Transcription

CONCRETE REPAIRSITE HANDBOOKHand Placed and Spray Applications

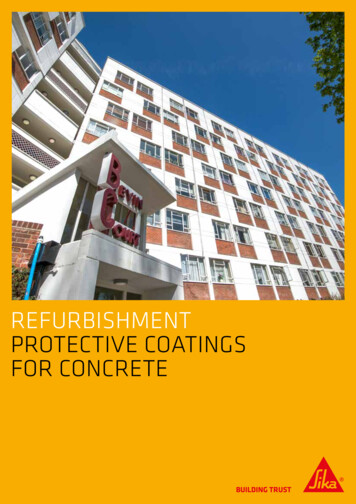

CONCRETE REPAIR SITE HANDBOOKHand Placed and Spray applicationSika MonoTop pore sealer/smoothing mortarsSika MonoTop repair and profilingmortarsSika MonoTop / SikaTop Armatec reinforcement corrosion protection2CONCRETE REPAIR SITE HANDBOOKSikagard protective coatings

CONTENTSBEFORE APPLICATION4Health and Safety5Useful Documents6Bag Layout7Climate Conditions8Equipment9Do’s and Don’tsCONCRETE REPAIR PROCEDURE10-11 1 Substrate Preparation122 Reinforcement Preparation133 Reinforcement Corrosion Protection144 Bonding Primer155 Repair Application by Hand166 Repair Application by Spray177 Smoothing MortarAFTER APPLICATION18Curing Protection18Curing Methods19Cleaning Tools19Environment/Accidents20MIXING21SIKA REPAIR SYSTEMSHINTS AND ADVICE22Over Head Application23Spray EquipmentCONCRETE REPAIR SITE HANDBOOK3

HEALTH AND SAFETY4WORK SAFELY!CONCRETE REPAIR SITE HANDBOOK

USEFUL DOCUMENTSMETHOD STATEMENT́́ Sika MonoTop Systemś́ Detailed step-by-step guide toconcrete repairPRODUCT DATA SHEET́́ Product useś́ Substrate qualitý́ Substrate preparatioń́ Mixing ratió́ Application conditions and toolś́ Pot lifé́ Curing treatmentSAFETY DATA SHEET́́ Hazardś́ First aid́́ Emergencý́ EcologyCONCRETE REPAIR SITE HANDBOOK5

BAG LAYOUTExamplePerformance ClassificationMain DescriptionSafety LabelCE MarkingBag SizeProduct NameStorage Details6CONCRETE REPAIR SITE HANDBOOK

CLIMATE CONDITIONSSTORAGÉ́ Dry, cool conditionś́ Undamaged original packagingAPPLICATIONProtect area from:́́ Direct sunlight́́ Wind́́ Raiń́ FrostTEMPERATURECheck acceptable limits:́́ Ambient temperaturé́ Substrate temperatureCONCRETE REPAIR SITE HANDBOOK7

EQUIPMENTHand ToolsMixing toolsMixing containerApplicationtoolsSpongeBrushes8CONCRETE REPAIR SITE HANDBOOK

DO’S AND DON’TSDO’SUse only clean potable waterMake sure tools are clean and well maintainedRemove only concrete as instructed by supervising officer orqualified engineerConsult product data sheet before startingDON’TSDo not contaminate mixture with other chemicalsDo not mix powders from different productsDo not add more water than recommendedDo not mix and apply the product in direct sunlightCONCRETE REPAIR SITE HANDBOOK9

1. SUBSTRATE PREPARATIONSURFACE PREPARATIOŃ́ Mark defective concreteCONCRETE REMOVAĹ́ Using a high pressure water jet, 1100bar (large area)oŕ́ With a hammer drill (medium area)oŕ́ Hammer and chisel (small patch repairs)Remove tie wires, nails etc.Remove only defective concrete as instructed.Do not reduce structural integrity.10CONCRETE REPAIR SITE HANDBOOK

EXTENT OF CONCRETE REMOVAĹ́ Remove concrete minimum 15mmbehind main bars15 mm MinimumCORRECT SUBSTRATE PREPARATIOŃ́ Rougher surface (2mm minimum)́́ Cut sides minimum 90 to avoidundercutting and maximum 135 toreduce debonding around edgeś́ Substrate shall be sound with no loosematerialInform a supervisor immediately if thereare any cracks in the substrate.CONCRETE REPAIR SITE HANDBOOK11

