Transcription

BSIElectricalElectronicContractorsNovember 1, 2019Department of General Services3rd Floor Arsenal Building1800 Herr StreetHarrisburg, PA 17103Attention: Toni DolanRE:DGS C-0251-0094 DBC P1Dear Toni:Thank you for the opportunity to provide a proposal for DGS Project DGS C-0251-0094-P1. Inaccordance with the Request for Proposal (RFP), this document serves as Brendan Stanton Inc.’s(BSI) cover letter. Outlined below is the information requested for the cover letter section of theRFP.Company Name:Company Mailing Address:Contact PersonContact Person Phone NumberContact Person Email AddressBrendan Stanton Inc.416 Stump RoadMontgomeryville, PA 18936Christopher Stanton, P.E.215-699-7700cstanton@bsielectric.comPlease find our full technical proposal, as outlined in the RFP, attached to this cover letter.Feel free to contact our office if you have any questions or need any clarifications.Sincerely,Christopher Stanton, P.E.Christopher J. Stanton, P.E.BRENDAN STANTON, INC. 416 Stump Road Montgomeryville, PA 18936Phone: (215) 699-7700 Fax: (215) 699-7785 Email: cstanton@bsielectric.com

.Pennsylvania Department of General ServicesProject No. DGS C-0251-0094 P1District 6-0 Montgomery County OfficeNew GeneratorUpper Merion TownshipMontgomery County, Pennsylvania.Technical SubmittalNOVEMBER 1, 2019.

DGS C-0251-0094 P1 Technical ProposalTechnical ProposalPennsylvania Department of General ServicesProject No. DGS C-0251-0094 P1District 6-0 Montgomery County OfficeNew GeneratorUpper Merion TownshipMontgomery County, PennsylvaniaBrendan Stanton, Inc.416 Stump RoadMontgomeryville, PA 18936PREFACEa) COMPANY OVERVIEW1)PROJECT MANAGEMENT TEAM OVERVIEW1) ORGANIZATIONAL CHART2) MANAGEMENT STRUCTURE3) MANAGEMENT STRUCTURE ADVANTAGES2)WORK PLAN1) DESIGN EFFORT2) DESIGN-BUILD CONCEPT3) DESIGN CHALLENGES4) RISK MANAGEMENT5) LONG LEAD ITEMS6) CRITICAL EQUIPMENT7) CUT OVER8) CONSTRUCTION PLAN9) PROJECT SAFETY & MONITORING10) QA/QC PLAN11) CLOSEOUT PROCESS3)PROJECT MASTER SCHEDULE1) CRITICAL PATH METHOD SCHEDULE2) DGS MILESTONES3) PROJECT SCHEDULE NARRATIVEBrendan Stanton Inc., 416 Stump Road, Montgomeryville, PA 18936

DGS C-0251-0094 P1 Technical ProposalTechnical ProposalPennsylvania Department of General ServicesProject No. DGS C-0251-0094 P1District 6-0 Montgomery County OfficeNew GeneratorUpper Merion TownshipMontgomery County, PennsylvaniaBrendan Stanton, Inc.416 Stump RoadMontgomeryville, PA 189364)QUALIFICATIONS1) DESIGN BUILD CONTRACTOR QUALIFICATIONS2) RETAINED DESIGN PROFESSIONAL QUALFICIATIONSAPPENDIXa) PROJECT LIST/REFERENCESb) EQUIPMENT LISTc) PROPOSAL SIGNATURE PAGEd) AFFIDAVIT FOR USE OF REQUIRED SUBCONTRACTORSe) NON-COLLUSION AFFIDAVITBrendan Stanton Inc., 416 Stump Road, Montgomeryville, PA 18936

DGS C-0251-0094 P1 Technical ProposalPREFACECompany OverviewSimilar to many successful companies in this country Brendan Stanton Inc.’s (BSI) beginningswere humble, founded from the back of a residential garage in 1977. From these humblebeginnings, BSI has grown into one of the top specialty electrical contractors in the great state ofPennsylvania. BSI currently operates out of Montgomeryville, Pennsylvania from a 47,000square foot industrial facility.BSI has been successfully operating for over 42 years and specializes in educational, municipal,and industrial electrical construction serving clients in both the private and public sectors. Clientneeds and expectations are continually exceeded through coupling the diverse talents of BSI’sworkforce with a full fleet of fully owned construction equipment. BSI’s vast array ofequipment, including emergency generators up to 1.7MW, allows BSI to complete the mostchallenging projects under the most challenging timelines.BSI has successfully completed numerous Department of General Services (DGS) projects andhas successfully completed numerous projects that closely mirror the District 6-0 GeneratorProject. BSI looks forward to the opportunity to serve DGS, once again, on the District 6-0Generator Project.Brendan Stanton Inc., 416 Stump Road, Montgomeryville, PA 18936

DGS C-0251-0094 P1 Technical ProposalSECTION 1PROJECT MANAGEMENT TEAM OVERVIEW1.1 Organizational ChartPlease See Attached Organizational Chart Insert.Brendan Stanton Inc., 416 Stump Road, Montgomeryville, PA 18936

ORGANIZATION CHARTBRENDAN STANTONPresidentCHRISTOPHER STANTON, P.E.ROBERT TAYLOR, P.E.ROBERT MILLERJEFFREY TRANAUSKASMELISSA REYNOLDSPROJECT MANAGEMENT.DESIGNESTIMATING TEAMSYSTEM INTEGRATIONACCOUNTINGFIELD OPERATIONS.DRAFTINGPANEL BUILDINGHUMAN ionBusiness Operations

DGS C-0251-0094 P1 Technical Proposal1.2 Management StructureBrendan Stanton Inc.’s (BSI’s) project team will consist of BSI’s most experienced employees.Brendan StantonPresident42 YearsBrendan Stanton is the owner and founder of Brendan Stanton Inc. (BSI). On projects ofthe size and complexity of the District 6-0 Generator Project, Brendan plays an active role.Brendan will assist in the overall design and overall execution for the District 6-0 generatorproject.Robert MillerProcurement21 YearsRobert Miller currently heads both the estimating and procurement departments. On theDistrict 6-0 Project, Robert will assist with the cost submittal portion of BSI’s proposal and willbe heavily involved in equipment procurement.Melissa ReynoldsProject Administrator20 YearsMelissa Reynolds currently works on the operations side of BSI’s business. Melissa willbe responsible for contracts, bonds, insurance, billing, and reporting on the District 6-0 Project.Robert Taylor, P.EDesign Engineer15 YearsRobert Taylor currently heads BSI’s engineering department. On the District 6-0 Project,Robert will serve as lead engineer, responsible for the final design.Christopher Stanton, P.EProject Engineer11 YearsChristopher Stanton currently heads BSI’s construction department. Christopher hasmanaged many of BSI’s DGS projects and will serve as project manager on the District 6-0project.As noted above the core of BSI’s project team has been working together for decades. Thisteam, along with additional support personnel has successfully completed projects of varyingscope and size. The team has worked with DGS in the past and looks forward to workingtogether on this project.The District 6-0 Generator Project involves a complete overhaul of the District 6-0’s electricaldistribution system. The existing generator will be replaced by a new diesel generator with1750kW of generating capacity. A new automatic transfer switch will be provided equippedwith bypass isolation. The bypass isolation feature allows the switch to be serviced/repairedwhile maintaining power to the facility. On the normal power distribution system a new PECOapproved load interrupter switch, new pad mounted transformer, and new main distributionswitchboard will be provided. The switch, transformer, switchboard and automatic transferswitch will be installed on a newly constructed concrete pad foundation. To feed the new padmounted equipment, the existing PECO medium voltage service will be re-routed through theuse of a sectionalizing cabinet. On the low-voltage end the new switchboard will feed theexisting building loads via a new conduit and cable system. The most challenging part of theproject will be the planning and execution of the electrical cut-over which will require carefulcoordination between the DBC, PECO and DGS. After the new service is on-line the existingpad mounted equipment will be demolished along with the pad the equipment resides on. TheBrendan Stanton Inc., 416 Stump Road, Montgomeryville, PA 18936

