Transcription

PLEASE 00 Nor REMOVE FRCM LIBRARYBureau of Mines Report of Investigations/1987Selective Elution of Mercury, Silver,and Gold From Strong-BaseAnion-Exchange ResinsBy W. L. Staker and R. G. SandbergUNITED STATES DEPARTMENT OF THE INTERIOR

rIReport of Investigations 9093i\Selective Elution of Mercury, Silver,and Gold From Strong-BaseAnion-Exchange ResinsBy W. L. Staker and R. G. Sandbergr!UNITED STATES DEPARTMENT Of THE INTERIORDonald Paul Hodel, SecretaryBUREAU OF MINESRobert C. Horton. Director

Library of Congress Cataloging in Publication Data:Staker, W. L. (W. Lyman)Selective elution of mercury, silver, and gold from strong·base anionexchange resins.(Bureau of Mines report of investigations ; 9093)Bibliography; p. 8 - 9.Supt. of Docs. no.: I 28.23: 9093.1. Mercury-Metallurgy. 2. Silver-Metallurgy. 3. Gold-Metallurgy. 4. Metallurgy-Ionexchange process. I. Sandberg, R. G. (Richard G.) II. Title. III. Series: Report of investigations (United States. Bureau of Mines) ; 9093.TN23.U43[TN790]622s[669'.2]

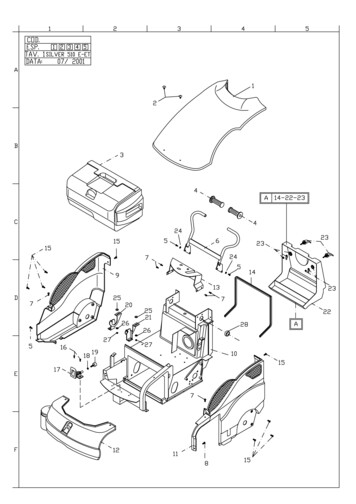

CONTENTSAbstract . ".Introduction . . ".12Materials, equipment, and operating procedure Results and discussion Elution of mercury and precious metals from resins 3334444«1 Mercury elution . .Silver elution Gold elution . .rSequential elution of mercury, silver, and gold Metal recovery . ". .Conclusion . " . .Ref e rences . . .I678ILLUSTRATIONS1.Elution of silver from IRA-430 resin with increasing concentrations of NaCI2.Flowsheet for recovery of mercury, silver, and gold from strong-base anion-in INHCl 0 exchange resins.46TABLES1.2.3.4.Elution of mercury from IRA-430 resin with H2S04 in 5 h Elution of gold from strong-base anion-exchange resins with NaCI04 Batch sequential elution of mercury, silver, and gold from strong-baseanion-exchange resins.Column sequential elution of mercury, silver, and gold from strong-baseanion-exchange resins.4557

UNIT OF MEASURE ABBREVIATIONS USED IN THIS REPORTiiBVBed volumeMmolarityBV/minBed volumes per minutemgmilligram cdegree CelsiusmLmilliliterggrammL/minmilliliter per minuteg/ft 3gram per cubic footNnormalitygiLgram per literoz/sttroy ounce per short tonhhourpctpercentininchatshort ton CU. S.)LliterVvoltIJ

I,IJi!.SELECTIVE ELUTION OF MERCURY, SILVER, AND GOLDFROM STRONG·BASE ANION-EXCHANGE RESINSItBy W. L. Staker1 and R. G. Sandberg2IABSTRACTThe Bureau of Mines investigated methods for selectively eluting mercury, silver, and gold from strong-base anion-exchange resins, includingRohm and Haas resins lRA-430 and 900 and Dow Chemical resins 2lK, SMA-I,and SBR. Resins were typically loaded to 145 oz/st of each metal.Loaded resins were eluted with H2S0 4 , NaCl-H Cl, NaOCl, and NaCl0 4 solutions.The resins tested had similar elution characteristics formercury and precious metals.The best selective elution scheme was achieved by eluting in a columnwith 2N H2S04 to recover 99 to 100 pct Hg, with 200 giL NaCl in IN HCIto rec;ver 99 to 100 pct Ag, and with 2M NaCl04 to recover 79 to 89 pctAu.1Research chemist.2Research supervisor.Salt Lake city Research Center, Bureau of Mines, Salt Lake City, UTe

