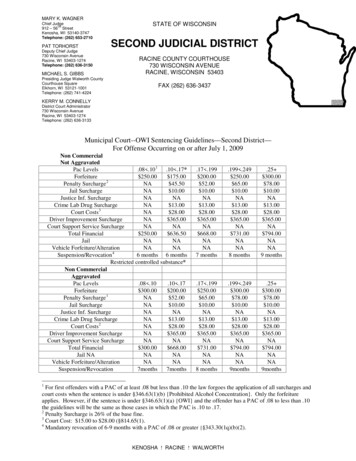

Transcription

2017 AT-PAC RINGLOCKSAFETY MANUAL& USER GUIDESUNITED KINGDOM

RINGLOCKSAFETY MANUAL & USER GUIDESTable of ContentsINTRODUCTION . 4RINGLOCK QUALITY FACTORS . 5DESIGNATION OF RINGLOCK . 5SAFETY GUIDELINES AND SAFE USE . 6NEVER . 8ALWAYS . 9ERECTION GUIDELINES FOR RINGLOCK SCAFFOLD . 10RECOMMENDATIONS . 10RISK ASSESSMENT . 11SCAFFOLDING ERECTION GUIDELINESSTEP 1 . 12STEP 2 . 13STEP 3 . 14STEP 3 . 15STEP 4 . 16STEP 5 . 17STEP 6 . 18STEP 7 . 19STEP 8 . 19SLOPESSHALLOW SLOPES . 20STEEP SLOPES . 20THREE PART SIDE PROTECTION . 21CORNER SOLUTIONSWITHOUT CANTILEVER PLATFORMS . 22WITH INTERNAL CANTILEVER PLATFORMS . 23BRIDGING SOLUTIONS . 24LADDER ACCESS. 25METHODS OF STABILISING SCAFFOLDSBUILDING TIES . 26RECOMMENDATIONS FOR STRAIGHT DOUBLE TIE . 26GUIDELINES TO DISMANTLING RINGLOCK SCAFFOLDS . 27ERECTION GUIDELINES FOR STAIR TOWER (10 LEG) . 28STAIR TOWER GENERAL ARRANGEMENT (10 LEG) . 29NOTES ON SAFE USE OF RINGLOCK STAIR TOWERS . 30STEP 1 . 31STEP 2 . 31STEP 3 . 31STEP 4 . 32STEP 5 . 32STEP 6 . 33STEP 7 . 33STEP 8 . 33RINGLOCK STAIR TOWER (10 LEG) LAYOUT . 34STAIR TOWER (10 LEG) QUANTITY LIST—U-TYPE . 35STAIR TOWER (10 LEG) QUANTITY LIST—O-TYPE . 362 Copyright 2017 Atlantic Pacific Equipment. All rights reserved.AP-UK-004-V1

RINGLOCKSAFETY MANUAL & USER GUIDESTable of ContentsERECTION GUIDELINES FOR ALUMINIUM STAIR TOWER (4 LEG). 37STAIR TOWER GENERAL ARRANGEMENT (4 LEG) . 38STEP 1 . 39STEP 2 . 39STEP 3 . 39STEP 4 . 40STEP 5 . 40STEP 6 . 41STEP 7 . 41STEP 8 . 42STEP 9 . 42STEP 10 . 42STEP 11. 43RINGLOCK ALUMINIUM STAIR TOWER (4 LEG) LAYOUT . 44ALUMINUM (4 LEG) STAIR TOWER QUANTITY LIST—U-TYPE . 45ALUMINUM (4 LEG) STAIR TOWER QUANTITY LIST—O-TYPE . 46ALTERNATIVE PLATFORM STAIR ACCESS . 47LOADING TOWER ERECTION GUIDELINES . 48RECOMMENDATIONS . 48RISK ASSESSMENT . 49STEP 1 . 50STEP 2 . 50STEP 3 . 51STEP 4 . 51STEP 5 . 52STEP 6 . 52STEP 7 . 53STEP 8 . 53SAFETY HARNESS CONNECTION POINT . 54CONNECTION TO A LEDGER . 55ADDITIONAL SAFETY GUIDELINES . 57SCAFFOLDING OPERATIONS . 57HANDLING & STORAGE . 60USE OF LADDERS . 61USE OF LADDERS . 61GIN WHEELS AND ROPES. 62GIN WHEELS AND ROPES. 62DISCLAIMER . 63AP-UK-004-V1Copyright 2017 Atlantic Pacific Equipment. All rights reserved. 3