2. REINFORCEMENT PREPARATIONCLEANING REINFORCEMENTRemove ALL:́́ Tie wireś́ Mortar/concreté́ Rust/scalé́ Other loose materialREMOVAL TECHNIQUES1. Steel wire brush or hand/power toolsTechnique applicable only in carbonated concreteand under environmental constraints wheretechniques 2 and 3 cannot be used.́́ Reinforcement uniformly cleaned2. Abrasive blast cleaning techniqueś́ Reinforcement uniformly cleaned́́ If chlorides are presentreinforcement should be cleanedwith water afterwards3. High pressure water jetting (1100 bar min)́́ Reinforcement uniformly cleanedInform a supervisor immediately of anybadly damaged reinforcement.12CONCRETE REPAIR SITE HANDBOOK

3. REINFORCEMENT CORROSIONPROTECTIONAPPLICATION OF CORROSIONPROTECTIOŃ́ Apply two 1mm thick layers(total 2mm minimum)Allow time for the first coat to harden beforeapplying the second coat. Allow application todry before applying repair mortar.APPLICATION TECHNIQUEŚ́ Hopper spray for large applicationsoŕ́ Brush for small applicationś́ Inspect bars after to ensure full coverageUse two brushes simultaneously toensure full application behind bars.CONCRETE REPAIR SITE HANDBOOK13

4. BONDING PRIMERAPPLYING BONDING PRIMER(if specified)́́ Wet the substraté́ Wipe away excess watersmall area: with spongelarge area: with air pressureAPPLICATION TECHNIQUÉ́ For small patches brush firmlyonto surfacé́ For large areas spray on withhopper gunPoint gun at different angles on the surface toensure even application behind the bars.14CONCRETE REPAIR SITE HANDBOOK

5. REPAIR APPLICATIONBy HandSURFACE PREPARATION(if bonding primer not applied)́́ Wet the substraté́ Wipe away excess watersmall area: with spongelarge area: with air pressureAPPLICATION TECHNIQUÉ́ Press the repair mortar firmly into therepair area using a trowel and/or handApply second layer when first layer is dryif application depth exceeds product’smaximum layer thickness.́́ Profile the surface and finish witha trowelFinish the surface with a wooden or PVCtrowel for best results. Do not sprayadditional water over the surface!CONCRETE REPAIR SITE HANDBOOK15

6. REPAIR APPLICATIONBy SpraySURFACE PREPARATIOŃ́ Wet the substraté́ Wipe away excess watersmall area: with spongelarge area: with air pressureAPPLICATION TECHNIQUÉ́ Point nozzle 200mm to 500mmfrom surfacé́ Finish with PVC or wooden trowelMake sure voids are filled behind bars. Pointspray nozzle at different angles to the surface.If 2nd layer is required surface should notbe too smooth.16CONCRETE REPAIR SITE HANDBOOK

7. SMOOTHING MORTARSURFACE PREPARATIOŃ́ Wet and clean the surface withwater (180 bar)SMOOTHING OR LEVELLING MORTAŔ́ Apply vertically using toothed troweĺ́ Apply with trowel approximate 45 tosurfaceUse different size toothed trowel forrequired layer thickness.́́ When the first layer is hard, applysecond layeŕ́ Smooth surface using woodentrowel after product has set0.25 - 4 hoursCONCRETE REPAIR SITE HANDBOOK17

AFTER APPLICATIONCURING PROTECTIONProtect application from:́́ Frost́́ Wind*́́ Rain*́́ Sun** Apply as soon as possible after application to avoidsurface cracking/crazingCURING METHODŚ́ Plastic sheetinǵ́ Fabric and wateŕ́ Other membraneś́ If no subsequent coating is to beapplied on the surface an approvedcuring agent could be used.18CONCRETE REPAIR SITE HANDBOOK

ADDITIONAL INFORMATIONCLEANING TOOLŚ́ Clean with waterHardened material can only be removedmechanicallyENVIRONMENT́́ Dispose of waste responsiblý́ Separate recycling materialsACCIDENTŚ́ Seek immediate medical attention inthe event of an injuryCONCRETE REPAIR SITE HANDBOOK19

MIXINGONE COMPONENT SYSTEM(eg Sika MonoTop )́́ Add powder to water and mixfor three minutesTWO COMPONENT SYSTEM(eg SikaTop )́́ Shake component A thoroughly andpour into a clean containeŕ́ Add in powder component C and mixfor three minutesDo not add extra water.THREE COMPONENT SYSTEM(eg Sika EpoCem )́́ Shake component A B separatelý́ Mix components A B togetheŕ́ Add A B to powder component C andmix for three minutesAdjust consistency to suit conditions usingpowder component C. Refer to product datasheet for more information.20CONCRETE REPAIR SITE HANDBOOK