2INTRODUCTIONNumerous low-grade gold-silver ore deposits throughout theWestern UnitedStates have been developed in the pastfew years.Cyanide leaching and carbonadsorption are generally used to recoverthe gold (l-10).3 Precious metals andother adsorbed metals are eluted from thecarbon with dilute caustic cyanide solutions.The elution process requireselevated temperatures and in some caseselevated pressures to increase elutionrates.These elution procedures are notselective, and expensive high-temperaturekilns are required to reactivate thecarbon after several adsorption cyclesresins that load well atpH valuesgreater than 10; however, some experimental resins have shown good adsorptionat pH values greater than 10 (21).A general mechanism for loading a weakbase resin follows:Protonation:Loading:(11-13).-roU-exchange is a well-developed technology and may have several advantagesover activated carbonfor recoveringprecious metals from cyanide solutions.Some of these advantages are (1) loadingis faster, (2) gold-loading capacity isgreater, (3) energy consumption in elution and regeneration is lower, (4) othervaluable metals dissolved in the cyanidesolution may be recovered when economicswarrant, and (5) calcium and organics donot appear to poison resins to the sameextent they do carbon (14).The firstfacility to use resin-in-pulp (RIP) ionexchange technology commercially to recover gold from cyanide pulp was at theworld's largest gold mine, in Muruntau,U.S.S.R. Resin-in-pulp is now used widely for gold extraction in the U.S.S.R.,and RIP processes offer definite economicadvantages overcarbon-in-pulpprocesses (,.!2-12).Both weak- and strong-base resins havebeen used to adsorb gold and other metalsfrom cyanidesolutions(14, - ).Weak-base resins are generally more selective for precious metals but havelower loading capacities.Because protonation of the weak-base resin is required to extract anions, a pH of lessthan 10 is usually required (20).Currently there are no commerciaY-weak-base3Underlined numbers in parentheses refer to items in the list of references atthe end of this report.Rz , NR2, H X , and M(CN)2- represent thepolymetricresinmatrix,functionalgroup, acid, and metal cyanide complex,respectively.Strong-base resins generally have higher loadings but are lessselective for precious metals; however,they are much less affected by pH thanweak-base resins ( .A general mechanism for loading a strong-base resin isRzNR3TX- M(CN)2- RzNR3 M(CN)2- X-a(C)Both resin types can be eluted at ambienttemperatures and pressures.The weakbase resins may be eluted with dilutecausticsolutions.Thestrong-baseresins have been eluted with thiosulfate(19), acetone plus hydrochloric acid,ethylacetate plus nitric acid dilutedwith water (19), zinc cyanide (15, 17),acid thiourea- (17, 22), and dimethylformamide (14). All, except zinc cyanidehave some isadvantages--usuallyfirehazard or noxious gas formation--or areuneconomical ( ).General mechanismsfor eluting weak- and strong-base resinsfollow:Strong base:RzNR3 M(CN)2- X- RzNR3 X- M(CN)2-.(D)

