Transcription

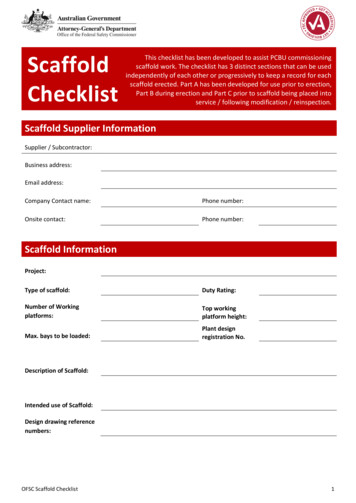

ScaffoldChecklistThis checklist has been developed to assist PCBU commissioningscaffold work. The checklist has 3 distinct sections that can be usedindependently of each other or progressively to keep a record for eachscaffold erected. Part A has been developed for use prior to erection,Part B during erection and Part C prior to scaffold being placed intoservice / following modification / reinspection.Scaffold Supplier InformationSupplier / Subcontractor:Business address:Email address:Company Contact name:Phone number:Onsite contact:Phone number:Scaffold InformationProject:Type of scaffold:Duty Rating:Number of Workingplatforms:Top workingplatform height:Max. bays to be loaded:Plant designregistration No.Description of Scaffold:Intended use of Scaffold:Design drawing referencenumbers:OFSC Scaffold Checklist1

Part A – To be completed prior to erectionCriteriaScaffold design plan / drawingsprovided by scaffold designerCompliant N/A CA required Additional comments If N/A above, a risk assessment has been conducted to justify no scaffold planDesigner qualifications verified Design of scaffold ties addressed indesign plan (Including if single leg tiesare proposed) Written advice on ground conditionsprovided to scaffold contractor Engineer advice / certificationobtained for any support on verandas,suspended flooring, compacted soil,parapets, awning or similar Evidence of high-risk work licences /training of scaffolders verified If a trainee scaffolder – training plan &qualified supervisor info supplied Safe system of work (SWMS / SOP /JHA) provided for hazards associatedwith scaffolding delivery, inspection,erection, dismantling etc. Addressing: Public protection andcontainment sheeting Procedures for high wind Controls for overhead services Controls for vehicle/crane/plant movement adjacentscaffold Exclusion zones & controls forfalling objects Safe access and egress Manual tasks Inspection and maintenance Other site-specific issues OFSC Scaffold Checklist2

Part A – To be completed prior to erectionCriteriaCompliant N/A CA requiredSWMS for HRCW reviewed andaccepted (work at height / nearelectrical installations / adjacenttraffic corridor / movement poweredmobile plant / near water or otherHRCW) Additional commentsWhere fall restraint/fall arrest isproposed – Risk assessmentcompleted, and system of workimplemented to verify Training of workers Maintenance and inspectionof equipment Training to install ordetermine anchorage points Attachment points design andcertificationEmergency procedures establishedOther Other CA No.Corrective action detailsIssued toDue dateClosed/statusCompleted by:Position:Signature:Date:OFSC Scaffold Checklist3

Part B – Physical inspection during erection ofscaffoldingCriteriaCompliant N/ACA requiredScaffold layout progressing as perdesign plan / drawings Scaffold ties, bracing, edge protectionand access is progressing relative tothe height and width of the scaffold Scaffold erection compliant withengineer’s advice / design forsupporting structure Workers sampled are licenced /trained scaffolders SWMS /SOP / JHA available on sitewith evidence that relevantscaffolders / workers were consulted,trained, and signed off on the systemof work. Access during erection safeand suitable Work at height controlsimplemented by scaffolders Falling object controlsimplemented by scaffolders Agreed exclusion zonesclearly delineated withappropriate signage Good housekeepingimplemented Controls for overheadservices implemented Ae controls in place toprevent impact to thescaffold from vehicle / plant /crane movement etc. Other SWMS controls implemented SWMS controls appropriate forobserved work activities Unauthorised access to scaffold byother workers prevented duringerection/modification OFSC Scaffold ChecklistAdditional comments4

Part B – Physical inspection during erection ofscaffoldingCriteriaCompliant N/ANo mixing of scaffold from differentmanufacturers / systems(without engineer approval andspecified controls implemented)CA required Other controls implemented Other controls implemented CA No.Corrective action detailsIssued toAdditional commentsDue dateClosed/statusCompleted by:Position:Time of Inspection:Signature:Date:OFSC Scaffold Checklist5

Part C– Prior to scaffolding being placed inserviceCriteriaCompliant N/ACA requiredAny changes to design authorisedby designer Scaffolders completion inspectionchecklist issued Handover certificate issued(Meets AS/NZS, drawings,legislation and duty rating etc.) Handover certificate signed byscaffolder or engineer whererelevant (In Qld refer Qld COP) Anchor verification documentationissued / verified(proof testing, anchor torquesettings, install date, location,competent person etc. whererelevant) Maintenance verified for scaffoldcomponents erected Engineer advice for supportstructures implemented / verified Working platforms, access, edgeprotection etc. as per design andsuitable(including design rating, gaps,penetrations, edge protection, maxstep height to access platforms,use of stairs where practicable etc.) ScaffTag or equivalent signage withcorrect duty loading installed ataccess Are controls in place to preventimpact to the scaffold from vehicle/ plant / crane movement etc. Public protection & exclusioncontrols implemented Perimeter containment screenserected to standard Reinspection frequency for scaffoldand support structures established OFSC Scaffold ChecklistAdditional comments6

Part C– Prior to scaffolding being placed inserviceCriteriaCompliant N/ACA requiredOther . Other . CA No.Corrective action detailsIssued toAdditional commentsDue dateClosed/statusCompleted by:Position:Signature:Date:This scaffold checklist was last updated 12 October 2021. The Office of the Federal SafetyCommissioner (OFSC) has prepared this checklist for general information only, and it does not replaceprofessional advice. This checklist is derived from a variety of sources and has been prepared withouttaking into account your individual objectives, situations or needs. You should consider your personalcircumstances, and if appropriate, seek independent legal, financial, or other professional advicebefore acting. The OFSC has endeavoured to ensure the currency and completeness of theinformation in this checklist at the time of publication; however, this information may change overtime. The OFSC expressly disclaims any liability caused, whether directly or indirectly, to any personin respect of any action taken on the basis of the content of this checklist.OFSC Scaffold Checklist7

Scaffold design plan / drawings provided by scaffold designer If N/A above, a risk assessment has been conducted to justify no scaffold plan Designer qualifications verified Design of scaffold ties addressed in design plan (Including if single leg ties are proposed) Written advice on ground conditions .