Transcription

CQI-7ISO/TS 16949:2002 IMPLEMENTATIONGUIDE

ISO/TS 16949:2002IMPLEMENTATION GUIDEAIAG PUBLICATIONSAn AIAG publication reflects a consensus of those substantially concerned with its scope and provisions. AnAIAG publication is intended as a guide to aid the manufacturer, the consumer and the general public. Theexistence of an AIAG publication does not in any respect preclude anyone from manufacturing, marketing,purchasing, or using products, processes, or procedures not conforming to the publication.CAUTIONARY NOTICEAIAG publications are subject to periodic review and users are cautioned to obtain the latest editions.MAINTENANCE PROCEDURERecognizing that this AIAG publication may not cover all circumstances, AIAG has established a maintenanceprocedure. Please refer to the Maintenance Request Form at the back of this document to submit a request.APPROVAL STATUSThe AIAG Board of Directors approved this document for publication by on May 29, 2003.Published by:Automotive Industry Action Group26200 Lahser Road, Suite 200Southfield, Michigan 48034Phone: (248) 358-3570 Fax: (248) 358-3253Web Site: www.aiag.orgAIAG Copyright and Trademark Notice:The contents of all published materials are copyrighted by the Automotive Industry Action Group unless otherwise indicated. Copyright is not claimed asto any part of an original work prepared by a U.S. or state government officer or employee as part of the person’s official duties. All rights are preservedby AIAG, and content may not be altered or disseminated, published, or transferred in part of such content. The information is not to be sold in part orwhole to anyone within your organization or to another company. Copyright infringement is a violation of federal law subject to criminal and civilpenalties. AIAG and the Automotive Industry Action Group are registered service marks of the Automotive Industry Action Group. 2003 Automotive Industry Action GroupCQI-71Issue: 01 Dated: 6/03Replaces: N/A Dated: N/A

ISO/TS 16949:2002IMPLEMENTATION GUIDEFOREWORDThe purpose of this implementation guide is twofold: Guide an automotive manufacturing organization to ISO/TS 16949:2002 registration when starting withoutregistration to any of the current automotive certifications (e.g. QS-9000 3rd, ISO/TS 16949:1999, VDA 6.1, etc.). To provide automotive suppliers with a guide to help transition their current QS-9000 3rd edition-based qualitymanagement systems to ISO/TS 16949:2002.One lesson learned from QS-9000 is the importance of utilizing proper planning when designing andimplementing the organization's Quality Management System (QMS). This implementation guide builds uponthis lesson by explaining what's new and different (between QS-9000 3rd edition and ISO/TS 16949:2002) andproviding strategies for implementation and clarification on how to conduct a process audit, which is new toISO/TS 16949:2002.ISO/TS 16949:2002 utilizes the "Process Approach" to the Quality Management System development andimprovement by identifying the organization’s processes, how these processes link to customer satisfaction,and the organization’s methods to measure and improve process effectiveness.CQI-72Issue: 01 Dated: 6/03Replaces: N/A Dated: N/A

ISO/TS 16949:2002IMPLEMENTATION GUIDEACKNOWLEDGEMENTSKraig Alexander – Federal-Mogul CorporationElizabeth Baker – Robert Bosch CorporationMichael Brennan – VisteonJohn Cole – Vehicle Certification AgencyJames L. Dulzer – PPG IndustriesDennis R. Gauthier – DaimlerChrysler CorporationBrenda Greca – Federal-Mogul CorporationJoseph Grim – Ford Motor CompanyLinda Haskins – Delphi CorporationRuss Hopkins – Ford Motor CompanyGeorge Hummel – International Quality ConsultantsGeorge Kasdorf – Freudenberg-NOKKevin Lange – DaimlerChrysler CorporationFrank Lomas – BSI Management SystemsTripp Martin – Federal-Mogul CorporationGary Marshall – Management Resources InternationalTeresa L. Pratt – Delphi Corporation (co-chair)Kelli Rogers – American Axle and ManufacturingJohn Ross – Dana CorporationMichael Sluder – Vehicle Certification AgencyDaniel R. Wozniak – Ford Motor Company (chair)Alan Peterson – Plexus CorporationCQI-73Issue: 01 Dated: 6/03Replaces: N/A Dated: N/A

