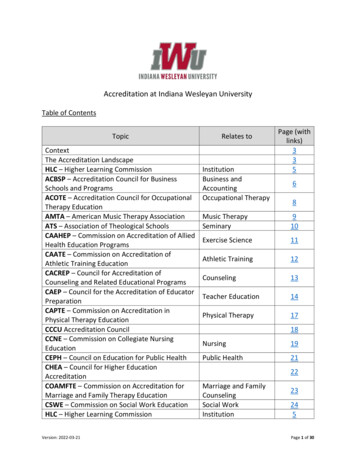

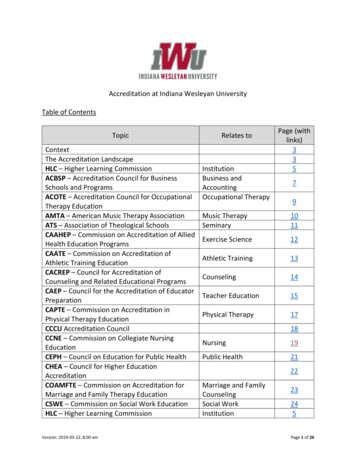

Transcription

HLC Accreditation 2016-2017Evidence DocumentResearch and Technology TransferNIAR Annual Report 2011Additional information:NIAR

2011 Annual ReportNational Institute for Aviation ResearchWichita State University

About UsThe National Institute for Aviation Research(NIAR) at Wichita State University (WSU)is dedicated to helping the Kansas aviationindustry maintain a strong competitiveposition in world aviation markets. NIAR’smission is to conduct research and transfertechnology for the U.S. aviation industry andfor federal agencies that support aviationsafety. NIAR research and development isdirected to new or improved techniques;product development processes; experimentaldatabases for design, development andcertif cation; and software for design,development and product realization.These research and development productsresult in reduced costs and/or increasedrevenues to the aviation industry in thedesign, development and manufacturing ofcommercial products.NIAR’s ten thrust areas encompass 255,000square feet of laboratory and off ce space.Major thrust areas for the Institute arecomposites and advanced materials,structures/fatigue, aging aircraft, CAD/CATIA, aerodynamics, full-scale testing,crashworthiness and environmental testingwhich are spread across nine locationsprimarily in south central Kansas.NIAR’s research expenditures have increasedsteadily since 1995; in fact, WSU/NIARranks second among all U.S. universitiesin aeronautical engineering researchexpenditures.

