Transcription

Roxul ComfortBatt Roxul ComfortBatt Thermal Batt Insulation for Residential& Commercial Construction

Roxul ComfortBatt Thermal batt insulationSuperior BuildingEnvelope PerformancePerformance Matters: ManagingMoisture In Wall AssembliesRoxul Comfortbatt is a semi-rigid batt insulationdesigned specifically for wood and steel studapplications for residential and commercialconstruction. The stone wool-based insulation is madefrom natural stone and up to 93% recycled content,which gives it properties that other insulation can’tmatch. It also offers superior acoustical performanceto wall assemblies and floors and can be used inacoustic applications required by building code.Roxul ComfortBatt is an unfaced semi-rigid battinsulation and a vapor retarder may be required bybuilding code depending on the geographic locationof the building.Fire-Safe Insulation ForWall Assemblies – Won’tBurn or Develop SmokeRoxul ComfortBatt stone wool insulation isnon-combustible as determined by ASTM E136 andCAN4-S114. It will not develop smoke or promoteflame spread, even when directly exposed to fire,as most other insulation materials will.nnnnn Extremely high melting point of 1177 C (2150 F) D oes not produce smoke or toxic gases in the eventof a fire E xcellent barrier against the spread of flames tohelp protect occupants and reduce property damageThe use of a vapor retarder will limit the amountof water vapor that will move to the outside wall –reducing condensation in the wall assembly. Even asmall hole in the vapor barrier can have a detrimentaleffect on the performance of the wall and insulation.nFire Test Performance Roxul ComfortBatt does not absorb water and hasa low water sorption rate. It will maintain its shapewithin the wall cavity ensuring maximum R-value ismaintained.CAN/ULC-S702-09Mineral WoolThermal Insulationfor BuildingsType 1, CompliesCAN4-S114Determination ofNon-CombustibilityNon-CombustibleDetermination ofNon-CombustibilityNon-CombustibleCAN/ULC S102Surface BurningCharacteristicsFlame Spread 0Smoke Developed 0ASTM E 84Surface BurningCharacteristicsFlame Spread 0Smoke Developed 0R14/1589 mm2.8 kg/m2NBC 2010,Article 9.25.2.2InsulationMaterialsConformsR22/23150 mm4.8 kg/m2CCMC EvaluationListingMaster Format07212: MineralWool BattInsulation12018-LR28/30184 mm5.9 kg/m2R32203 mm6.5 kg/m2DensityASTM C 612-00 – 32 kg/m3 (2 lb/ft3)FireCAN/ULC S102 Surface Burning CharacteristicsFlame Spread 0ASTM E 136nn Eliminates the risk of insulation accidently catchingfire during installation E xcellent Passive Fire Protection – ComfortBatt canadd up to an additional 15 minutes of fire protectionto wall assemblies2011-2012n When insulation material such as fiberglass getswet, it can absorb moisture, reducing R-value andpresenting the risk of slumping and sagging withinthe wall cavity.The Insurance Bureau of Canada (IBC) reference to NFPA 285: Standard Fire Test Method for Evaluation ofFire Propagation Characteristics of Exterior Non-Load-Bearing Wall Assemblies Containing CombustibleComponents has led to several rainscreen wall system manufacturers to test with Roxul cavity wallinsulation. The use of SPUF insulation does not allow rainscreen manufacturers to meet this requirement. Roxul ComfortBatt is resistant to water, rot, mold,mildew and bacterial growth.Better Fit Equals BetterWall PerformanceTo ensure the labeled R-value is achieved, battinsulation in wood and steel stud wall cavities mustbe gap-free and void-free. Gaps and voids are mostprevalent around electrical boxes, wires and pipes.Roxul ComfortBatt is produced at a slight overthickness to ensure a friction fit within the wall cavity.The batts will stay in place and perform equally wellin horizontal, sloped, dormer, vertical and overheadapplications.Roxul ComfortBatt’s unique flexible edge ensuresthe semi-rigid batts compress and expand betweenstuds and joists to eliminate slumping or sagging andconform to off-standard wood studs.Higher density batts reduce airflow within the wallcavity, reducing convective losses. This translatesinto a better performing and more comfortablethermal wall. Wall assembly construction is not perfect, butRoxul ComfortBatt can minimize moisture risk.Compliance & Specification › 2 lb/ft3 32 kg/m3Smoke Developed 0MoistureResistanceASTM C 1104 Moisture Sorption 0.03%Roxul cuts quickly and accurately with a serratedknife, such as a bread knife, so you can easily achieveoptimal fit around pipes, electrical boxes, wiring,ductwork, and between studs and joists that areless than a standard width.Studies have proven that wall assemblies with gaps and voids canresult in 35% loss of the stated R-value. Roxul ComfortBatt’s higherdensity batts make it simple for precise cutting to ensure a fitwithout gaps and voids.

