Transcription

REDEFININGHANDPROTECTIONCATALOGUE 2020

PROTECTION DEXTERITY GRIP SAFETYAt Wonder Grip , we believe that optimal hand safety is the result of the combination of these 3elements. Always striving to perform beyond customers’ expectations, our gloves offer the highest levelof dexterity and grip in their categories. Wonder Grip gloves are redefining hand protection.-2-PROTECTIONDEXTERITYGRIPWonder Grip offers the bestprotection for the job at hand.Each Wonder Grip glove isdesigned to give the highestlevel of performance, from alight protective glove to a highlytechnical cut resistant glove. Eachstep of our research, developmentand manufacturing process ismet with the same philosophy ofnever compromising. Every glovegoes through a thorough qualitycheck at multiple stages of themanufacturing processes. All glovesare tested for compliance to ANSIand EN388 for cut resistance andmechanical risks.Wonder Grip ’s philosophy is tooffer our customers the best gloveswithout compromise.We strive to offer our customersproducts that go beyond theirbasic protection function, offeringunrivalled levels of comfort anddexterity. Each Wonder Grip modelis designed and manufacturedwith the same utmost attentionto detail. Our gloves are formedon an ergonomic mold shapereproducing the natural form of aresting hand, increasing comfort andreducing fatigue when performingdemanding tasks. Our gloves arewashed 3 times to ensure a softerfeel and proper fit. Our WonderGrip knit wrist goes higher on thehand than our competitors’ gloves, toensure a snug fit in all conditions. Ourdesign and manufacturing processfocuses on fit and flexibility, allowingusers to be better at their job whileprotecting them from job hazards.Wonder Grip gloves are finishedwith our in-house engineeredcoating: Wonder Grip Technology ,Wonder Grip Performance ,HDML , Xtended PerformancesXP! They all benefit from a uniquecomposition designed toincreases the coefficient of friction,maximizing the grip in dry, oily andwet environment. Wonder Grip augmented grip reduces the forcerequired when performing physicaltasks, reducing ergonomic stressand fatigue, thus contributing toincrease productivity and reduceinjuries.Our factory, located in Dongtai, China, has acquired ISO9001, ISO 14001 and OHSAS 18001 certifications. All theproduction processes - from raw materials to the finalproduct - are managed at high standards. Our factorypossesses the latest production facility to maintain acontinuous supply of products of the highest quality.ISO 9001ISO 14001OHSAS 18001Our ISO 9001 certification meansthat our organisation satisfies allprerequisite conditions for anefficient and appropriate qualitymanagement system.Wonder Grip’s policy towardscontinuous improvement enables usto guarantee that our products aremanufactured according to strictquality requirements.ISO 14001 certification is aninternationally renowned standardfor corporate environmentalmanagement. Thanks to WonderGrip’s advanced EMS system, wecan control our impact on theenvironment.ISO 14001 certification is accreditedby UKAS.Wonder Grip was awarded OHSAS18001 accreditation thanks to itscommitment to building a greenerfuture, respectful of the safety andthe well-being of all its staff membersand their families.-3-

EUROPEANSTANDARDSfor protective glovesWonder Grip organises its research and development activities around three key themes: coating mixes, weavingtechniques and mould ergonomics. In recent years, Wonder Grip has actively adopted a systematic patentapplication approach, in order to guarantee the authenticity of its products’ unique characteristics and theirassociated technologies.EN511:2006EN 420:2003 A1:2009GENERAL REQUIREMENTSabcThe pictogram indicates that the user has to consult the Instructions of use.This standard measures how well the glove can withstand bothconvective cold and contact cold. In addition, water permeation istested after 30 minutes.The performance levels are indicated with a number from 1 to 4 nextto the pictogram, where 4 is the highest level.EN 420 lays out the general requirements of most types of protectivegloves as: ergonomy, construction (PH neutrality: shall be greater than 3.5and less than 9.5, amount of detectable Chrome v1, less than3mg/kg andno allergenic substances), innocuousness and comfort (size).Dexterity following to handle pins defined from 5mm to 11 mm: level 1 to 5.Performance level:- Protection against convective cold (0 to 4)- Protection against contact cold (0 to 4)- Water impermeability (0 or 1)If requested, electrostatic properties must be measured according to EN16350:2014 and test procedure 5.5 - EN 1142:1997 clause 7. Indications ofperformances (1 minimum to 4 very good) even 5 for cut protection.