Funding Profile

ClientsNIAR’s laboratories and research programs are tailoredto meet the needs of the Wichita aviation industry, butour reach is global. From small start-up organizations toAAR Composites Clearwater, FLACCRAbond Inc. Olive Branch, MSACT Aerospace Gunnison, UTAero-Mach Labs Inc. Wichita, KSAerospace Manufacturing Corp.Fredonia, KSAerospace Systems & Components Inc.Wichita, KSAerospace Technologies GroupBoynton Beach, FLAeroVironment Inc. Simi Valley, CAAGCO Corporation Hesston, KSAirbus North America Engineering Inc.Wichita, KSAlbany Engineered CompositesRochester, NHAMETEK Advanced Industries Inc.Wichita, KSAnemErgonics LLC Arvada, COAORC Lexington, KYApplied Composite Technology Fayette, UTARCCA Inc. Penns Park, PAArizona Paradrogue Systems Kingman, AZATK Alliant Techsystems Inc.Plymouth, MNAviation Consulting & EngineeringSolutions Wichita, KSB/E Aerospace Wellington, FLThe Boeing Company Seattle, WABombardier Aerospace Montreal, Quebec,CanadaBurnham Composites Inc. Wichita, KSCessna Aircraft Company Wichita, KSCIBOR Inc. Wichita, KSCirrus Design Corp. Duluth, MNCSI Aerospace Inc. Broken Arrow, OKCytec Engineered MaterialsValley Center, KSDassault Systemes Services LLCCharlotte, NCDiamond Aircraft Ontario, CanadaEast/West Industries Inc. Ronkonkoma, NYlarge established international companies; from Texas tothe Netherlands; our labs provided services to each of thefollowing organizations in fiscal year 2011.The Engineering Institute LLCFarmington, ARFairmount Technologies Wichita, KSFiber Dynamics Inc. Wichita, KSFlint Hills Solutions LLC Augusta, KSGaltronics Corporation Tempe, AZGarmin International Ltd. Olathe, KSGeneral Atomics Aeronautical SystemsSan Diego, CAGKN Aerospace Service Hazelwood, MOGreat Plains Industries Inc. Wichita, KSGreene, Tweed & Company Kulpsville, PAGulfstream Aerospace CorporationSavannah, GAHarley Davidson Motor Co.Wauwatosa, WIHawker Beechcraft Wichita, KSHexcel Corporation Wet Valley City, UTHonda Aircraft Company Greensboro, NCKaman Aerostructures Inc. Wichita, KSKelly Manufacturing Co. Wichita, KSLearjet Wichita, KSLee Air, Inc. Wichita, KSLiberty Aerospace Melbourne, FLLockheed Martin Corp. Lakeland, FLMetal Improvement CompanyLivermore, CAMid-Continent Instruments Wichita, KSMillennium Concepts Inc. Wichita, KSMILTEC Corporation Huntsville, ALNASA Goddard Space Flight CenterGreenbelt, MDNaval Surface Warfare CenterWest Bethesda, MDNewport Adhesives and Composites Inc.Irvine, CAThe Nordam Group Tulsa, OKNorthrop Grumman CorporationSan Diego, CAOceaneering International Inc.Panama City, FLOrthopaedic Research Institute Inc.Wichita, KSOtto Engineering Carpenterville, ILPark Aerospace Materials Corp.Fullerton, CAPolaris Industries Inc. Roseau, MNPratt-Miller Engineering New Hudson, MIRadiance Technologies Huntsville, ALRCO Engineering Inc. Roseville, MIRECARO Aircraft Seating Inc.Fort Worth, TXRegent Aerospace CorporationValencia, CARocky Mountain Composites Inc.Spanish Fork, UTRoyal Plastic Mfg. Inc. Minden, NESaratech Inc. Dana Point, CASeats of Australia PTY. LTDVictoria, CanadaShadowfax, LLC Rancho Santa Fe, CASikorsky Aircraft Strafford, CTSpirit AeroSystems Inc. Wichita, KSStratasys Eden Prairie, MNTASS-SAFE Delft, NetherlandsTENCATE Advanced Composites Inc.Morgan Hill, CAToho Tenax of America Rockwood, TNToray Composites America Inc.Tacoma, WAUniversal Lubricants LLC Wichita, KSUniversity of Kansas Lawrence, KSUS Army Redstone Arsenal, ALUSB FireWire/RR Business Ventures LLCWichita, KSValdez International CorporationColorado Springs, COWichita Area Technical College Wichita, KSWork Force Alliance Wichita, KSZodiac Aerospace Provo, UTZoltek St. Louis, MO

Organizational Chart

Industry Advisory CouncilNIAR takes advantage of its location in the “Air Capitolof the World,” through the Executive Industry AdvisoryCouncil. This group of senior level management fromBoeing Integrated Defense Systems, Bombardier Learjet,Cessna, Hawker Beechcraft and Spirit AeroSystemsJames M. (Mike) RushChief Engineer, Global Transport& Executive SystemsBoeing Integrated Defense SystemsDavid BrantSenior Vice President,Product EngineeringCessna Aircraft Companyprovides NIAR researchers with input from key playersin the local aviation industry. The information offered bythese individuals helps outline and prioritize future researchtopics, equipment updates and laboratory additions.Stephen McCulloughVice President, ProductDevelopment - Learjet 85Bombardier AerospaceHeidi McNaryVice President and Chief Technical OfficerProduct Development and EngineeringHawker Beechcraft CorporationH. David WalkerSenior Vice President - Chief TechnologyOfficer, Business DevelopmentSpirit AeroSystems

