Transcription

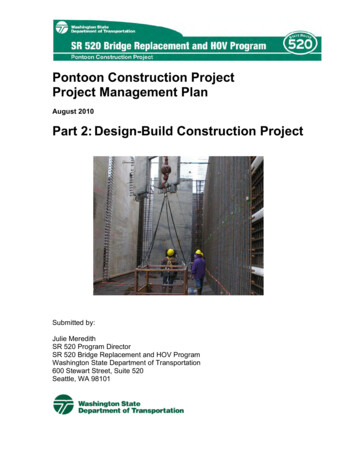

Pontoon Construction ProjectProject Management PlanAugust 2010Part 2: Design-Build Construction ProjectSubmitted by:Julie MeredithSR 520 Program DirectorSR 520 Bridge Replacement and HOV ProgramWashington State Department of Transportation600 Stewart Street, Suite 520Seattle, WA 98101

Table of ContentsPROJECT ENDORSEMENT . 31. PROJECT DESCRIPTION . 51.11.21.31.4INTRODUCTION . 5PROJECT SCOPE . 5MISSION STATEMENT OF THE PONTOON CONSTRUCTION PROJECT: . 6MAJOR MILESTONES . 62. TEAM ALIGNMENT. 72.12.22.32.42.52.6TEAM VISION. 7VALUES . 7MEASURES OF SUCCESS . 7TEAM IDENTIFICATION . 7ORGANIZATION CHART . 8ROLES AND RESPONSIBILITIES . 83. BUSINESS ADMINISTRATION AND PROJECT CONTROLS . .153.163.173.183.193.203.213.223.23BUSINESS GROUP STAFF RESPONSIBILITIES . 12CONTRACT COMPLIANCE . 13CHANGE MANAGEMENT . 14SCHEDULING ANALYSIS . 15FINANCE AND BUDGET. 16RISK MANAGEMENT . 16PERFORMANCE MEASURES . 16CONTRACTOR PAYMENTS . 17REPORTING . 17OFFICE MANAGEMENT. 17DOCUMENTATION . 17PROJECTWISE . 18CENTRIC PROJECT . 18PROJECT CLOSEOUT . 18FINAL RECORDS. 19DESIGN DOCUMENTATION . 19CONSTRUCTION RECORDS . 19PERMANENT FINAL RECORDS . 20TEMPORARY FINAL RECORDS . 21ADMINISTRATIVE RECORDS . 21FINAL RECORDS PREPARATION . 21FINAL RECORDS STORAGE . 22OFFICE CLOSEOUT. 224. COMMUNICATIONS PLAN . 234.14.24.34.4PROGRAM . 23DESIGN-BUILDER . 23INTERNAL . 24EXTERNAL . 25Pontoon Construction Project – Project Management PlanPart 2: Design-Build ConstructionData Date: August 2010Page 1

4.54.64.7KEY AUDIENCES . 25KEY ISSUES . 28PUBLIC PERCEPTION . 295. ENVIRONMENTAL DOCUMENTATION AND PERMITTING . 306. QUALITY MANAGEMENT APPROACH . 327. DESIGN OVERSIGHT PLAN . 337.17.27.3DESIGN-BUILD ALIGNMENT . 33DESIGN REVIEWS . 33QUALITY OVERSIGHT . 348. CONSTRUCTION OVERSIGHT . 358.18.28.3CONSTRUCTION QUALITY PARTNERING PROCESS . 35CONSTRUCTION OVERSIGHT AND AUDIT PROCESS . 36INDEPENDENT QUALITY VERIFICATION PROCESS . 389. ENVIRONMENTAL COMPLIANCE OVERSIGHT . 399.19.29.39.49.59.69.79.8GOALS . 39TEAM IDENTIFICATION . 39ROLES AND RESPONSIBILITIES . 40ENVIRONMENTAL COMPLIANCE OVERSIGHT PARTNERING PROCESS . 40ENVIRONMENTAL OVERSIGHT AUDIT PROCESS . 41ENVIRONMENTAL OVERSIGHT TOOLS AND STRATEGIES . 42INTERNAL COMMUNICATIONS . 44EXTERNAL COMMUNICATIONS . 4510.SAFETY . 4610.110.210.310.4SAFETY PROCESS . 46OFFICE SAFETY . 46ON-SITE SAFETY . 47TRAFFIC MANAGEMENT . 4711.11.111.211.311.411.511.6TRANSITION PLAN AND PROJECT CLOSURE. 48PHASING OUT OF CONSULTANT RESOURCES . 48TRANSITION OF SR 520 PROJECT STAFF . 48TRANSITION OF OLYMPIC REGION STAFF . 48PROJECT PHASES . 48EMPLOYEE TRANSITION PLAN . 49EMPLOYEE DEVELOPMENT . 50APPENDIX 1:CONTACT LISTAPPENDIX 2:RESPONSIBILITY MATRICES AND TASK FORCE ASSIGNMENTSAPPENDIX 3:RISK MATRIX FORMAPPENDIX 4:PROCESS DOCUMENTSAPPENDIX 5:SR 520 PROGRAM CHARTERPontoon Construction Project – Project Management PlanPart 2: Design-Build ConstructionData Date: August 2010Page 2

