Transcription

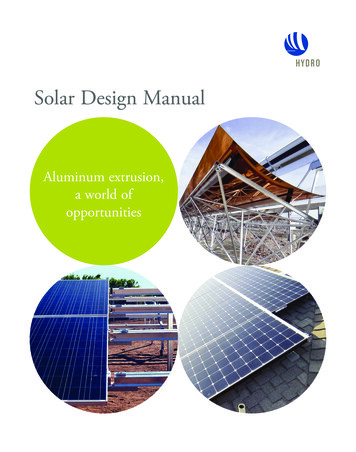

Solar Design Manual 8.qx HydroTemp 7/3/12 6:33 PM Page 1Solar Design ManualAluminum extrusion,a world ofopportunities

Solar Design Manual 8.qx HydroTemp 7/3/12 6:33 PM Page 2Aluminum — The material of the futureAluminum has been described as the “materialof opportunity” and more and morecompanies in the solar industry are realizingthe obvious benefits of using aluminum.A significant benefit of aluminum and thealuminum extrusion process is the almostunlimited opportunity to adapt the shape of theproduct to optimize performance, maximizestiffness and strength, and reduce the numberof parts to assemble and fabricate; all of whichcontribute to lowering cost. The low density ofaluminum can also ease handling andtransportation throughout the supply chain bycreating lighter weight components andassemblies. And, aluminum is highly durable,almost maintenance-free, and 100% recyclable.www.hydro.com/northamerica/solarAs it relates to solar applications, aluminum’sunique properties include: High strength-to-weight ratioVery cost effective, with proper system designExcellent formability and ease of fabricationExcellent electrical and thermal conductivityExcellent resistance to corrosionAttractive surface finishExcellent reflector of light and heatEasy and economical recycling

Solar Design Manual 8.qx HydroTemp 7/3/12 6:33 PM Page 3Table of ContentsSolar applications for aluminum extrusions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4PV and solar thermal collector module frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4Solar mounting systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4Solar inverters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5Solar thermal applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5PV solar frame & mounting system design considerations . . . . . . . . . . . . . . . . . . . . . 6IBIS PV mounting structure analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8Concentrating Solar Power (CSP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10IBIS CSP frame structure analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13Solar thermal design considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15Aluminum, the green metal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16The properties of aluminum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18Aluminum alloys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20Corrosion resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22Types of extrusions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24Extrusion design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24Joining options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26Anodizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28Hydro plant capabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29North American resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Solar Design Manual 8.qx HydroTemp 7/3/12 6:33 PM Page 4Solar applications for aluminum extrusionsPV and solar thermal collector module framesPhotovoltaic (PV) and solar thermal arraysdeliver efficient, environmentally-friendlyalternatives to fossil-fuel-based powergeneration. Technological advances have led tolower production and installation costs. Amongthese advances is the use of creative design withaluminum extrusion components in the framestructure and other areas of the solar array.With the number of solar parks androoftop installations increasing, people arebecoming more concerned about the aestheticsand maintenance of the array structure. Ownersand operators are looking to solar as a source ofenergy while remaining as unobtrusive aspossible. Architects desire solar systems thatblend in with the rest of the building andsurrounding area.Extruded aluminum frame structures meet orexceed the strength and flexibility requirementswhile delivering a lower lifetime cost comparedto steel frames, especially with a properlydesigned custom solution. Aluminum alsoprovides a high level of aesthetic appeal throughanodizing or powder coating to achieve thedesired surface finish. And, an aluminum framestructure will remain free of rust and resistantto corrosion for the life of the structure.Long life, simple design, easy installation,and greater aesthetic appeal over the life of thestructure – combined with lower lifetime cost –makes aluminum the metal of choice for solar.Solar mounting systemsSolar mounting systems attach the solar panelarray to either the ground or rooftop forresidential and commercial applications. Forrooftop installations, a variety of frame designsare used depending on whether the system ismounted to a pitched or flat roof.Aluminum ideal for rooftop weight limitationsExisting rooftops typically were not designed tosupport the weight of a solar installation. Butthe low density of aluminum helps to make asolar installation feasible, especially on thoserooftops that simply cannot handle the highweight of a steel frame structure.Aluminum extrusions deliver superiordesign flexibility, high strength-to-weight ratio,excellent corrosion resistance and ease ofhandling and assembly – all of which areessential for a successful commercial rooftopinstallation. These characteristics makealuminum the metal choice for solar framestructures installed on carports, commercialbuildings and home rooftops.4www.hydro.com/northamerica/solarGround installationAluminum extrusions are ideal for PV and CSPconstruction because they provide: Stiffness to maintain reflector geometry at alltimes (CSP) Strength to withstand the dead and live loads Excellent durability and corrosion resistance Ease of assembly Lower Total Cost of OwnershipWith aluminum, you gain a lightweightstructure that is easy to handle, transport, andinstall; a structure which is easy to maintainover a long life and resistant to the corrosiveeffects of weather. Aluminum is especiallydesirable for solar parks constructed overlandfills or other areas where escaping gases orother environmental impacts may corrode steelframe structures.

