Transcription

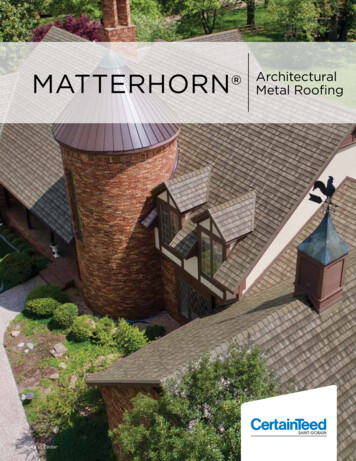

Matterhorn Shake & Slate Install Guide800-728-4010bestbuymetals.com

Table of ContentsSystem Components . 2General Conditions, Safety and Roof Preparations . 3. 4Eave/Drip Edge . 5Inner Gable . 6Outer Gable . 7Open Valley Method . 8Closed Valley Method . 9Valley Detail . 10Valley Cap Detail.11Panel Layout and Installation . 12Sidewall With Siding Option 1 . 17Sidewall With Siding Option 2 . 18Endwall Option 1 & 2 . 19Vents, Pipes and Skylights . 20Brick Sidewall/Chimney Option 1 . 21Brick Sidewall/Chimney Option 2 . 22Transition Detail Option 1. 23Transition Detail Option 2. 24Roof Jack Assembly . 25Vented Ridge Cap . 26Non-Vented Ridge Cap . 27Tools and Accessories . 28Watch detailed Matterhorn Shake and Slate installation videosonline at bestbuymetals.com1

System ComponentsGeneral Conditions, Safety and Roof PreparationsGeneral Installation GuidelinesA. Shake PanelA. Slate PanelADHLB. 1.5" EL T-StyleC. Ridge CapD. CertainTeed Ridge VentE. Inner Gable Shake/SlateEAIMF. Outer GableProduct HandlingCertainTeed recommends tearing off existing roofsystems and installing Matterhorn a clean deck.bending and warping.roof deck. The roof deck must be 15/32" to 1/2" thickplywood, or 7/16" thick non-veneer or nominal 1" thickwood deck.Walking along panels: Wear clean, soft-sole,non-marking shoes when walking on installed roofpanels. Step only on areas that have full contact tothe roof deck.Safety GuidelinesDiamondDeck synthetic underlayment andMetaLayment/WinterGuard HT high temperatureself-adhering underlayment must be installed prior toG. Side Wall FlashingH. End Wall TrimI. Valley Closure Shake/SlateBFJRetention ClipJ. 3" Valley Closure CapFollow all governmental safety procedures, including, butnot limited to, all OSHA guidelines. Always wear safetygloves, safety glasses and fall protection gear whento local building code.MetaLayment/WinterGuard HT is required in all valleysand eaves.K. .016 x 24" WL W-ValleyL. Weep TrimCGRoof Preparations:Slope requirements:KPrior to installing the synthetic and self-adheringunderlayments, clear the roof of any debris or protrusionsthat could puncture or damage the protective membrane.10-16 5/8"M. Valley Cleatmust be used over the entire roof deck.C10-16 1-1/4"FValleys, as well as eave/drip edge, rake, endwall andVentilationLAEwave in the material is not a cause for rejection of theproduct.)DG10-12 2"When cutting panels to length, begin cutting fromthe top of the panel, cutting downwards towardsthe preformed bend at the bottom. This ensures thecleanest shear and keeps the rolled edge intact foroptimal locking.10-12 3"Always install Matterhorn Slate and Shake panels fromright to left, then bottom to top, beginning withthe bottom right corner of the roof deck.HBAll screws usedwhile installingMatterhorn Slateor Shake must beof a recommendedscrew type. Screwsmust be long enoughto penetrate theroof deck. Refer todiagram on page 4.IJKMRefer to the bid sheet at the end of the manual for actual components sizes and detailed information.Proper ventilation must be achieved to avoid moisture andheat buildup in the attic space, or between the layers ofthe building envelope. Consult local building code for NFA(Net Free Area) rating requirements.Intake vs. exhaust:through the attic, the amount of intake at the eavemust be less than or equal to the exhaust at the ridge.are found on the underside of the eaveoverhang. This is the primary source for the intake ofair to the attic.non-marking shoes when walking on installed panels.Upon completion of the installation, inspect the roofsurface for metal shavings or other loose material.Remove by wiping softly with a cloth, being carefulnot to scratch the painted surface. Remove dirt witha damp rag.Ridge vents are located at the peak of the roof and arethe primary exhaust outlet for accumulated hot, moist air.Class A Fire RatingFasteningFasten all panels to the roof using only the requiredscrew type, inserting one into each of the holesalong the top of the panel. For high wind areas threeadditional screws must be installed (see page 6).Ensure each panel is fully engaged to the one belowvia the pre-rolled feature at the bottom of the panelbefore fastening it to the roof deck.existing 3-tab shingles.Overlap clips must be installed on every panel.2Watch detailed Matterhorn Shake and Slateinstallation videos online at bestbuymetals.com3Watch detailed Matterhorn Shake and Slateinstallation videos online at certainteed.com

