Transcription

FOR COMMERCIAL BUILDINGSInsulation Systems Catalog

TABLE OF CONTENTSINSULATION SYSTEMS FOR COMMERCIAL BUILDINGSPRODUCT OVERVIEWFIBERGLAS INSULATIONECOTOUCH THERMAL BATT INSULATIONFlexible fiberglass insulation batts for a wide range of wall and roof/ceiling applicationsare available unfaced or faced with kraft or foil vapor retarders in thicknesses from 31/2"to 12" and R-values from 11 to 38.Page 2Page 4ECOTOUCH FLAME SPREAD 25/FLAME SPREAD 25 EXTENDED FLANGESA light-density, flexible batt insulation for use in walls, ceilings and floors where insulationwill be left exposed or where a low flame spread FSK or PSK vapor retarder is needed.Page 5R-values range from 11 to 30.SOUND ATTENUATION BATT INSULATIONLightweight, flexible glass fiber insulation batts in standard metal framing widths andthicknesses from 21/2" to 31/2". Sound Attenuation Batts are designed to control noisein interior partitions.Page 6SONOBATTS INSULATIONFlexible, glass fiber insulation batts with R-values from 11 to 38 for economical noisecontrol and thermal performance in ceiling systems.Page 8CURTAINWALL INSULATIONDesigned to provide excellent thermal properties in curtainwall spandrel systems,Curtainwall Insulation/CW 225 is a semirigid fiberglass insulation available unfacedor with an FSK facing in thicknesses from 1" to 4".Page 9FIBERGLAS 700 SERIES INSULATIONFlexible, semirigid and rigid rectangular boards of varying densities and thicknessesor unfaced with FSK or ASJ facings. Each series has thermal, acoustical and physicalproperties which suit them to a variety of specific construction applications.Page 10FOAMULAR EXTRUDED POLYSTYRENE (XPS) INSULATIONExtruded polystyrene rigid foam insulation with stable, high insulating values andexcellent moisture resistance. An integral skin and the closed-cell nature of thematerial eliminate the need for facers.Page 12ELAMINATOR METAL BUILDING INSULATION SYSTEMThe ELAMINATOR Insulation System installs ELAMINATOR Insulation with patentedmachines on metal building roofs with 300 Series machines providing safety solutionsfor fall protection.Page 14CERTIFIED R METAL BUILDING INSULATIONCertified R Metal Building Insulation is laminated with specified facings to provideinsulation for metal building walls and roofs.Page 15APPLICATION RECOMMENDATIONSInstalling insulation for thermal and acoustical performance, health aspects andapplicable standards.ENVIRONMENTAL AND SUSTAINABILITYATTACHMENT SYSTEMSGUIDE SPECIFICATIONSINDUSTRY STANDARDSINSULATION SYSTEMS FOR COMMERCIAL BUILDINGS Page 16Page 21Page 22Page 23Page 24PAGE 1

PRODUCT OVERVIEWOwens Corning commercial building insulation products providesolutions for maximizing protection from the elements and minimizingnoise. With a full range of products to meet every insulation need,from Fiberglas 700 Series Insulation for energy savings to SoundAttenuation Batt Insulation for noise reduction, these proven productsprovide commercial builders with the tools they need for just aboutevery job.EcoTouch Flame Spread 25Sound Attenuation Batts InsulationEcoTouch Thermal Batt InsulationFOAMULAR Continuous Insulation “ci”FOAMULAR 150/250/INSUL-DRAIN /PINK-DRAIN XPS InsulationPAGE 21-800-GET-PINK www.owenscorning.com

Sound Attenuation Batt Insulation (Fiberglass)THERMAPINK XPS InsulationFiberglas 700 Series Insulation& Curtainwall InsulationSonobatts InsulationINSULATION SYSTEMS FOR COMMERCIAL BUILDINGS PAGE 3

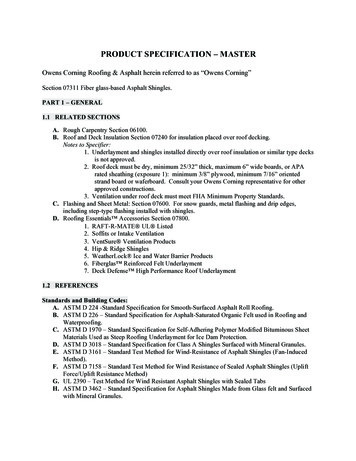

