Transcription

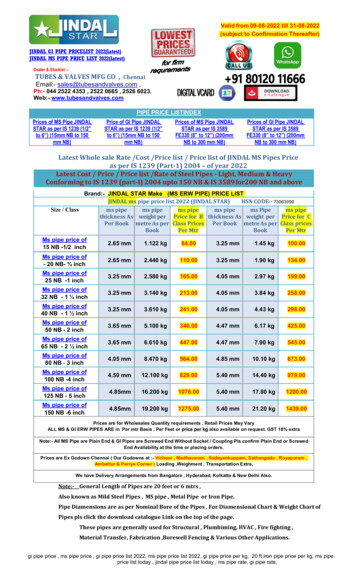

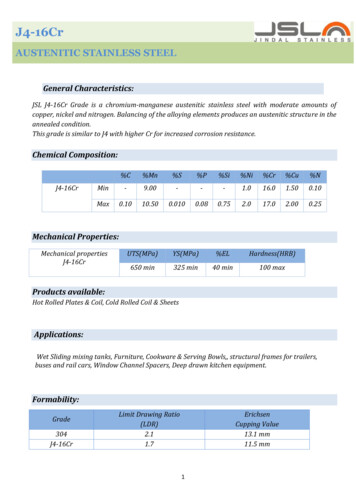

J4-16CrAUSTENITIC STAINLESS STEELGeneral Characteristics:JSL J4-16Cr Grade is a chromium-manganese austenitic stainless steel with moderate amounts ofcopper, nickel and nitrogen. Balancing of the alloying elements produces an austenitic structure in theannealed condition.This grade is similar to J4 with higher Cr for increased corrosion resistance.Chemical 2.000.25Mechanical Properties:Mechanical 0 min325 min40 min100 maxProducts available:Hot Rolled Plates & Coil, Cold Rolled Coil & SheetsApplications:Wet Sliding mixing tanks, Furniture, Cookware & Serving Bowls,, structural frames for trailers,buses and rail cars, Window Channel Spacers, Deep drawn kitchen equipment.Formability:Grade304J4-16CrLimit Drawing Ratio(LDR)2.11.7ErichsenCupping Value13.1 mm11.5 mm1

Corrosion Resistance:IGC testing as per ASTM A 262Test as per ASTM A262Practice BPractice CPractice ECorrosion Rate (mmpy)Boiling Ferric Sulfate50% Sulphuric AcidType J4-16CrType 304DB65% Nitric Acid, BoilingType J4-16CrType 304CBCopper/16% Copper Sulfate/Sulfuric Acid, BoilingType J4-16CrNo cracksType 304No cracksOxalic Acid etch TestPractice AType J4-16CrStep StructureType 304Step StructureThe technical information in this document describes typical characteristics and performance of the product. JSL and its affiliatedcompanies do not accept responsibility for errors or for information which is found to be ambiguous and for the end use orapplication of products. Before using products customer should satisfy himself for their suitability. The information presented in thisdocument is subject to change without notice.2

J4AUSTENITIC STAINLESS STEELGeneral Characteristics:J4 Grade is a chromium-manganese austenitic stainless steel with moderate amounts of copper,nickel and nitrogen. Balancing of the alloying elements produces an austenitic structure in theannealed condition.Type J4 is suitable for replacing chromium-nickel grades 301, 304 in many applications. Lowercost manganese and nitrogen additions render this grade more economical while endowing it withgood strength and high formability making it highly suitable for a wide variety of consumer andstructural applications. Presence of copper in this steel reduces work hardening rate. The alloy isnon-magnetic in annealed condition and like 304 becomes lightly magnetic after cold working dueto formation of martensite. Thus J4 can display a wide range of mechanical strength depending onthe degree of cold working, which is essential for certain structural applications.Chemical Mechanical Properties:Mechanical propertiesJ4UTS(MPa)YS(MPa)%ELHardness(HRB)650 min325 min40 min100 maxProducts available:Hot Rolled Plates & Coil, Cold Rolled Coil & SheetsApplications:Deep drawn kitchen equipment, Furniture, Bins, Coal Bucket, Wear Plate Liners andHoppers, Cookware & Serving Bowls, Window Channel Spacers etc.1