Roxul ComfortBatt Thermal batt insulationSpecifically Engineered for Use inAll Residential Thermal ApplicationsIdeal Applications for ComfortBatt Insulation Roxul ComfortBatt ’s higher density ensures a snug friction fit in thewall cavity. Note: A vapor retarder may be required in the wall assembly,depending on the geographical location of the building.7The ComfortBatt Residential Wall AssemblyCathedral CeilingsAttics62➊ Cladding➋ Air Barrier➌ Sheathing➍ 2” x 6” Wood Studs➎ 5.5” ComfortBatt➏ Vapor Retarder➐ Gypsum45(shown from outside to inside)319In addition to residential applications, Roxul ComfortBatt is ideal as acomponent of the BEDR cavity wall system.BEDR Wall Components (shown from outside to inside)Exterior Walls Above GradeExposed FloorsBasement Walls7➊ Terra Cotta Cladding➋ 1” Air Space (1/2” minimum)➌ 1”-2” CavityRock MD Insulation (R4.2–R8.4)or 2.5”–5” CavityRock DD (R10.75–R21.5)➍ Permeable Air Barrier➎ Exterior Gypsum Board➏ 3.5” or 6” Steel Stud➐ 3.5” or 6” ComfortBatt Insulation➑ Vapor Barrier➒ 5/8” Gypsum BoardWhen insulating attics, use two layers of ComfortBatt to achievethe required R-value. The bottom layer should run parallel to thejoists and the top layer run in the opposite direction. For attics andcathedral ceilings, only a single layer of ComfortBatt is requiredbetween the roof trusses.86543122135The ComfortBatt Roof/Attic AssemblyEnvironmental Benefits That Go Beyond Residential HomesThe GREENGUARD Environmental Institute (GEI) is a non-profit organization that oversees theGREENGUARD Children & Schools standards. The GEI’s mission is to protect human health andquality of life through programs that improve indoor air that people breat he. They offer strictcertification criteria for products intended for use in schools, daycares or other environmentswhere children spend significant periods of time. Roxul ComfortBatt products are certified tothis standard and are recognized by the United States Green Building Council’s (USGBC) LEED program. ComfortBatt is also recognized by CaGBC (Canadian Green Building Council).4(shown from outside to inside)➊ Shingles➋ Tar Paper➌ Sheathing➍ 2” x 10” Roof Trusses➎ ComfortBatt (R30/R32)➏ Ceiling Joists➐ ComfortBatt (R22/R23 or R28/R30)two layers running perpendicular476