ECOTOUCH THERMAL BATT INSULATIONFIBERGLASS INSULATION–PRODUCT DATADESCRIPTION & USES Unfaced Kraft-Faced Foil-Faced For roof/ceiling and interior/exterior wallapplications; installed in wood or metal framingcavities or between furring channels. Flexible fiberglass insulation 31/2" to 12" thickavailable unfaced, foil-faced or kraft-faced.FEATURES & BENEFITS Sized for metal or wood framing; can be stapledor friction-fit. Easy to handle and install. Trimand fabricate with a utility knife. Meets thermal specifications. Improves interior noise control. Inorganic. Non-corrosive to steel, aluminumor copper. Dimensionally stable and will not decay orslump in the cavity. SpaceSaver packaging reduces freight andstreamlines handling.DESIGN CONSIDERATIONS In commercial roof/ceiling thermal applications,the building envelope must block air movement.Do not rely on the insulation or facing toprovide an air barrier. Adding insulation inside a structure’s perimeterexposes the exterior building materials togreater temperature extremes and expansionand contraction forces. Equip curtainwall buildings with sprinklersystems for fire protection as required bybuilding codes. Luminaire performance may be affected byclosely placed insulation. The National ElectricCode requires: Unless fixtures are approved forsuch use, do not install insulation on top of orwithin 3" of recessed light fixtures. Evaluate the use of vapor retarders based onthe project’s unique requirements. Maintainfacing integrity for vapor retarder performance. Kraft facings on this insulation will burn andmust not be left exposed. Facings should beinstalled in substantial contact with approvedceiling, wall or floor material.ECOTOUCH THERMAL BATT INSULATION TECHNICAL DATA/WALL OR CEILINGWIDTHMETAL FRAME CONSTRUCTION16" 406 mm16" 406 mm16" 406 mmWOOD FRAME CONSTRUCTION15" 381 mm 19.25" 48911" 279 mm 15" 381 mm 19.25" 48915" 381 mm11" 279 mm 15" 381 mm 19.25" 48915" 381 mmROOF/CEILING CONSTRUCTION11" 279 mm 15" 381 mm16" 406 mm 19.25" 48915" 381 mm 19.25" 48915" 381 mm16" 406 mm 19.25" 48915" 381 mm12" 305 mm 16" 406 mm 19.25" 48915.5" 394 mm12" 305 mm 16" 406 mm15.5" 394 mmLENGTHTHICKNESSR-VALUE131 2" 89 mm31 2" 89 mm61 4" 159 mm11.013.019.031 2"31 2"31 2"61 4"51 2"89 mm89 mm89 mm159 mm139 mm11.013.015.019.021.061 4"61 4"63 4"8"8"91 2"91 2"81 4"12"101 4"15915917120320324124120930526024" 609 mm 48" 1219 mm 96" 2,438 mm24" 609 mm 48" 1219 mm 96" 2438 mm24" 609 mm 48" 1219 mm 96" 2438 mmmm 23" 584mm 23" 58423" 584mm 23" 58423" 584mm93"mm93"mm93"mm 48" 1219 mm 93"mm93"23" 584mm 24" 609mm 23" 58423" 584mm 24" 60923" 584mm 24" 60923.75" 60324" 60923.75" 603mmmmmmmmmmmmmmmmmmmm48" 121948" 121948" 121948" 121948" 121948" 121948" 121948" 121948" 2667266726672667mmmmmmmmmm 93" 2362 mmmm 96" 2438 mmmmmm 96" 2438 mm96" 2438 .030.030.030.0 C238.038.0 C21. R-values differ. Find out why in the seller’s fact sheet. Higher R-values mean greater insulating power.2. C Cathedral ceilings.Unfaced EcoTouch Thermal Batt Insulation complies with the property requirements of ASTM C665, Type Iand ASTM E 136. Kraft-Faced Thermal Batt Insulation complies with ASTM C665, Type II and Class C. Check foravailability in your service area. Foil-Faced EcoTouch Thermal Batt Insulation complies with ASTM C665, Type III,Class B and C.SURFACE BURNING CHARACTERISTICS/BUILDING CODE CONSTRUCTIONCLASSIFICATIONSPRODUCT TYPESEcoTouch Unfaced InsulationEcoTouch Foil-Faced InsulationEcoTouch Kraft-Faced InsulationFLAME SPREAD1075N/RSMOKE DEVELOPED10150N/RICBOAll TypesIII, IV, VIII, IV, VBOCAAll TypesAll TypesIII, IV, VSBCCIAll TypesAll TypesIII, V, VIICCAll TypesIII, IV, VIII, IV, VEcoTouch Thermal Batt Insulation complies with the International Building Code (ICC), Uniform Building Code(ICBO), National Building Code (BOCA) and Standard Building Code (SBCCI) model code requirements forbuilding construction types listed above. Kraft and standard foil facing on EcoTouch Thermal Batt Insulation willburn and must not be left exposed. The facing must be