Formability:1.2H max / g height (h / HmaxGrade304J4Limit Drawing Ratio(LDR)2.11.7ErichsenCupping Value13.1 mm11.5 mmThe technical information in this document describes typical characteristics and performance of the product. JSL and its affiliatedcompanies do not accept responsibility for errors or for information which is found to be ambiguous and for the end use orapplication of products. Before using products customer should satisfy himself for their suitability. The information presented inthis document is subject to change without notice.2

J201AUSTENITIC STAINLESS STEELGeneral Characteristics:J201 type steels are lean nickel alloy austenitic stainless steel designed as a cost-effectivesolution for 301 grades in various applications.Chemical .017.51.00.25Mechanical Properties:GradeMechanical propertiesYS(MPa)UTS(MPa)%ELHardness201-1* ASTM A2402605154095201-2* ASTM A24031065540100S20100J201S20103J201LASTM A2402606554095S20153J201LNASTM A24031065545100*201-1 and 201-2 represent the rich and lean types of 201 respectivelyMechanical Properties of different tempers in 201LN:J201LN can be provided in different tempers. The feasibility is subject to customerrequirements.Products available:Hot Rolled & Cold Rolled coils and sheets

Applications: J201Structural members, siding and roofing for railway cars and trailers and a variety ofseverely formed parts. J201LLow temperature components, heavy section services, Pots, Pans, Flatware, Counters,Counters, Sinks, Appliance components, Dishwashers, Ovens, Refrigerators, Hinges, Doors,Frames, Roll formed sections, Spring clips J201LNWelded constructions, structural uses and low temperature applications - Examplesinclude sides & roofs of trains, liquefied gas storage vessels, structural members/chassis ofrailway rolling stock, trucks & trailers, coal handling equipment.Corrosion Resistance:J201 grades have comparable corrosion resistance to 301 grades.The technical information in this document describes typical characteristics and performance of the product. JSL andits affiliated companies do not accept responsibility for errors or for information which is found to be ambiguous andfor the end use or application of products. Before using products customer should satisfy himself for their suitability.The information presented in this document is subject to change without notice.

J202AUSTENITIC STAINLESS STEELGeneral Characteristics:J202 is manganese alloyed austenitic stainless steel which is designed as a cost-effectivesolution to 302 grade with similar corrosion and mechanical properties.Chemical hanical ardness (BHN)ASTM A240620 min260 min40 min241 maxProducts available:Hot Rolled Plates & Coil, Cold Rolled Coil & SheetsApplications:Antennas, Refrigerator trays, Wire mesh, Cookware & Sinks, Hose Clamps, Frames,Industrial Strapping, Railway Rolling Stock, Furniture, BinsCorrosion Resistance:J202 grade is comparable to 304 grades in moderately corrosive media.The technical information in this document describes typical characteristics and performance of the product. JSL andits affiliated companies do not accept responsibility for errors or for information which is found to be ambiguous andfor the end use or application of products. Before using products customer should satisfy himself for their suitability.The information presented in this document is subject to change without notice.1

J204 DIN 1.4376AUSTENITIC STAINLESS STEELGeneral Characteristics:J204 is a chrome-manganese stainless steel belonging to 200 series of austenite stainlesssteel family with moderate amounts of nickel and nitrogen.J204 is a new alloy that bridges the cost / property gap between 200 and 300 seriesstainless steel. Manganese as austenite former replaces a part of nickel and has beneficialeffect on weldability. Consequently J204 has a higher annealed strength, similar corrosionresistance in a variety of mild corrosive media and similar formability & weldability incomparison with 304. It can replace Type 304 in numerous applications where higherstrength, high formability and lower cost are required .Chemical Composition Range: 0.108.000.0150.0451.004.520.50.250.30Mechanical Properties:Mechanical propertiesUTS(MPa)YS(MPa)%ELHardness(HRB)700 min350 min40 min100 maxProducts available:Hot Rolled Plates & Coil, Cold Rolled Coil & SheetsApplications:Cookware & Sinks, Hose Clamps, Trailer, Frames, Industrial Strapping, Railway Rolling Stock.1