“0” : level 1 was not reached“X” : test was not performedSelection of the protective glove size according to hand lengthGlove sizeMinimal length abcdefEN 388:2016Why a new cut test method?PROTECTION AGAINST PHYSICALAND MECHANICAL RISKSThe Coup Test runs into problems when testing materials such ashigh-performance fabrics based on materials glass fibre or stainlesssteel, all of which have a dulling effect on the blade. Consequently,the test can yield an inaccurate result, providing a cut level that ismisleading as a truly indicative of the real cut resistance of the fabric.The TDM-100 test method is designed to better simulate real-worldsituations such as an accidental cut or slash.The figures in the table for EN standards indicate results the glovesobtained in each test. The test values are given as a six-figure code.The higher figure is the better result.Abrasion resistance (0-4), Circular blade cut resistance (0-5), Tearresistance (0-4), Straight blade cut resistance (A-F) and impactresistance (P or no mark)TEST / PERFORMANCE LEVEL0123For materials that are shown to dull the blade during an initial testsequence in the Coup Test, the new EN388:2016, will state EN ISO13997 score. From level A to level F.45a. Abrasion resistance (cycles) 10010050020008000-b. Blade cut resistance (factor) 1.21.22.55.010.020.0c. Tear resistance (newton) 1010255075d. Puncture resistance (newton) 202060100150-TEST / PERFORMANCE LEVELABCDEFe. Straight blade cut resistance(newton)2510152230f. Impact resistance (5J)-Pass P / Fail or not performed No markWonder Grip expects that hand protection will fall into one of fourcategories according to the ISO test for cut performance:- B & C: acknowledged risk. Most common applications in industriesrequiring medium cut resistance.- Abrasion: new abrasion paper will be used on the testing- E & F: Specific applications and very high risk. Very high riskand high exposure applications that demand ultra-high cutresistances As for the cut test EN388:2009, the new EN standardsaddress cut protection, but it should not be used as the sole criteriawhen selecting hand protection. Other important factors includeabrasion resistance, tactility, lifespan and comfort, which have to beconsidered as well.- A new marking with 6 performance levelsabcdefEN 407:2004PROTECTION AGAINST HEATThis standard regulates the minimum requirements and specific testmethods for safety gloves in relation to thermal risks.The performance levels are indicated with a number from 1 to 4 nextto the pictogram, where 4 is the highest level.Performance level:- Resistance to flammability (in seconds) (0 to 4)- Resistance to contact heat (0 to 4)- Resistance to convective heat (0 to 4)- Resistance to radiant heat (0 to 4)- Resistance to small splashes of molten metal (0 to 4)- Resistance to large splashes of molten metal (0 to 4)“0” : level 1 was not reached“X” : test was not performed- A: Very low risk. Multipurpose gloves.- D: High risk. Gloves suitable for applications where high cutresistance.- Impact: a new test method (fail: F or pass for areas claiming impactprotection)-4-ISO 13997RISK SEGMENTATIONEN 388:2016 What is new & whySummary of the main changes vs EN 388:2003- Cut: new EN ISO 13997, also known as TDM-100 test method. Cuttest will be graded with letter A to F for cut resistant gloveEN 511:2006PROTECTION AGAINST COLDEN ISO 374-5EN 374-5:2016CHEMICAL PROTECTIONEN 375-5:2016 : terminology and performance requirements formicro-organisms risks.This standard defines the requirement for protective gloves againstmicrobiological agents. For bacteria and fungi, a penetration test isrequired following the method described in EN 374-2:2014: air-leakand water-leak tests. For protection against viruses, compliance toISO 16604:2004 (method B) standard is