Transcription

FACT SHEET(Pursuant to Nevada Administrative Code (NAC) 445A.40 1)Permittee Name:Bullfrog Mines LLCProject Name:Bullfrog MinePermit Number:NEVOO8 023Review Type/Year/Revision:Renewal 2021, Revision 00A.Location and General DescriptionLocation: The Bullfrog Mine is located in Nye County, approximately 3 miles southwestof Beatty along Nevada State Highway 374. The Bullfrog Mine lies adjacent to LaddMountain and on the northern end of the Amargosa Desert, within Sections 9, 10, 11,14, 15, 16, 21, 22, 23, 26, 27, 28, 33, 34 and 35, Township 12 South (T12S), Range 46East (R46E); Sections 3 and 4, T13S, R46E, Mount Diablo Baseline and Meridian. Themine site is located on approximately 461 acres of private land and 55.5 acres on landsadministered by the U.S. Bureau of Land Management, Battle Mountain District,Tonopah field Office.General Description: This facility is in permanent closure. When operating, it consistedof three open pits and underground mining with ore processing by milling andconventional carbon-in-pulp technology (CIP). Precious metal recovery followingmilling was obtained by electrowinning. The facility was required to be designed,constructed, operated, and closed without any discharge or release of process fluids inexcess of the standards established in regulation except for meteorological events whichexceed the design storm event. This was a large-scale facility, processing in excess of2,500,000 tons of ore per year. The facility included an administrative office, warehouse,lab, two maintenance shops, three open pits, a crusher, CIP mill, CIP facilities, fourtailings ponds, two reclaim water collection ponds for the tailings facility, twoevaporation ponds, and two infiltration basins. Land disturbed during Barrick Bullfrogmining! milling operation totaled approximately 1,400 acres including haul and accessroads.B.SynopsisHistory: Mining in the area began in the early 1900s. The existing Bullfrog Mine beganoperations in July 1989 by Bond Gold. In June 1991, LAC Minerals Inc. purchased theproperty and underground mining was added to the Bullfrog Pit. Open pit operationsceased in 1997 and underground mining ended in December 1998. Milling andprocessing concluded on 11 November 1999. All beneficiation facilities were dismantledand removed by 15 December 2000. Banick Gold Corporation (BGC) had acquired themine in September 1994. BGC sold the property to Rocky Mountain Minerals Corp. in2020. In early 2021, the new Permittee requested that the Permit be transferred to itssubsidiary Bullfrog Mines LLC. Transfer documents, as required by NAC 445A.419,were received by the Division and the 2021 Renewal includes the new Permittee name.