Drawability:Drawability1.23042041GradeLimiting Drawing Ratio[ 40.50.6rp / DCylinder Drawing Limit RatioCorrosion Resistance:Test Media taken for the tests are various mixtures of acids & salts.Test Media3% NaCl for 720 hrs at RT(3%NaCl 0.5%Acetic 0.5%Lactic) for 720 hrs at RT(3%NaCl 0.5%Citric 0.5%Tartaric) for 720 hrs at RT(0.5%Citric 0.5%Tartaric) for 720 hrs at RT3% NaCl for 100 hrs at Boiling Temp.(3%NaCl 0.5%Acetic 0.5%Lactic) for 100 hrs at Boiling Temp.(3%NaCl 0.5%Citric 0.5%Tartaric) for 100 hrs at Boiling Temp.(0.5%Acetic 0.5%Lactic) for 120 hrs at Boiling Temp(5%Lactic) for 120 hrs at Boiling Temp.(5% citric) for 120 hrs at Boiling Temp(5% acetic) for 120 hrs at Boiling TempCorrosion rate(mmpy)304J204AAAAAAAAAAAAAAAAAAAAAAThe technical information in this document describes typical characteristics and performance of the product. JSL andits affiliated companies do not accept responsibility for errors or for information which is found to be ambiguous andfor the end use or application of products. Before using products customer should satisfy himself for their suitability.The information presented in this document is subject to change without notice.2

J204 CuAUSTENITIC STAINLESS STEELGeneral Characteristics:J204Cu is a chrome-manganese stainless steel belonging to 200 series of austenite stainless steelfamily with moderate amounts of nickel, copper and nitrogen. J204Cu is a new alloy that bri dgesthe cost / property gap between 200 and 300 series stainless steel. It has better formability thanJ201 and 304 due to Cu addition which lowered the work hardening rate to provide cold workingproperties superior to 200 series stainless steel and similar to type 304. Copper improves corrosionresistance and stress corrosion cracking resistance in certain media. Nitrogen increases strengthand pitting resistance of stainless steel. Manganese as austenite former replaces a part of nickeland has beneficial effect on weldability. Consequently J204Cu has a higher annealed strength,similar corrosion resistance in a variety of mild corrosive media and similar formability &weldability in comparison with 304. It can replace Type 304 in numerous applications w herehigher strength, high formability and lower cost are required.Chemical 000.25Mechanical Properties:As 20 min310 min40 min100 maxProducts available:Hot Rolled Plates & Coil, Cold Rolled Coil & SheetsApplications:As an effective cost alternative to type 201/304, J204Cu finds a wide range of applications. Themajor areas are:1.Catering and food process: Deep drawn kitchenware , utensils, cookware , industrial kitchenequipment , flasks , milk cans , Ice and water dispensers , water filters ,domestic and commercialrefrigerator outer body parts2. Consumer durables: Sinks, Toasters, microwave ovens outer body parts, Baking ovens, Thermowares, washing machines outer body parts, mobile case /parts1