installed in substantial contact with an approved interiorpartition construction material. Protect facing from open flame or other heat source. Due to the potential for skinirritation, unfaced EcoTouch Thermal Batt Insulation should not be used for exposed applications where it will besubject to human contact.VAPOR RETARDERSPerms Maximum1WATER VAPOR SORPTIONMaximum by WeightDIMENSIONAL STABILITYLinear ShrinkageKRAFT1FOIL0.55%Less than 0.1%1. Products are tested in accordance with: R-valueSurface Burning CharacteristicsPerm RatingASTM C518ASTM E84ASTM E96APPLICABLE STANDARDS Surface burning characteristics comply with ASTME84, a standard used to measure and describeproperties of products in response to heat andflame under laboratory conditions. The results arenot intended to reflect hazards presented underactual fire conditions. Base material is classified asnoncombustible when tested per ASTM E136. See tables for data and other applicable standards.PAGE 4PRODUCT 98%APPLIES TO UNFACED PRODUCTAPPLIES TO UNFACED PRODUCTAPPLIES TO FACED PRODUCTPRODUCT 57%APPLIES TO KRAFT-FACED PRODUCT1-800-GET-PINK www.owenscorning.com

ECOTOUCH FLAME SPREAD 25/FLAME SPREAD 25 EXTENDED FLANGESFIBERGLASS INSULATION–PRODUCT DATADESCRIPTION & USES FSK-Faced (Foil) PSK-Faced (White) Install between metal or wood framing orattach with impaling pins. Light-density, flexible batt insulation withlow flame spread FSK or PSK facing, andR-values* from 11 to 30. For walls, ceilings and floors where alow flame spread vapor retarder is requiredor where insulation will be exposed.Also suited for concealed applicationsin noncombustible constructions.FEATURES & BENEFITS Meets thermal specifications. Meets building code requirements for exposedapplications thereby eliminating the need for acovering or separate finish. Improves acoustical performance. Easy to install and fabricate with 11 4" or 4"flanges for installation in framing applications.Widths accommodate metal and wood framing.DESIGN CONSIDERATIONS In commercial roof/ceiling thermal applications,the building envelope must block the movementof air into the conditioned space. Do not relyon the insulation or its facing to provide anair barrier. Adding insulation inside a structure’sperimeter exposes the exterior buildingmaterials to greater temperature extremes andexpansion and contraction forces. Equip curtainwall buildings with sprinkler systemsfor fire protection as required by building codes. Luminaire performance may be affected byclosely placed insulation. The National ElectricCode requires: Unless fixtures are approved forsuch use, do not install insulation on top of orwithin 3" of recessed light fixtures.ECOTOUCH FLAME SPREAD 25 FIBERGLASS INSULATION TECHNICAL DATAWIDTH(S)METAL FRAME CONSTRUCTION16"406 mm16"406 mm16"406 mm16"406 mmWOOD FRAME CONSTRUCTION16"406 mmLENGTH24"NA24"24"609 mm23"THICKNESSR-VALUE1609 mm609 mm96"96"96"48"2438243824381219mmmmmmmm31 2"31 2"61 4"91 2"89 mm89 mm159 mm241 mm11.013.019.030.0584 mm96"2438 mm61 4"159 mm19.01. R-values differ. Find out why in the seller’s fact sheet. Higher R-values mean greater insulating power.Check for availability in your service area.SURFACE BURNING CHARACTERISTICS/BUILDING CODE CONSTRUCTIONCLASSIFICATIONSPRODUCT TYPES FLAME SPREAD SMOKE CAll TypesAll TypesAll TypesAll TypesAll TypesAll TypesAll TypesAll TypesEcoTouch Flame Spread 25 Fiberglas Insulation complies with the International Building Code (ICC), UniformBuilding Code (ICBO), National Building Code (BOCA) and Standard Building Code (SBCCI) model coderequirements for building construction types listed above.VAPOR RETARDERSPerms MaximumWATER VAPOR SORPTIONMaximum by WeightDIMENSIONAL STABILITYLinear ShrinkageLIGHT REFLECTANCEPSK-Faced—Per ASTM