ContactsJohn Tomblin, Ph.D.Executive Directorjohn.tomblin@wichita.edu(316) 978-5234Center for Friction Stir Processing(CFSP)Dwight Burford, Ph.D.dwight.burford@wichita.edu(316) 978-3204NDT TrainingJohn Saundersjsaunders@niar.wichita.edu(316) 677-1410Tom AldagDirector of Research &Developmenttom.aldag@wichita.edu(316) 978-5326Center of Excellence forComposites & Advanced Materials(CECAM)Tracee Friesstracee.friess@wichita.edu(316) 978-5597Metrology LabDon Hansendon.hansen@wichita.edu(316) 978-8240Jerry AntesDirector of Operationsjerry.antes@wichita.edu(316) 978-5888Center of Excellence for GeneralAviation Research (CGAR)Gabrielle Dodoshgabrielle.dodosh@wichita.edu(316) 978-5218National Center for AdvancedMaterials Performance (NCAMP)Yeow Ngyeow.ng@wichita.edu(316) 978-5212Tracee FriessMarketing & CommunicationManagertracee.friess@wichita.edu(316) 978-5597Composites & Advanced MaterialsLabTom Aldagtom.aldag@wichita.edu(316) 978-5326National Center for AviationTraining (NCAT)www.ncatkansas.org(316) 677-9400Advanced Coatings LabBrandon Huntbrandon.hunt@niar.wichita.edu(316) 677-1334Computational Mechanics LabGerardo Olivares, Ph.D.gerardo.olivares@wichita.edu(316) 978-7273National Center of Innovationfor Biomaterials & OrthopaedicResearch (CIBOR)Rich Sullivanrich.sullivan@ncibor.org(316) 247-7900Advanced Joining &Processing LabDwight Burford, Ph.D.dwight.burford@wichita.edu(316) 978-3204Crash Dynamics LabChad Gadberrychad.gadberry@wichita.edu(316) 978-5239NIAR/Industry/StateGabrielle Dodoshgabrielle.dodosh@wichita.edu(316) 978-5218Aircraft Design & ManufacturingResearch Center (ADMRC)Gabrielle Dodoshgabrielle.dodosh@wichita.edu(316) 978-5218Environmental Test LabsMatthew Willsmwills@niar.wichita.edu(316) 978-5776Research Machine ShopArt Porterarthur.porter@wichita.edu(316) 978-3656Aging Aircraft LabMelinda Laubach-Hockmelinda.laubach-hock@wichita.edu(316) 978-8205Full-Scale Structural Test LabTim Hickeythickey@niar.wichita.edu(316) 978-8204Quality & PerformanceWalter Leewalter.lee@wichita.edu(316) 978-6139CAD/CAM LabShawn Ehrsteinshawn@cadcamlab.org(316) 978-5234Kansas Small BusinessDevelopment Center (KSBDC)Marcia Stevens, Ph.D.marcia.stevens@wichita.edu(316) 978-3193Virtual Reality CenterFernando Toledofernando.toledo@wichita.edu(316) 978-8333Mechanical Test LabsTom Aldagtom.aldag@wichita.edu(316) 978-5326Walter. H. Beech Wind TunnelJohn Laffenjohn.laffen@wichita.edu(316) 978-5481

Advanced Coatings LaboratoryCAPABILITIES New coatings technology research and development Customized formulation of interiorand exterior high performancecoatings Materials/process evaluation andoptimization Coatings application processimprovement Product testing to military, OEM,industry specif cations Workforce development Physical Testing, application,surface preparation, and color andappearance equipmentPROJECTS Materials for EMI Protection ofComposite Airframe Structures –Development of Conductive CoatingsSystem (U.S. AFRL) Non-chrome primer evaluationsMulti-Angle Spectrophotometer –Effect Pigment Evaluation Gloss Meter Orange Peel/DOI Measurement Unit Light Booth Microscope Rheology Viscosity Cups Brookf eld Viscometer Stormer ViscometerApplication Automated Panel Sprayer Gravity Feed Spray Guns – HVLP,Compliant Pressure Feed Spray Guns – HVLP,Compliant Pressure Pots Electrostatic Spray Gun – AirAssisted, Airless Fresh Air Breathing System Virtual Paint Training Unit UV Cure Lamp IR Cure LampSurface Preparation Central Dust Collection System Sanders Buffers/Polishers Easily Manipulated Mechanical ArmUnits – Temple AllenCONTACTBrandon Hunt, Directorbrandon.hunt@niar.wichita.edu(316) 677-1334EQUIPMENTTest Chambers Salt Fog Cabinet Temperature/Humidity Chamber– Exposure Testing, FiliformCorrosion Accelerated Weathering Units –Xenon, QUV Low Temperature FreezerPhysical Testing Impact testers – Standard and G.E. Abrasion tester Mandrels for f ex testing – standardand conical Adhesion Test Kits Water Immersion Bath Dry Film Thickness – MagneticInduction, Eddy Current, Ultrasonic Hardness - PencilColor and Appearance Spectrophotometer – ngs