3. Architecture, Building and construction: Handrails for staircase, elevators, escalators, internalpanels, Door window frames, thermal window spacers4. Transport (Automotive): Automotive hose clamps, safety belt anchors, truck and bus framesCorrosion Resistance:Study of Leaching of iron, Chromium, Nickel and Copper in different food products when cooked instainless steel coupons/cookware .Results are tabulated for eight food simulants and actual foodmedia for Fe, Cr, Ni and Cu. The value of leached elements obtained through Atomic absorptionspectrometry after keeping coupons of size 50mmx70mm and cookware 100mm diameter(madeby deep drawn process) in 150 ml of simulant for boiling 30 minutes. The solution wasconcentrated on water bath for removal of water content in simulant solution /food. Theconcentrate was subsequently made into ash by digesting in electrically heated muffle furnace .Ashsolutions were prepared for each simulant by dissolving the respective ashes in 2% Nitric acidsolution. The ashed solution was then used for Atomic absorption spectrometry.Test couponsFeNiFood itemsGradepHCu3% Acetic acidJ204Cu2.59 0.10.19293042.59 0.1J204Cu2.82304Test cookwareFeNiCrCu 0.1 0.1 0.10.1748 0.1 0.10.2104 0.1 0.1 0.10.1764 0.1 0.1 0.10.2565 0.1 0.1 0.10.2675 0.1 0.12.82 0.10.3048 0.1 0.1 0.10.2968 0.1 0.1J204Cu2.800.111.1010 0.1 0.10.23371.194 0.1 0.13042.800.20921.5789 0.1 0.10.22960.9914 0.1 25.826.86.86.16.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.10.76300.80200.56160.50020.28910.8042 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.25900.2396 0.1 0.1 0.1 0.1 0.1 0.11.27541.05920.77260.67800.87430.2940 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1Refined sunflower oilJ204Cu1.6 0.1 0.1 0.1 0.1 0.10.11 0.1 0.13041.6 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1Tomato soupJ204Cu3043.63.6 0.1 0.10.86970.6219 0.1 0.1 0.1 0.1 0.1 0.11.597 0.1 0.1 0.1 0.1 0.13% Citric acid3% Lactic acid1% Tartaric acid10% EthanolDistilled water4%Common saltCr*All values are in ppm (1 ppm 1 mg/Kg or µg/ml)Conclusion:The leaching values of Chromium and Nickel are very low in all cases 0.1 ppm It was observedthat there was no surface corrosion spot/rust marks in the tested coupons/cookware and nomeasurable weight loss when compared before and after the experiment.IGC test:J204Cu and type 304 are immune from intergranular corrosion if properly heat treated.Intergranular attack test were performed as per ASTM A 262 on J204Cu and 304 grade samples.2

Corrosion rate (mmpy)Practice EPractice CAfter sensitizationAlloyTreatmentJ204CuAnnealed at 1050ºC3.80150.7419Not crackedType 304Annealed at 1050ºC1.34790.6010Not crackedPractice BDrawabilitiy and formability1.2H max / D10.8204Cu3040.60.40.2000.10.20.30.40.50.6rp / DlDrawing height (h / c/lHmaxJ204Cu can readily be cold rolled, cold drawn and formed in similar manner as Type 304. J204Cucan take upto 80% cold reduction withoutintermediate annealing. Effect of cold work onMartensite formation: J204Cu will undergo magnetic transformation due to cold reduction. Thismagnetism is the result of forming deformation martensite with cold work. This martensiteincreases the strength, work hardening rate and abrasion resistance of alloy.The amount of martensite forming on cold working in J204Cu is much less than in type 304.%Cold work1928455767% Martensite0.310.61.11.63.0The technical information in this document describes typical characteristics and performance of the product. JSL and itsaffiliated companies do not accept responsibility for errors or for information which is found to be ambiguous and for the enduse or application of products. Before using products customer should satisfy himself for their suitability. The informationpresented in this document is subject to change without notice.3