3Weak base:RzNR2H M(CN)2- X- Rz NR 2H X- M(CN)Z-'(E)The flowsheet for resin-in-column issimilar to that forcarbon-in-column(20).The loading section is nearlyidentical, but the elution section doesnot require elevated temperatures, pressures, or expensive reactivation kilns.The objectives of this Bureau of Minesinvestigation were to (1) investigateadsorptionof preciousmetalsfromcyanide solutions with strong-base anionexchange resins and (2) selectively elutemercury, silver,and goldfrom theresins, using inorganic aqueous eluantsat ambient conditions.MATERIALS, EQUIPMENT, AND OPERATING PROCEDUREPregnant synthetic solutions preparedfrom reagent-grade mercury, silver, andgold chemicals were used to load resins.Feedsolutions contained5 ppm eachof mercury, silver, and gold and about0.5 giL free cyanide; pH values were 10.5to 11.4.Rohm and Haas IRA-430 and IRA900 and Dow Chemical 2IK, SMA-I, and SBRstrong-base anion-exchange resins wereused in this investigation. 4 The IRA-430and Dowex 2IK resins have been used formany years for RIP in the uranium industry (17, 23-25). The other resins testedhave similar--characteristics, and someare reported to be very resistant tophysical breakdown and organic fouling(26-27).The resins consist of divinylbenzene cross-linked with styrene and aquaternary ammoniumfunctional group.Resin particle sizes were plus 20 mesh.Resin loading was conducted by adding2.5 mL of resin to 1 L of solution containing 5 mg each of mercury, silver, andgold and their radiosotopes to a plasticbottle. The bottle and contents were rotated or rolled on a set of horizontalrolls.After loading, the solution wasremoved from the resin by aspirationthrough a glass frit.The resin waswashed with water, and the radioactivitywas counted. Final resin loading was 145ozlst dry weight (56.6 gift' wet volume)of each metal.Resins were eluted by rolling with 10to 100 mL of prepared eluting solutionfor a specified time, aspirating the solution, washing with water, and countingthe radiOisotopes left on the resin.Elution and counting were repeated asneeded.Solution analyses were accomplished by atomic adsorption or by counting radioisotopes in the solutions on aTracor-Northern TN-I7IO gamma counter.Radioisotopes analyses compared well withatomic adsorption analyses.Therefore,self-determination correction factors fordifferent sample compositions and gammaray energies were not necessary.",I11RESULTS AND DISCUSSIONELUTION OF MERCURY AND PRECIOUSMETALS FROM RESINSThe solubility of mercury cyanide inacids and of silver compounds in strongchlorides suggested that mercury and silver could be eluted from strong-baseresins with dilute acidsand strongchloride solutions, respectively.Goldelution would require an eluant thatwould oxidize the gold cyanide complex or4Reference to specific products doesnot imply endorsement by the Bureau ofMines.be more strongly adsorbed on the resinthan gold cyanide.Preliminary testswere conducted to elute (1) mercury withdilute H2S04, HNO"and HCI solutions,(2) silver with NaCl-RCl solutions, and(3) gold with NaOCI and NaCI04 solutions.The preliminary testsshoweddiluteH2 S0 4 elute mercury only, RNO, elutedconsiderable silver with the mercury, andNaCI-RCI eluted silver and suppressedmercury elution.Therefore, additionaltesting was conducted with dilute H2 S0 4for mercury recovery.Preliminary testsalso showed good elution of silver withstrong acid chlorides, and good goldI'II,i 'iI'1",i:I"'/:,I 1,i :"1I) "II,i:I;I:, 1

4elutionwith either NaOCI or NaCI04'Additional testing was conducted to determine the conditionsfor selectivemercury, silver, and gold elution fromfive strong-base anion-exchange resins.that silverelutionincreasedfrom30 to 98 pct in 6 h, as the concentrationof chloride in the solution increasedfrom 51 to 157 giL (25 to 200 giL NaCI).Gold ElutionMercury ElutionMercury-, silver-, and gold-loaded IRA430 resin was eluted with increasing concentration of dilute H2S0 4 , Loaded resinwas rolled 5 h with 100 mL of acid, theacid was removed, and elution was determined by isotope counting.The test results listed in table 1 show 0.2N to 2NH2S04 effectively recovered 95 to-98 petof the mercury in 5 h, only 2 to 9 pct ofthe silver, and less than 2 pct of thegold.Silver ElutionStrongacid chloride solutions rapidly desorbsilver from strong-baseresins. Therefore, tests were conductedusingIN HCIcontainingincreasingconcentrations of NaCI. Figure 1 showsTABLE 1. - Elution of mercury fromIRA-430 resin with H2S0 4 in 5 hAcidstrength,Metal stripped, pctAuAgHgli0.2 5 1 2 021.9276995999798Preliminary testing indicated that alkaline hypochlorite and perchlorate elutemercury, silver, and gold from strongbase resins.Therefore, 1-h elutiontests were conducted to assess the technique under more controlled conditions.Loaded IRA-900 was eluted for ten 1-hperiods with a solution containing 150giL NaCI plus 5 giL NaOH and 0.75 pctNaOCl. Recoveries were 87, 92, and 86 pctHg, Ag, and Au, respectively. A mercuryand silver-freeresinwas similarlytested.Gold-loaded resin was contactedwith solutions containing 0.25 and 0.75pct NaOCI, 150 giL NaCl, and 5 giL NaOH.Gold elution was 78 pct in 2 h in the0.75-pct solution and 89 pct in 16 h inthe 0.25-pct solution.Gold-loaded Dowex SMA-1 and SBR resinswere elutedwit:h 0.5M NaCI0 4 , and theIRA-900 resin was eluted with 0.5M, 1M,and 2M NaCI04'Results of the tests,given-in table 2, show 85 to 93 pct ofthe gold was eluted from the resins in 10h with 0.5M NaCI04'Using 2M NaCI04 94pct was recovered in 5 h; 1 NaCI0 4 recovered 95 pct in 6 h.The tests showrelatively good recovery of gold fromstrong-base resins in 5 to 10 h usingeither NaCI04 or NaOCI.Sequential Elution Of Mercury,Silver, and Gold100r-----r-----r-----r----- 80R6 60L1Jf-jL1J40 20o:34ELUTION TIME, h56FIGURE 1.-Elutlon of sliver from IRA·430 resin with Increasing concentrations of NaCI In 1N HCI.Elution procedures for mercury, silver,and gold discussed in previous sectionssuggest a possible flowsheet (fig. 2).To evaluate the elution scheme, loadedstrong-base resins were contacted with2N H2S04 to elute mercury, with 200 giLNaCl in IN HCI to elute silver, and with0.75-pct NaOCI in 150 giL NaCI plus 5 giLNaOH or 2M NaCI04 to elute gold. Twoseries of tests were conducted.Results of the first test series usingthe batch elution method are given intable 3. These tests show 100 pct of themercury was eluted from IRA-900, IRA-430,

5TABLE 2. - Elution of gold from strong-base anion-exchangeresins with NaCI04, cumulative pctCumulativeelutiontime, h2MNaCI0 460802 3 88914 . . . 5 94NAp6 NAp7 8 NAp9 NAp10 NAp11 NApNAp Not applicable.1 lRA-9001MNaCI04487283880.5MNaCI0 48305163SMA-l0.5MNaCI0 19393SBR0.5MNaCI04524384855737480838588TABLE 3. - Batch sequential elution of mercury, silver, and goldfrom strong-base anion-exchange resins, cumulative percentCumulativeelutiontime, hlRA-430Hg fAg I AulRA-900Hg lAg IAUHg21KlAgI AuELUANT SOLUTION 2N HL.2 SO'4000784093002 92009960073 00 10050 1000ELUANT SOLUTION 200 g /L Na CI IN IN4 . . 100620 100656900 1002 1005 100850 100880896 100970 100961955 1007 100987 100990 1009828 100 1008 100 10040 100 10049 8 100 100100 1000 100 100ELUANT SOLUTION a 75 PCT Na OCI IN 150 g,/1 Na CI10 100 100 75 100 100 83 100 100 3111 100 100 83 100 100 91 100 100 5812 100 100 87 100 100 95 100 100 7913 . . .100 100 87 100 100 95 100 100 9114 . . 100 100 88 100 100 97 100 100 9315 100 100 89 100 100 97 100 100 9516 . . . 100 100 91 100 100 97 100 100 9617 100 100 92 100 100 97 100 100 9618 100 100 i 93 100 100 98 100 100 971 8298100.Dowex f1K, Dowex SMA-I, and Dowex SBRresins in 3 h.No gold was eluted fromNoany of the resins with the mercury.silver was eluted from the lRA-430 resinwith the mercury, but 5 to 20 pct Ag waseluted from other resinsin 2N H2S04solution. All of the remaining -silverwas eluted from all the re Ins· with 00100100100100SMA-1AgAu359010I I5784939698995 g /1100100100100100100100100100SBRHg 1 Ag 1 Au62951001818200002 1002 1002 1005 1005 1005 100Na OH28 10056 10067 10076 10085, 10092 10098 10098 10098 87987909192949495g/1 NaCI in IN HCI.Gold elution rangedfrom a to 8 pct in the strong chloridesolution and from 93 to 98 pct in 9 h inthe 0.75-pct NaDCI solution. Silver andgold cyanides are not soluble in diluteacid solutions; therefore, any silvereluted with the mercury and gold eluted

6Pregnant cyanideleach solution(Hg, Ag, Au)Cyanide solutionrecycleHgindicates that an elution scheme to elutemercury with H2S04 could not be performed in a fluidized-bed column unless afilter followed the mercury elution toremove the AgCN precipitate. It was alsonecessary to remove acid from the resinby washing or neutralizing prior to goldelution to prevent AuCN precipitation inthe gold elute.METAL RECOVERYAg200 giL NaCIIn I HCI150 giL NaCI--.---J iplus 5 giL NoOHIn 0.75 pet NaOCIAu'--t-oc-----'Resin regenerationFIGURE 2.-Flowsheet for recovery of mercury, silver, andgold from strong-base anion-exchange resins.with silver could be easily filtered fromthe solutions.The second elution test series was conducted in columns using 25 mL of loadedresin.TheIRA-430, Dowex 21K, andDowex SBR resins were loaded with 145oz/st of each metal,transferred toplastic tube columns, and eluted withsolution downflow at 0.015 BV/min (0.375mL/min).Cuts of 100 mL (4 BV) of theeluate were collected for assay.Testresults given in table 4 show 99 to 100pct of the ercury was eluted with 32 BVof 2N H2S04, 99 to 100 pct of the silverwas eluted with 28 BV of 200 gIL NaCl inIN HCl, and 79 to 89 pct of the gold waseluted with 24 BV of 2M NaCI04.No silver or gold was eluted-With the mercury,and no gold was eluted with the silver.It was noted, however, that considerable AgCN precipitated in the columnsafter the H2S04 elution, although nonethrough intheeluate.ThiscameIn addition to elution, research wasconducted to recover precious metals fromNaOCl and NaCl04 solutions.Both ofthese solutions elute mercury and silverwith the gold if mercury and silver arenot removed prior to gold removal fromthe resin. For those operations not containing mercury, the NaOCl or NaCl04would be the preferred eluant.Therefore, tests were conducted at ambienttemperaturetorecoverthe elutedmetals by precipitation or electrowinningtechniques.Precipitation tests were conducted byadding slurried powdered zinc or aluminumto 1 L of eluate (150 gIL NaCl, 5 gILNaOH, 0.8 pct NaOCl, or 2M NaCl04) containing 80 ppm Au, 12 ppm Ag, and 70 ppmHg.Powdered zinc or aluminum, cleanedwith NaOH, was added to the eluate andstirred.Samples of solution were takenevery 10 min and analyzed.Over 90 pctof the mercury, silver, and gold wereprecipitated in 10 min from both theNaOCl and NaCl04 solutions with aluminumZinc powder precipitated 62 pctpowder.of the mercury, 64 pct of the silver, and15 pct of the gold, in 30 min.Electrolytic tests to recover the metalfrom the NaOCI and NaCI04 eluants wereconducted in a compartmented flowthroughcell.The cell consisted of a Teflonfilter cloth bag 1 in in diameter by 5 inlong, filled with steel wool (cathode).The bag was placed in a 500-mL beakercontaining a platinum screen anode.Solution, similar to that used in the precipitation tests, was pumped into thecell with gravity flow from the cell.Cell voltage was maintained at 3.5 to 4 Vand ambient temperature. About 95 pct ofthe gold andsilver wererecovered