C523FSK0.02PSK0.025%Less than 0.1%— Surface burning characteristics tests performedin accordance with ASTM E84, a standard usedsolely to measure and describe properties ofproducts in response to heat and flame undercontrolled laboratory conditions. Results arenot intended to reflect hazards presented bythis material under actual fire conditions. It alsocomplies with the MEA 332-83-M requirementsof New York City. Facing permeance tests conducted inaccordance with ASTM E96 (desiccant method).85%EcoTouch Flame Spread 25 with 4" ExtendedFlanges shown in a 2" x 4" exposed ceiling. Evaluate the use of vapor retarders basedon the unique requirements of each project.APPLICABLE STANDARDS ASTM C518 tests were used to determineR-values.* Listed R-values are for insulation only. Complies with ASTM C665, Type III, Class Awhen FSK-faced. Complies with the propertyrequirement of ASTM C665, Type II, Class Awhen PSK-faced or Poly-faced.PRODUCT 78%APPLIES TO FSK-FACED PRODUCT* R-values differ. Find out why in the seller's fact sheet onR-values. Higher R-values mean greater insulating power.INSULATION SYSTEMS FOR COMMERCIAL BUILDINGS APPLIES TO FACED PRODUCTPAGE 5

SOUND ATTENUATION BATT INSULATIONFIBERGLASS INSULATION–PRODUCT DATADESCRIPTION & USES SAB Unfaced Designed to deliver noise control in standardmetal-framed interior partitions, SABs areslightly wider than stud spaces and up to 9' longto accommodate easy, friction-fit installation. Lightweight, flexible fiberglass insulation batts,Owens Corning Sound Attenuation Batts/SABsare manufactured in thicknesses of 21 2", 31 2"and 51 2".FEATURES & BENEFITS Sound Attenuation Batts can improve SoundTransmission Class (STC) ratings by 4 to 10points, depending on the construction methodused. See next page for STC performance data. Classified as noncombustible by model buildingcodes. When installed in wall systems andtested per ASTM E119, assembly fire resistanceratings up to 2 hours can be achieved. SoundAttenuation Batt Surface Burning Characteristicsmeet the code requirements for all building typesas described by the Standard Building Code(SBCCI), the National Building Code (BOCA),the Uniform Building Code (ICBO) and theInternational Building Code (IBC). Adhesives and fasteners are not required. Easily cut or split to fit around wires, pipes,electrical service boxes and other obstructions,SABs are simply placed in the metal studframing cavity for a friction-fit. Adds thermal value in applications where atemperature differential exists.PAGE 6SOUND ATTENUATION BATT INSULATION TECHNICAL 24"24"609609609609LENGTH96" 243896" 2438108" 2438108" 2438mmmmmmmmTHICKNESS31 2" 89 mm21 2" 64 mm21 2" 64 mm31 2" 64 mmmmmmmmmm1. R-values differ. Find out why in the seller’s fact sheet on R-values. Higher R-values mean greater insulating power.R-value ASTM C518Sound Attenuation Batt Insulation complies with the property requirements of ASTM C665, Type I and ASTM E136.SURFACE BURNING CHARACTERISTICS/BUILDING CODE CONSTRUCTIONCLASSIFICATIONSPRODUCT TYPESUnfacedFLAME SPREAD10SMOKE DEVELOPED10ICBOAll TypesBOCAAll TypesSBCCIAll TypesICCAll TypesSound Attenuation Batt Insulation complies with the International Building Code (ICC), Uniform Building Code(ICBO), National Building Code (BOCA) and Standard Building Code (SBCCI) model code requirements forbuilding construction types listed above.WATER VAPOR SORPTIONMaximum by WeightDIMENSIONAL STABILITYLinear Shrinkage5%Less than 0.1%Products are tested in accordance with: Surface Burning Characteristics ASTM E84.STEEL STUDSTCTEST NO.CONSTRUCTION DESCRIPTIONDOUBLE LAYER WALL SYSTEM56TL-93-351 5 8" Type “X” gypsum; 35 8" SS, 31 2" thick Sound Attenuation Batt Insulation54 NBC No. S3a 5 8" Type “X” gypsum; 21 2" SS, 21 2" thick