RINGLOCKSAFETY MANUAL & USER GUIDESIntroductionINTRODUCTION TO AT-PACSince 1995, AT-PAC has offered Complete Scaffolding Solutions to our strategic clientsthroughout the world, matching our expertise to the specific needs of our Customers.With our extensive experience in the industrial market, we specialise in Oil, Gas &Chemicals, Power & Energy and Mining & Refining projects. AT-PAC hires and sells thehighest quality products by ensuring that our production processes adhere to ourrigorous quality assurance program and quality control.AT-PAC has locations throughout the UK, USA, Canada, Australia and South America.We currently supply Asia-Pacific, Africa, the Middle East and beyond. Our unparalleledexpertise and professionalism enables us to consistently deliver Complete ScaffoldingSolutions. Our experienced customer driven team provides a seamless service fromproduct development, supply chain management, production, quality control, deliverywith local engineering support available for fast effective solutions where required.AT-PAC Ringlock is a modular system scaffold which enables users to quickly andefficiently erect, use and dismantle temporary work structures. The AT-PAC Ringlocksystem conforms to European standards BS EN12810 and BS EN12811. AT-PAC Ringlockis compliant with The National Access & Scaffolding Confederation (NASC) Code ofPractice for System Scaffold.AT-PAC LTD. is a Non-Contracting Full Member of theNational Access & Scaffolding ConfederationISO 9001RegisteredISO 14001RegisteredOHSAS18001RegisteredFor information on Ringlock system components not contained in this documentplease refer to the Ringlock Brochure.4 Copyright 2017 Atlantic Pacific Equipment. All rights reserved.AP-UK-004-V1

RINGLOCKSAFETY MANUAL & USER GUIDESRinglock Quality Factors & DesignationRINGLOCK QUALITY FACTORSAll of AT-PAC Euro range of Ringlock products are engineered to meet the highestquality standards based on three simple factors:MATERIALFITFINISHWe only use the highest quality steel in our products. Our steel iscertified and tested, it conforms to or exceeds industry standards nomatter the location or climate.AT-PAC products are engineered with versatility and usability inmind. Our modified product designs increase efficiencies andproductivity, saving your projects time and money.Where applicable, our products are finished and protected by hotdipped zinc galvanizing. This method of finishing maximizes theutilization and extends the product life.For additional information on Ringlock system components please consult your localAT-PAC representative.DESIGNATION OF RINGLOCKThe Designation of Ringlock is in accordance with BS EN 12810-1:2003 and reference shouldbe made to the Ringlock Technical Manual for further information.AP-UK-004-V1Copyright 2017 Atlantic Pacific Equipment. All rights reserved. 5

RINGLOCKSAFETY MANUAL & USER GUIDESSafety Guidelines and Safe UseSAFETY GUIDELINES AND SAFE USEThe guidance given here is not intended to replace any relevant UK/Europeanstandards, Company Procedures, Work at Height Regulations and other legislation,but is a practical guide to good scaffolding practice using AT-PAC Ringlock Systemscaffolding. Please refer to the latest versions of BS EN12810, BS EN12811, the NASCGuidance Notes and current legislation prior to starting your work.1. Ensure that you follow your Company’s safe systems of work at all times.2. Ensure that your staff erecting, dismantling or modifying any Ringlock scaffold arelicensed to carry out the task.3. Ensure that all persons erecting, dismantling or modifying the scaffold structure areworking to the latest version of the applicable UK / European standards and currentlegislation.4. Ensure all Personal Protective Equipment (PPE) is suitable and sufficient and worn asappropriate.5. Consideration should also be given as to where additional hazards may be presentwhilst scaffolding operations are taking place, such as overhead power cables,roadways, schools and if public protection is required, if the scaffold is to be sheeted,who is responsible for the design.6. Ringlock scaffold structures are recommended to be inspected and recorded: Prior to being put into use for the first time After any alteration or adverse weather After any event likely to affect its stability Regular intervals as per site requirements or Company procedures but generallynot exceeding 7 days7. Access and egress should be considered as early as practicable, for both the scaffoldoperatives and the end user in mind. Ladders should be used by the scaffolderswhen erecting, modifying or dismantling any Ringlock scaffold. Ledgers and bracecomponents etc. must not be used as a means of support. Ensure that access andegress routes including ladders and stairways, are kept clear.Below is the hierarchy of measures to consider when selecting methods to prevent aperson falling at access and egress points:6 Install staircases Install ladder Access Bays with Single Lift Ladder Install ladder Access Bays with Multiple Lift Ladders Install internal ladder access with protection i.e. ladder trap/handrails etc. Install external ladder access using the Ringlock adjustable Swing Gate Copyright 2017 Atlantic Pacific Equipment. All rights reserved.AP-UK-004-V1

RINGLOCKSAFETY MANUAL & USER GUIDESSafety Guidelines and Safe Use—(Cont’d.)8. Employers have an obligation to ensure that Work at Height is: Properly planned Appropriately supervised Done in a safe manner “so far as is reasonably practicable” Include planning for emergencies & rescue Weather conditions do not jeopardise health and safety9. Before allowing people or materials on the Ringlock scaffold, ensure that it has beenerected correctly and complies with the specified requirements and all applicablelegislation.10. Ensure that all people using the Ringlock scaffold are aware of the purpose for which itis intended to be used and the maximum loading to which it can be subjected.11. Ensure users understand that any unauthorised modification to the Ringlock scaffold orremoval of components could cause a safety hazard. Alteration or extensions should becarried out only by a licensed person.12. Provide barriers and warning notices to prevent access to incomplete sections ofscaffolding.13. Do not overload and ensure that crane and forklift drivers understand loadingrestrictions on each part of the scaffold structure.14. Because of the increased use of mechanical lifting plant on site there is an increasedpossibility for scaffolding components to become fouled/caught. When using cranesor other mechanical lifting devices near any Ringlock scaffold care should be taken toensure that nothing catches under any part of the scaffold. Otherwise uplift could occurwith potentially dangerous consequences.15. Pigtail Pins/ Toggle Pins or Standard Leg Locks available to positively fix standardstogether if your Method Statement/Risk Assessment indicates that uplift cannot beeliminated.16. Scaffold access should be secured when not in use to prevent unauthorised access ontoscaffolding. Ladders should be kept in a storage compound or container.17. Consider enclosing the base of the scaffolding to prevent climbing, especially nearoccupied premises.18. Consider the environment particularly with respect to pedestrian and vehiclemovements.If you are in any doubt regarding any information contained within this Safety Manual andUser Guide, please contact your local AT-PAC representative.AP-UK-004-V1Copyright 2017 Atlantic Pacific Equipment. All rights reserved. 7

RINGLOCKSAFETY MANUAL & USER GUIDESSafety Guidelines and Safe Use—NeverSAFETY GUIDELINES AND SAFE USE—NEVERNever Throw Ringlock scaffold equipment or any other materials up or down.Never Undertake work at height when there is a potential to fall without wearing yoursafety harness correctly and clipping the lanyard to a secure anchor point.Never Do any overhead or street work without displaying warning signs, or segregatingothers from the live working zone (barriers).Never Use any defective / modified equipment.Never Overload the scaffold you are erecting, altering or dismantling with sparematerials.Never Rest scaffold equipment against an object if there is a potential for it to fallNever Leave partly erected or dismantled scaffolds in an unsafe condition, (alwaysensure adequate signage is displayed to warn others).Never Accept an instruction from a customer or anyone else that does not comply withsafety regulations or current legislation.Never Leave an exposed edge where people or building materials could fall.Never Remove ties except when using trained operatives, working to your agreed siterequirements and instructions.Never Remove guardrails, toeboards, or brick guards except when using trainedoperatives, working to your agreed site requirements and instructions.Never Remove components or adapt the Ringlock scaffolding with non-genuineequipment.Never Create gaps in platform by removing Ringlock Steel Planks from platform thusleaving an exposed edge.Never Work on or use a Ringlock scaffold which is being erected or dismantled.Never Remove ladders or staircases.Never Overload the scaffold.Never Undermine the scaffold by digging trenches or foundations under or adjacent to it.Never Add sheeting or netting to scaffold without the approval of the scaffold designer.Never Forklift loads directly onto access scaffold (instead, use a loading tower).NEVER TAKE RISKS—THE ODDS ARE AGAINST YOU8 Copyright 2017 Atlantic Pacific Equipment. All rights reserved.AP-UK-004-V1

RINGLOCKSAFETY MANUAL & USER GUIDESSafety Guidelines and Safe Use—AlwaysSAFETY GUIDELINES AND SAFE USE—ALWAYSAlways Ensure all on-site users know for what purpose the Ringlock scaffold is intendedand the load it is designed to support.Always Prepare the ground for the scaffold and the load it will impose.Always Ensure that you provide agreed storage areas for your Ringlock scaffolding on siteto reduce handling and prevent tripping hazards.Always Keep access routes clear.Always Inspect your scaffold each time before use.Always Inspect your scaffolds and issue reports.Always Give consideration to the use of a tagging system i.e. Scaftag.Always Prevent access to incomplete and/or unsafe scaffolds and ensure that you have“scaffold not to be used” signs in place.Always Inform the Scaffolding Manager if the scaffold gets damaged, repairs can then bearranged.Always Protect scaffold from damage by site plant.Always Ensure loads on the platform are evenly distributed.Always Consider the weight of the materials you are loading on the scaffold and instructoperatives on maximum loading.Always Instruct forklift driver on maximum loading.Always Instruct the operatives who will be using the scaffold not to make anyadaptations.Always Report scaffold defects to scaffolding contractor—you may be saving a life.ALWAYS LOOK AFTER YOUR RINGLOCK SCAFFOLDING. BE SAFEAP-UK-004-V1Copyright 2017 Atlantic Pacific Equipment. All rights reserved. 9