J216LAUSTENITIC STAINLESS STEELGeneral Characteristics:J216L is a Chrome-Nickel-Molybdenum austenitic stainless steel with manganese, nitrogenand copper, which offers a number of advantages over conventional 316L stainless steel.The corrosion resistance of this stainless steel is comparable to type 316L. This alloy hasnearly 50% higher strength in annealed condition, higher elevated temperature strengthcoupled with better fatigue resistance. It can be cold rolled to significantly higher tensilestrength while retaining a very low magnetic permeability.A part of nickel & molybdenum of 316L is replaced by a combination of copper, manganeseand nitrogen in this grade to retain austenitic structure and similar corrosion resistance.Synergy between molybdenum and nitrogen enhances the beneficial effect of molybdenumon corrosion resistance of the alloy. Simultaneous addition of molybdenum and copperimproves corrosion resistance in sulphuric acid. Addition of nitrogen improves theresistance to pitting, crevice and intergranular resistance.Such a combination of properties makes J216L highly suited for numerous applications inchemical, petrochemical, pulp, paper, oil & gas industries which currently use 316L.Chemical 02.002.000.25Mechanical Properties:YS(MPa) 310UTS(MPa) 520%ELHardness 40 100Products available:Hot Rolled Plates & Coil, Cold Rolled Coil & SheetsApplications:J216L is a cost-effective substitute for 316L in major applications.1

Typical applications are architectural trims, marine exteriors, chemical processingequipment, food processing equipment, petroleum refining equipment, pharmaceuticalsequipment, photographic equipment, pulp & paper processing equipment and textilefinishing equipment.Corrosion Resistance:Boiling test results for this grade shows excellent corrosion resistance when comparedwith 316L.Medium5% Citric Acid5% Tartaric Acid5% Acetic Acid100% Acetic Acid2% HCl65% HNO325% Orthophosphoric 316LJ216L316LJ216L316LCorr. Rate 0849 PREN Pitting Resistance Equivalent NumberPREN %Cr 3.3 Mo 16N MARC Measure of Alloying for Resistance to CorrosionMARC %Cr 3.3 Mo 20C 20N – 0.5Mn – ingOutstandingOutstanding

iodynamic Test Results in 3.5% NaCl at 23 .009Corr. 372Blue line corresponds to 316LPink line corresponds to J216LFabrication:Since J216L and 316L have comparable work hardening rate and sufficiently highductility, the fabrication techniques are essentially similar. However on account of itshigher strength, J216L requires more power to shear & form. The drilling speeds have tobe lower compared to 316L for comparable tool life.Weldability:The alloy possesses good weldability like stainless steels of 300 series. Gas tungsten-arcand gas metal-arc techniques have been used for such grade. It can be welded to otherstainless steels with conventional welding electrodes currently used. 316L electrodes havebeen used to weld this alloy.The technical information in this document describes typical characteristics and performance of the product. JSL andits affiliated companies do not accept responsibility for errors or for information which is found to be ambiguous andfor the end use or application of products. Before using products customer should satisfy himself for their suitability.The information presented in this document is subject to change without notice.3

JSL AUSAUSTENITIC STAINLESS STEELGeneral Characteristics:JSL AUS is a chromium-manganese nickel austenitic stainless steel. Modest amount of nitrogenadded to these steel results in higher annealed strength than AISI 304. However copper additionreduces work hardening rate to facilitate cold working /forming. The alloy is non-magnetic inannealed condition and like AISI 304 becomes mildly magnetic after cold working. Cold formingcharacteristics are superior to AISI 201 and 202 and the chemistry is so optimized as to achievedrawability similar to grade 304.JSL AUS has been used for many applications where type AISI 304 was traditionally chosen. JSLAUS is relatively economical compared to AISI 304 having formability and weldabilitycomparable to AISI 304 with corrosion resistance superior to AISI 430. Type JSL AUS is used bothin fully annealed and in partially or fully cold rolled condition.The mechanical properties vary considerably depending upon the amount of cold workintroduced. The strength of JSL AUS is slightly higher than conventional austenitic steel such as304. Considering its lower cost JSL AUS can replace conventional AISI 304 in a wide range ofapplication.Chemical anical Properties:Mechanical propertiesUTS(MPa)550 minYS(MPa)205 min%ELHardness40 min95 HRB maxProducts available:Hot Rolled Plates & Coil, Cold Rolled Coil & SheetsApplications:Deep-drawing utensils, ordnance components, water filters, storage, and milk cans, water tank,food industry, Automotive trim, Wheel caps, Wiper arms, Rims, Auto accessories.1