ISO/TS 16949:2002IMPLEMENTATION GUIDECQI-74Issue: 01 Dated: 6/03Replaces: N/A Dated: N/A

ISO/TS 16949:2002IMPLEMENTATION GUIDETABLE OF CONTENTSAIAG PUBLICATIONS. 1CAUTIONARY NOTICE. 1MAINTENANCE PROCEDURE. 1APPROVAL STATUS . 1FOREWORD. 2ACKNOWLEDGEMENTS. 31.0 OVERVIEW . 72.0 WHAT'S "NEW AND DIFFERENT" . 92.1 CUSTOMER ORIENTED PROCESSES . 103.0 EXPLANATION OF PROCESS APPROACH / AUDIT . 153.1 WHAT TO EXPECT FROM THE PROCESS APPROACH SECTION . 153.2 BENEFITS OF USING THE PROCESS APPROACH . 153.3 WHAT IS A PROCESS? . 163.4 THE BUILDING BLOCKS OF A PROCESS . 173.5 THE PROCESS APPROACH . 184.0 SETTING UP THE QUALITY MANAGEMENT SYSTEM . 214.1 STEP 1 – PROCESS IDENTIFICATION . 214.2 STEP 2 – PROCESS MAPPING . 214.3 STEP 3 – EFFECTIVENESS . 224.4 STEP 4 - AUDITING . 234.5 STEP 5 – DOCUMENTATION TO CERTIFICATION BODY . 295.0 STRATEGY FOR IMPLEMENTING ISO/TS 16949:2002. 316.0 REGISTRATION PROCESS . 377.0 PITFALLS TO AVOID . 39APPENDIX A - CROSSOVER MATRIX QS-9000 3RD TO ISO/TS 16949:2002 . 47APPENDIX B – CROSSOVER MATRIX ISO/TS 16949:2002 TO QS-9000 3RD . 103APPENDIX C – PROCESS IDENTIFICATION TOOL . 151APPENDIX D – RECOMMENDED TRAINING . 153APPENDIX E – IATF CONTACT INFORMATION . 155APPENDIX F – ISO/TS 16949:2002 MANUALS . 157APPENDIX G – HEAT TREAT PROCESS EXAMPLE . 159APPENDIX H – THE QUALITY MANAGEMENT SYSTEM AUDIT. 165APPENDIX I – THE MANUFACTURING PROCESS AUDIT . 169APPENDIX J – PROCESS MAPPING EXAMPLES . 171APPENDIX K - CERTIFICATION/SURVEILLANCE AUDIT PLAN INSTRUCTIONS . 191APPENDIX L - DOCUMENTATION STRATEGY. 197APPENDIX M - BIBLIOGRAPHY . 201ABOUT AIAG . 203PURPOSE STATEMENT . 203CORE VALUES . 203AIAG ORGANIZATION . 203AIAG PROJECTS. 203MAINTENANCE REQUEST . 205CQI-75Issue: 01 Dated: 6/03Replaces: N/A Dated: N/A

ISO/TS 16949:2002IMPLEMENTATION GUIDECQI-76Issue: 01 Dated: 6/03Replaces: N/A Dated: N/A