Aging aircraft LaboratoryThe Aging Aircraft Lab supports theEQUIPMENTfederal government and the aviation 21-cubic ft. dry blast paint strippingindustry with investigations into thebooth for removal of organiceffects of age on commercial and militarycoatingsaircraft. Magnaflux L-10 coil Parker Research AC/DC yoke Liquid penetrant inspection systemCAPABILITIES Magneto optic imaging systemAssessment of Aging Aircraft Staveley workstationStructures through: Nortec 2000S eddy scope Large-Scale Extraction Sonic 1200 ultrasonic unit Precision Detailed Disassembly Meiji Inc 7-45x optical microscope Chemical Coatings Removal Hirox Co. 50-300x optical Non-Destructive Inspectionmicroscope- Close Visual Inspection Rene Co. digital optical micrometer- Florescent Penetrant Inspection Joel scanning electron microscope- Eddy Current Inspection (Bolt Chemical coating removal facilityHole and Surface Scan- Magneto Optic ImagingInspection (Eddy CurrentTechnique)- Ultra Sonic Inspection (PulseEcho and Thru Transmission) Metallurgical and FractographicAnalysis (Optical and ScanningElectron Microscope)- Crack Origins- Crack Growth Mechanisms- Corrosion Characterization- Hardness Testing- Chemical Composition Analysis- Conductivity Testing Finite Element Modeling of AircraftStructures Damage Tolerance Assessment ofAircraft StructuresCLIENTSFederal Aviation Administration,Department of Defense, United StatesAir Force, Lockheed Martin, BoeingCo., Valdez International CorporationCONTACTMelinda Laubach-Hock, Directormelinda.laubach-hock@wichita.edu(316) 978-8205PROJECTS KC-135 teardown examination C-5A aft crown skin testing,inspection and analysis F-16 STA teardown examination A-10 BHEC specimen generation B-52 landing gear and flight controlteardown and inspection FAA Metallurgical/ FractographicEvaluation of raft

CAD/CAM LaboratoryThe CAD/CAM Laboratory offersCATIA and ENOVIA courses at theNational Center for Aviation Trainingand on-site at various manufacturingcompanies. Non-credit courses areavailable in addition to courses thatcarry credit through Wichita AreaTechnical College and Wichita StateUniversity.COURSES AVAILABLE CATIA Basic Concepts CATIA Composites CATIA Part Design & Sketcher CATIA Assembly Design CATIA Drafting CATIA Wireframe & Surfaces CATIA Prismatic Machining CATIA Surface Machining CATIA Fitting Simulation &Kinematics CATIA Functional Tolerancing &AnnotationCATIA Stress AnalysisCATIA KnowledgewareCATIA Sheet Metal DesignCATIA Electrical SpaceReservationCATIA Electrical DesignCATIA Electrical Harness DesignCATIA Tubing and PipingCATIA ErgonomicsENOVIA DMU ViewerENOVIA VPLM Basic ConceptsENOVIA VPLM AdvancedConceptsENOVIA VPLM Product DesignENOVIA VPLM NavigatorFiberSIMCOURSES IN DEVELOPMENT CATIA Reverse Engineering Polyworks CATIA V6PROJECTS Provide training courses forindustry, Wichita State Universityand Wichita Area TechnicalCollege Development of course instructionmanuals V4 – V5 Migration into ENOVIA Commercial CATIA work ConsultationCLIENTS Hawker Beechcraft Spirit AeroSystems Manufacturing IndustrialTechnologies Center of Innovation forBiomaterials in OrthopaedicResearchPARTNERSHIPS CGTech Vericut Firehole Technologies V5 EngineeringCONTACTShawn Ehrstein, Directorshawn.ehrstein@wichita.edu(316) 978-3283www.cadcamlab.org

Composites & Advanced Materials LaboratoryResearch engineers and lab techniciansin the Composites & AdvancedMaterials Lab perform lay-up andbonding operations to understand theeffects of heat, moisture, contaminationand repairs on advanced materials. Thelab also has a fully capable machineshop for preparing panels and worksdirectly with NIAR’s Mechanical TestLab. CAPABILITIES Lay-up Material equivalence testing Qualification testing Fatigue, stress and tension testing Mechanical testing/ designallowable generation Quality assurance testing Investigation of adhesive behavior Bonded repair Damage resistance & tolerance ofsandwich panels Laminate allowable generation Aging studies Adhesive characterization offatigued and damaged bonded joints Characterization of composite repair Full-scale structural testing Multiple environmental chambersand conditioning environmentsDynamic mechanical analysis unitsDifferential scanning calorimetryThermogravimetric analyzerOptical microscope with videoanalysisStereoscope x350 with hand-heldinspection unitFilament winding machine (4-axis)3 Programmable walk-in ovens(500 F)Ultrasonic NDI units to performpulse and echo and TTU scanswith curved panel capabilityRTM resin pumpsWalk-in freezers (-20 F)Lay-up roomsMachine shop specialized forcomposite material processing Instron Dynatup 8250 withenvironmental chamberX-ray diffractometerCoordinate measuring machinePheonix 4000 SEM and energydispersive systemThermal shock chamber (-160 F to500 F)CLIENTSBoeing, Cessna, Hawker Beechcraft,Lockheed Martin, Bombardier Learjet,FAACONTACTTom Aldag, Director of R&Dtom.aldag@wichita.edu(316) 978-5326PROJECTS Bonded Repair of CompositeAirframe Laminate and SandwichStructures Adhesive Joint Characterizationand Standards Effects of Defects and NDIStandards Material Qualification andEquivalency Industry-Directed Special Projectsand Element AllowablesEQUIPMENT Autoclaves- 3’ x 5’, 800 , 400 PSI- 3’ x 6’, 800 , 200 PSI- 6’ x 12’, 800 , 200 PSIwww.niar.wichita.edu/composites

Computational mechanics LaboratoryThe Computational MechanicsLaboratory provides research focusedin the development and application ofnumerical methods in areas of: Crashworthiness Injury biomechanics Structures Numerical optimization techniques Virtual product development Certification PROJECTS Crashworthiness Certification byAnalysis of Composite Structures,Federal Aviation Administration Bird Strike Numerical ModelDevelopment and Validation,NIAR/Industry/StateCOMPUTATIONAL RESOURCES 20 HP 8 Core Workstations (160Cores) HPPC Cluster A: 8 nodes (64Cores) HPPC Cluster B: 2 nodes (64Cores) Data Storage System 16 TB Secure Area/Data Access Passenger Protection in RailTransit Vehicles , Federal TransitAdministrationEvaluation HIII 95th and 5thPercentile ATD for AutomotiveApplications, American OccupantRestraint CouncilCertification by Analysis ofAircraft Interiors, Federal hCONTACTGerardo Olivares, Technical Directorgerardo.olivares@wichita.edu(316) 978-7273

Crash Dynamics LaboratoryThe Crash Dynamics Lab providesresearch, testing and certification fortransportation seats and restraintssystems under dynamic impactconditions.EQUIPMENTMTS Model 888.20 servo-hydrauliccrash simulator Nominal force: 2,000 kN (450kips) Max velocity w/ 1,500 kg; 81 km/h(50 mph) Dynamic response: 150 Hz Acceleration w/ 1,500 kg: 65g Acceleration w/ 1,000 kg: 75gPhotometrics AOS Technologies S-VIT Imagers High-resolution color (800x600) 1,000 frames per second (10,000fps at reduced resolution Immediate availability of videos in.avi formatCAPABILITIES FMVSS 208 FMVSS 213 CMVSS 208 ECE R94 Euro NCAP IIHS OSACode of Federal Regulations Title 14 Part 23.562 Title 14 Part 25.562 Title 14 Part 27.562 Title 14 Part 29.562Anthropomorphic Test DummyCalibration On-site calibration capability forHybrid II and Hybrid III ATDs On-site calibration foraccelerometersCLIENTSAircraft, automotive and militaryvehicle seat manufacturers, internallyfunded research centers, crash researchcentersCONTACTSRobert Huculak, Managerrobert.huculak@wichita.edu(316) 978-5239Gerardo Olivares, Ph.D., TechnicalDirectorgerardo.olivares@wichita.edu(316) 978-7273PROJECTS Certification by Analysis - SeatModeling Techniques Evaluation HIII 95th & 5thPercentile ATD for AutomotiveApplications Certification by Analysis - SledTesting for ATD Validation Mass Transit Bus CrashworthinessI and IIAREAS OF RESEARCH Aircraft occupant protection Implementation of child restraintsin aerospace applications Mass transit occupant safety Aircraft component certificationwww.niar.wichita.edu/crashdynamics