Drawability:1.2H max / D1JSL AUS3040.80.60.40.2000.10.20.30.40.50.6rp/DlDrawing height (h / l)1.210.8JSL AUS3040.6rc0.40.2l000.10.20.30.40.50.6rc/lHmaxJSL AUS is very tough and ductile and readily amenable to deep drawing, bending, stretchforming and spinning. After heavy cold working, it is only mildly magnetic like 304.Study of Leaching of iron, Chromium , Nickel and Copper in different food products when cookedin stainless steel coupons/cookware. Results are tabulated for eight food simulants and 3 actualfood media for Fe, Cr, Ni and Cu.pHCuFeNiCrSimulated food items3% Acetic acid2.59 0.10.1136 0.1 0.13% Citric acid2.82 0.10.2390 0.1 0.13% Lactic acid2.8 0.10.888 0.1 0.11% Tartaric acid2.27 0.10.8008 0.1 0.110% Ethanol5.82 0.10.8130 0.1 0.1Distilled water6.8 0.10.1990 0.1 0.12

4%Common salt6.1 0.1 0.1 0.1 0.1Refined sunflower oil1.6 0.1 0.1 0.1 0.10.3522 0.1 0.1Actual Food ItemsTomato soup3.6 0.1*All values are in ppm (1 ppm 1 mg/Kg or µg/ml)It was observed that there was no surface corrosion spot/rust marks in the testedcoupons/cookware and no measurable weight loss when compared before and after theexperiment.Conclusion: - The values of leaching in the tests conducted are within the limit for JSL AUSgrade of stainless steel and will behave similar to type 304 during normal cooking.The technical information in this document describes typical characteristics and performance of the product. JSL and itsaffiliated companies do not accept responsibility for errors or for information which is found to be ambiguous and for the enduse or application of products. Before using products customer should satisfy himself for their suitability. The informationpresented in this document is subject to change without notice.3

JSL U DDAUSTENITIC STAINLESS STEELGeneral Characteristics:JSL U DD is a Chromium-Manganese austenitic stainless steel with moderate amounts of copperand nitrogen and low amounts of Nickel. Balancing of the alloying elements produces a fullyaustenitic structure in annealed condition.The presence of nickel and copper in this steel reduces work hardening rate and improvesductility and drawability. Lower cost manganese and nitrogen additions render this grade moreeconomical while endowing it with good strength and high formability making it highlysuitable for various consumer and structural applications.Chemical 20Mechanical Properties:Mechanical properties(Product standard Range)UTS(MPa)YS(MPa)%ELHardness(HRB)JSL U DD70035040100Products available:Hot Rolled Plates & Coil, Cold Rolled Coil & Sheets.Applications:JSLU DD: Medium and Deep drawn utensils. Drawn and spun utensils.Suitable for Deep Drawn Utensils upto 10 inch deep.Corrosion Resistance:The corrosion behavior of Cr-Mn grade JSL U DD was comparable with AISI 304 stainless steelsin a variety of mild and moderate chemical environments.The technical information in this document describes typical characteristics and performance of the product. JSL and itsaffiliated companies do not accept responsibility for errors or for information which is found to be ambiguous and for theend use or application of products. Before using products customer should satisfy himself for their suitability. Theinformation presented in this document is subject to change without notice.1

JSL J4-16Cr Grade is a chromium-manganese austenitic stainless steel with moderate amounts of copper, nickel and nitrogen. Balancing of the alloying elements produces an austenitic structure in the annealed condition. This grade is similar to J4 with higher Cr for increased corrosion resistance. Chemical Composition: