Transcription

Technical Manual, Timber FrameClad System

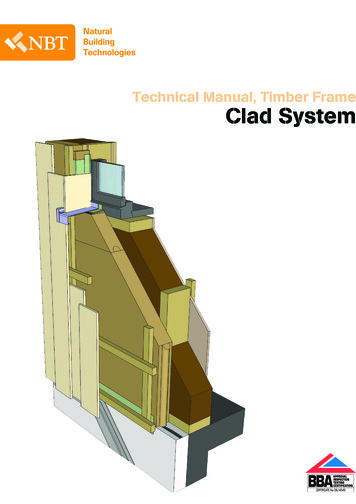

NBT TIMBER FRAME EWI - CladIntroductionDescription of Timber Frame SystemsPerformance GuideAirtightnessSummer OverheatingNBT CLAD SystemSystem Build upPhysical PropertiesKey Considerations - DesignersKey Considerations - InstallersInstallation ProceduresComponents & AccessoriesDetail Drawings NBT CLAD System2345wContent6789101315No limits to architectual design: NBT CLAD System and NBT RENDERSystem facades interact togetherNBT Timber Frame Clad SystemsThe building system is a timber frame structure insulatedbetween studs and externally with woodfibre (Pavaflexand ISOROOF or PavathermPlus respectively) andfinished with either timber clad, brick clad, metal etc.Made from over 95 % waste softwood and under5 % inert water-proofing additives, NBT PAVATEXISOROOFORPAVATHERM-PLUS,areagenuinely sustainable non-toxic building material.To produce NBT PAVATEX boards, waste woodfibres are pulped and mixed with water.The pulpis heated to activate the natural lignin they containin order to glue the fibres together. The pulp isthen pressed into boards, dried, and cut to size.The advanced manufacturing process uses the inherentproperties of wood fibres to produce boards with manyexcellent technical qualities for thermal and acousticinsulation, thermal storage capacity, vapour permeabilityand moisture control.2Natural Building Technologies LtdThe Hangar, Worminghall Road, Oakley, Buckinghamshire. HP18 9ULT: 01844 338338 F: 01844 338525info@natural-building.co.uk www.natural-building.co.uk

NBPerformance GuideA modern wall insulation system must do more thanjust protect building occupants from cold. It must create a comfortable and healthy environment in all possible combinations of external and internal conditionsand control the effects of external heat, cold, noise andinternal moisture generation.NBT Building SystemsKeep the building warm for longer in cold weather:Low thermal conductivity and high vapour permeabilityprovide high thermal insulation with no risk of interstitial condensation. Vapour barriers are unnecessary.Woodfibre boards reduce the effect of thermal bridgingand the interlocking board design easily achieves goodwindtightness, so increasing thermal performance. Energy use for heating is significantly reduced leading tolower CO2 emissions and running costs.atTNu r al I ns u la ti o n P r o du ctsfor:Simple and robustImproved heat storage for light weight structuresExcellent sound insulation for light weight structuresHighly vapour permeable constructions that donot need membranes to control interstitial condensationSubstantial saving of build cost compared withconventional timber frame constructionSimple robust construction has few skilled operationsand is easily adapted for off site manufactureReduced thermal bridging - ideal to achievehigh standard and beyondKeep the building quieter:The high mass and the fibrous texture of NBT PAVATEXwoodfibre boards give excellent acoustic performanceto buildings.Keep the building cooler in hot weather:The unique combination of high density, high specificheat capacity and low thermal conductivity gives External Wall Insulation (EWI) solutions the effect of thermalmass that would normally be associated with renderonto masonry. Compared to conventional EWI materialthe risk of condensation behind the render during coldnights is minimized as the boards will store the day’sheat.Keep the building dry and breathable:NBT PAVATEX woodfibre boards are very vapour permeable and hygroscopic. This allows them to disperseaccumulating short term moisture and protect vulnerable elements of the building fabric, with no reduction inthe performance of the boards themselves. The boardsallow moisture from within the structure to pass easilyto the outside. This provides a safeguard against highmoisture content. This is vital for the long-term healthof the building fabric, and is completely overlooked bymost conventional insulation systems.For more information please visit www.natural-building.co.uk3