SIKA REPAIR SYSTEMSPRODUCTTypeBS EN 1504ReferenceApplicationSika MonoTop -612Repair MortarHandWet sprayPart 3 - R4Sika MonoTop -615Repair MortarHandWet sprayPart 3 - R3Sika Rapid Repair MortarRepair MortarHandSikaCem -133 Gunite SRepair MortarDry sprayPart 3 - R4SikaCem -133 F GuniteRepair Mortar withfibresDry sprayPart 3 - R4SikaCem -133 CP GuniteRepair Mortar lowresistivityDry sprayPart 3 - R4SikaCem -133 CP GuniteCP OverlayDry sprayPart 3 - R4Sika MonoTop -614FRepair MortarFlowableSika MonoTop -610Bonding Primerand ReinforcementCorrosion ProtectionHandSprayPart 7SikaTop Armatec -110EpoCem Bonding Primerand ReinforcementCorrosion Protection(chlorides)HandSprayPart 7Sika MonoTop -620Smoothing Mortar/Pore SealerHandPart 2Sikagard -720 EpoCem Smoothing Mortar/Pore SealerHandPart 2Part 3 - R4Part 3 - R4CONCRETE REPAIR SITE HANDBOOK21

HINTS AND ADVICEOver Head Applicatioń́ Apply mortar tightly behindreinforcement until bars arecovered́́ Press firmly to ensure pores in concretesubstrate are filled́́ From same end apply second layerin same direction as first́́ Repeat layers until void is filled́́ Smooth surface using woodentrowel22CONCRETE REPAIR SITE HANDBOOK

HINTS AND ADVICESpray EquipmentWET SPRAY PROCESSWet mixCompressedairHydraulic conveyance(dense stream)Air streamconveyance(thin stream)Air forconcrete pumpVariableDRY SPRAY PROCESSDry mixCompressedairAir stream conveyance(thin stream)Water feedVariableCONCRETE REPAIR SITE HANDBOOK23

SIKA FULL RANGE SOLUTIONSFOR CHANTSEALING AND BONDINGFLOORINGROOFINGINDUSTRYFOR MORE INFORMATION:WHO WE ARESika Limited and Sika Ireland Limited are part of the global Sika Group,specialising in the manufacture and supply of chemical based products. Sikahave a leading position in the development and production of systems andproducts for bonding, sealing, damping, reinforcing, and protecting in the buildingsector and the motor vehicle industry. Sika has subsidiaries in 97 countriesaround the world and manufactures in over 190 factories. With over 17,000employees Sika generates annual sales of CHF 5.75 billion ( 4.69bn). We arealso committed to providing quality, service, safety and environmental care.EMS 45308OHS 585274SIKA LIMITEDHead OfficeWatchmeadWelwyn Garden CityHertfordshire, AL7 1BQUnited KingdomContactPhone 44 1 707 394444Fax 44 1 707 329129E-Mail A IRELAND LIMITEDSika HouseBallymun Industrial EstateDublin 11, D11 DA2VIrelandContactPhone 353 1 862 0709Fax 353 1 862 0707E-Mail info@ie.sika.comwww.sika.ieWP/1K/Jan2018FM 12504REFURBISHMENT/CONCRETE REPAIR SITE BANDBOOKThe information, and, in particular, the recommendations relating to the application and end useof Sika products, are given in good faith based on Sika’s current knowledge and experience ofthe products when properly stored, handled and applied under normal conditions. In practice,the differences in materials, substrates and actual site conditions are such that no warranty inrespect of merchantability or of fitness for a particular purpose, nor any liability arising out of anylegal relationship whatsoever, can be inferred either from this information, or from any writtenrecommendations, or from any other advice offered. The proprietary rights of third parties mustbe observed. Please refer to our homepage www.sika.co.uk for our current standard terms &conditions applicable to all orders. Users should always refer to the most recent issue of the ProductData Sheet for the product concerned, copies of which will be supplied on request.JANUARY 2018In the UK and Ireland, we provide market-leading solutions for concrete,waterproofing, roofing, flooring, refurbishment, sealing & bonding, andindustry, and have manufacturing sites in Welwyn Garden City, Preston,Leeds and Dublin with more than 700 employees and a turnover of more than

2. REINFORCEMENT PREPARATION CLEANING REINFORCEMENT Remove ALL : ́ Tie wires ́ Mortar/concrete ́ Rust/scale ́ Other loose material REMOVAL TECHNIQUES 1. Steel wire brush or hand/power tools Technique applicable only in carbonated concrete and under environmental constraints where techniques 2 and 3 cannot be used. ́ Reinforcement uniformly .