Environmental Test LaboratoriesThe Environmental Test Laboratoriesprovide the equipment and technicalexpertise needed to meet environmentalstandards regulated by the FAA technicalstandard orders using RTCA DO-160certification standards. Our personnelhave many decades of combinedexperience in the field of environmentaltesting for aviation and other industries.CAPABILITIES RF cable insertion loss and VSWRtesting Radome transmissivity testing Hi-pot testing services 60kV and 100kV P-Static testingsystems In-Flight Antenna Patterns Aircraft Test Hangar 100x100x30ft,door 75ft X25ft. Integral foam fire suppression system for fueled aircrafttestingAircraft Hot Fuel Testing (Weatherpermitting, 85 F. min.)DO-160C through F, GSection 4: Temperature & AltitudeSection 5: Temperature VariationSection 6: HumiditySection 7: Shock and Crash SafetySection 8: VibrationSection 9: Explosion Atmosphere(Category H Only)Section 14: Salt FogSection 15: Magnetic EffectsSection 16: Power Input (ExcludingCategory D – Abnormal SurgeVoltage (DC 270V)Section 17: Voltage SpikeSection 18: Audio Frequency Controlled SusceptibilitySection 19: Induced SignalSusceptibility (Excluding CategoriesCC, CN & CW)Section 20: Radio FrequencyControlled SusceptibilitySection 21: Emission of RadioFrequency EnergySection 22: Lightning InducedTransient SusceptibilitySection 24: Icing (ExcludingCategory B)Section 25: Electrostatic DischargeEQUIPMENT 20 ft. x 20 ft. semi-anechoicchamber 30 ft. x 50 ft. x 25 ft. fully anechoicchamber 25 ft. x 17 ft. reverb chamber 12,000 lb. vibration table Rate table capability of 50 lbs. totalweight Indirect effects of lightning testsystem 40 kW AC/DC power input testsystem Temperature/humidity/altitudechambers (capability up to 100,000 ft.) Large environmental chamber 12’Wx10’Hx48’L (-40 degrees) Salt Fog ChambersCLIENTSRCO Engineering, Inc., HawkerBeechcraft Co., Aerospace Systems andComponents, Inc., AMETEK AdvancedIndustries, Inc. PWI IncorporatedCONTACTPaul Jonas, Directorpaul.jonas@wichita.edu(316) 978-5727John Laffen, Directorjohn.laffen@wichita.edu(316) 978-5481www.niar.wichita.edu/environmental

Full-Scale Structural Test LaboratoryThe Full-Scale Structural Testing Labassesses the structural performance anddurability of commercial and militaryaircraft by performing full-scale andcomponent testing (static, durabilityand damage tolerance), pressure cyclictesting, hail strike testing and materialtesting.CAPABILITIES Test load development fromsupplied aircraft loads Test fi xture design and fabrication Load system design and fabrication Strain gage and miscellaneoustransducer installation Data and load control systemdevelopment and installation Testing services and data handlingR&D, Certification or Qualification Full-scale and component testing(static, durability and damagetolerance) Pressure cyclic testing Hail strike testing Material testing Data acquisition systems capable ofrecording 2,500 channels of dataSecured data ports for customerdata transferARAMIS photogrammetrysystem, a 3D deformationmeasuring system to characterizedisplacements and strains incomponentsCATIA V5 capabilitiesLoad cells ranging from 50 lbs. 200,000 lbs.Load frames with stroke and loadcontrol for material and componenttesting up to 200,000 lbs.Large durability test base fi xturesfor rapid development of durabilitytest setup for aircraft up throughbusiness-size jetsPROJECTS Bombardier Learjet LJ200 FullScale certification testing Spirit G250 and G650 Flapcertification testing Boeing 787 Center Bridge testing Hawker Beech Model 4000Fuselage and Empennage Full ScaleDADT testing DoD Non Destructive EvaluationReliability Assessment ToolDevelopment FAA and NIS research MilTec Structural HealthMonitoring Development testingon surrogate C130 Rainbow FittingEQUIPMENT 4 Load control systems with 280channels and 13 separate loadstationswww.niar.wichita.edu/fullscale Pressure control equipment forfuselage cyclic and static pressuretesting including a 6” shop airsupply and a stand-alone 655cubic foot per minute 125 HP aircompressorHail gunCLIENTSDepartment of Defense, Boeing AircraftCo., Spirit AeroSystems, BombardierLearjet, Lockheed Martin, SikorskyAircraft, Hawker Beechcraft, RadianceTechnology, MiltecCONTACTTim Hickey, Directorthickey@niar.wichita.edu(316) 978-8204