System ComponentsGeneral Conditions, Safety and Roof PreparationsGeneral Installation GuidelinesA. Shake PanelA. Slate PanelADHLB. 1.5" EL T-StyleC. Ridge CapD. CertainTeed Ridge VentE. Inner Gable Shake/SlateEAIMF. Outer GableProduct HandlingCertainTeed recommends tearing off existing roofsystems and installing Matterhorn a clean deck.bending and warping.roof deck. The roof deck must be 15/32" to 1/2" thickplywood, or 7/16" thick non-veneer or nominal 1" thickwood deck.Walking along panels: Wear clean, soft-sole,non-marking shoes when walking on installed roofpanels. Step only on areas that have full contact tothe roof deck.Safety GuidelinesDiamondDeck synthetic underlayment andMetaLayment/WinterGuard HT high temperatureself-adhering underlayment must be installed prior toG. Side Wall FlashingH. End Wall TrimI. Valley Closure Shake/SlateBFJRetention ClipJ. 3" Valley Closure CapFollow all governmental safety procedures, including, butnot limited to, all OSHA guidelines. Always wear safetygloves, safety glasses and fall protection gear whento local building code.MetaLayment/WinterGuard HT is required in all valleysand eaves.K. .016 x 24" WL W-ValleyL. Weep TrimCGRoof Preparations:Slope requirements:KPrior to installing the synthetic and self-adheringunderlayments, clear the roof of any debris or protrusionsthat could puncture or damage the protective membrane.10-16 5/8"M. Valley Cleatmust be used over the entire roof deck.C10-16 1-1/4"FValleys, as well as eave/drip edge, rake, endwall andVentilationLAEwave in the material is not a cause for rejection of theproduct.)DG10-12 2"When cutting panels to length, begin cutting fromthe top of the panel, cutting downwards towardsthe preformed bend at the bottom. This ensures thecleanest shear and keeps the rolled edge intact foroptimal locking.10-12 3"Always install Matterhorn Slate and Shake panels fromright to left, then bottom to top, beginning withthe bottom right corner of the roof deck.HBAll screws usedwhile installingMatterhorn Slateor Shake must beof a recommendedscrew type. Screwsmust be long enoughto penetrate theroof deck. Refer todiagram on page 4.IJKMRefer to the bid sheet at the end of the manual for actual components sizes and detailed information.Proper ventilation must be achieved to avoid moisture andheat buildup in the attic space, or between the layers ofthe building envelope. Consult local building code for NFA(Net Free Area) rating requirements.Intake vs. exhaust:through the attic, the amount of intake at the eavemust be less than or equal to the exhaust at the ridge.are found on the underside of the eaveoverhang. This is the primary source for the intake ofair to the attic.non-marking shoes when walking on installed panels.Upon completion of the installation, inspect the roofsurface for metal shavings or other loose material.Remove by wiping softly with a cloth, being carefulnot to scratch the painted surface. Remove dirt witha damp rag.Ridge vents are located at the peak of the roof and arethe primary exhaust outlet for accumulated hot, moist air.Class A Fire RatingFasteningFasten all panels to the roof using only the requiredscrew type, inserting one into each of the holesalong the top of the panel. For high wind areas threeadditional screws must be installed (see page 6).Ensure each panel is fully engaged to the one belowvia the pre-rolled feature at the bottom of the panelbefore fastening it to the roof deck.existing 3-tab shingles.Overlap clips must be installed on every panel.2Watch detailed Matterhorn Shake and Slateinstallation videos online at certainteed.com3Watch detailed Matterhorn Shake and Slateinstallation videos online at bestbuymetals.com

Eave/Drip EdgeStep 13.000 .050Eave Edge Detail:MRS3Screw Must Penetrate Thru Decking2.000 .050DiamondDeck1. Fasten drip edge to the roof deck every 12" with panheadscrews.2. Ensure that drip edge is installed securely, the drip edge isMetaLayment/WinterGuard HTEave / Drip Edge,Step 2Roof SheathingMRS2Fastener forFirst Row ofMetal ShingleBottom Hemof PanelRuns overDrip Edge3. When installing, ensure that drip edge is straight and squareto the roof plane and does not follow any wave in the fascia.This may require a chalk line.1.250 .050MRS1.25FasciaBoardStep 2Drip EdgeFirst PanelHooks toDrip Edge4. Matterhorn drip edge is designed to be installed on uppitches, drip edge can be bent in a siding brake for easierinstallation. By bending forward the leg of the drip edge it!!StandardStandard 4 Screw Installation UsingPre Punched Holes.1. Cut and bend drip edge trim on theoutside to conform to rake edge andinner and outer gable.2. When adjoining sections of drip edge,cut the front nose on an angle to allow for3. Sometimes the bottom hem will alsoneed to be cut to make sure there is aof the width halfway up the roof.High Wind AreasHigh Wind Area 7 Screw Installation. Add3 More Screws Centered Between thePre Punched Holes for 130 MPH Rating.4. After the drip edge is completely installed on eaves, install MetaLayment/WinterGuard HT over the drip edge in accordance to local building codes, followed by DiamondDeck .4Watch detailed Matterhorn Shake and Slate installationvideos online at bestbuymetals.com5Watch detailed Matterhorn Shake and Slateinstallation videos online at certainteed.com

Eave/Drip EdgeStep 13.000 .050Eave Edge Detail:MRS3Screw Must Penetrate Thru Decking2.000 .050DiamondDeck1. Fasten drip edge to the roof deck every 12" with panheadscrews.2. Ensure that drip edge is installed securely, the drip edge isMetaLayment/WinterGuard HTEave / Drip Edge,Step 2Roof SheathingMRS2Fastener forFirst Row ofMetal ShingleBottom Hemof PanelRuns overDrip Edge3. When installing, ensure that drip edge is straight and squareto the roof plane and does not follow any wave in the fascia.This may require a chalk line.1.250 .050MRS1.25FasciaBoardStep 2Drip EdgeFirst PanelHooks toDrip Edge4. Matterhorn drip edge is designed to be installed on uppitches, drip edge can be bent in a siding brake for easierinstallation. By bending forward the leg of the drip edge it!!StandardStandard 4 Screw Installation UsingPre Punched Holes.1. Cut and bend drip edge trim on theoutside to conform to rake edge andinner and outer gable.2. When adjoining sections of drip edge,cut the front nose on an angle to allow for3. Sometimes the bottom hem will alsoneed to be cut to make sure there is aof the width halfway up the roof.High Wind AreasHigh Wind Area 7 Screw Installation. Add3 More Screws Centered Between thePre Punched Holes for 130 MPH Rating.4. After the drip edge is completely installed on eaves, install MetaLayment/WinterGuard HT over the drip edge in accordance to local building codes, followed by DiamondDeck .4Watch detailed Matterhorn Shake and Slateinstallation videos online at certainteed.com5Watch detailed Matterhorn Shake and Slateinstallation videos online at bestbuymetals.com