DGS C-0251-0094 P1 Technical Proposaldemolished area will be raked, seeded and restored.BSI has successfully completed numerous design/build projects of varying scope and scale.Specific details of these projects are listed in Section 4.1.a.1.3 Management Structure AdvantagesThe proposed management structure will effectively serve the interests of the District 6-0Generator Project in many fashions. All project members are intimately familiar with projects ofthis scope and size. The project manager has worked on many DGS projects in the past and alsoserved as project manager on DGS project A960-120 which is almost a mirror image of theDistrict 6-0 Generator project. Details on project A960-120 are located in Section 4.1.c. Inaddition to scope and customer familiarity, the project team structure ensures oversight andaccountability at the highest level, with committed involvement from BSI ownership.Brendan Stanton Inc., 416 Stump Road, Montgomeryville, PA 18936

DGS C-0251-0094 P1 Technical ProposalSECTION 2WORK PLAN2.1 Design EffortUpon Notice of Selection, Brendan Stanton Inc. (BSI) will immediately begin finalizing thedesign as the stamped construction drawings are a critical path pre-requisite to permit acquisitionand equipment procurement. Once the design is finalized, the drawings will be stamped by alicensed professional engineer and submitted for permit. Parallel to the permit submission willbe initiation of the PECO Service & Meter (S&M) request, which registers the project intoPECO’s system and assigns the project a work order number. The associated PECO work ordernumber will be continually referenced during shop drawing review, pre-energization inspection,and final cut-over.2.2 Design-Build ConceptBrendan Stanton Inc. (BSI) has completed numerous design/build projects of varying complexityand scope. Specific projects are listed and described in Section 4.1. The design/build conceptunifies two traditional project segments by combining the design and construction teams into oneentity. This collaborative approach opens the lines of communication earlier in the projectdelivery channel and allows problems/challenges to be worked out much sooner. BSI willperform both the design and construction efforts in house providing a more collaborative effortthan normally encountered when the entities are separate.2.3 Design ChallengesFrom a technical perspective, the initial design appears comprehensive. Potential designchallenges, on this particular project, would be related to the construction portion of the projectand whether or not there is a better way to minimize exposure to PECO’s schedule andinherently minimize potential shutdowns.2.4 Risk ManagementThe project management team will be a collaborative unit from the onset of the project. DGSwill be actively involved in all design/construction related issues and changes. Communicationand early detection are two of the most effective ways to manage risk and these two staples willbe part of the District 6-0 Project.2.5 Long Lead ItemsThe District 6-0 Generator Project contains several long lead equipment items. The primaryswitch, pad mount transformer, and main distribution switchboard will have long shop drawinglead times and long delivery lead times. The generator and automatic transfer switch will alsohave long lead times.Brendan Stanton Inc., 416 Stump Road, Montgomeryville, PA 18936

DGS C-0251-0094 P1 Technical Proposal2.6 Critical EquipmentAs mentioned above, the District 6-0 Generator Project contains several long lead equipmentitems. These items are critical to the completion of the project from both a shop drawing anddelivery perspective. Approved shop drawings are required to effectively layout the equipmentpads and utility stub-ups. Equipment delivery is required to energize the new equipment andperform the electrical changeover. These challenges will be managed head on at the onset of theproject. Equipment will be procured swiftly and shop drawings will be pushed for immediatelyafter order. As soon as shop drawings are available they will be expedited through the approvalprocess to expedite eventual release. After release BSI’s project management team willcontinually stay abreast to each manufacturer’s timeline and push to ensure committedmanufacturing dates are upheld.2.7 Cut OverThe goal of any project requiring a utility cut-over is always to perform as much of the workahead of time and to minimize exposure to outside entities, namely PECO. The District 6-0Generator Project would be no different. Prior to any cut-over, all pad mounted equipmentwould be installed. All cables running between new equipment would be completely terminated.Cables run from new equipment to existing equipment would be installed and terminated at thede-energized end. The cables would be left close to the energized end, prepared for finaltermination. The new generator would undergo startup and load bank testing prior to any cutover. The actual cut-over would be carefully coordinated with DGS, PECO, and BSI to ensure aseamless transition.2.8 Construction PlanSite Operations: BSI’s on-site team will be led by a superintendent with on-site personnelreporting directly to the superintendent.Site Layout: The bridging documents clearly outline the work area. BSI plans to perform thenecessary work within this area.Logistics: BSI/DGS will need to coordinate logistical items such as the protocol for dailydeliveries and the protocol for the large equipment deliveries.Lay-Down/Parking: Parking and lay-down are typically coordinated with the owner making itdifficult to address those items specifically at this time. There are 5 parking spots adjacent to theexisting pad-mounted equipment that would serve as likely candidates for BSI equipment andvehicles. BSI will receive all equipment, with the exception of the generator, at our warehousefacility in Montgomeryville, Pennsylvania. These pieces of equipment will not be sent to siteuntil they are ready to be set directly on the pad. This ensures no storage area required on sitefor said equipment. The generator will be delivered directly to the site and will only be deliveredwhen BSI is ready to set the unit directly on the pad. The balance of material, including rebarand conduit will take up minimal real estate and can be laid down in careful coordination withthe owner.Field Office: With the actual construction time being somewhat limited, as it relates to theoverall project value, BSI does not anticipate a field office. More than likely a Sea-Crate, formaterial storage, will be set on a coordinated location on site. BSI will provide adequate sanityfacilities for all BSI personnel.Brendan Stanton Inc., 416 Stump Road, Montgomeryville, PA 18936

DGS C-0251-0094 P1 Technical Proposal2.9 Project Safety & MonitoringBrendan Stanton Inc. (BSI) takes an active approach to safety ensuring all employees fullyunderstand and adhere to BSI’s safety plan. All personnel are equipped with proper safety attireranging from hard hats, to safety glasses, to proper work gloves. BSI’s safety officer randomlyvisits all of BSI’s construction sites to ensure compliance and add instruction to project specificconcerns. The construction site will be surrounded by safety fencing as a precautionary measure.2.10 QA/QC PlanBrendan Stanton Inc.’s (BSI) QA/QC plan for the project will have two main objectives. Froman equipment perspective BSI will ensure all major equipment is received, handled and deployedwithout damage. BSI will receive all equipment, with the exception of the generator, at ourwarehouse facility in Montgomeryville, Pennsylvania. Receiving and storing the equipment atBSI’s warehouse allows BSI to immediately address any shipping issues and allows a safestorage facility while the project readies for delivery. Equipment will be deployed to siteutilizing BSI’s owned fleet of transportation vehicles and rigging equipment.From a construction perspective, BSI project management will regularly visit the project site toensure quality workmanship is upheld and project specifications are met.2.11 Closeout ProcessBSI will provide closeout procedures in accordance with the specifications. Factory certified onsite commissioning will be performed on the emergency generator and the automatic transferswitch. During the on-site commissioning, designated personnel will undergo factory training onthe respective units. Operation and Maintenance Manuals will be provided outlining operationand maintenance recommendations/procedures for all newly installed equipment. As-Builtdrawings will be providing outlining any field changes to the construction drawings.Brendan Stanton Inc., 416 Stump Road, Montgomeryville, PA 18936

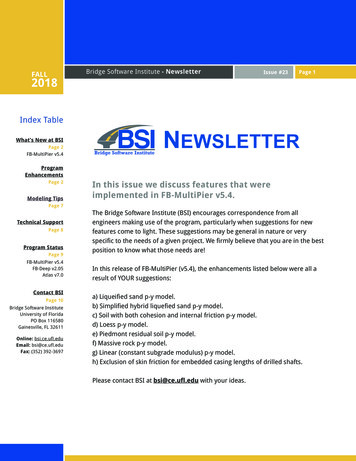

DGS C-0251-0094 P1 Technical ProposalSECTION 3PROJECT MASTER SCHEDULE3.1 Project Master SchedulePlease See Project Master Schedule InsertBrendan Stanton Inc., 416 Stump Road, Montgomeryville, PA 18936

IDTask 829DurationStartFinish10/27Proposal Submission0 daysLetter of Intent0 daysNotice to Proceed0 daysInitial Job Conference1 dayFinalize Design20 daysStamp Drawings & Submit for Permit20 daysSubmit PECO Service and Meter Request1 daySubmittals (a.)60 daysReceive Equipment90 daysEarthwork, Excavation and Backfill (b.)15 daysExterior Pad Preparation (c.)15 daysConcrete Pour (d.)10 daysGenerator Installation (e.)1 day5kV Switch Installation (f.)1 dayPad Mounted Transformer Installation (g.)1 dayAutomatic Switch Installation (h.)1 dayMain Distribution Switchboard Installation (i.)1 dayPECO Sectionalizing Cabinet Installation (j.)5 daysInterior Conduit Above Ceiling Installation (k.)20 daysInterconnection Wiring to De‐Energized20 daysEquipment (l.)Wiring Testing and Test Reports (m.)1 dayPECO Shutdown and Re‐Route of Conductors (n.) 1 dayTue 11/19/19Mon 12/2/19Mon 1/6/20Mon 1/6/20Tue 1/7/20Tue 2/4/20Tue 3/3/20Wed 3/4/20Wed 5/27/20Mon 6/1/20Mon 6/22/20Mon 7/13/20Wed 9/30/20Thu 10/1/20Fri 10/2/20Mon 10/5/20Tue 10/6/20Wed 10/7/20Wed 10/14/20Wed 11/11/20Feeder Installation from Main Switchboard toSelect Loads (o.)Feeder Cut‐Overs to New Electrical DistributionSystems (p.)Emergency Generator Testing/Startup (q.)Demolition of Exterior Equipment (r.)Demolition of Exterior Equipment Pads (s.)Final Grade, Rake and SeedCompete As‐Builts and Manuals5 daysFri 12/11/20Thu 12/17/201 dayFri 12/18/20Fri 12/18/202 days10 days5 days5 days8 daysMon 12/21/20Wed 12/23/20Wed 1/6/21Wed 1/13/21Wed 1/20/21Tue 12/22/20Tue 1/5/21Tue 1/12/21Tue 1/19/21Fri 1/29/21Project: District 6-0 County Office-New Gen Schedule-MileDate: Wed 10/30/1911/3Tue 11/19/19Mon 12/2/19Mon 1/6/20Mon 1/6/20Mon 2/3/20Mon 3/2/20Tue 3/3/20Tue 5/26/20Tue 9/29/20Fri 6/19/20Fri 7/10/20Fri 7/24/20Wed 9/30/20Thu 10/1/20Fri 10/2/20Mon 10/5/20Tue 10/6/20Tue 10/13/20Tue 11/10/20Tue /92/162/2312/21/6Wed 12/9/20 Wed 12/9/20Thu 12/10/20 Thu 12/10/20TaskProject SummaryManual TaskStart-onlyDeadlineSplitInactive ive MilestoneManual Summary RollupExternal TasksManual ProgressSummaryInactive SummaryManual SummaryExternal MilestonePage 13/13/8March3/15

IDTask 829DurationStart3/22Proposal Submission0 daysLetter of Intent0 daysNotice to Proceed0 daysInitial Job Conference1 dayFinalize Design20 daysStamp Drawings & Submit for Permit20 daysSubmit PECO Service and Meter Request1 daySubmittals (a.)60 daysReceive Equipment90 daysEarthwork, Excavation and Backfill (b.)15 daysExterior Pad Preparation (c.)15 daysConcrete Pour (d.)10 daysGenerator Installation (e.)1 day5kV Switch Installation (f.)1 dayPad Mounted Transformer Installation (g.)1 dayAutomatic Switch Installation (h.)1 dayMain Distribution Switchboard Installation (i.)1 dayPECO Sectionalizing Cabinet Installation (j.)5 daysInterior Conduit Above Ceiling Installation (k.)20 daysInterconnection Wiring to De‐Energized20 daysEquipment (l.)Wiring Testing and Test Reports (m.)1 dayPECO Shutdown and Re‐Route of Conductors (n.) 1 dayTue 11/19/19Mon 12/2/19Mon 1/6/20Mon 1/6/20Tue 1/7/20Tue 2/4/20Tue 3/3/20Wed 3/4/20Wed 5/27/20Mon 6/1/20Mon 6/22/20Mon 7/13/20Wed 9/30/20Thu 10/1/20Fri 10/2/20Mon 10/5/20Tue 10/6/20Wed 10/7/20Wed 10/14/20Wed 11/11/20Feeder Installation from Main Switchboard toSelect Loads (o.)Feeder Cut‐Overs to New Electrical DistributionSystems (p.)Emergency Generator Testing/Startup (q.)Demolition of Exterior Equipment (r.)Demolition of Exterior Equipment Pads (s.)Final Grade, Rake and SeedCompete As‐Builts and Manuals5 daysFri 12/11/201 dayFri 12/18/202 days10 days5 days5 days8 daysMon 12/21/20Wed 12/23/20Wed 1/6/21Wed 1/13/21Wed 1/20/21Project: District 6-0 County Office-New Gen Schedule-MileDate: Wed 5/316/7June6/146/216/287/5July7/127/197/268/2Wed 12/9/20Thu 12/10/20TaskProject SummaryManual TaskStart-onlyDeadlineSplitInactive ive MilestoneManual Summary RollupExternal TasksManual ProgressSummaryInactive SummaryManual SummaryExternal MilestonePage 28/9August8/168/238/

IDTask 829DurationStart8/30Proposal Submission0 daysLetter of Intent0 daysNotice to Proceed0 daysInitial Job Conference1 dayFinalize Design20 daysStamp Drawings & Submit for Permit20 daysSubmit PECO Service and Meter Request1 daySubmittals (a.)60 daysReceive Equipment90 daysEarthwork, Excavation and Backfill (b.)15 daysExterior Pad Preparation (c.)15 daysConcrete Pour (d.)10 daysGenerator Installation (e.)1 day5kV Switch Installation (f.)1 dayPad Mounted Transformer Installation (g.)1 dayAutomatic Switch Installation (h.)1 dayMain Distribution Switchboard Installation (i.)1 dayPECO Sectionalizing Cabinet Installation (j.)5 daysInterior Conduit Above Ceiling Installation (k.)20 daysInterconnection Wiring to De‐Energized20 daysEquipment (l.)Wiring Testing and Test Reports (m.)1 dayPECO Shutdown and Re‐Route of Conductors (n.) 1 dayTue 11/19/19Mon 12/2/19Mon 1/6/20Mon 1/6/20Tue 1/7/20Tue 2/4/20Tue 3/3/20Wed 3/4/20Wed 5/27/20Mon 6/1/20Mon 6/22/20Mon 7/13/20Wed 9/30/20Thu 10/1/20Fri 10/2/20Mon 10/5/20Tue 10/6/20Wed 10/7/20Wed 10/14/20Wed 11/11/20Feeder Installation from Main Switchboard toSelect Loads (o.)Feeder Cut‐Overs to New Electrical DistributionSystems (p.)Emergency Generator Testing/Startup (q.)Demolition of Exterior Equipment (r.)Demolition of Exterior Equipment Pads (s.)Final Grade, Rake and SeedCompete As‐Builts and Manuals5 daysFri 12/11/201 dayFri 12/18/202 days10 days5 days5 days8 daysMon 12/21/20Wed 12/23/20Wed 1/6/21Wed 1/13/21Wed 1/20/21Project: District 6-0 County Office-New Gen Schedule-MileDate: Wed r12/1312/2012/271/3January1/101/17Wed 12/9/20Thu 12/10/20TaskProject SummaryManual TaskStart-onlyDeadlineSplitInactive ive MilestoneManual Summary RollupExternal TasksManual ProgressSummaryInactive SummaryManual SummaryExternal MilestonePage 31/241/312

DGS C-0251-0094 P1 Technical Proposal3.2 DGS Milestonesa) Generation of Electronic Submittals for Reviewb) Start and Completion Date of Earthwork, Excavation, and Backfillc) Start and Completion Date of Exterior Pad Preparationd) Start and Completion Date of Concrete Pours and Construction of Equipment Foundationse) Start and Completion Date of Replacement Generator Installationf) Start and Completion Date of Replacement 5kV Switch Installationg) Start and Completion Date of Pad Mounted Transformer Installationh) Start and Completion Date of Service Entrance Rated Automatic Transfer Switchi) Start and Completion Date of Main Distribution Switchboard Installationj) Start and Completion Date of PECO Approved Sectionalizing Cabinet Installationk) Start and Completion Date of All Interior Conduit Above Ceilingsl) Start and Completion Date of all Interconnecting Wiring to De-Energized Equipmentm) Start and Completion of Wiring Testing and Testing Reportsn) Start and Completion Date of PECO Coordinated Shutdown and Re-Route of Conductorso) Start and Completion Date of Feeder Installation from Main Switchboard to Select Loadsp) Start and Completion Date of Feeder Cut-Overs to New Electrical Distribution Systemq) Start and Completion Date of Emergency Generator Testing and Startupr) Start and Completion Date of Demolition of Exterior Equipments) Start and Completion Date of Demolition of Exterior Equipment Pads and Restoration3.3 Project Schedule NarrativeThe project schedule will effectively follow the milestones laid out in the specifications and inSection 3.2 above. After reception of the Notice to Proceed, BSI will begin the 3 critical pathtasks that drive the schedule, namely Material Procurement, Permit Submission, and PECOService and Metering. Shop drawings, for critical equipment, will be expedited through theapproval process to ensure quick release. After approval from DGS and PECO, equipment willbe released and foundation layout will being, with excavation and concrete pads followingshortly thereafter. Concrete will be poured and duct banks between pads and duct banks to thebuilding will be completed. Indoor conduit work will take the conduits from the duct bank wallpenetrations to their ultimate destinations. Once received, equipment will be deployed and set onsite. All conductors will be installed and terminated where applicable. Conductors that re-feedexisting equipment will be installed to the termination point and made ready for the switch-over.The generator will be tested/commissioned and conductors will be tested. After all conductorshave been installed/terminated/tested and equipment has been commissioned/readied the projectwill undergo the electrical cut-over. Following successful cut-over to the new equipment, theexisting equipment will be demolished and the site will be restored.Brendan Stanton Inc., 416 Stump Road, Montgomeryville, PA 18936

DGS C-0251-0094 P1 Technical ProposalSECTION 4QUALIFICATIONSDESIGN BUILD CONTRACTOR4.1.a Design Build ProjectsBSI has completed numerous design/build projects of varying scope and scale. Outlined belowis a subset of design-build projects. The projects listed below closely align with the District 6-0Generator project, from a PECO Coordination, Medium Voltage Re-Work, and MinimizedDowntime perspective. Additional project(s) and project descriptions can be provided if needed.Abington Junior High School 1,174,012.00Name:Energy Renovations ProjectDate:October 2019Owner:Abington School District970 Highland AvenueAbington, PA 19001Thomas Schneider, 215-881-2525Type:Design/BuildOwner Rep: Reynolds Energy Services3330 North 3rd StreetHarrisburg, PA 17110Jeffrey Harris, 717-943-9154Description: BSI was contracted to perform design/build services for the AbingtonSchool District Junior High School Energy Renovations Project. Theproject involved a new 35kV electrical service from a new 35kV polemounted utility switch to new 35kV metal enclosed switchgear. From thenew switchgear, the medium voltage service was distributed to two padmounted transformers with 2000kVA and 1000kVA capacity,respectively. Each transformer fed a series of switchboards, whichreplaced existing switchboards. The school’s existing equipment and newequipment were fed from the new switchboards. The project consisted ofnumerous electrical shutdowns, which were carefully planned andcoordinated with the owner and the project team. The design,construction, and scheduling was all carefully coordinated with PECO.Brendan Stanton Inc., 416 Stump Road, Montgomeryville, PA 18936

DGS C-0251-0094 P1 Technical ProposalPhiladelphia Macaroni Company 555,294.00Name:PECO Service Upgrade and IQF Line 2 ProjectDate:February 2019Owner:Philadelphia Macaroni CompanyCounty Line & Jacksonville RoadWarminster, PA 18974-4804Frank Radano, 215-441-5520Type:Design/BuildDescription: BSI was contracted to perform design/build services for the PhiladelphiaMacaroni Company IQF Process Line Project. The project involved a new35kV electrical overhead service from the PECO service point to a new1500kVA pad mounted transformer. The 35kV distribution line utilized aseries of overhead utility poles to distribute the 35kV cables from theutility service point to the pad mounted transformer. The new padmounted transformer fed a new 2000A low voltage switchboard whichpowered existing loads along with new loads associated with the new IQFprocess line. In a manufacturing environment downtime equates to lostproduction and lost revenue. BSI successfully coordinated with PECO,the owner, and the project team to minimize the downtime typicallyassociated with a service upgrade project.New Age Industries 1,486,823.00Name:Unit 151 Cleanroom ProjectDate:March 2018Owner:New Age Industries145 James WaySouthampton, PA 18966John Fox, 215-768-0875Type:Design/BuildDescription: BSI was contracted to perform design/build services for the New AgeIndustries Cleanroom 151 Project. The project involved two new 35kVelectrical services from two new 35kV pole mounted switches. The two35kV services were distributed to two 2500kVA pad mountedtransformers and subsequently to a new 3000A Main-Tie-Mainswitchboard. The new switchboard re-fed existing loads and providedpower to new equipment. In a manufacturing environment downtimeequates to lost production and lost revenue. BSI successfully coordinatedwith PECO, the owner, and the project team to minimize the downtimetypically associated with a service upgrade project.Brendan Stanton Inc., 416 Stump Road, Montgomeryville, PA 18936

DGS C-0251-0094 P1 Technical ProposalGriffin Pipe Products 1,970,000.00Name:Griffin Pipe SubstationDate:December 2008Owner:Griffin Pipe Products1100 West Front StreetFlorence, NJ 08518Type:Design/BuildDescription: BSI was contracted to perform design/build services for the Griffin PipeProducts 27kV dual feed substation. The project involved two 27kVutility lines from PSE&G, automatic primary switch operation, two5MVA unit substations, 5kV outdoor metal clad switchboard withautomatic tie circuit breaker, and a new 5kV underground distributionsystem.

Melissa Reynolds currently works on the operations side of BSI's business. Melissa will be responsible for contracts, bonds, insurance, billing, and reporting on the District 6-0 Project. Robert Taylor, P.E Design Engineer 15 Years . Robert Taylor currently heads BSI's engineering department. On the District 6-0 Project,