necessary. This leads to newmarking on the packaging for gloves protecting against bacteria andfungi, and for gloves protecting against bacteria, fungi and viruses.EN ISO 374-1Type AabcdefEN ISO 374-1Type BEN ISO 374-1Type CabcEN 374-1:2016CHEMICAL PROTECTIONChemicals can cause seriously harm for both the personal health andthe environment.Two chemicals, each with known properties, can cause unexpectedeffects when they are mixed. This standard gives directives of how totest degradation and permeation for 18 chemicals but doesn’t reflectthe actual duration of protection in the workplace and the differencesbetween mixtures and pure chemicals.PenetrationChemicals can penetrate through holes and other defects in the glovematerial.To be approved as a chemical protection glove, the glove shall notleak water or air when tested according to penetration, EN374-2:2014.DegradationThe glove material might be negatively affected by chemical contact.Degradation shall be determined according to EN374-4:2013 for eachchemical. The degradation result, in percentage (%), shall be reportedin the user instruction.PermeationThe chemicals break through the glove material at a molecularlevel. The breakthrough time is here evaluated and the glove mustwithstand a breakthrough time of at least:- Type A – 30 minutes (level 2) against minimum 6 test chemicals- Type B – 30 minutes (level 2) against minimum 3 test chemicals- Type C – 10 minutes (level 1) against minimum 1 test chemicalCODEChemicalCas No.ClassAMethanol67-56-1Primary trile compoundDDichloromethane75-09-2Chlorinated hydrocarbonECarbon disulphide75-15-0Sulphur containing organiccoumpundAromatic ineHTetrahydrofuran109-99-9Heterocyclic and ether compoundIEthyl acetate141-78-6EsterJn-Heptane142-82-5Saturated hydrocarbonKSodium hydroxide 40%1310-73-2Inorganic baseLSulphuric acid 96%7664-93-9Inorganic mineral acid, oxidizingMNitric acid 65%7697-37-2Inorganic mineral acid, oxidizingNAcetic acid 99%64-19-7Organic acidOAmmonium Hydroxide 25%1336-21-6Organic basePHydrogen peroxide 30%7722-84-1PeroxideSHydrofluoric acid 40%7664-39-3Inorganic mineral acidTFormaldehyde 37%50-00-0Aldehyde-5-

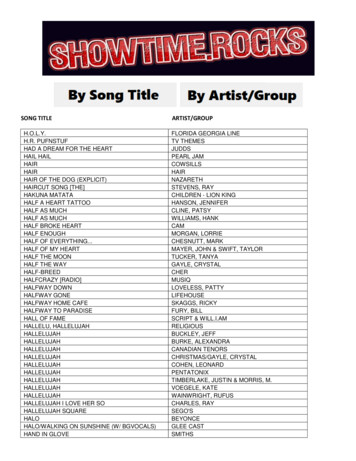

GeneralpurposeWG1857W WG-300 WG-310 WG-355 WG-500 WG-550 WG-555 WG-422 WG-522 WG-787 WG-640 WG-728L WG-718 WG-780 WG-788 WG-790 Liquids Industrialoils OP-1865 OP-765OP-775OP775HYOP-785OP-795WG-318 WG-333 WG-510 WG-528L WG-338 WG-380 WG-320 WG-538 OP-600L WG-758L WG-658L WG518W WG-733 level B Cut resistancelevel CCutresistanceChemicalHeatWG-1887 ColdPROTECTIONCut-resistanceWG1855HYlevel Dlevel E EN 407 ISO 3741 : 2016 ISO 3745 : 2016Foodcontact EN 511CutNORMS-6- resistanceCutresistance -7-

TECHNOLOGIESWonder Grip’s DNA:research, developmentand innovationOur PU coating does not derogateto Wonder Grip’ quality charter.Xtended performances XP! Smoothcoating offers excellent flexibility,uncompromising anti-wear propertiesand a superb grip in dry environment.Wonder Grip organises its researchand development activities aroundthree key themes: coating mixes,weaving techniques and mouldergonomics. In recent years,Wonder Grip has actively adopteda systematic patent applicationapproach, in order to guaranteethe authenticity of its products’unique characteristics and theirassociated technologies.At Wonder Grip, the definition ofcomfort goes beyond the feeling ofphysical ease. We strive to developunique hand protection solutionsproviding to the users a condition ofwell-being, contentment and security.The upper part of the liner is made offibres whose technical characteristicsguarantee real feeling of second skinand ensure free movement. The lowerpart of the liner is made of nylonand reinforced by a unique supportdeveloped by our R&D department. Itgoes up to the middle of the hand toensure a snug and secure fit preventingthe inflammation of joints and tendons.SZNT stay flexible and grippy inextreme cold environment, down to-20C.-8-All our gloves are produced via ourTPDT technology. Placed inside amould that reproduces the naturalshape of a hand at rest during soaking,our gloves are also washed and driedvia a method specifically developed byour in-house engineers. This methodoffers our users freedom of movementand the increased sensitivity that hasearned Wonder Grip its internationalreputation.OEKO-TEX Wonder Grip strives to constantly offerits clients more added value. One ofthe main reasons that spurred us torequest this certification was so thatwe could demonstrate that WonderGrip stands out from its competitorsthanks, not only to the technical qualityof its products, but also to the intrinsicquality of the raw materials used.Whereas certain competitors continueto use toxic solvents, which are a hazardfor production line operators and endproduct users, Wonder Grip’s differencelies in its OEKO-TEX accreditation.Wonder Grip Accreditation No.17.HCN.14623Based on this concept, Wonder Gripdeveloped a new series of linersdesigned to reduce nervous andmuscular fatigue aiming to preventmusculoskeletal disorders.Contrary to standard nitrile formula,Wonder Grip’s in-house engineeredSub-Zero Nitrile Technology is speciallyformulated to remain flexible in belowfreezing environment, so gloves will notstiffen, crack, or lose their industrial oilresistant properties.Wonder Grip enhanced its coatingto answer today’s digital workingenvironment. Users stay protected andfreely can use any devices with gloveson.This technology consists of creatingspecific asperities on the coated surfaceof the glove, hence reproducing thesucking effect of a force cup. Thisspecifically designed augmented griptechnology offers the user considerablyincreased grip equally in damp, dryor oily conditions. In other words,Wonder Grip Technology reducesthe force required to move objects andconsiderably increases grip controlof all objects, in both dry or slipperyenvironments.Results of tests conducted by BOKENJapan, an independent materials testand control agency, demonstratedan increase in the friction coefficient,i.e. prehension force or grip, of 58%*for Wonder Grip Technology latexcoatings, and of 36% for Wonder GripTechnology nitrile coatings.In house engineered, Wonder GripPerformance has been developed toanswer today’s complex and changingworking environment.The Wonder Grip Performance formula properties, have allowed thedevelopment of a remarkable thin andsmooth protective coating providingexceptional levels of sensitivity anddexterity at fingertips. Wonder GripPerformance special blendedNBR coating is also free of latex andsilicon. As a result, users will benefitan outstanding flexibility, high level oftactility and uncompromising controlduring tasks in in dry environment.Wonder Grip certifies that all the rawmaterials used in the manufacture of itsproducts conform to European Unionregulations (regulation n 1907/2006):regulation for chemical productsand their use’, referred to as REACH(Registration, Evaluation, Authorisationand Restriction of Chemicals). Thekey aim of this directive is to offer theutmost level of protection and safety forhuman health and the environment.TOYOBO’S HIGHPERFORMANCEFIBRELatest innovation from Wonder Grip,Bee-series encapsulate a full set oftechnologies offering a yet to seenexperience.Our team of researchers pioneered anew knitting technique, inspired by thegeometrical shape of honeycombs.Thisshape uses the least amount of materialto hold the most weight.Wonder Grip released a new generationof latex coating. HDML formula resultsof a delicate process of combiningspecific substances in order to obtain ahigher molar concentration compare toformal concentration of standard latex.This new coating inherently combineseffective high-friction coefficient,excellent wear resistance properties andthe high less fatiguing grip performancein its segment.REACHBased on the same concept, linersknitted with Bee-series technique,can handle a lot of torque force whileoffering twice the breathability* versusstandard knitting, thanks to its doubleknitting technique. Bee-series linersare ultra lightweight and also the firstknitting technique enhancing the gripdue to its shape on the palm.*diameter 10mm 300pa 2857.6mm/svs1503.6mm/sTo knit the support for each of ourgloves, fibres are selected according tohighly specific criteria. This is the caseof Tsunooga polyethylene, the fibrewe have chosen to knit our cut-resistantgloves from.It is produced by the Japanese firmToyobo. This fibre is not only extremelyresistant, offering excellent anti-cutproperties, but it is also ideal formanufacturing soft and comfortablytextured gloves. No solvents are used toproduce this fibre, hence rendering itmore hygienic and healthier to use thanother polyethylene fibres. Tsunooga fibre also boasts specific high thermalconductivity properties, which enableit to absorb and distribute natural bodyheat. The incorporation of this fibreenables us to produce gloves that offera feeling of freshness on the skin.-9-

GENERALHANDLINGWG-1855HY U-FEELWG-1855HY U-Feel is a glove with a single nitrile coating constructed on a 18-gauge polyester andspandex liner. Our Wonder Grip Performance dipping offers an outstanding thin and smoothprotective coating, delivering incomparable levels of sensitivity and dexterity at your fingertips.Incredibly thin and soft, it gives users a second skin feeling, providing an exceptional level of comfortand precision ideal glove for precision tasks.WG-1855HY is certified free of silicone.TYPE OF PROTECTIONGeneral purpose; Heat resistanceAPPLICATIONIndustries: Aeronautical, Self-employed trades, Assembly, Automotive industry, Public authorities,Electronics, Finishing and inspection, Industry, Logistics, Maintenance, 121XX1XXXXCOATING- Material: Nitrile- Type: Single, Palm fitSUPPORT- Gauge: 18- Polyester- Spandex- Color: «Hi-Viz» YellowPACKAGING- 12 pairs / polybag ;- 144 pairs / boxWG-1857W NEOWG-1857W Neo is a single nitrile coated glove, constructed on an 18-gauge extra fine nylon andspandex liner. Thanks to Wonder Grip Technology , the nitrile coating provides users grip andresistance in dry and slightly oily environments.Incredibly thin and light, bringing the feeling of second skin, WG-1857W offers an unrivalled level ofcomfort, precision and an exceptional softness. This is the ideal glove for precision tasks.TYPE OF PROTECTIONGeneral purposeAPPLICATIONIndustries: Aeronautical, Assembly, Automotive industry, Finishing and inspection, Logistics,Maintenance, Small component handling, InstallationINFORMATIONSEN388:2016NORMS- 10 -COATING- Material: Nitrile- Type: Single, Palm fitSUPPORT- Gauge: 18- Nylon- Spandex- Color: Dark redPACKAGING- 12 pairs / polybag ;- 144 pairs / box4121X- 11 -

WG-550 AIR LITEWG-550 Air Lite is a single nitrile coating on a 15-gauge nylon andpolyester liner. WG-550 Air Lite offers great elasticity, making hand movements easier, hence increasing thedexterity needed when performing precision tasks. The improved coating and liner are designed to give thegreatest breathability and make it the most comfortable glove to wear for prolonged periods.TYPE OF PROTECTIONINFORMATIONSCOATING- Material: Nitrile- Type: Single, PalmfitGeneral purposeAPPLICATIONIndustries: Aeronautical, Assembly and installation in dry andslightly oily environments, Automotive industry, Mechanicalindustry, MaintenanceEN388:2016WG-300COMFORT LITEWG-300 Comfort Lite is our high-qualityentry-level product for the latex range. With asingle latex coating on a 15-gauge nylon andpolyester base, WG-300 Comfort Lite offersgreat elasticity making hand movementseasier, increasing the dexterity needed whenperforming precise tasks.WG-310 COMFORT WG-355 DUALWG-310 Comfort is a glove with a single latexcoating constructed on a 13-gauge polyesterliner. Thanks to Wonder Grip Technology , thecoating provides users grip and resistance indry and slightly wet environments.WG-310 Comfort offers a high level of comfortand sensitivity making this glove the must-havesolution for performing specific tasks in a dryor wet environment. single coating improvesabrasion resistance for longer life.NORMSSUPPORT- Gauge: 15- Nylon- Polyester- Color: BluePACKAGING- 12 pairs / polybag ;- 144 pairs / box4121XWG-355 Dual is based on our an innovativeDuaLiner : the nylon knit wrist goes up to themiddle of the hand to ensure a snug and securefit, while the breathable microfibre knit linerfor the knuckles and fingers provides excellentdexterity, softness and fingertip precision.The single latex coating of WG-355 Dual helpsto maintain excellent grip in a wide varietyof applications, helping you overcome workchallenges with precision, every day.TYPE OF PROTECTIONTYPE OF PROTECTIONGeneral purposeTYPE OF PROTECTIONGeneral purposeGeneral : Aeronautical, Self-employed trades,Construction and public works, Fork lift truckoperation, Electronics, Logistics, Handling andassembly in dry or slightly damp environmentsINFORMATIONSCOATING- Material: Latex- Type: Single, PalmfitPACKAGING- 12 pairs / polybag ;- 144 pairs / boxSUPPORT- Gauge: 15- Polyester- Nylon- Color: GreenIndustries: Aeronautical, Self-employed trades,Construction and public works, Fork lift truckoperation, Electronics, Logistics, Handling andassembly in dry or slightly damp environmentsIndustries: Aeronautical, Self-employed trades,Construction and public works, Fork lift truckoperation, Electronics, Logistics, Handling andassembly in dry or slightly damp environmentsINFORMATIONSINFORMATIONSCOATING- Material: Latex- Type: single, Palm fitPACKAGING- 12 pairs / polybag ;- 144 pairs / boxSUPPORT- Gauge: 13- Polyester- Color: «Hi-Viz»Yellow or Orangeor RedCOATING- Material: Latex- Type: Single, PalmfitPACKAGING- 12 pairs / polybag ;- 144 pairs / 31XX1XXXXSUPPORT- Gauge: 15- Nylon- Microfibre- Color: Grey and RedWG-555 DUOWG-555 Duo is based on our innovativeDuaLiner : the nylon knit wrist goes up to themiddle of the hand to ensure a snug and securefit, while the breathable microfibre knit linerfor the knuckles and fingers provides excellentdexterity, softness and fingertip precision.WG-555 Duo’s breathable foam nitrile coatingcontributes towards keeping your hands dryand maintains a great grip in a wide varietyof applications, helping you overcome workchallenges every day.EN388:2016NORMSTYPE OF PROTECTION2131XWG-422BEE-SMARTWG-422 Bee-Smart encapsulates our brand-new Beeseries knitting technique and our new generationof latex in-house developed, the HDML coating.The upper part of the gloves is made of an ultralightweight liner offering both high resistance totorsion and unmatched breathability. Bee-series knitting technique create a unique shape on the palmmaximizing the coefficient of friction delivered by thecoating itself. The low part of the glove benefit from theDuaLiner technology and its special support on theback of hand ensuring a snug and secure fit. WG-422Be-Smart sets a new standard for comfort at work, andbecome the ultimate glove for general handling work.WG-522BEE-TOUGHWG-522 Bee-Tough combines Bee-series knittingtechnique and a nitrile coating providing oil-resistanceand an optimal long-lasting grip. The upper part ofthe gloves is made of an ultralightweight liner offeringboth high resistance to torsion and unmatchedbreathability. Bee-series knitting technique create aunique shape on the palm maximizing the coefficientof friction delivered by the coating itself. The low partof the glove benefit from the DuaLiner technologyand its special support on the back of hand ensuringa snug and secure fit. Features with Bee-series ,DuaLiner and a nitrile coating, WG-522 Be-Toughsets a new standard for comfort at work, in greasy andoily environment.General purposeTYPE OF PROTECTIONAPPLICATIONWG-500 Flex is a glove with a single nitrile coating constructed around a 13-gauge nylon liner. The economicalsolution, that benefits from Wonder nitrile micro foam coating technology, brings an exceptional grip andcomfort for tasks such as parts assembly and warehouse handling. The WG-500 Flex is an excellent choice for ageneral-purpose glove that performs well in wet, slightly oily and dry conditions.TYPE OF PROTECTIONGeneral purposeAPPLICATIONEN388:2016NORMS- 12 -4131XIndustries: Aeronautical, Assembly and installation in dry andslightly oily environments, Automotive industry, Mechanicalindustry, MaintenanceGeneral purpose; Heat resistanceIndustries: Aeronautical, Assembly andinstallation in dry and slightly oily environments,Automotive industry, Mechanical industry,MaintenanceWG-500FLEXINFORMATIONSCOATING- Material: Nitrile- Type: Single, PalmfitPACKAGING- 12 pairs / polybag ;- 144 pairs / boxSUPPORT- Gauge: 13- Nylon- Color: Red or BlueINFORMATIONSCOATING- Material: Nitrile- Type: Single, PalmfitPACKAGING- 12 pairs / polybag ;- 144 pairs / boxEN388:2016NORMSTYPE OF PROTECTIONSUPPORT- Gauge: 15- Nylon- Microfibre- Color: Grey andBlackAPPLICATIONAPPLICATIONIndustries: Logistics, Maintenance, Self-employedtrades, Construction and public works, Roadmaintenance, Green spaces, Part sortingMachine tooling, Fork lift truck operationINFORMATIONSCOATING- Material: Latex- Type: Single, PalmfitPACKAGING- 12 pairs / polybag ;- 144 pairs / box4121XNORMSGeneral purpose; Heat resistanceEN388:2016EN407:20043131XX1XXXXSUPPORT- Gauge: 13- Polyester- Color: Black & BlueIndustries: Logistics, MaintenanceAssembly and installation in dry and slightly oilyenvironments, Construction and public works,Road maintenanceINFORMATIONSCOATING- Material: Nitrile- Type: Single, PalmfitSUPPORT- Gauge: 13- Polyester- Color: Blue & LightbluePACKAGING- 12 pairs / polybag ;- 144 pairs / boxNORMSEN388:2016EN407:20044121XX1XXXX- 13 -

CUT-RESISTANCEWG-787 DEXCUT WG-640 LITE CUT 3 WG-718 DEXCUT WG-728LDEXCUT The WG-787 Dexcut is a glove with asingle nitrile coating constructed on a13-gauge knitted spandex, high performancepolyethylene Tsunooga and mineral fibreliner. The high-performance polyethyleneTsunooga fibre offers an excellent cutresistance (ISO 13997 level D), an outstandingflexibility while leaving a feeling of freshnesson the skin. Wonder Grip Technology nitrilecoating combined with our preformed moldsTPDT technology (Thermo-set Pre-CurvedDesign Technology ) makes WG-787 theperfect solution for excellent ergonomicperformance and unrivalled grip in dry, slightlywet or oily conditions. The WG-787 is the choiceof professionals seeking for an innovative cutresistant glove.WG-640 Lite Cut 3 combines our signatureflexibility, dexterity and grip, while offeringexcellent cut resistance (ISO 13997 gradeC). Developed using our proprietary highperformance blend of reinforced nylon andmineral fibre, WG-640 Lite Cut 3 is the idealglove for all your applications requiringmedium-level cut resistance in dry, humid andoily environments.WG-728L Dexcut is a triple nitrile fullcoated anti-cut glove using Tsunooga highperformance polyethylene fibres to providesuperior cut resistance (ISO 13997 grade E) whilemaintaining excellent flexibility and comfort.WG-728L Dexcut offers unrivalled abrasionresistance and grip. It is the ultimate industrialglove with long sleeves. The liner incorporatesspandex in order to add fit, flexibility andcomfort.TYPE OF PROTECTIONCut-resistanceIndustries: Assembly, Automotive industry,Maintenance, Handling of very sharp objects orparts, Metallurgy, Installation, Recycling, Iron andsteel, Part sortingINFORMATIONSCOATING- Material:Nitrile- Type: Single, PalmfitSUPPORT- Gauge: 13- Spandex- Tsunooga - Mineral fibre- Color: GreenPACKAGING- 12 pairs / polybag ;- 144 pairs / box- 14 -Cut-resistanceLiquids; Cut-resistance; Industrial oilsAPPLICATIONIndustries: Assembly, Automotive industry,Maintenance, Handling of very sharp objects orparts, Metallurgy, Installation, Recycling, Iron andsteel, Part sortingCOATING- Material: Nitrile- Type: Single, PalmfitSUPPORT- Gauge: 13- Nylon- Mineral fibre- Color: Grey / BlackPACKAGING- 12 pairs / polybag ;- 144 pairs / boxNORMSEN388:2016ANSI4342CCUTA4Industries: Automotive industry, Stamping,Glass industry, Mechanical industry, Handlingof very sharp objects or parts, Metallurgy,Petrochemicals, Recycling, Iron and steel, PartsortingCOATING- Material: Nitrile- Type: Triple, Fullydipped knitwristfitPACKAGING- 12 pairs / polybag ;- 144 pairs / boxANSI4X42DCUT4X43DIndustries: Automotive industry, Stamping, Glassindustry, Mechanical industry, Handling of verysharp objects or parts in very oily or very dampenvironments, Metallurgy, Petrochemicals,Recycling, Iron and steel, Part sortingINFORMATIONSINFORMATIONSEN388:2016Liquids; Cut-resistance; Industrial oilsAPPLICATIONAPPLICATIONNORMSEN388:2016TYPE OF PROTECTIONTYPE OF PROTECTIONINFORMATIONSAPPLICATIONNORMSTYPE OF PROTECTIONWG-718 Dexcut is a glove with a triple nitrilecoating constructed on a 13-gauge knittedspandex, Tsunooga high performancepolyethylene and mineral fibre liner. The highperformance polyethylene Tsunooga fibreoffers an excellent cut-resistance (ISO 13997level D), an outstanding flexibility while leaving afeeling of freshness on the skin.100% impermeable to

Always striving to perform beyond customers' expectations, our gloves offer the highest level of dexterity and grip in their categories. Wonder Grip gloves are redefining hand protection. . C Acetonitrile 75-05-8 Nitrile compound D Dichloromethane 75-09-2 Chlorinated hydrocarbon . - Resistance to small splashes of molten metal (0 to 4 .