Inner GableOuter GableInsert Screw BetweenLock and DiverterInner Gable Detail 1:DiamondDeck1.LockDiverterInstall the inner gable up the rake edges usingpanhead screws every 12". The opening of theinner gable should face toward the roof deck.The back side should align with the outsideedge of the roof deck.2.Overlap inner gable trim as per the sequencebelow. Overlap by at least 6".3.In high wind areas check your local coderequirements for approved installation techniques.Outer Gable Detail 1:1.Install the outer gable over the inner gable. This may require opening the hem slightly.3.Outer gable should be hemmed to inner gable and fastened with painted 5/8" hex head screw.Note: For high-wind areas additional fasteners may be needed into the fascia.Consult local codes to determine if your area is a high wind area.Outer Gable Step 1Cut bottom of inner gable so outsideweeping channel will protrude past dripedge ¼".Cut out top leg of inner gable trim toallow for tight, waterproof overlapping.When overlapping, apply sealant underoverlap. Be sure to screw every 12" betweenthe diverter and the water lock.Outer Gable, Step 1Outer Gable, Step 2Outer Gable Step 1Outer Gable Step 2Cut Out(first Row Only)Cut OutDiamondDeckLockInsert Zinc CoatedPanhead ScrewBetween Lock andDiverter5/8" Painted HexHead ScrewPanelDiverterDiamondDeckLockInstall inner gable as a whole piece.When adding a second inner gable trim, together with a hand seamer.open up the water lock and cut out thetop section to allow for tight, overlapping,6Watch detailed Matterhorn Shake and Slateinstallation videos online at bestbuymetals.com7Watch detailed Matterhorn Shake and Slateinstallation videos online at certainteed.com

Inner GableOuter GableInsert Screw BetweenLock and DiverterInner Gable Detail 1:DiamondDeck1.LockDiverterInstall the inner gable up the rake edges usingpanhead screws every 12". The opening of theinner gable should face toward the roof deck.The back side should align with the outsideedge of the roof deck.2.Overlap inner gable trim as per the sequencebelow. Overlap by at least 6".3.In high wind areas check your local coderequirements for approved installation techniques.Outer Gable Detail 1:1.Install the outer gable over the inner gable. This may require opening the hem slightly.3.Outer gable should be hemmed to inner gable and fastened with painted 5/8" hex head screw.Note: For high-wind areas additional fasteners may be needed into the fascia.Consult local codes to determine if your area is a high wind area.Outer Gable Step 1Cut bottom of inner gable so outsideweeping channel will protrude past dripedge ¼".Cut out top leg of inner gable trim toallow for tight, waterproof overlapping.When overlapping, apply sealant underoverlap. Be sure to screw every 12" betweenthe diverter and the water lock.Outer Gable, Step 1Outer Gable, Step 2Outer Gable Step 1Outer Gable Step 2Cut Out(first Row Only)Cut OutDiamondDeckLockInsert Zinc CoatedPanhead ScrewBetween Lock andDiverter5/8" Painted HexHead ScrewPanelDiverterDiamondDeckLockInstall inner gable as a whole piece.When adding a second inner gable trim, together with a hand seamer.open up the water lock and cut out thetop section to allow for tight, overlapping,6Watch detailed Matterhorn Shake and Slateinstallation videos online at certainteed.com7Watch detailed Matterhorn Shake and Slateinstallation videos online at bestbuymetals.com

Open Valley MethodClosed Valley Method3 Piece Valley, Step 1Open Valley Method:Closed Valley Method:1. Be sure to run MetaLayment/WinterGuard HT in all the roof valleys.2. Install the w-valley at the bottom of every roof valley overhanging the drip edge. Lap the next 10' piece over the3 Piece Valley, Step 11. Install the valley closures using panheadscrews every 12" between the diverteras shown in diagram from the secondwater diversion rib.MetaLayment/WinterGuard HTZinc CoatedPanhead ScrewValley ClosureTwo rows of sealant are required in the overlap.2.3. Tack the valley metal in place with panhead screws 1" down from the water lock. Push the metal down into the4. The valley cleat is installed on top of the w-valley, fastening every 12". Before fastening, apply bead or tape sealantbetween the cleat and valley. Use the ribs in the valley to align the cleat parallel to the center rib at the desired width.angle. For valleys longer than 10',overlap the sections at least 6", withbutyl sealant between the layers ofmetal. Cut the top off the valley closureand open up the water lock. This will5. Angle cut the roof panel leaving 1" of extra metal to be folded under the cleat. “V” cut the course breaks and removeinside the lower valley closure.Sheathing3 Piece Valley, Step 23 Piece Valley, Step 2Cut OuFirst C tourse6. Hook the cut and bent tabs of the panel on the valley cleat before fastening through the nail holes along the topof the panel.MetaLayment/WinterGuard HTStep 1Zinc CoatedPanhead Screw3 Piece Valley, Step 3W-ValleyValley Cleat3 Piece Valley, Step 3Valley CapSheathingMetaLayment/WinterGuard HTStep 2Zinc CoatedPanhead ScrewW-ValleyValley Cleat1”SheathingMetaLayment/WinterGuard HTZinc CoatedPanhead ScrewStep 3W-ValleyValley Cleat1. Install Valley Closure Trim in themanner illustrated and shown above.Sheathing8Watch detailed Matterhorn Shake and Slateinstallation videos online at bestbuymetals.com2. When overlapping, apply sealant underoverlap. Be sure to screw every 12",between the diverter as shown in abovediagram.9Valley Closure Trim.Watch detailed Matterhorn Shake and Slateinstallation videos online at certainteed.com

Open Valley MethodClosed Valley Method3 Piece Valley, Step 1Open Valley Method:Closed Valley Method:1. Be sure to run MetaLayment/WinterGuard HT in all the roof valleys.2. Install the w-valley at the bottom of every roof valley overhanging the drip edge. Lap the next 10' piece over the3 Piece Valley, Step 11. Install the valley closures using panheadscrews every 12" between the diverteras shown in diagram from the secondwater diversion rib.MetaLayment/WinterGuard HTZinc CoatedPanhead ScrewValley ClosureTwo rows of sealant are required in the overlap.2.3. Tack the valley metal in place with panhead screws 1" down from the water lock. Push the metal down into the4. The valley cleat is installed on top of the w-valley, fastening every 12". Before fastening, apply bead or tape sealantbetween the cleat and valley. Use the ribs in the valley to align the cleat parallel to the center rib at the desired width.angle. For valleys longer than 10',overlap the sections at least 6", withbutyl sealant between the layers ofmetal. Cut the top off the valley closureand open up the water lock. This will5. Angle cut the roof panel leaving 1" of extra metal to be folded under the cleat. “V” cut the course breaks and removeinside the lower valley closure.Sheathing3 Piece Valley, Step 23 Piece Valley, Step 2Cut OuFirst C tourse6. Hook the cut and bent tabs of the panel on the valley cleat before fastening through the nail holes along the topof the panel.MetaLayment/WinterGuard HTStep 1Zinc CoatedPanhead Screw3 Piece Valley, Step 3W-ValleyValley Cleat3 Piece Valley, Step 3Valley CapSheathingMetaLayment/WinterGuard HTStep 2Zinc CoatedPanhead ScrewW-ValleyValley Cleat1”SheathingMetaLayment/WinterGuard HTZinc CoatedPanhead ScrewStep 3W-ValleyValley Cleat1. Install Valley Closure Trim in themanner illustrated and shown above.Sheathing8Watch detailed Matterhorn Shake and Slateinstallation videos online at certainteed.com2. When overlapping, apply sealant underoverlap. Be sure to screw every 12",between the diverter as shown in abovediagram.9Valley Closure Trim.Watch detailed Matterhorn Shake and Slateinstallation videos online at bestbuymetals.com

Valley DetailValley Cap DetailValley Cap DetailValley Cap Detail1. Install valley closure, lining up theinner diverter with the drip edge.Attach closure with screws betweenthe two diverters.3. Cut the roof panels at the angle ofthe bottom of the valley closure. This willallow the valley closure to overhang the dripedge.1. Install the Valley Cap by sliding it down fromthe top or up from the bottom. Hem to valley orsecure with painted screws as necessary.of the valley closure as possible. Extrafasteners may be needed to secure thepanels in the valley.Make sure the joints in the valley cap arestaggered from the joints in the valley closure.Overlap sections of the valley cap byapproximately 1" to keep water from enteringbetween valley closures.to slide over the valley, open up the hems onthe valley cap and attach from the side. Thenre-hem the valley cap using a hand seamer.1.4. At the top of the valley applysealant and install valley closure to bewater tight. Apply sealant neatly andcompletely along all sides of the valleytrim.5. Both sides of the valley closure need tobe water tight.Bend out6. On a gable protrusion, when installingpanels into valley, take frequentValleyCap BendDetailcourse abovethe valleypeak willbe1 Cap Bend DetailValley1 Valley Cap Bend Detail12.Install and bend legs back222Install screws3.3At the bottom of all trim pieces, allow forweeping of water. Panels will need to benotched out to allow water to escape.10Watch detailed Matterhorn Shake and Slateinstallation videos online at bestbuymetals.com3311Watch detailed Matterhorn Shake and Slateinstallation videos online at certainteed.com

Valley DetailValley Cap DetailValley Cap DetailValley Cap Detail1. Install valley closure, lining up theinner diverter with the drip edge.Attach closure with screws betweenthe two diverters.3. Cut the roof panels at the angle ofthe bottom of the valley closure. This willallow the valley closure to overhang the dripedge.1. Install the Valley Cap by sliding it down fromthe top or up from the bottom. Hem to valley orsecure with painted screws as necessary.of the valley closure as possible. Extrafasteners may be needed to secure thepanels in the valley.Make sure the joints in the valley cap arestaggered from the joints in the valley closure.Overlap sections of the valley cap byapproximately 1" to keep water from enteringbetween valley closures.to slide over the valley, open up the hems onthe valley cap and attach from the side. Thenre-hem the valley cap using a hand seamer.1.4. At the top of the valley applysealant and install valley closure to bewater tight. Apply sealant neatly andcompletely along all sides of the valleytrim.5. Both sides of the valley closure need tobe water tight.Bend out6. On a gable protrusion, when installingpanels into valley, take frequentValleyCap BendDetailcourse abovethe valleypeak willbe1 Cap Bend DetailValley1 Valley Cap Bend Detail12.Install and bend legs back222Install screws3.3At the bottom of all trim pieces, allow forweeping of water. Panels will need to benotched out to allow water to escape.10Watch detailed Matterhorn Shake and Slateinstallation videos online at certainteed.com3311Watch detailed Matterhorn Shake and Slateinstallation videos online at bestbuymetals.com

Panel Layout and InstallationPanel Layout and InstallationSlate PanelsWhen starting rows of panels, ensureWhen installing panels, it is best to install inthat the drip edge is straight and true.pairs. Install screw at a 90 angle. Do notYou can do this by snapping a chalk line. stand on unsecured panel. Ensure thatpanel is locked in at the bottom and sidelapis aligned properly.Cut Out WeepHole For theFirst Row12Clip is used between the verticaloverlap to keep seam closed. It will alsoeliminate panel uplift in extreme weather.Ensure clip is engaged while installingscrews.!!!Clip placement on panel. The cliprests inside a recessed indent/pocket.Watch detailed Matterhorn Shake and Slateinstallation videos online at bestbuymetals.com13Watch detailed Matterhorn Shake and Slateinstallation videos online at certainteed.com

Panel Layout and InstallationPanel Layout and InstallationSlate PanelsWhen starting rows of panels, ensureWhen installing panels, it is best to install inthat the drip edge is straight and true.pairs. Install screw at a 90 angle. Do notYou can do this by snapping a chalk line. stand on unsecured panel. Ensure thatpanel is locked in at the bottom and sidelapis aligned properly.Cut Out WeepHole For theFirst Row12Clip is used between the verticaloverlap to keep seam closed. It will alsoeliminate panel uplift in extreme weather.Ensure clip is engaged while installingscrews.!!!Clip placement on panel. The cliprests inside a recessed indent/pocket.Watch detailed Matterhorn Shake and Slateinstallation videos online at certainteed.com13Watch detailed Matterhorn Shake and Slateinstallation videos online at bestbuymetals.com

Panel Layout and InstallationPanel Layout and Installation: Shake OnlyShake PanelsShake OnlyStock edge of panel should just cover the mountinghole, or centered between the holes.Mounting Hole Numbers1!!1/221/231/24!Row 6 RepeatRow 5, Center of Hole 2 & 3Row 4, Center of Hole 1 & 2Row 3, Hole 3Row 2, Hole 2Row 1, Full PanelCut panel on line beforemounting.14Watch detailed Matterhorn Shake and Slateinstallation videos online at bestbuymetals.com15Watch detailed Matterhorn Shake and Slateinstallation videos online at certainteed.com

Panel Layout and InstallationPanel Layout and Installation: Shake OnlyShake PanelsShake OnlyStock edge of panel should just cover the mountinghole, or centered between the holes.Mounting Hole Numbers1!!1/221/231/24!Row 6 RepeatRow 5, Center of Hole 2 & 3Row 4, Center of Hole 1 & 2Row 3, Hole 3Row 2, Hole 2Row 1, Full PanelCut panel on line beforemounting.14Watch detailed Matterhorn Shake and Slateinstallation videos online at certainteed.com15Watch detailed Matterhorn Shake and Slateinstallation videos online at bestbuymetals.com

Panel Layout and Installation: Slate OnlySidewall With Siding Option 1Option 1Slate Only1. Apply MetaLayment/WinterGuard HT.Stock edge of panel should just cover the mountinghole, or 4 to the right of holes 1 & 2.2. Install inner gable before the panel, fastening every12", between the water lock and the diverter.3.Mounting Hole Numbers14”24”3the inner gable, hooking the bottom hem of the44. Cut panel to the length needed to meet the sidewallinside the inner gable.5. Install the panel with the cut side inside the innergable.Row 6 RepeatSidewall Option 1 DetailRow 5, 4 to the Right of Hole 2Wall SheathingRow 4, 4 to the Right of Hole 1MetaLayment/WinterGuard HTSidingRow 3, Hole 3MetaLayment/WinterGuard HTRow 2, Hole 2J-ChannelRow 1, Full PanelCut panel on line beforemounting.DiamondDeckInner Gable for SidewallSidewall FlashingFastenerRoof Sheathing16Watch detailed Matterhorn Shake and Slateinstallation videos online at bestbuymetals.com17Watch detailed Matterhorn Shake and Slateinstallation videos online at certainteed.com

Panel Layout and Installation: Slate OnlySidewall With Siding Option 1Option 1Slate Only1. Apply MetaLayment/WinterGuard HT.Stock edge of panel should just cover the mountinghole, or 4 to the right of holes 1 & 2.2. Install inner gable before the panel, fastening every12", between the water lock and the diverter.3.Mounting Hole Numbers14”24”3the inner gable, hooking the bottom hem of the44. Cut panel to the length needed to meet the sidewallinside the inner gable.5. Install the panel with the cut side inside the innergable.Row 6 RepeatSidewall Option 1 DetailRow 5, 4 to the Right of Hole 2Wall SheathingRow 4, 4 to the Right of Hole 1MetaLayment/WinterGuard HTSidingRow 3, Hole 3MetaLayment/WinterGuard HTRow 2, Hole 2J-ChannelRow 1, Full PanelCut panel on line beforemounting.DiamondDeckInner Gable for SidewallSidewall FlashingFastenerRoof Sheathing16Watch detailed Matterhorn Shake and Slateinstallation videos online at certainteed.com17Watch detailed Matterhorn Shake and Slateinstallation videos online at bestbuymetals.com

Sidewall With Siding Option 2Endwall Option 1 & 2Option 2 (Applies to masonry/stucco)Endwall Option 1MetaLayment/WinterGuard HTJ-Channel1. Add MetaLayment/WinterGuard HT from sidewall1. Bend the top of a metal panel up theend wall.Endwall Flashing2. Install MetaLayment/WinterGuard HTor sealant along bend if the kinked metalcreates a hole.2. Bend the metal panel up the wall a minimum of3. Add MetaLayment/WinterGuard HT to bent area ofpanel when needed.3.DiamondDeck andMetaLayment/WinterGuard HTover the bent panel.4.shape and install.4.the hemmed end covers the panelbelow appropriately.5.WallSheathinginstallation.Roof SheathingSidingSidewall Option 2 DetailEndwall Option 21. Install inner gable.Wall Sheathing2.inner gable. Bend sidewallJ-ChannelSidewall FlashingMetaLayment/WinterGuard HTInner GableSidingDiamondDeck andMetaLayment/WinterGuard HTWallSheathingMetaLayment/WinterGuard HTRoof SheathingMetaLayment/WinterGuard HTDiamondDeckJ-ChannelRoof Sheathing18Watch detailed Matterhorn Shake and Slateinstallation videos online at bestbuymetals.com19Watch detailed Matterhorn Shake and Slateinstallation videos online at certainteed.com

Sidewall With Siding Option 2Endwall Option 1 & 2Option 2 (Applies to masonry/stucco)Endwall O

4 Watch detailed Matterhorn Shake and Slate installation videos online at bestbuymetals.com Eave/Drip Edge 5 Watch detailed Matterhorn Shake and Slate installation videos online at certainteed.com!! MRS2 MRS1.25 1.250 .050 2.000 .050 3.000 .050 MRS3 Screw Must Penetrate Thru Decking Standard 4 Screw Installation Using Pre Punched Holes.