Sound Attenuation Batt InsulationUNBALANCED WALL SYSTEM (2 LAYER/1 LAYER OF GYPSUM)54TL-92-368 Unbalanced 5 8" Type “X” gypsum; 35 8" SS, 31 2” thick, Sound Attenuation BattInsulation51TL-93-036 Unbalanced 5 8" Type “X” gypsum; 21 2" SS, 21 2” thick, Sound Attenuation BattInsulationSINGLE LAYER WALL SYSTEM49TL-92-349 Single layer 5 8" Type “X” gypsum; 35 8" SS, 21 2” thick, Sound Attenuation BattInsulation44TL-93-033 Single layer 5 8" Type “X” gypsum; 21 2" SS, 21 2” thick, Sound Attenuation BattInsulationFIRE TESTFIRE RATINGUL-U423NBC No. S3a2 Hr.2 Hr.UL-U4651 Hr.ULC W4091 Hr.UL U4651 Hr.ULC W4091 Hr.1-800-GET-PINK www.owenscorning.com

SOUND ATTENUATION BATT INSULATIONFIBERGLASS INSULATION–PRODUCT DATADESIGN CONSIDERATIONSSeveral important design and construction detailscan significantly improve acoustical performance ofinterior drywall partitions.Door specifications: For optimum noise control,solid wood core or metal doors should bespecified. A soft weather-stripping should beused to gasket door tops and sides. Air seals orthreshold closures at the bottom of the doorwill reduce sound transmission. Stagger doors onhallways so that doors do not open across fromone another.Ducts: Pay special attention to duct design whenplanning the layout because outdoor soundsare easily transmitted into the building interiorthrough them. Vertical ducts and ventilation shaftsoften rattle in windy areas or pop due to thermalexpansion and contraction. Owens Corning offersa variety of products—including duct wraps andliners—to effectively reduce duct noise.Equipment: Ideally, HVAC equipment should bepositioned away from areas where acousticalperformance is important. A well-insulated roomwith a solid core door can help to isolate the noiseof furnaces, air conditioners and other equipment.Plumbing: Eliminate unwanted sounds in piperuns by designing in swing arms so expansion andcontraction can occur without binding. Isolatepiping from surrounding structures with resilientmounts. Avoid back-to-back fixture installation. Foroptimum acoustical integrity, plumbing openingsmade in walls should be caulked.INSTALLATION Select the SAB product that completely fills thecavity space. Friction-fit Sound Attenuation Batts in placeuntil the interior finish is applied. Supplementary support should be provided ifthe cavity is open on one side greater than 8'. Cut or split insulation to fit around obstructionssuch as wiring, junction boxes and outlets. Keep product dry during storage, shipping andinstallation.APPLICABLE STANDARDS Sound Attenuation Batts comply with ASTMC665, Type I and ASTM E136. ASTM C665replaces canceled Federal Specification HH-I521F and the MEA 332-83-M requirements ofNew York City. Sound Attenuation Batt Insulation surfaceburning characteristics were derived fromproducts tested in accordance with ASTM E84,a standard used solely to measure and describeproperties of products in response to heat andflame under controlled laboratory conditions.The resulting numerical values—reportedto the nearest 5 rating—are not intended toreflect hazards presented by this or any othermaterial under actual fire conditions.Electrical: Electrical service boxes, switches andoutlets can increase sound transmission if placedback-to-back. Position them on well-insulatedinterior walls, not on party or corridor walls.Seal the perimeter: Use a nonhardening caulksuch as a butyl rubber-based compound to sealwalls at both top and bottom plates. Two layersof properly staggered wallboard, with jointcompound and tape, will effectively seal cornerswhere required.Special: Unfaced Thermal Batt Insulation shouldnot be used for applications where it could besubject to human contact because of the potentialfor skin irritation.PRODUCT 98%APPLIES TO UNFACED PRODUCTAPPLIES TO UNFACED PRODUCTINSULATION SYSTEMS FOR COMMERCIAL BUILDINGS PAGE 7