7TABLE 4. - Column sequential elution of mercury, silver, andgold from strong-base anion-exchange resins, cumulativepercentCumulativeelution,BVIRA-430Hg AgI AuHgI21KAgSBRI AuHgELUANT SOLUTION 2N H2S0 4054001000480113308 0722762000012 " 97950016 63000859900 10020 0 1 10 10024 950 10028 98.10 100.20 10032 .2.30 100990 100ELUANT SOLUTION 200 giL NaCl IN IN-0 HCl36 . . . 100270 10023100770 10040 . . . 100510 10044 . . 1000 100970 1007148 . . . 1000 100 1000 1008752 1000 100 1000 1009556 . .1000 100 1000 1009860 . . 1000 100 1000 10099ELUANT SOLUTION 2M Na CIO 464 . 100 10014 100 10015 10068 . . 100 10044 10043 100 10072 100 10062 10062 100 10076 100 10076 100 10072 10080 . . 100 10078 10085 100 10084 100 10089 100 10080 1004 0 on the steel wood cathode from both theNaOCl and NaCl04 eluants.Mercury 010010010010010033536572previously been removed asearlier sections.7779describedinCONCLUSIONSFive strong-base anion-exchange resinswere tested for elution of mercury, silver, and gold with inorganic acids andsalts.The resins tested included theRohm and Haas resins IRA-430 and IRA-900,and the Dow Chemical resins 21K, SMA-I,and SBR. These resins were found to havesimilarelution characteristicswithonly minor differences. Resins loaded to145 oz/st of each metal were eluted inbatch and column tests.Mercury elution of 99 to 100 pct wasobtained in 3 h, with 2N H2S04 in batchtests, and in 32 resin- BV of acid incolumn tests.Silver elution of 99 to100 pct was obtained in 6 h with 200 giLNaCl in IN HCl in batch tests, and in28 resin -BV of acid in column tests.Gold elution of 93 to 98 pct was obtainedin 9 h with 0.75 pct NaOCl plus 150 gNaCl and 5 giL NaOH in batch tests. Goldelution of 94 to 95 pct was obtained in6 h with 2M NaCl04 in batch tests, and79- to 89-pct elution was obtained in 6 hin 24 resin BV in column tests.In the batch elution tests, some silverwas removed from the resins with H2S04,and some gold was removed with strongchloride solutions; however, the silverand gold were not soluble in the diluteacids and could be easily filtered fromthe mercury solutions.In the columntests, no silver or gold was recoveredwith themercury, andno gold wasrecovered with the silver.

8Over 90 pct of the mercury, silver, andgold were recovered in 10 min from theNaOCl and NaCI0 4 eluants by precipitationwith aluminum powder. Zinc powder wasnot as effective, with only 62 pct of themercury, 64 pct of the silver, and 15 pctqf the gold being precipitated in 30 min.In addition, 95 pct of the gold and silver were recovered from both the NaOCland NaCI04 eluants by electrolysis usinga Teflon-bagged cathode.REFERENCES1. Engineering andMining Journal.Alligator Ridge Uses Heap Leaching ToProduceGoldBullion Bars.V. 182,No.8, 1981, pp. 35, 37.Exploration and De2. Grace, K. A.velopment in 1981. World Min., v. 35,No.8, 1982, pp. 52-66.3. McDonald, G. J., and R. D. Handcock. Activated Carbon and Gold - A Literature Survey. Miner. Sci. and Eng.,v. 12, No.2, 1980, pp. 85-99.4. Jackson, D. Jerrit Canyon Project. Eng. and Min. J., v. 183, No.7,1982, pp.54-58.5. Crabtree, E. H., Jr., V. W. Winters, and T. G. Chapman. Application ofActivated Carbon to Cyanidation. Trans.AIME, v. 187, 1950, pp. 217-222.6. Skillings, D. N., Jr. Pinson Mining Co. Marking First Full Year of GoldProduction. Skillings' Min. Rev., v. 71,No. 28, 1982, pp. 8-12.7.Homestake Proceeding WithIts McLaughlin Gold Project. Skillings'Min. Rev., v. 72, No.4, 1983, pp. 3-6.8. Steel, G. L.Candelaria: FamousSilver Producer Reactivated After 100Years. Min. Eng., v. 33, No.6, 1981,pp. 658-660.9. Arizona Pay Dirt. Gold Fields Develops State of Art Leaching System atOrtiz. June 1982, pp. 41-42, 44, 46, 48.10. Skillings, D. N., Jr. Getty mining Co. Starting Up Its Mercury GoldOperation in Utah. Skillings' Min. Rev.,v. 72, No. 17, 1983, pp. 4-9.11. Laxen, P. A., G. S. M. Becker, andR. Rubin. Developments in the App1icaation of Carbon-in-Pu1p to Recovery ofGold From South African Ores.J. S.Afr. Inst. Min. and Meta11., v. 79,No. 11, 1979, pp. 315-326.12. Laxen, P. A.Carbon-in-Pu1p Processes In South Africa. Hydrometa11urgy,v. 13, 1984, pp. 169-192.13. Poter, G. M., and H. B. Salisbury.Innovations in Gold Metallurgy. Pres. atAm. Congr. Min. Conv. Environmental Show,Denver, CO, Sept. 9-12, 1973, 11 pp.;available upon request from Librarian,Salt Lake City Research Center, BuMines,Salt Lake City, UTe14. von Michaelis, H. Innovations inGold and Silver Recovery. Soc. Min. Eng.AlME, reprint 83-119, 1983, 16 pp.15. Fleming, C. A., and G. Cromberge.The Extraction of Gold From Cyanide Solutions by Strong- and Weak-Base AnionExchangeResins. J.S.Afr. Inst.Min. and Meta11., v. 84, No.5, 1984,pp. 125-137.Soviet Byproduct16. World Mining.Gold Production. V. 34, No.6, 1981,pp. 64-70.17. Fleming, C. A., and M. J. Nicol.Alternative Process to Filtration: Carbon-in-Pu1p and Resin-in-Pu1p intheMetallurgical Industry. Hydrometal1urgy'81 {Proc. Soc. Chem. Ind. Symp., Univ.Manchester,England, (June 3D-July 3,1981). Soc. Chem. Ind. (Vnited Kingdom),1981, pp. C2/1-C2/16.18. Hussey, S. J. Application of IonExchange Resins in the Cyanidation of aGold and Silver Ore. BuMines RI 4374,1949, 34 pp.19. Bursta11, F. H., P. J. Forrest,N. F. Kember, and R. A. Wells. IonExchange Process for Recovery of GoldFrom Cyanide Solution. Ind. and Eng.Chem., v. 45, No. 81, 1953, pp. 16481658.20. Mooiman, M. B., J. D. Miller,J. B. Hiskey, and A. E. Hendriksz. Comparison of Process Alternatives for GoldRecovery From Cyanide Leach Solutions.Paper in Proceedings SME-AIME Fall Meeting, Salt Lake City, UT, (Oct. 19-21,1983). Soc. Min. Eng. AIME, Littleton,CO, 1984, pp. 93-107.