Metrology LaboratoryThe Metrology Lab provides calibrationservices for test and measurementequipment traceable to NationalInstitute of Standards Technologyreference materials.CAPABILITIESIn most measurement domains, we canboth generate and measure. DC/Low Frequency to 1000 VoltsAC/DC (Multimeters, PowerSupplies, Oscilloscopes)Temperature -70 C to 600 C(Digital Thermometers, IRThermometers, TemperatureSensors)RF/Microwave to 26.5 GHz(Power Meters, Attenuators, SignalGenerators and Analyzers) Force 500 lbs to 100,000 lbsTension & Compression (LoadCells)Pressure to 10,000 psi Oil & Air(Pressure Gauges, PressureTransducers)Vibration 5 Hz to 10 kHz(Accelerometers)Additional Capabilities inResistance, AC/DC Current,Humidity, Capacitance,Inductance, PowerEQUIPMENT CALIBRATEDElectronic Ammeters Capacitance bridges and standards Function generators Impedance meters Inductance bridges and standards Hypots Multimeters Oscilloscopes Power supplies RCL meters Resistance decades and standards Timing devices Signal conditioners Tachometers Multifunction calibrators X-Y plotters and chart recordersRadio Frequency Signal generators Spectrum analyzers Counters RF attenuators Distortion analyzersTemperature & Humidity Digital thermometers Dial thermometers Relative humidity devices Environmental chambers* Ovens Dry block temperature calibrators Temperature controllers Temperature and humidityrecorders Thermocouple and RTD calibratorsMechanical and Pressure Force machines** Accelerometers Load cells Scales PSI gauges Absolutes gauges Vacuum gauges Air data test sets Pressure controllers Altimeters Air speed indicators Rate of climb indicators TransducersCONTACTDon Hansen, Managerdon.hansen@wichita.edu(316) 978-8240* Local area only** Up to 200k lbswww.niar.wichita.edu/metrology

Mechanical Test LaboratoryThe Mechanical Test Laboratoryprovides the highest standards in staticand fatigue testing for composites andmetals to generate material strengthallowables and evaluate materialproperties.CAPABILITIES Static and cyclic testing (ASTMand non-standard) Impact drop testing Slow-cycle fatigue testing High temperature testing to 2500 F ASTM/ Boeing/ SACMA standardtesting Ability to design and fabricate nonstandard test fi xtures and performnon-standard tests Aging studies Damage tolerance of sandwichpanels Specimen conditioning Environmental testing (-200 F to 600 F) Full-scale structural testing Specimen machining (ASTM andnon-standard) Strain gauging and specimen QC Wide variety of ASTM test fixturesHigh-rate load frame (600 in/sec)PROJECTS Off-axis core shear properties ofhoneycomb core Compression after impact testingto determine environmentalknockdown effects (NIARIndustry-State) Fatigue and static testing oftitanium and stainless steelmaterials ARAMIS photogrammetry onfriction stir welded panels ARAMIS photogrammetry onpatella inserts for alternate ACLhuman knee repairCLIENTSHawker Beechcraft, Sikorsky Aircraft,NAVAIR, Via ChristiCONTACTRoyal Lovingfossrlovingfoss@niar.wichita.edu(316) 978-5317EQUIPMENT 5-kip to 220-kip load frames withenvironmental testing chambers Slow-cycle fatigue machines Impact tower Laser extensometer Multiple MTS displacementinstruments (uni-axial and bi-axial) MTS high-temperature chamber(up to 2552 F) and hightemperature uniaxial extensometer Strain Smart (multichannel strainindicating software) Strain calibrators Aramis (offers non-contact 3Doptical deformation and strainanalysis) 60,000 in-lb torsion test framewww.niar.wichita.edu/mechanicaltest