ISO/TS 16949:2002IMPLEMENTATION GUIDE1.0 OVERVIEWThis implementation guide is written to help transition the organization’s current quality management system(QMS) from QS-9000 3rd edition to ISO/TS 16949:2002. Since this implementation guide serves as only aguidance document there will be some duplication. This was done intentionally so that the reader does nothave to read different sections to find an answer to a question.Keep in mind that ISO/TS 16949:2002 uses ISO 9001:2000 as its base specification. For better understandingand clarification purposes, it will be important to access the International Organization for StandardizationWeb site at www.iso.org for additional information prior to using this implementation guide.The following IATF ISO/TS 16949:2002 publications (e.g. 4 pack) are available through the AIAG: IATF ISO/TS 16949:2002 Technical Specification (required document) IATF Guidance to ISO/TS 16949:2002 IATF Quality System Assessment Checklist IATF Rules for achieving IATF recognitionSome of the ISO/TS 16949:2002 customer specifics still require use of the core tools identified in the QS-9000manual. It is suggested that copies of these manuals are on hand when designing and implementing a qualitymanagement system. Production Part Approval Process (PPAP) Advanced Product Quality Planning (APQP) Measurement Systems Analysis (MSA) Statistical Process Control (SPC) Potential Failure Mode and Effects Analysis (FMEA)Refer to each customer’s requirements for applicability.When transitioning to ISO/TS 16949:2002, it is recommended that the certification body be contacted withany questions regarding the interpretation of any requirements. Sanctioned Interpretations, Frequently AskedQuestions (FAQs) and other useful information can be found on the International Automotive OversightBureau Web site at www.iaob.org.It is important to remember that ISO/TS 16949:2002 uses the new terminology of "Process Approach" and isfurther clarified in this implementation guide. Depending on how the organization’s current qualitymanagement system is set up, the QMS may already be in compliance to the "Process Approach” (versus QS9000 traditionally using an "Elemental Approach").ISO/TS 16949:2002 focuses on customer satisfaction. It is important to design, implement and maintain theorganization’s quality management system based on this focus. This includes greater attention to customerspecific requirements and the organization’s ability to satisfy them. It is no longer good enough to documentwhat you do and do what is documented, but also to verify the effectiveness of the organization’s processes inmeeting customer and internal requirements.As part of the continual improvement process, all changes/revisions to this guidance document and responsesto questions are posted on the AIAG Web site at www.aiag.org. Refer to the Maintenance Request form atthe end of this manual to see how to submit comments.CQI-77Issue: 01 Dated: 6/03Replaces: N/A Dated: N/A

ISO/TS 16949:2002IMPLEMENTATION GUIDECQI-78Issue: 01 Dated: 6/03Replaces: N/A Dated: N/A

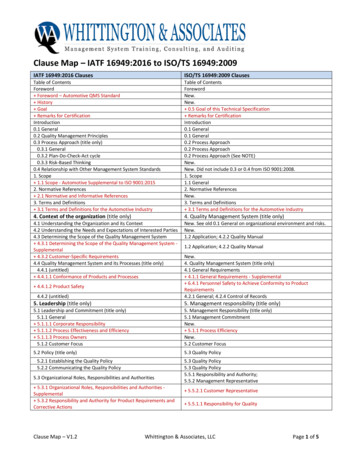

ISO/TS 16949:2002IMPLEMENTATION GUIDE2.0 WHAT'S "NEW AND DIFFERENT"It is important to understand what is new and different before converting the organization’s qualitymanagement system from QS-9000 3rd to ISO/TS 16949:2002. The following are some key points of interest:QS-9000 3rdISO/TS 16949:2002AIAG ManualsQS-9000 7 PackBase StandardISO 9001:1994 (italicized text)ISO/TS 4 Pack plus APQP, FMEA, MSA,SPC, PPAPISO 9001:2000 (boxed text)Change in Terms Supplier / Sub contractorProceduresExecutive ManagementSpecified Requirements Changes in Intent ConformityQuality AssuranceDocumented ProceduresMeeting ProductRequirementsSkillsOrder DrivenDocumentation for conformityProduct measurementFormat20 elementOrganization / SupplierProcess and ProceduresTop ManagementISO/TS 16949 and CustomerRequirements Performance Customer Satisfaction Managed Processes Meeting needs and expectations ofparties Competence Customer Dr

ISO/TS 16949:2002 focuses on customer satisfaction. It is important to design, implement and maintain the organization’s quality management system based on this focus. This includes greater attention to customer specific requirements and the organization’s ability to satisfy them. It is no longer good enough to document what you do and do what is documented, but also to verify the .