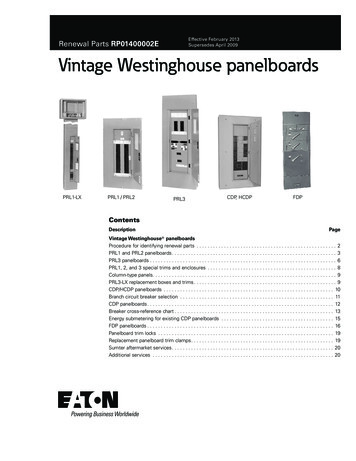

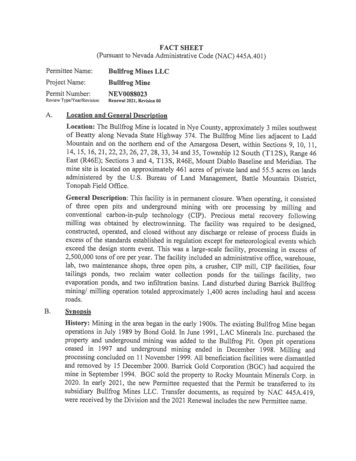

Barrick Bullfrog Inc.Bullfrog MineNEV0088023 (Renewal 2021, Fact Sheet Revision 00)Page 2 of9Geology: The Bullfrog Mine is located within the Basin and Range Tectonic Province.The southern Bullfrog Hills are mainly composed of a thick sequence of Tertiaryvolcanic rocks erupted from several calderas near Timber Mountain to the east of theBullfrog Hills. North striking, west dipping normal faults have tilted and rotated much ofthe volcanic section to as much as 40-90 degrees in a series of east-facing blocks.Mineralization consists of a series of open spaced fissure veins, vein breccias, andstockworks of quartz and calcite with manganese oxides. The tailings facility is locatedsouth of Ladd Mountain and is underlain by alluvial basin deposits. These deposits ofsand and gravel are well graded and have a thickness of approximately 1,000 feet in thetailings area.Open Pits (3):Bonanza Mountain PitApproximate size is 1 acres and extends to a depth ofapproximately 400 feet below the adjacent topography. This pit is not free draining andthere are occasional accumulations of meteoric water occur.-Montgomery-Shoshone Pit Approximate size is 52 acres and extends to a depth ofapproximately 200 feet below the adjacent topography. The pit is not free draining butdoes not impound water.-Bullfrog Pit- Approximate size is 194 acres with depth of pit being 1,000 feet belowadjacent topography. Underground mining operations occurred in the high wall of thispit. This pit was partially backfilled in April 2000 to a predicted elevation to prevent a pitlake from forming. Subsequently, field measurements and groundwater modeling haveshown that the continued influx of groundwater into the pit has resulted in the formationof a pit lake. Material selected to use for additional backfill had been characterized andwas submitted with the 6 December 2013 pit lake update (“Design Criteria andConstruction Drawings Bullfrog Partial Pit Backfill”). This was the only pit thatintercepted the groundwater table. All pit lithologies were tested and determined topossess net neutralizing characteristics. During an 18 July 2016 meeting with the NevadaDivision of Environmental Protection (Division) and a subsequent amendment (17November 2016), the Permittee submitted an updated pit lake model justifying the levelof backfill for the Bullfrog Pit. The Permittee planned to add additional backfill,1,223,000 cubic yards, which would raise the pit floor approximately to 3,041 feetAMSL. Coarse-grained material from the west waste rock borrow source on thesouthwest corner of the pit was used to bring the bottom of the pit floor elevation up fromprevious models. An additional 3 feet of fine-grained material from the west fines alluvialbench borrow area on the southeast corner of the pit or fines from the east sideunderground fines backfill stockpile area, or both, was used. This work was concluded,and a record of construction document was approved by the Division on 8 January 2018.Visual inspections of the pits are conducted semi-annually. Other than occasionalephemeral ponded meteoric water, the pits have remained dry. See figure 1 formonitoring locations map.P:\BMRR\RegClos\Projects\Bullfrog Mine\PermitDocs\2021 RenewahNOD\2021 0324LK 00 8023 BullfrogjactSheet.docx

