2 and, optionallyO2 concentration.For the first time, beverages with invertingsugar can be analyzed with speed andprecision independently from storage timeand storage temperature.It took more than one hour so far .The sugar inversion complicates the measurementof beverage samples containing beet sugar or canesugar: During storage, the sugar in the beveragechemically transforms into a mixture of glucoseand fructose. This changes the density based onwhich the Brix value is determined. Depending ontemperature and acidity, the inversion process cantake from a few hours up to several weeks.With the common measuring method for inverting samples,the sample is chemically treated to reach full inversion,then the density is determined. The whole procedureincluding the CO2 determination takes about 75 minutes. now PBA-SI M does it in five minutes.The Anton Paar developers found a surprisingly easyanswer to the question of sugar inversion: In additionto density, the very same instrument measures thesound velocity in the sample solution. By using thesevalues and taking the CO2 content into account, theinstrument calculates not only the current Brix, butalso the Brix value of the fresh sample before thebeginning of the inversion, as well as the Brix invertedvalue of the sample after complete inversion.Get informed on the past, present and future of yourbeverage sample – highly precise and within five minutes.

PBA-S M and PBA-SI Mat a GlanceZwei, die gleich zur Sachekommen4 High-precision measurement of Brix and CO24 Measurement at any degree ofsugar inversion (PBA-SI M)4 No sample preparation (degassing,filtering etc.)4 Measurement directly from glassbottles, PET bottles or cans4 Easy to use4 Measuring time of only 3 minutes(PBA-S M) or 5 minutes (PBA-SI M)4 Minimal space requirement4 Easy connection to PC/LIMS/printer4 Sample filling without pump, viapressurized gas4 Modular setup (Plug and Play)Generation M for an expandableand future-proof system4 Optional Xsample 510: Automatedpackage sampler for PET and glassbottles and cans of different sizes4 Optional O2 sensor for determiningdissolved oxygen content

Flexible Data HandlingSamples are either identified directly viaDMA M (or the Soft Drink Analyzer M/P) oroptionally via an external USB keyboard oran USB bar code reader.The measurement results can be shownon the display, stored in the memory orexported to a USB flash drive.Further, the data can be sent to a printer(Ethernet, USB or RS-232) and to a PC(via Ethernet or RS-232).The Excel-based data acquisition softwarefor RS-232, AP-SoftPrint is available. ForEthernet (LAN) data export, the easy-to-useLIMS Bridge software is provided. Both arefree of charge (www.anton-paar.com).Optional Accessories4 External USB keyboard4 USB bar code reader4 USB/Ethernet printer and RS-232 printer4 CO2 standards4 PET bottle adaptersfor different bottleneck diameters4 Special filter for high fruit pulp content4 Automated package sampler Xsample 5104 Oxygen sensor for upgrading the CarboQC MEDMA M density meters and Soft Drink Analyzer M densityand sound velocity meters developed in cooperation withLabor für Messtechnik Dr. H. Stabinger GmbH, Graz

Technical DataPBA-S M (with DMA 5000 M)PBA-SI MConcentration sugar0 Brix to 15 Brix0 Brix to 15 BrixConcentration sugar fresh/inverted-0 Brix to 15 BrixDegree of inversion-0 % to 100 %CO20 g/L to 12 g/L (0 to 6 vol.)0 g/L to 12 g/L (0 to 6 vol.)O21)0 ppm O2 to 10 ppm O20 ppm O2 to 10 ppm O2Concentration sugar0.01 Brix2)0.01 BrixConcentration sugar fresh/inverted-0.02 BrixDegree of inversion-1%CO20.01 g/L (0.005 vol.)0.01 g/L (0.005 vol.)O21)5 ppb 3)5 ppb 3)Sample temperature4 C to 25 C (39 F to 77 F)15 C to 25 C (59 F to 77 F)Typical measuring time3 minutes4)5 minutesMeasuring rangesRepeatability standard deviationAdditional information120 mL to 150 mL5)Sample volumeXsample 51018 positionsPressurized gas supply6 bar 0.5 bar (87 psi 7 psi), relativeInterfacesUSB, Ethernet (LAN), VGA, RS-232 for printer / PCAdditional output valuesDensity, specific gravity, CO2-corrected density and specific gravity, package pressure,air content1)With Option O24)With DMA 4500 M/DMA 4100 M: 2 minutes2)With DMA 4500 M: 0.015 Brix; DMA 4100 M: 0.025 Brix5)With Option O2: 170 mL - 200 mL3)For low O2 concentrations

Photos: Croce FotostudioAnton Paar GmbHAnton-Paar-Str. 20A-8054 GrazAustria - EuropeTel: 43 (0)316 257-0Fax: 43 (0)316 257-257E-mail: info@anton-paar.comWeb: www.anton-paar.comInstruments for:Density & concentrationmeasurementRheometry & viscometrySample preparationMicrowave synthesisColloid scienceX-ray structure analysisRefractometryPolarimetryHigh-precision temperaturemeasurementSpecificationssubject to changewithout notice.06/11 C60IP001EN-C

DMA 4100/4500/5000 M: The DMA M density meters measure density with the oscillating U-tube method. Subsequently, the Brix value is calculated with the density. Depending on the accuracy you need, use DMA 4100 M, DMA 4500 M or the most accurate density meter on the market, DMA 5000 M. The DMA M unit controls the entire measurement.