Pontoon Construction Project – Project Management PlanPart 2: Design-Build ConstructionData Date: August 2010Page 4

1. PROJECT DESCRIPTION1.1IntroductionThe SR 520 Pontoon Construction Design-Build Project has several uniquefeatures that make it different from the way WSDOT traditionally managesconstruction projects. These unique features present both challenges andopportunities for successful implementation of the project.At the time of bid opening, the project was the largest bid opening in WSDOThistory. Design-Build is an alternative project delivery method for WSDOT andhas been used on several WSDOT projects to date. It is also the first project inthe United States that has been awarded prior to the completion of NEPAEnvironmental Impact Statement and Record of Decision. Additionally, theWSDOT project team will blend teams from different WSDOT regions.A Project Management Plan (PMP) was prepared in July 2009 for the pre-awardphase of the pontoon construction facility and pontoons. Subsequently, theschedule for procurement was accelerated. A request for proposal was issuedon August 24, 2009 and the contract was executed on February 12, 2010. ThisDesign-Build Project Management Plan will be implemented for the design-buildcontract phase of the project and serves as Part 2 of the overall updated PMP.This Project Management Plan (PMP) will describe the general responsibilities ofthe Project Team. In addition to the PMP several plans will be developed andimplemented to ensure compliance with this PMP as well as State and Federalpolicy. The specific plans will include processes, flow diagrams, responsibilitymatrices, organizational charts, and other pertinent information to guide theproject staff.1.2Project ScopeThe SR 520 Pontoon Construction Project is a Design-Build (DB) project underthe oversight of the SR 520 Bridge Replacement and HOV Program. KiewitGeneral (K-G) was selected as the Design-Builder through a competitive designbuild procurement process.The purpose of the Pontoon Construction Design-Build Project is to deliverpontoons needed to replace the existing traffic capacity of the SR 520 EvergreenPoint Bridge. The pontoons will be stored in case they are needed forcatastrophic failure response, or until they can be incorporated into the proposedEvergreen Point Bridge replacement.To achieve this purpose, this project will build a new casting basin facility thatcan accommodate simultaneous construction of multiple pontoons and constructthe pontoons needed for the first phase of the proposed bridge replacement.WSDOT intends to maintain the availability of the proposed facility forPontoon Construction Project – Project Management PlanPart 2: Design-Build ConstructionData Date: August 2010Page 5

construction of additional pontoons needed to accommodate foreseeableimprovements to the Evergreen Point Bridge.When the facility is no longer needed to build SR 520 bridge pontoons, WSDOTwould maintain the facility while adhering to environmental regulations applicableto the site and facility until decisions are made about the facility’s future. Optionsfor the facility include 1) reopen the facility for future unforeseen WSDOTpontoons or other types of construction projects, 2) sell the property with theimprovements, or 3) decommission the facility and restore the site to its previouscondition before development before selling it. Any future uses of the facility,including decommissioning, will require a new and separate environmental andpermitting process with public input.1.3Mission Statement of the Pontoon Construction Project:Deliver high quality pontoons for timely replacement of the SR 520 FloatingBridge employing the highest standards for stewardship of public resources andthe environment.1.4Major Milestones Contract Award . January 2010 Contract Execution . February 2010 Record of Decision . January 2011 Casting Facility Construction . January 2011Update, December 2010: Construction will begin after all permits are received, which isexpected to be within two to four months after ROD signature. Operationally Complete . October 2011 Cast Pontoons. November 2011 Final Contract Completion . March 2014Update, December 2010: Contract and project closeout to be completed by the end of2014.Pontoon Construction Project – Project Management PlanPart 2: Design-Build ConstructionData Date: August 2010Page 6

2.TEAM ALIGNMENT2.1Team VisionSet the WSDOT standard for managing design-build projects.2.2ValuesWe value leading the Project with a commitment that allows for nothing butsuccess. By embracing new ideas, working well with our partners, meetingchallenges with enthusiasm, and serving as positive advocates for the project,we will provide the leadership required for exceptional delivery.We value managing the Project well by clarifying our priorities, definingexpectations and directing all efforts toward addressing the most critical issuesfirst. Working hard to determine what must be done to guide potential towardopportunity will provide the focus we need to succeed.We value the resources entrusted to us. By developing and recognizing ourstaff, practicing fiscal responsibility, measuring and reporting on performance,delivering what we promise, keeping to a schedule, and communicating withhonesty and transparency, we will demonstrate our integrity.2.3Measures of Success Safety: No Recordable or lost time injuries and reportable injuries lowerthan the industry average Schedule: Meet or beat established project milestones Budget: Manage risks to contain costs within budget Quality: Conform to project requirements without adverse effects onmilestones or budget Environmental Compliance: Complete project without permit violations Public Perception: Strong community support through effectivecommunication2.4Team IdentificationDelivery of the PCP is accomplished by a team assembled specifically for thisproject. The Team consists of members from the SR520 Program, OlympicRegion, and Headquarters.Pontoon Construction Project – Project Management PlanPart 2: Design-Build ConstructionData Date: August 2010Page 7

2.5Organization ChartProject DirectorB. DyerWMS4520 CommunicationsSR 520 Pontoon ConstructionDesign-Build Project TeamJuly 2010Principal EngineerD. ZieglerWMS4 3W076PIOJ. IrwinCC-2Business ManagerJ. DanksSecretary SeniorJ. SchlongaSS30550CN PED. MatlockWMS3 3W105Design PEB. ClarkeWMS3 3W012Ass’t. CN PEG. SanoyWMS2 3W106Ass’t Design PEC. LavraWMS2Asst. Business MgrM. MinerTE430627Pontoon Field EngT. CushmanTE33P134Site Civil Field EngineerTE3Quality OversightD. DavisTE33P135Environ. ManagerD. DaviesTPS4 3P137Bridge SupportP. ClarkeDesign OversightJ. SlavicekTE3Contract Compl.EngineerI. NathTE132040CN OversightTE2CN OversightTE2Ass’t Quality OversightTE2EnvironmentalComplianceTPS3/TE2Bridge SupportT. MessmerDesign OversightD. MuehlbauerTE2Change EngineerVacantTE2CN OversightTE2CN OversightTE2VI Mats TestingTT2Env. Support NEPAL. AmtmannBridge SupportE. FerlugaAdmin. Asst.K. SchimelfenigCN OversightTE2Office Engineer LiaisonTE2VI Mats TestingTT2Env. Support PermitsS. WhiteGeotech SupportB. HeggeVI Mats TestingTT2Env. Support ESAC. CzieslaProject ControlsA. FriedrichDesign OversightB. HarrisElectrical/MechSupportEnv. Support Cultural ResourcesTBDFill as Needed2.6Roles and ResponsibilitiesA project leadership team has been formed consisting of the Design-BuildDirector, Principal Engineer, Business Manager, Project Engineers and AssistantProject Engineers to provide project team leadership operating under thefollowing guidelines:Pontoon Construction Project – Project Management PlanPart 2: Design-Build ConstructionData Date: August 2010Page 8

1. Create an intention of becoming the best functioning team in theorganization.2. Remain positive, be supportive, strive for high performance3. Recognize each other’s successes.4. Individual success on this team depends on the whole team’s success; sothink of the team’s needs first to guarantee your own success.5. Improve coordination, communication & productivity by measuring teamprocesses and evaluating the way in which each manager is performingtheir job.6. See what is necessary and begin doing it.7. Ask yourself whether everything you do or assign to others is meaningfulaction or pointless activity.8. Have the courage to take risks to continue on your path to selfimprovement.9. Ensure everyone receives clear expectations, guidance and coaching.10. Be concerned about the impact your decisions have on others.11. Hold effective team meetings where information is shared, decisions aremade and action is taken to make progress or priorities.Each member of the leadership team is given responsibility for leadership andmanagement of the functional groups within the project team.Senior LeadershipBob Dyer, Design-Build DirectorDave Ziegler, Principal EngineerResponsible for the following: Overall leadership for Business/Construction/DesignPersonnel issues and recruitmentCoordination among teamsMentoring and coaching of team membersLiaison with Design-Build leadershipExternal CommunicationsCommunication with WSDOT executive-level managementDispute resolution and communication within project leadership teamForecasting issues before they become issuesBusiness GroupJon Danks, Business ManagerResponsible for the following: Project Management PlanBudget reporting and paymentsSchedule analysis and reportingProject status reportingPontoon Construction Project – Project Management PlanPart 2: Design-Build ConstructionData Date: August 2010Page 9