Barrick Bullfrog Inc.Bullfrog MineNEV0O 8023 (Renewal 2021, Fact Sheet Revision 00)Page 3 of 9Underground:There were four portals and four ventilation shafts. The portals were backfihled withwaste rock pushed into the declines from 50 feet behind the entrance to withinapproximately 15 feet from the portal entrance. The final 15 feet were sealed by pushingcemented backfill into place from floor to roof. The ventilation shafts were backfihledwith waste rock to the surface. Two feet of alluvial material was mounded over thebackfihled shafts to provide for vegetative cover.Waste Rock Storage Facilities (WRSFs, 7):There are seven WRSFs at the Bullfrog Mine. They are the Lower Bonanza, UpperBonanza, Lower Montgomery-Shoshone, Upper Montgomery-Shoshone, North, South,and West WRSFs. Waste rock removed from the pits consisted of oxidized, silicified andargillically altered volcaniclastic and lacustrine sediments and healed breccias. Acidgeneration potential from both the ore and waste rock was determined to be very lowwith a maximum pyrite content of 1-3% and a high neutralization potential based onacid-base accounting conducted on the rock samples. The remaining acres of disturbedground, including the WRSFs, have been or will be regraded and seeded during the finalclosure of the site.Tailings Storage Facility (TSF):The four cells of the Bullfrog TSF are located on private land and were constructed in anequal cell arrangement of approximately 90 acres each. All four cells were constructedwith synthetic liners. Cell 1 has a 40-mil polyethylene liner; Cells 2, 3, and 4 have a 60mu high-density polyethylene (HDPE) liner. A final lift of the embankment wasconstructed around Cells 1 and 2; the resulting facility is referred to as the Composite 12, which has been closed according to a plan submitted by Barrick Bullfrog Inc. (BBI) inNovember 1995. A final lift of the embankment was constructed around Cells 3 and 4;the resulting facility is referred to as the Composite 3-4. A two-part closure plan for Cells3-4, submitted 3 November 1999, has been implemented. An engineered cover consistingof topsoil and alluvial soils 12-14 inches thick overlying dewatered tailings wascompleted in 2000 (Part 1). This closure and reclamation included all but approximately30 acres of the TSF. The closure of the remaining 30 acres (Part 2) was completed inJanuary 2008. This work included the abandonment of 10 piezometers; installing a 12-14inch soil cover over the tailings material; construction of drainage swales; construction ofthe rip-rap lined spillway and stilling basin; removal of the abandoned inclined-decantstructure to a level below the tailings surface and the revegetation of the surface.In 2011 Golder Associates (Golder) produced a draindown study on behalf of BBI(“Lined Pond Closure Project, Updated Water Balance,” 20 July 2011). The reportpredicted a draindown rate of 2 gallons per minute (gpm) by 2015. The actual 2015draindown was approximately 10 gpm (see Table 1). The Golder model incorporatedlocal precipitation and evaporation rates as well as anticipated meteoric water for a 100year, 24-hour storm event (2.6 inches of precipitation). The model tracked predictedflows into the evaporation ponds from tailings Cell 1-4, pump flows from the reclaimponds prior to decommissioning and flows from direct precipitation.P:\BMRR\RegClos\Projects\Bullfrog Mine\PermitDocs\2021 Renewal\NOD\202 I 0324LK 0088023 Bullfrog factSheet docx

Barrick Bullfrog Inc.Bullfrog MineNEV0O 023 (Renewal 2021, fact Sheet Revision 00)Page 4 of 9Table 1: Bullfrog Mine Tailings Impoundment Average Draindown RateYear2006Draindown Rate (gpm)852010201518.51020207.4Table 2 below provides long-term water quality for parameters elevated or relevant tothis discussion. Draindown solution from the tailings impoundment is piped to thedischarge box at the evaporation cell.Table 2: Bullfrog Mine Tailings Impoundment Draindown Parameters of InterestParameter1995(a) Tailings Pond(mgJL)2020(b)Discharge Box(mg/L)Alkalinity, total (No DRV)t35825Arsenic (DRV: 0.0 10)0.020.141.90.880.020.100.0073 0.00047.70.249.78.90.027 0.0058901,2002,0462,6000.01 1Iron (DRV: 0.60)Manganese (DRV: 0.10)Mercury (DRV: 0.002)Nitrate Nitrite (as N) (DRV: 10)pH (SU) (DRV: 6.5 8.5)Selenium (DRV: 0.05)—Sulfate (DRV: 500)IDS (DRV: 1,000)WAD Cyanide (DRV: 0.2)()(a)(b)(c)(d)17Annual 1995 Monitoring Report.Fourth Quarter 2020 Monitoring Report.DRV Division Reference Value in mg/L, unless otherwise noted.SU Standard units.The sampling of the downgradient monitoring wells EW- 1 and MW-2 will continue asscheduled in the Permit as part of the verification of the integrity of the rog Mine\PermitDocs\2021 Renewal\NOD\202 I 0324LK 0088023 BullfrogjactSheet.docx