SONOBATTS INSULATIONFIBERGLASS INSULATION–PRODUCT DATADESCRIPTION & USES Unfaced Kraft-Faced Designed and sized for application overstandard suspended ceiling tiles, they controlnoise and improve the thermal performance ofceiling systems. Sonobatts flexible fiberglass insulation isavailable in R-values* ranging from 11 to 38 andeither unfaced or kraft-faced in thicknesses from31 2" to 12".FEATURES & BENEFITS Ideal for renovation and remodeling projects;install in suspended ceiling systems by simplylaying the product on top of the ceiling panels. Because of the excellent thermal resistanceof Sonobatts insulation, it may be possible toreduce the size and/or operating cost of HVACequipment. Significantly improves ceiling STC ratings by 4 to10 points. Sonobatts insulation has been testedfor air erosion (according to UL 181) and can beused in a return air plenum at air velocities upto 1,000 fpm for acoustical benefit.DESIGN CONSIDERATIONS For Sonobatts insulation to improve energyefficiency when installed on suspended ceilingsystems, the building envelope must block themovement of air from the outdoor environmentto the conditioned space. Do not rely on theinsulation or its facing to provide an air barrier. Minimizing the number of penetrations inthe ceiling will help to maximize thermalperformance. Large (4' x 4') ceiling panels andsurface-mounted lighting can be used to reducepenetrations and improve thermal performance. Using the area above the insulation as areturn air plenum would render the insulationthermally ineffective, as the air above the ceilingwould be at the same temperature as the roombelow. In return plenum applications, thermalinsulation would best be added at the side wallsand roof.SONOBATTS INSULATION TECHNICAL DATAWIDTH24" 60924" 60924" 60924" 609LENGTH48" 121948" 121948" 121948" 1219mmmmmmmmNote: Unfaced Sonobatts insulation complies with the property requirements of ASTM C665, Type I and ASTME136. Kraft-faced Sonobatts Insulation complies with the property requirements of ASTM C665, Type II, Class C.SURFACE BURNING CHARACTERISTICS/BUILDING CODE CONSTRUCTION CLASSIFICATIONSPRODUCT TYPESFLAME SPREADSMOKE DEVELOPEDICBOBOCASBCCIICC10N/R10N/RAll TypesIII, IV, VAll TypesIII, IV, VAll TypesIII, IV, VAll TypesIII, IV, VUnfacedKraft-FacedSonobatts insulation complies with the International Building Code (ICC), Uniform Building code (ICBO), NationalBuilding Code (BOCA) and Standard Building Code (SBCCI) model code requirements for building constructiontypes listed above. Kraft facing on Sonobatts insulation will burn and must not be left exposed. The facing mustbe installed in substantial contact with an approved ceiling construction material. Protect facing from open flame orheat source.VAPOR RETARDERSPerms Maximum1WATER VAPOR SORPTIONMaximum by WeightDIMENSIONAL STABILITYLinear ShrinkageAIR EROSIONAir Velocities per UL 181 up to 1000 fpmKRAFT15%Less than 0.1%Less than 0.1%1. Products are tested in accordance with: R-valueSurface Burning CharacteristicsPerm Rating Kraft facings on this insulation will burn andmust not be left exposed. Facing should beinstalled in substantial contact with an approvedceiling construction material.INSTALLATION Easily installed by simply laying them on topof the ceiling panel and suspension system. FitSonobatts together tightly to reduce heat loss. Keep product dry during storage, shippingand installation.ASTM C518ASTM E84ASTM E96APPLICABLE STANDARDS Refer to the ceiling system manufacturer’srecommendations for maximum backloadingand for information on fire-resistance ratedfloor or roof-ceiling assemblies. Adding insulation inside a structure’s perimeterexposes the exterior building materials togreater temperature extremes and expansionand contraction forces.PAGE 8R-VALUE(1)38.030.019.011.01. R-values differ. Find out why in the seller’s fact sheet on R-values. Higher R-values mean greater insulating power. For acoustical control in floor-to-ceilingpartition systems, insulation placed at thetop of a suspended ceiling will reduce thetransfer of sound over the partition. If thermalperformance is not a factor, the area above theinsulation may serve as a return air plenum.