Research Machine ShopThe Research Machine Shop supportsresearch at NIAR, WSU and within theaviation industry. The staff ’s intimateknowledge of the wind tunnels andother research tools greatly increases theshop’s value and efficiency.EQUIPMENT & FACILITIES 5,000 sq. ft. of shop space Mastercam X5 software CATIA V5 R19 software HAAS TL-3 CNC Lathe 20” DIA.x 60” CC HAAS VF-2 five-axis VMC 30” x16” x 20” travel HAAS VF-2 four-axis VMC 30” x16” x 20” travel HAAS VF-4 five-axis VMC 50” x20” x 25” travel FADAL 8030 VMV, 80” x 30” x30” travel HAAS HRT-310, 12” Rotary TableHAAS HRS-210, 9” Rotary TableGrey Planer Mill 96” x 30” x 30”travel with Bridgeport mill headK&T #2 Rotary Head die millK&T K4 Horizontal mill withBridgeport mill head attachmentHarding high-speed tool room latheColchester 15” x 50” lathe withtracerSouth Bend 24” x 100” lathe withtracerThompson surface grinder 12” x36”Wood working machines; cabinetand pattern capabilitiesWelding; mig, stick arc and oxyacetyleneHawkey borescope with Sony videocamera/capturePROJECTS Full-Scale Structural Testing Labsupport Lightning strike research support Friction stir welding researchsupport Beech Wind Tunnel upgradesand support for several tests Crash Dynamics Lab upgradesand support for several tests Composites and Fatigue &Fracture labs tooling andspecimens Nordam Transparency Divisiontooling and specimens Aircraft icing research projectsupport Support for the Center ofInnoviation for Biomaterials &Orthopaedic Research (CIBOR) Support for FairmountTechnologiesCONTACTArt Porter, Managerarthur.porter@wichita.edu(316) 978-3656www.niar.wichita.edu/shop

Virtual Reality CenterThe Virtual Reality Center develops appliedresearch and provides technical expertisein PLM/virtual reality and associatedtechnologies for WSU, NIAR, the aviationindustry and other non-aviation projects.CAPABILITIES ErgonomicsSales/marketingVirtual prototypingInteractive environments3-D ScanningReverse engineeringRapid prototypingDigital inspectionEQUIPMENT 1,800 sq. ft. visualization room withseating for 25 active stereo glasses users 15 x 7 ft. flat screen with activestereoscopic view and rear projection Sensics’ xSight 6123 large field-ofview head-mounted display with1920x1200@60Hz per eye and123/45 degrees horizontal/vertical forcombined eyes DLP HDTV 65” active stereo withtwo-handed interface Space Grips VICON 602 with 10 high-speedcameras for full body optical motioncapture/tracking Ascension’s Nest of Birds with4 sensors with extended rangetransmitter for magnetic motiontracking for head, hands and wand Fakespace Lab manipulation glovesand wand OPTIS portable gonioreflectometerOMS2 for capture of surface opticalproperties CAD/CAE/VR simulation softwareincluding DS CATIA V5, DS 3DVIAVirtools, CEI Ensight Gold, EONReality, PTC Division Reality, RightHemisphere’s Deep Exploration Photometric-based visual andillumination software simulation: OPTIS SPEOS CAA V5Web-based ray-tracing visualsimulation: Mental Images’RealityServerPROJECTS Virtual Environment Study involvingCATIA to VR, mixed reality,photometric simulation, ECS:smoking Immersive design review for AGCOcombine cabs Immersive Medical Environment forDistributed Intuitive Consultation(iMEDIC) Phase 2, developed withDigital ArtForm for US Army subcontract Visual ergonomics analysis for UAVplatform display subsystem - GA-ASI,under sub-contract Support of CAE results inwww.niar.wichita.edu/vrc immersive environment for NIARComput

Solutions Wichita, KS B/E Aerospace Wellington, FL Th e Boeing Company Seattle, WA Bombardier Aerospace Montreal, Quebec, Canada Burnham Composites Inc. Wichita, KS Cessna Aircraft Company Wichita, KS CIBOR Inc. Wichita, KS Cirrus Design Corp. Duluth, MN CSI Aerospace Inc. Broken Arrow, OK Cytec Engineered Materials Valley Center, KS