Barick Bullfrog Inc.Bullfrog MineNEV0088023 (Renewal 2021, Fact Sheet Revision 00)Page 5 of9pvr%Bullfrog Mine VOO88O23ELM\‘ tt% !LMELM1*.’ELM--.F’vrMontgomery-Shoshone Pit-ELMLower Montgomery-Shoshone WRSF‘Upper Montgomery6LMShoshone WRSFFYII.FYIELMDW4sELMNorthWRSFFYIELMBullfrog PitFYI—-West WRSFBMMW 30-95FYIReclaim Pond 34(Closed)Reclaim Pond 1-21.ELM.sDischarge Box7E-cell I.-—t—FYI—MW-A-E-Pond 2-E-cell 1 LDS.-.-BMMW 31-95NEW-1CCZSCSlull?12EUCC.3Figure 1: Site facilities and monitoring locations.P:\BMRR\RegClos\Projects\Sullfrog Mine\PentitDocs\2021 Renewal\NOD\202 10324LK 0088023 BullfrotFactSheet.docx

Barrick Bullfrog Inc.Bullfrog MineNEV0088023 (Renewal 2021, Fact Sheet Revision 00)Page 6 of9Ponds (4):All ponds were constructed with a 60-mil HDPE liner placed over a 40-mil HDPEsecondary liner. A 0.25-inch thick geogrid leachate collection and recovery system wasconstructed between the two geomembranes. The original Reclaim Pond was closed byan earthwork contractor during Phase I closure of the composite tailings impoundment.The re-constructed reclaim pond was referred to as the Reclaim Pond 1-2 and functionedas a retaining pond for the underdrain solution from Cells 1 and 2. Underdrain solutionfrom the Cells 3 and 4 discharged to the Reclaim Pond 3-4 located on the southwest sideof Cell 4. Solution in the Reclaim Pond 1-2 was periodically pumped into the ReclaimPond 3-4.In 2005, two new ponds were constructed to manage the tailings draindown; these wereEvaporation Ponds 1 and 2 (EP-1 and EP-2). The solution flow from the reclaim pondswas diverted to the evaporation ponds so that the Reclaim Ponds could be closed. Alldraindown currently reports to EP-2 (now an e-cell) through the use of a distribution box.EP-1 functions as an overflow pond and is planned to be either closed or converted to ane-cell at some point in the future.In April 2013, BBI submitted a request to convert EP-l into an evaporation cell. TheDivision approved this request; construction was carried out in 201 . The constructionplan for the evaporation cell included “salt wicks” to address high total dissolved solidsconcentrations. However, these ended up not being installed due to questions regardingefficacy.Reclaim Ponds 1-2 and 3-4 were approved for closure following Division review of aFinal Plan for Permanent Closure submitted by BBI on 25 May 2016. The pondshave since been closed and reclaimed. As-built documentation for the closures wasapproved by the Division on 23 July 2018.Infiltration Basins (2):The Infiltration Basins were designed to infiltrate groundwater pumped from dewateringthe Bullfrog Pit. One basin has been regraded and revegetated. The remaining one will beclosed and reclaimed during final closure of the facility; it currently exists as astormwater basin.Monitoring Wells (6):EW-1, BMMW-30-95, BMMW-3 1-95, MW-2, and MW-4 are all down-gradient of oradjacent to the tailings impoundment. Well DW-4 is north of the Bullfrog Pit and ismonitored only for groundwater elevation. Low levels of weak acid dissociable(WAD) cyanide ( 0.2 mg/L) have been detected in MW-4. The Permittee is required tomonitor this well to ensure the WAD cyanide does not increase to levels above Divisionreference values. See Table 3 for monitoring well chemistry.P:\BMRR\RegClos\Projects\Bullfrog Mine\PermitDocs\202 l Renewal\NOD\20210324LK 0088023 Bullfrog factSheetdocx