AirtightnessAirtightnessPrincipleAbuilding areenvelopebe airtightwhen all ventilaopeningsclosed.shouldThe designrequirementfor airtionopeningsTherequirementforchangeshas toarebeclosed.providedbydesignopeningthe smanually, other controllable ventilation openings ormanually,other controllableventilationsuitable mechanicalventilationsystems. openings or suitable mechanical ventilation systems.When assessing the air permeability of the buildingWhenassessingthe air permeabilityof theenenvelope,the followingaspects mustbe buildingconsideredvelope,the following aspects must be considered sepaseparately:rately: Individual building components must exhibit the necessaryIndividual airtightnessbuilding componentsmustwithexhibitthein accordancebuildingnecessary standardsairtightness in accordance with buildingcomponentcomponentstandards Theoverall airpermeability of the building envelope mustThe overallair limitingpermeabilityof the buildingmeet theand targetvalues esofbuildingregulationsregulations Localair permeability (leaks, primarily on the inside) canLocal(leaks,becauseprimarilyonallowthe inside)leadairtopermeabilitymoisture damagetheymoistcan leadto infimoisturedamagebecause they allowinteriorair toltrate theconstructionmoistairinteriorair to infiltratethe construction Localpermeabilityand associateddraughts can haveLocala ffectthe thermalcomfortcanofhavea and canalsoonleadincreasedenergythe occupants and can also lead to increased enconsumptionergy consumptionAir permeabilityAir permeabilityThe airpermeability of thethe buildingbuilding envelopeenvelope isis specifiedspecifiedTheair permeabilityof surfacesurface areaby the ratio ofarea ofof thethe buildingbuilding to the hourlyPaPapressuredifference.In Partair exchangeexchangeraterateforfora a5050pressuredifference.InL BuildingRegulationsan airanpermeabilityof 10.0m3 /PartL BuildingRegulationsair permeabilityof 10.0/h 2is/hallowed,for 0.6ESTAirbestpractice for CSH3 anm23/mis allowed.changes/hourat 50levelPa pres32air permeabilityof 3.0surefor Passivhaus. m /m /h, for higher CSH levelsan air permeability of 1.0 m3/m2/h and for PASSIVHAUSanair permeabilityof 0.6 m3/m2/h are accepted as theDesignand constructionmaximum.To ensure that the building envelope has the necessarydegree of airtightness, an airtightness layer is requiredDesignandconstructionoverall partsof theconstruction on the warm side ofthe thermal insulation. Generally, the vapour controlTo ensurethat thebuildingenvelopehas the necessarylayerand airtightlayerfunctionsare combinedand prodegreeeairtightnesslayer typeis requiredvidedby ofoneairtightness,membrane,ansheetingor a boardmateover(OSB,all partsof the board,constructionon thewarm fibreboard,side of e vapourcontrol layeretc.).SuchmaterialsGenerally,require fixingsand providedbytight seals at joints and junctions in the form of adhesiveone membrane,sheetingor a boardmaterialtape,glue, mechanicalfastenersetc.,typeor mayneed (OSB,to bemulti-plyboard,plywood,heldin placewithbattens.gypsum fibreboard, etc.). Suchmaterialsrequirefixings and permanentair tightseals atRockwooland glass-fibreboards, ivetape,glue,wooden panelling, planking, acoustic linings, buildingmechanicalfastenersmay needto betheheldin greeofwith .Rockwool andglass-fiboards,wood fibreboards,wooden panelling, planking, acoustic linings, buildingThe airtightnesslayermust bethe designpapersetc. cannotachievetheconceiveddegree entirebuildingenrequired for modern buildings.velope, planned with its practical installation in mind,and airtightnessshown as layera separateon allatdrawings.Themust belayerconceivedthe nformationthe tenasa “seamless”over the entirebuildinginenvelope,der documentsdetailinstallationin the workingand andfabricationplannedwith itsandpracticalin tightas a separate layer on all drawings. Good planning includesnessc o r r e smustp o n d i ender docuadjoiningelements and detailmentssuchasin the workingwindows,doorsand ionmaterialsused toofseveralthelayersachieveaireachof whichtightnessmustarepartiallybe onlysealedairairtightwillnottight at junctionsresulta buildwith inadjoiningingwith suchan adSketch of the principle of an airtightelementsasequatedegreeofness layer: Build tight, ventilate right.windows, doorssealing.and foundations. The installation of several layers each ofwPrincipleA building envelope should be airtight when all ventilationwhich are only partially airtight will not result in a buildingTestingwithan adequate degree of sealing.In order to achieve an airtight building envelope, measuresand checks during construction and after compleTestingtion of the building are necessary. If the airtightness layer orderhas beenproperlydesignedand planned,Into achievean ormeasurements,leakdetectionbymeansand checks during construction and after ssarythe building are necessary. If the airtightness layer hascosts properlyof repairsdesignedcan be saved.beenand planned, expensive blowerdoor measurements, leak detection by means of smokeAproperlydesigned andbuildingwilltestsor IR thermography,andconstructedunnecessary costsof dforcan be saved.further special work. NBT systems provide properdesignand designedsite supportensure thatbuildingthe htnessareachieved.fulfil airtightness requirements without the needfor further special work. NBT systems provide properdesign and site support to ensure that the correctlevels of airtightness are achieved.Natural Building Technologies LtdThe Hangar, Worminghall Road, Oakley, Buckinghamshire. HP18 9ULT: 01844 338338 F: 01844 338525info@natural-building.co.uk www.natural-building.co.uk

after the external solar radiation peak – this means thatthe decrement delay of a wall or roof construction shouldbe between 6 - 12 hours.mer overheating is caused by any or a combination ofreasons:o great internal gains from appliances, people,achines etc.o much sun directly through windows due to poormmer shadingat passing directly through the wallsIn terms of achieving these satisfactory values, an insulationmaterial that has a high thermal mass is needed toproduce better values. A combination of density, thermalconductivity and specific heat capacity is required.Summer OverheatingNBT PAVATEX woodfibre boards have an excellentolution to the first is to reduce the gains or ventilate,econd requires better shading,55he third is solved by reducing peak50gain to the room by changing thement delay and factor.Decrement delay (time lag)40External amplitudement delay and factor can beght of as the amount a peaknal surface temperature isTemperature C45353025Temperature on the external surface of the wallInternal amplitude2015Temperature on the inside surface106hDay 19h12h15h18h21h24h3h6hDay 2combination of low λD (k-value) (0.038 - 0.047 W/m²K),a low decrementfactorneeded,and more importantly,(2100J/kgK)andisforinsulationSelecting the right insulation high specific heat nsity(140240kg/m³).Thesevaluesfarby between 6 - 12As part of a building’s design it is important tohoursaftertheexternalsolarradiationconsider the effects of summer overheatingexceedcontrol,any conventional insulation material. This means peak – this meansthat thewoodfidecrementdelay ofaaroofwall oror roof constructionparticularly when there are rooms in roofsor wherethat withNBT PAVATEXbre insulationshould be between 6 - 12 hours.the construction system is lightweight“lightweight”such as steelstructure such as lightweight frame buildingor timber frame.can perform as though it was a much more massiveIn terms of achieving these satisfactory values, anstructure.Summer overheating is caused by any or a combination insulation material that has a high thermal mass isneeded to produce better values. A combination ofof three reasons:The consequence isdensity,the reductionof conductivityinternal temperaturesthermaland specific heat capacity high internal gains from appliances, people,by 4 C or more inis summercomparedto a room whichrequired.machines etc.mayhavethe same U-value but conventional insulation. high solar gain through windows due topoorsummerNBT PAVATEX woodfibre boards have an excellentshadingcombination of low λ (k-value) (0.038 - 0.047 W/m²K), heat passing directly through the wallshigh specific heat capacity (2100J/kgK) and forThe solution to the first is to reduce the gains or insulation boards a high density (140 - 240 kg/m³).ventilate, the second requires better shading, and the These values far exceed any conventional insulationthird is solved by reducing peak heat gain to the room by material. This means that with NBT PAVATEXwoodfibre insulation a roof or “lightweight”changing the decrement delay and factor.structure such as lightweight frame building canDecrement delay and factor can be thought of as the perform as though it was a much more massiveamount a peak external surface temperature is smoothed structure.out by the structure, and the time that the peak is delayedbefore it reaches the inside.To reduce the solar heat passing through a roof or a wall,The consequence is the reduction of internal temperatures

air exchange rate for a 50 Pa pressure difference. In Part L Building Regulations an air permeability of 10.0 m3/ m2/h is allowed, . wooden panelling, planking, acoustic linings, building papers etc. cannot achieve the degree of airtightness required for modern buildings. The airtightness layer must be conceived at the design stage as a “seamless” layer over the entire building envelope .