921. Palmer, G. R. Ion-Exchange Research in PreciousMetalsRecovery.Paper in Precious Metals Recovery FromLow-Grade Resources.Proceedings: Bureau of Mines Open Industry Briefing Session at the National Western Mining Conference, Denver, CO, February 12, 1986,compiled by staff, Bureau of Mines.BuMines IC 9059, 1986, pp. 2-9.22. Stromboliadis, E., J. McHardy, andT. Salman. Ion Exchange Techniques forthe Recovery of Gold From Cyanide Solutions. Can. Min. and Metall. Bull.,v. 796, 1978, pp. 124-128.23. Rohm & Haas Co. Technical Bulletin, Fluid Process Chemicals, "Amberlite"lRA-430. Philadelphia, PA, 1978.U,S, GOVERNEMNT PRINTING OFFICE: 1987 - 605 01716004824. Traut, D. E., I. L. Nichols, andD. C. Seidel. Design Requirements forUraniumIon ExchangeFromAmmoniumBicarbonate Solutions in aFluidizedSystem. BuMines RI 8280, 1978, 27 pp.25. Dow Chemical Co. Dowex 21K AnionExchange Resin Information Sheet 8, Midland, MI, Form No. 176-1089-69.26. Dowex Macroporous Resins. Ion Exchange, v. 3, No.1, 1980, Form No.177-1257-80.27. Rohm & HaasCo. ,"Amberlite"IRA-gOO Technical Notes, Philadelphia,PA, Dec. 1982.INT.-BU.OF MINES,PGH.,PA. 28494

Mercury Elution Mercury-, silver-, and gold-loaded IRA-430 resin was eluted with increasing con centration of dilute H2S04, Loaded resin was rolled 5 h with 100 mL of acid, the acid was removed, and elution was deter mined by isotope counting. The test re sults listed in table 1 show 0.2N to 2N