Solar Design Manual 8.qx HydroTemp 7/3/12 6:33 PM Page 5Solar invertersA solar inverter changes the direct current(DC) electricity produced by a photovoltaicarray into alternating current (AC). AC is thetype of current used in commercial andhousehold electrical applications.Inverter cabinetsInverter electrical components are housed in acabinet that can be produced using aluminumextrusions for a cost-effective and highlyutilitarian result. Aluminum inverter cabinetsare lighter weight and offer greater designflexibility than steel cabinets. Aluminumextrusions deliver a faster prototyping capability.With aluminum extrusions you gain theability to create complex enclosures using twoor more simpler extrusions. You can simplifyassembly and optimize product performancewith aluminum. Select your choice of a varietyof finish options, like anodizing. Certain finishattributes, like decorative grooves, can bedesigned into the extrusion. The end result is alower cost, corrosion resistant, lower weightcabinet that also offers the possibility of addingmore components without adding significantlyto the original weight.Heat sinksHeat sinks are used in inverter cabinets todissipate heat. The efficiency of a heat sinkdepends on its ability to transfer heat quicklyaway from the components that requirecooling. Good heat transfer is achieved byusing materials of high thermal conductivitythat can be shaped to give high surface areas.Aluminum extrusions satisfy all of theserequirements, and can be integrated into thestructure.The extrusion process allows you toproduce components in many shapes and sizessuch as the closely spaced narrow fins requiredin heat sinks for heat dissipation. Incomparison to other materials the combinationof aluminum and shape results in lower costcomponents.Solar thermal applicationsAluminum extrusions offer a variety ofsolutions for solar thermal collectors andconnecting lines. For all absorbers, substitutingcopper tubes with aluminum gives immediatecost and weight advantages.Plate and tube absorbersAluminum offers long life, ease of installation,high strength and low corrosion compared toother tube materials such as copper. Thealuminum alloys used to produce solarabsorber tubes meet or exceed all requirementsfor the solar absorber market with excellentflow rate and heat transfer properties.High performance absorbersUsing aluminum in solar absorbers provides theneeded flexibility to implement novel designsolutions (e.g. combining plate and tube).Micro-channel profiles may be assembled tomanifolds and coated to combine the functionsof heat absorption and fluid transport.Connecting linesWith interest in the use of aluminum inabsorbers increasing, it is natural to extend thisto connecting lines, where the cost advantagesare obvious.Extruded aluminum tubing products havebeen proven for handling hot liquids in theautomotive, trucking, specialty vehicle anddefense industries, among others. Withaluminum tube connector lines, you will takefull advantage of the many proven propertiesof aluminum, including its ability to resistdamage in corrosive conditions, non-magneticand non-sparking, lightweight and highstrength. Aluminum delivers design flexibility,high performance, efficiency, reliability andlow cost.5www.hydro.com/northamerica/solar

Solar Design Manual 8.qx HydroTemp 7/3/12 6:33 PM Page 6PV solar frame & mounting system design considerationsEase and speed of assemblyA good solar design optimizes the number ofparts that need to be fastened together on site,as well as assembly and training required for theinstallation team, lowering the total cost. Lowerlabor costs and fast installation are competitiveadvantages resulting from a proper designincorporating aluminum extruded components.You also will experience lower heavy equipmentcosts because lighter weight loads can behandled manually or by smaller machines,saving costs on cranes, front end loaders andother construction machinery. And lightweightaluminum extruded components ship for less.Coatings and cosmetic appearanceUnder normal circumstances, aluminumextruded frame components left unfinished(mill finish) will outlast the 20- to 30-year lifeexpectancy of a commercial or residential roofand current solar panel technology. This isdue to aluminum’s natural resistance tooxidation and other environmental effects.Where aesthetics is a design concern, the useof a finish will add to the look of the solarinstallation. Common finishing techniquesinclude powder coat painting and anodizing inthe designer’s choice of colors, with powdercoating being the significantly more affordableoption.Tight tolerance for mitering and corner jointsDesign your frame structure so that it snapstogether without gaps that would allowmoisture penetration. Aluminum extrudedcomponents can be designed for quick, easysnap-together construction with tight ustable PV frame designBecause the industry has not developed astandard size for solar panels, design yourframe structure to be adaptable for differentsize panels. An adjustable frame design givesyour solar panel vendor selection flexibility aswell as design adaptability. One of thestrengths of aluminum extrusion framecomponents is the ease with which they can beadapted to different size requirements. Forexample, the same extrusion profile can befabricated to different lengths and assemblyrequirements (holes, notches, etc.) at the plantfor ready-to-assemble delivery.Racking and mountingDesign your racking and mounting structuresthat work with your frame to form a complete,unified structure. With a proper design, yoursolar system will work great and cost less.Roof- and ground-mounted solar systems eachhave their own design issues.Roof-Mounted Systems: Decide whether to use apenetration or ballast mount. A penetrationsystem places less weight on the roof structureand is suitable where weight is an issue. Yourdesign needs to be consistent with therequirements of the roof warranty to assure thatthe design doesn’t void the warranty. For thesereasons, penetration designs should be avoidedunless a ballast mount design is not possible.Ballast mount does not require penetration of

Solar Design Manual 8.qx HydroTemp 7/3/12 6:33 PM Page 7the existing roof structure, but the ballasts doadd significant weight. Design considerationsinclude: Roof pitchFrame structure angleEase of access to the roof for installationEase of access to the frame system formaintenance and repair after installation Existing roof hazards such as cables andother obstaclesFor most applications, the preferred roofdesign for solar is a ballast mount system witha low angle to minimize wind exposure.Ground-Mounted Systems: Design your groundmount solar system to be adjustable fordifferences in land contours. In many cases, youmay want your system to be be self-leveling,especially for uneven areas like landfills wherethe ground will shift significantly over time.Modularity & scalabilityDesign your solar system to fit the spaceavailable and to expand as additional spacebecomes available. A modular system

Solar mounting systems attach the solar panel array to either the ground or rooftop for residential and commercial applications. For rooftop installations, a variety of frame designs are used depending on whether the system is mounted to a pitched or flat roof. Aluminum ideal for rooftop weight limitations Existing rooftops typically were not designed to