* R-values differ. Find out why in the seller’s fact sheet onR-values. Higher R-values mean greater insulating power.THICKNESS12" 305 mm91 2" 241 mm61 4" 159 mm31 2" 89 mmmmmmmmmm Tests conducted according to ASTM C18 wereused to determine thermal resistance values. Thelisted R-values* are for insulation only. Sonobatts insulation complies with ASTMC665, Type I and ASTM E136 (unfaced) andwith ASTM C665, Type II, Class C (kraft-faced.) The surface burning characteristics forSonobatts insulation were derived fromproducts tested in accordance with ASTM E84,a standard used solely to measure and describeproperties of products in response to heat andflame under controlled laboratory conditions.The resulting numerical values—reportedto the nearest 5 rating—are not intended toreflect hazards presented by this or any othermaterial under actual fire conditions. Tests conducted in accordance with ASTM E96(desiccant method) were used to produce thevapor retarder permeance of the kraft facingson Sonobatts insulation.PRODUCT 98%APPLIES TO UNFACED PRODUCTAPPLIES TO UNFACED PRODUCTAPPLIES TO FACED PRODUCTPRODUCT 57%APPLIES TO KRAFT-FACED PRODUCT1-800-GET-PINK www.owenscorning.com

CURTAINWALL INSULATIONFIBERGLASS INSULATION–PRODUCT DATADESCRIPTION, USES & DESIGNCONSIDERATIONSCURTAINWALL INSULATION/CW 225 TECHNICAL DATA Unfaced Faced (FSK) Provides thermal performance in curtainwallspandrel systems when placed between orover framing members and held in place withmechanical fasteners. Semirigid, board-like fiberglass insulation isavailable unfaced or FSK (foil-reinforced kraft)faced in thicknesses from 1" to 4". (Evaluate theuse of vapor retarders based on the projectrequirements.) Equip curtainwall buildings with sprinklersystems for fire protection as required bybuilding codes.FEATURES & BENEFITS The standard size is 24" x 48"; nonstandardlengths and widths are available. Accommodates most thermal specifications. Will not decay or slump within the wall cavity,and its fibers will not shrink or warp.INSTALLATION Impaling pins, if used, should be 3" to 8"from the edges. Follow pin manufacturer’srecommendations. Cut with a utility knife and fit into irregularlyshaped areas. Install on impaling pins, friction-fitbetween furring strips, or install with appropriateadhesive. Seal joints and repair facing tears andpunctures with a pressure-sensitive foil tape.DENSITY 2.25 PCF—K-VALUE .23WIDTH24" 609 mm24" 609 mm24" 609 mm24" 609 mm24" 609 mm24" 609 mm24" 609 mmLENGTH48" 121948" 121948" 121948" 121948" 121948" 121948" 1219THICKNESS4" 102 mm31 2" 89 mm3" 76 mm21 2" 64 mm2" 51 mm11 2" 38 mm1" 25 . R-values differ. Find out why in the seller’s fact sheet on R-values. Higher R-values mean greater insulating power.Note: CW 225 FSK-faced is not available in 1" thicknesses. Contact your Owens Corning sales representative forcomplete details on size availability and minimum order quantities.SURFACE BURNING CHARACTERISTICS/BUILDING CODE CONSTRUCTIONCLASSIFICATIONSPRODUCT TYPESUnfacedFSKFLAME SPREAD2025SMOKE DEVELOPED2050ICBOAll TypesAll TypesBOCAAll TypesAll TypesSBCCIAll TypesAll TypesICCAll TypesAll TypesCurtainwall Insulation/CW 225 complies with the International Building Code (ICC), Uniform Building Code(ICBO), National Building Code (BOCA) and Standard Building Code (SBCCI) model code requirements forbuilding construction types listed above.VAPOR RETARDERSPerms Maximum1WATER VAPOR SORPTIONMaximum by WeightDIMENSIONAL STABILITYLinear Shrinkage at Maximum Use TemperatureFSK.025%Max. 2%1. Products are tested in accordance with: R-valueSurface Burning CharacteristicsPerm RatingASTM C518ASTM E84ASTM E96PERIMETER FIRE CONTAINMENT JOINT1Up To48" Keep product dry. Use adhesives appropriate for lightweight boardinsulation. Follow manufacturer’s recommendations.APPLICABLE STANDARDS ASTM C518 tests determined R-values. ListedR-values are for insulation only.*Up To96"Recommended impaling pin pattern. Pinsshould be located 3" to 8" from the edge(s)of the board. Surface burning characteristics were determinedwith ASTM E 84, a standard used solely tomeasure and describe properties of productsin response to heat and flame under controlledlaboratory conditions. The results are notintended to reflect hazards presented underactual fire conditions. Complies with ASTM C612, Type 1A/1B. ASTMC 612 replaces Federal Specification HH-I-558B.1. See approved System Listing Directories for fullsystem details. NRC data produced through ASTM C423 testing. Facing permeance determined through ASTME96 (desiccant method) and the MEA 87-84requirements of New York City.* R-values differ. Find out why in the seller’s fact sheet onR-values. Higher R-values mean greater insulating power.INSULATION SYSTEMS FOR COMMERCIAL BUILDINGS PAGE 9

FIBERGLAS 700 SERIES INSULATIONFIBERGLASS INSULATION–PRODUCT DATADESCRIPTION & USESSPECIFICATION COMPLIANCE Unfaced FSK-faced (Foil-Scrim Kraft) ASJ (All Service) Flexible, semi-rigid and rigid rectangular boardsformed from inorganic glass fibers with athermosetting resin binder. 701, 702, 711—Unfaced, lightweight, resilientinsulation in a sheet form, used on vessels withirregular surfaces where an exterior finish willbe supported mechanically. 703, 704—Semi-rigid boards for use onequipment, vessels and air conditioningductwork. Available unfaced, with factoryapplied FSK, ASJ or vapor retarding facings. 705—High-strength, rigid board for use onequipment where high abuse resistance andgood appearance are required. Availableunfaced or with factory-applied FSK, ASJ orvapor retarding facings. 707—For acoustical wall panels and specializedceiling applications.FEATURES & BENEFITSASTM C553, Mineral Fiber Blanket Thermal Insulation, Types I, II, III—Type 701, 711ASTM C612, Mineral Fiber Block & Board Thermal Insulation, Types IA, IB—Types 702, 703, 704, 705, 707ASTM C795, Thermal Insulation For Use Over Austenitic Stainless Steel1ASTM C1136, Flexible Low Permeance Vapor Retarders for Thermal Insulation, Type I: ASJ; Type II: FSKNuclear Regulatory Commission Guide 1.36, Non-Metallic Thermal Insulation1New York City MEA No. 227-83—Types 703 & 705, plain and FSK-facedCAN/CGSB-51.10—Type I, Class I–Types 703, 7042NFPA 90A and 90BCalifornia Insulation Quality Standards CA-T0521. Preproduction qualification testing complete and on file. Chemical analysis of each production lot required for totalconformance.2. Standard obsolete, replaced by ASTM C612.PHYSICAL PROPERTY DATAPROPERTYEquipment Operating TemperatureLimitationInsulation Jacket Temperature LimitationJacket PermeanceJacket Puncture ResistanceCompressive Strength (Minimu

Owens Corning commercial building insulation products provide solutions for maximizing protection from the elements and minimizing noise. With a full range of products to meet every insulation need, from Fiberglas 700 Series Insulation for energy savings to Sound Attenuation Batt Insulation for noise reduction, these proven products