Risk identification and analysisPrimary contact with D-B for compliance and paymentsProcess and negotiate change ordersEnsure compliance with State and federal laws and regulationsChange managementProject documentationProject closeoutDesign OversightBrenden Clarke, Design Project EngineerChristine Lavra, Design Assistant Project EngineerResponsible for the following: Design oversight through participation on task force teamsDesign-side quality auditsLiaison with construction and business groupsCoordinate environmental support through NEPA and until permitsgrantedCoordination with WSDOT support groups, including Bridge & StructuresManagement of design and environmental consultant task ordersUse PE model for division of responsibilitiesPE focused on liaison/communications, environmental, & pontoonsAssistant focused on casting facility and site development, consultantcontractsPontoon Construction Project – Project Management PlanPart 2: Design-Build ConstructionData Date: August 2010Page 10

Construction OversightDewayne Matlock, Construction Project EngineerGaius Sanoy, Construction Assistant Project EngineerResponsible for the following: Verification, manage construction quality groupProviding WSDOT constructability perspective during design phaseEnsure Design-Builder meets specifications and work activities arecompliant with safety requirementsAlign with Design-Builder whether it’s at task force level or point of contactVerify schedule progress in support of contractor paymentsField solutions to problemsLiaise with WSDOT support groups during construction phaseTraditional construction office—work as a team but focus:o PE—pontoon constructiono APE—casting facilityEnvironmental complianceSafetyPontoon Construction Project – Project Management PlanPart 2: Design-Build ConstructionData Date: August 2010Page 11

3.BUSINESS ADMINISTRATION AND PROJECTCONTROLSThe Business Group (BG) was established to lead and manage all businessaspects of the project including budget and cost, risk analysis, schedule trackingand analysis, contractor payment, change management, contract compliance,reporting, and all office administration and document control. The BG willdevelop performance measures in conjunction with the other managers on theteam and report on all job performance on a monthly basis.Goals within the Business Group include: Developing and implementing effective business processes Providing resources and tools to assist the entire team Completing change management in a thorough and timely manner Meeting established BG performance measures Communicating well within and outside the group and project Ensuring compliance and being accountable for all businessresponsibilitiesMuch of what the BG manages and is responsible for is typically consideredOffice Engineering and/or Project Controls, however, to better describe thesefunctions the following subcategories are used, which for the most part, alignswith staff assignments.3.1Business Group Staff ResponsibilitiesThe list below is the anticipated staffing level needed at the peak of the project.Until that workload is reached, duties listed for some of the positions may becombined into fewer positions.Business ManagerOverall responsibility for all Business functions. Work closely with SR 520 DBDirector, Principal Engineer, Design-Builder, 520 Team, Region and HQ toensure plans and data are managed properly to achieve goals.Pontoon Construction Project – Project Management PlanPart 2: Design-Build ConstructionData Date: August 2010Page 12

Assistant Business ManagerResponsible for the Office Engineering and Management team including contractcompliance, office management, documentation, cost, change management, andperformance measures.Change EngineerResponsible for overall change management process including developingestimates, analyzing DB proposals and creating change documents.Contract Compliance EngineerEnsure compliance with Project, State, and Federal requirements. Responsiblefor document control including final records oversight.Project Controls EngineerResponsible for scheduling analysis and assist in reporting.Administrative Assistant/Reporting EngineerResponsible for developing, preparing and distributing reports and assisting in alladministrative matters.Secretary(s) and Office Assistant(s)Support entire project team and ensure office and staff follow establishedprocedures including employee orientation and training, accounts payable, officesupplies, payroll, mail distribution, vehicle coordination and all other officefunctions.3.2Contract ComplianceThe Business Group will establish processes to ensure contract compliance.This includes requirements for the Design-Builder as well as compliance byWSDOT in State and FHWA matters. WSDOT project staff will track requireddocumentation in areas including: Equal Employment Opportunity (EEO) Disadvantaged Business Enterprise (DBE) Certified Payroll / Minimum Wages Subcontractor Compliance including Sublet Documents Foreign Steel Allotments Review and track American made materialsPontoon Construction Project – Project Management PlanPart 2: Design-Build ConstructionData Date: August 2010Page 13

3.3Change ManagementThe change management (CM) process will document all changes to theContract in accordance with project and all standard WSDOT policies andprocedures. Changes will include change orders and claims resulting from eitherthe design or construction phases of the Contract.Information systems used to administer and track changes to the Contract, willinclude CCIS and project detailed documentation and tracking. Centric Project,an on-line collaboration tool will be used by WSDOT and the Contractor.The Business Group, in conjunction with the Construction and Design teams, willevaluate change proposals in a collaborative effort with the DB. A final processwill be developed that includes: 1) Issue Initiation, 2) Change Management, and3) Change Order Execution. During Issue Initiation, potential changes areidentified, a technical review is completed, change approval is granted, andapproval is issued to the Contractor to proceed with the change. The primarymethods within change management may include: Request for Information (RFI)Process, Request for Change (RFC) Process, Request for Proposal (RFP)Process, and other processes as defined specifically for design-build projects.Depending on the type of change, Value Engineering Change Proposals (VECP)will be used.Once change approval has been received Change Management is initiated todocument, track, and allow further evaluation prior to assigning a change ordernumber within CCIS. This interim phase is used by the Business Group to detailthe development of cost information and negotiations on the value of the change.Once all change approvals have been documented and the value of the changenegotiated, the Change Order Phase is used to complete the change orderdocumentation based on the following process: Set up New Change Order inCCIS, Add CO document in project system, Develop CO Checklist, Draft COBody, Draft Memo to Olympia, Review, Approval, and Execution. Potential andrealized changes will be communicated to Program to ensure budget impacts aremonitored and addressed.As the project processes are further developed the "WSDOT DB Project DeliveryGuidance Statement for Change Orders" will be used. A few key differencesfrom typical Design-Bid-Build projects are: Change must be written; oral orders will not be used Equal or Better proposed changes are at the sole discretion of WSDOTand are not subject to partnering, consideration by the DRB, or appeal Category A Changes can only be changed through Value EngineeringChange Proposals or WSDOT directed changes. This type of changeapplies to the General Provisions, Mandatory Standards, BasicConfiguration, and Proposal documents. Change Order form shall bePontoon Construction Project – Project Management PlanPart 2: Design-Build ConstructionData Date: August 2010Page 14

used. Basic Configuration Changes can be either "Necessary" or "D-BProposed" Category B Changes can only be changed through a Design-BuilderProposed Change or a WSDOT directed change. This type of change isfor Technical Requirements, Standard Specifications, Special Provisions,and Amendments to the Special Provisions. Approval and Execution Authorityo Project Engineer approval is required for all Contract changes.Execution may be delegated if checklist items 1-7 are not included.o The Principal Engineer will provide Region approval when requiredfor Contract changes. Execution may not exceed 500,000 or 30days.o State Construction Engineer approval/execution is per the checklistand delegation to Assistants may be done.o FHWA shall be involved per 1-2.4C(3)(I)[1] of the ConstructionManual. Change Order forms - use CO Form and DB Minor Change FormFor issues that cannot be resolved by the change process, Sections 1-09.11through 1-09.13 of the General Provisions addressing Disputes and Claims willbe followed.3.4Scheduling AnalysisThe scheduling processes and requirements provide several uses and benefitsand enable WSDOT to 1) understand KG’s plan to deliver the project within thetime allowed, 2) plan WSDOT work force and other resource requirements, 3)advise the public and executive staff of major milestones, and 4) enable theProject Team to actively manage impacts to the Contract. To accomplish theseobjectives, each month KG submits an update to the Critical Path Method (CPM)schedule, which shows the manner by which KG intends to prosecute the workthrough physical completion within the specified contract time.To supplement the “big picture” CPM schedule, KG produces site-specific, 5week and 120-day schedules. The 5-week schedules provide “as-built” dates forthe construction activities performed the previous week and a 4- or 5-week lookahead for activities to be performed. The 120-day schedule gives a detailed fourmonth look-ahead for construction activities.To actively manage potential impacts to the highly critical schedule, WSDOToffice and field staff will closely track and document actual progress anddeviations from intended progress. Specifically, field engineers and inspectorswill need to document—in the Inspector’s Daily Report (IDR)—issues or eventsPontoon Construction Project – Project Management PlanPart 2: Design-Build ConstructionData Date: August 2010Page 15

that delay progress toward completion. Office staff will collect and incorporatethese deviations in schedule analysis tools to determine the scope of immediateand potential impacts.3.5Finance and BudgetA project budget has been developed through a "bottoms-up" estimate andincludes the primary ingredients of the DB contract am

Pontoon Construction Project - Project Management Plan Part 2: Design-Build Construction Data Date: August 2010 Page 5 1. PROJECT DESCRIPTION 1.1 Introduction The SR 520 Pontoon Construction Design-Build Project has several unique features that make it different from the way WSDOT traditionally manages construction projects.