Barrick Bullfrog Inc.Bullfrog MineNEVO08 023 (Renewal 2021, Fact Sheet Revision 00)Page 7 of 9Table 3: Selected chemistry of site monitoring wells (in 3698.1596.4250200210230200 0.0050.006 0.005 0.0050.007Fluoride DRV: 4.04 3(c)4.454.82.7Iron DRV: 0.60 0.10 0.10 0.10 0.10 0.10Magnesium DRV: 1500.592.66.84.95.3Manganese DRV: 0.10Nitrate Njtrite (as N)DRV: 10 0.01 0.010.023 0.01 0.01 ,500500660560630 0.01 0.010.034 0.01 0.01ParameterDateDepth to water (ft bgs)Alkalinity(asCaCO3)ArsenicDRV(b):p11 DRV: 6.5—0.0108.5SU’Sulfate DRV: 500TDS DRV: 1,000WAD Cyanide DRy:0.20(a) ft bgs: feet below ground surface.(b) DRV: Division Profile I reference value in mg/L.(c) Exceedances are in bold.(d) SU: standard units.C.Receiving Water CharacteristicsGroundwater occurs in hydraulically distinct fractured bedrock and basin-fill alluvialaquifers within the upper Amargosa Desert hydrographic basin. The nearest surfacewater course is the intermittent Amargosa River located 3.5 miles east of the BullfrogMine. Drainage from the mine site is to the southwest towards the playa flats of theAmargosa Desert via shallow washes. F low in the drainage is ephemeral and occurs onlyin response to large precipitation events. Groundwater monitoring, since 1989, indicatesthat the depth to groundwater ranges from approximately 200 feet below ground surface(bgs) near the toe of the Bullfrog Hills to more than 600 feet bgs on the alluvial plain inthe vicinity of the tailings impoundment. The annual precipitation at the Bullfrog Minesite averages 4.6 inches per year with a pan evaporation rate of 6 inches per year.D.Procedures for Public CommentThe Notice of the Division’s intent to issue a Permit authorizing the facility to close,subject to the conditions within the Permit, is being published on the Division website:https://ndep.nv.gov/posts/category/land. The Notice is being mailed to interested personson the Bureau of Mining Regulation and Reclamation mailing list. Anyone wishing tocomment on the proposed Permit can do so in writing within a period of 30 daysfollowing the date the public notice is posted to the Division website. The commentP:\BMRR\RegClos\Projects\Bullfrog Mine\PermitDocs\2021 Renewal\XOD\202 I 0324LK 0088023 Bullfrog FactSheet.docx

Barrick Bullfrog Inc.Bullfrog MineNEV0088023 (Renewal 2021, Fact Sheet Revision 00)Page 8 of 9period can be extended at the discretion of the Administrator. All written commentsreceived during the comment period will be retained and considered in the finaldetermination.A public hearing on the proposed determination can be requested by the applicant, anyaffected State or intrastate agency, or any interested agency, person or group of persons.The request must be filed within the comment period and must indicate the interest of theperson filing the request and the reasons why a hearing is warranted.Any public hearing determined by the Administrator to be held must be conducted in thegeographical area of the proposed discharge or any other area the Administratordetermines to be appropriate. All public hearings must be conducted in accordance withNAC 445A.403 through NAC 445A.406.E.Proposed DeterminationThe Division has made the tentative determination to issue the renewed Permit.F.Pathway to Final Closure and Permit TerminationIn accordance with NAC 445A.409 and 445A.446, for final closure and Permittermination the Permittee must demonstrate to the Division that: 1) all sources at thefacility have been stabilized, removed, or mitigated; 2) any applicable requirements inNAC 445A.429, 445A.430, and 445A.431 have been achieved; and 3) sufficient postclosure monitoring has occurred to verify the adequacy of these actions to ensure thelong-term protection of waters of the State, human health, and wildlife under thephysical, chemical, and climatic conditions reasonably expected to occur at the site. Ifthe facility includes a long-term trust and/or requires perpetual treatment or maintenance,post-closure monitoring statusmay never be reached, and the Division may not be able toterminate the Permit.The pathway to final closure and Permit termination at this facility includes the followingspecific actions: Complete approved permanent closure activities on the TSF including, but notnecessarily limited to, establishment of one or two evaporation cells (e-cells) for thecontrol of draindown from the TSF; Complete the closure of Evaporation Pond 2 by backfill or converted to an e-cell; Provide a determination of the source of the elevated constituents in downgradientmonitoring well EW- 1. A work plan may be pending depending on findings; Submit a final closure report for the TSF; Monitor the facility through major storms and large winter/spring seasons to verifythat closed components and the fluid management system remain functional with nopotential to degrade waters of the State; Discuss with the Division whether the facility is ready for final closure and Permittermination. If so, submit for review and approval a request for final closure andPermit termination including a demonstration of compliance with all applicableP:\BMRR\RegClos\Projects\Bullfrog Mine\PermitDocs\202 I Renewal\NOD\2021 0324LK 0088023 Bullfrog FactSheet.docx

Barrick Bullfrog Inc.Bullfrog MineN1V00 023 (Renewal 2021, Fact Sheet Revision 00)Page 9 of 9closure requirements (e.g., NAC 445A.379, 445A.409, 445A.424, 445A.429,445A.43 0, 445A.43 1, 445A.446, 445A.447).G.Rationale for Permit RequirementsThe facility is located in an area where annual evaporation is greater than annualprecipitation. Therefore, it must operate under a standard of performance whichauthorizes no discharge(s) except for those accumulations resulting from a storm eventbeyond that required by design for containment.This site is in permanent closure and must continue to monitor tailings impoundmentdraindown through the evaporation cell. Pit lake and waste rock storage facilities will bemonitored for the presence of water. Monitoring wells EW- 1, MW-2, MW-4, BMMW30-95 and BMMW-31-95 must be monitored for water quality and elevation. Theprimary methods for identification of impacts to waters of the State will be placed onrequired routine visual inspections of the tailings impoundment, pits, and waste rockstorage facilities as well as the sampling of monitoring wells. Specific monitoringrequirements can be found in the Water Pollution Control Permit.H.Federal Mi%ratory Bird Treaty ActUnder the Federal Migratory Bird Treaty Act, 16 U.S. Code 701-718, it is unlawful to killmigratory birds without license or permit, and no permits are issued to take migratorybirds using toxic ponds. The Federal list of migratory birds (50 Code of FederalRegulations 10, 15 April 1985) includes nearly every bird species found in the State ofNevada. The U.S. Fish and Wildlife Service is authorized to enforce the prevention ofmigratory bird mortalities at ponds and tailings impoundments. Compliance with Statepermits may not be adequate to ensure protection of migratory birds for compliance withprovisions of Federal statutes to protect wildlife.Open waters attract migratory waterfowl and other avian species. High mortality rates ofbirds have resulted from contact with toxic ponds at operations utilizing toxic substances.The Service is aware of two approaches that are available to prevent migratory birdmortality: 1) physical isolation of toxic water bodies through barriers (e.g., by coveringwith netting), and 2) chemical detoxification. These approaches may be facilitated byminimizing the extent of the toxic water. Methods which attempt to make uncoveredponds unattractive to wildlife are not always effective. Contact the U.S. Fish and WildlifeService at 1340 Financial Boulevard, Suite 234, Reno, Nevada 89502-7147, (775) 86163 00, for additional information.Prepared by:Date:LA. Kreskeyl9March2O2lRevision 00:Renewal 2021, effective 23 May 2021P:\BMRR\RegClos\Projects\Bullfrog Mine\PeimitDocs\2021 Renewal\NOD\20210324LK 0088023 BullftogfactSheet.docx

and removed by 15 December 2000. Banick Gold Corporation (BGC) had acquired the mine in September 1994. BGC sold the property to Rocky Mountain Minerals Corp. in 2020. In early 2021, the new Permittee requested that the Permit be transferred to its subsidiary Bullfrog Mines LLC. Transfer documents, as required by NAC 445A.419,