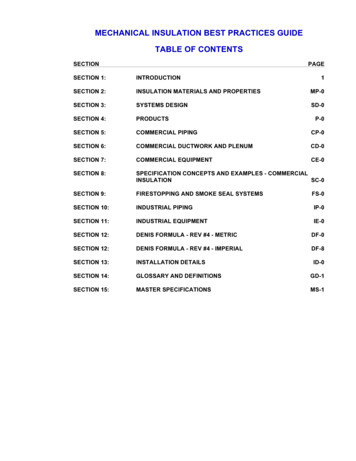

ComfortBatt Roxul ComfortBattRoxulThermal batt insulation A Range of Roxul ComfortBatt Productsto Suit All Your Building Requirements Availablein CanadaAvailablein USRSI ValueR1447R144R15CoverageSq. ��23”47”30.0R-ValueWidthLength(per bag)Wood StudSteel 0.4* Roxul ComfortBatt Thermal Insulation products have been tested and certified by BHFTI (The Bureau of Home Furnishings and Thermal Insulation). The Bureau is a government bodyunder the California Department of Consumer Affairs that certifies thermal insulation performance and conducts periodic compliance testing of sample.Roxul ComfortBatt Green ManufacturingReport CardUsing Roxul insulation products is one of the mostcost-effective ways to make homes and buildingsacross North America more energy efficient. Butthe company’s commitment to the environment goesbeyond the benefits of the products themselves. Itextends to the way the insulation is made, as well.Roxul’s newest manufacturing facility in Milton,Ontario utilizes state-of-the art technologies toeliminate waste, reduce energy consumption andminimize the company’s impact on the planet infive critical “green” areas.1. Recycling and Waste ReductionOur new plant has an innovative recycling system thatturns all production waste into new raw materialsto be reused in the process. Roxul insulation nowcontains up to 93% recycled materials. The facilityrecycles over 99% of its production waste, whichdramatically reduces the impact on local landfill sites.2. Water ConservationWater used in the manufacturing process is collectedand reused for production. Storm water from theplant site is also collected and used in the productionprocess. This significantly reduces the amount neededfrom municipal drinking water resources.3. Energy EfficiencyHeat generated during our production process iscaptured and recycled throughout the factory andwarehouse for warmth during cold weather. Energyefficient lighting has been installed throughout thefacility.4. Lower Vehicle EmissionsA strict no-idle policy for trucks and other vehicles atthe facility minimizes exhaust emissions.5. Air QualityRoxul uses advanced emission control technology toensure manufacturing emissions are lower than theair quality standards set and regulated by the OntarioMinistry of the Environment (MOE). In all instances,the Roxul facility is significantly below MOE levels.

Roxul ComfortBatt A Global LeaderEnvironmentally SustainableRoxul Inc. is part of Rockwool International, the largestproducer of stone wool insulation, which is made fromnatural basalt rock and recycled material.Our stone wool production process utilizes some ofthe most advanced technology available. The Roxulfacility is designed to capture and recycle rainwater,reduce energy consumption, and create zero wasteto landfill by recycling raw materials back into theproduction process.ECYCLED CONTENTTMRE*C*Roxul ComfortBatt is an innovative insulation offeringa world of green features. When Roxul is the specifiedinsulation, green building developers can earn a varietyof LEED (Leadership in Energy and EnvironmentalDesign) points across four key categories towardsustainable development.Roxul is pleased to have third-party certification ofour products’ recycled content for our Milton facility,completed by ICC-ES SAVE . All Roxul productsproduced in the Milton facility contain a minimum of75% recycled content. Our Milton facility is certifiedto produce products containing up to 93% recycledcontent. For further details, contact your Roxul SalesRepresentative. Roxul products produced in ourGrand Forks facility are currently under ICC-ES SAVE Certification review. Please visit www.roxul.com forthe latest information.LCYCLAB .ilso ntERoxul is the Better InsulationRIn addition to thermal insulation for residential andcommercial construction, Roxul also manufacturesa range of other premium insulation products formultiple applications.Roxul insulations are created using naturallyoccurring, inorganic raw materials and materialswith a high-recycled content. Stone wool insulationis non-combustible and achieves its thermalperformance without the use of blowing agents.The products do not off-gas and are fully recyclable,therefore contributing to a sustainable environment.HIGHRockwool International was founded in 1909 and todayoperates worldwide with more than 8,800 employees,with 27 factories across three continents. For morethan 20 years, Roxul has been serving the NorthAmerican market.act us for detaROXUL INC.FireResistantWaterRepellentSoundAbsorbentRoxul ComfortBatt is a trademark of Roxul Inc.LEED is a registered trademark of United States Green Building Council. GREENGUARD is a registered trademark of Greenguard Environmental Institute.SavesEnergyMadefrom StoneRecycledContentROX-2409 0612420 Bronte Street SouthSuite 105Milton, Ontario L9T 0H9Tel: 1-800-265-6878www.roxul.com

the wall cavity. n Roxul ComfortBatt does not absorb water and has a low water sorption rate. It will maintain its shape within the wall cavity ensuring maximum R-value is maintained. n mildew and bacterial growth. n Wall assembly construction is not perfect, but Roxul ComfortBatt can minimize moisture risk. Better Fit Equals Better Wall .