RINGLOCKSAFETY MANUAL & USER GUIDESErection Guidelines for Ringlock ScaffoldERECTION GUIDELINES FOR RINGLOCK SCAFFOLDRECOMMENDATIONSPRIOR TO ERECTING RINGLOCK THE FOLLOWING IS RECOMMENDED:1. The job site should be inspected to ensure thatthe ground or other supporting structure isstrong enough to safely support the self-weightof the scaffold and the imposed loads on theplatforms. In addition, please make yourselfaware of the proximity of power lines, overheadobstructions and weather conditions. Thesecould pose a possible danger during the erection,use and dismantling of Ringlock and shouldbe evaluated and adequately addressed inaccordance with the requirements for provisionof Risk Assessments and Method Statements.2. Check the condition of the building façade at theproposed tie locations.3. The spacing of the Standards should be in accordance with the relevant layouts,if available.4. If design drawings of the scaffold are required, check the requirements of thelocal authority with respect to what must be shown on the drawings (load rating,erection/dismantling instructions etc.)5. All equipment should be inspected prior to use to ensure that it is in good conditionand is serviceable. Damaged or deteriorated equipment must not be used.6. Avoid storing or handling scaffold components below or close to electrical powerlines. Check the requirements of the authority having jurisdiction for the exclusionszones.7. Care must be taken when scaffolding work is in close proximity to exposed andinsulated electrical lines and hidden electrical cables (for example, cable concealedbehind a surface where a scaffold anchor is to be fitted).8. Be aware of all Client and work related site safety procedures as well as reference tolocal/ regional and legislation.9. Be aware of possible dangers regarding explosions or fire.10. Ensure that the scaffolders are trained and fully instructed to erect Ringlock systemscaffolding.11. Check the safety and function of all the tools that are used during erection.10 Copyright 2017 Atlantic Pacific Equipment. All rights reserved.AP-UK-004-V1

RINGLOCKSAFETY MANUAL & USER GUIDESErection Guidelines—Risk AssessmentRISK ASSESSMENTPRIOR TO STARTING ERECTION CONDUCT A RISK ASSESSMENTA risk assessment is simply a means of determining what could cause harm within yourworkplace and developing suitable control measures to prevent accidents. It is also alegal requirement and you have duties under HSE legislation.BEFORE STARTING ERECTION OF RINGLOCK SCAFFOLDING, WE WOULD RECOMMEND YOUCONSIDER THE FOLLOWING: Ensure that all scaffolders have seen the risk assessment and ensure that theyunderstand it. Ensure that all scaffolding workers sign the risk assessment form. Double check the worksite, ensure that all scaffolding workers have checkedtheir tools. Secure the work area, isolate from others and establish drop zones. Consider the job at hand and ensure that nothing has been missed. Never be taken in by the “Big Risk” and miss other potential problems (such astrip hazards, people working nearby, possibility of dropping objects etc.)ONCE YOU START THE ERECTION WORK: Never work outside the scope of the Risk Assessment. Always stop work and re-assess if conditions change or if additional hazards,which are not included in the Risk Assessment, become apparent. Always stop work if you feel unsafe.AP-UK-004-V1Copyright 2017 Atlantic Pacific Equipment. All rights reserved. 11

RINGLOCKSAFETY MANUAL & USER GUIDESErection Guidelines—Step 1SCAFFOLDING ERECTION GUIDELINES STEP 11. Prepare the foundation for the scaffold.2. Install Base Collars on the Adjustable ScrewJacks, and set them out roughly in positionwith their corresponding Ledgers. Pick thehighest ground level for the starting point tosimplify later adjustment. It helps if the BaseJack adjusting handle is near the bottom of thethread. This will allow maximum adjustment onthe lower ground levels.3. The Base Jack must be located centrally onsole plates.4. For level surfaces, start at one end wherethe scaffold is required, and build towardsthe other end. Set the Base Jack as low aspossible. On level surfaces, they should all be atapproximately the same height.5. Each rosette has eight openings. The smaller openings are generally used to helpguide the scaffolding to make 90 degree connections, whereas the larger openingenable connections at variable angles to be achieved.6. Unless erecting a scaffold around a circular building structure, align the BaseCollar rosettes so that one of the small openings in the rosette points in the Ledgerdirection. The small openings at right angles to the first will automatically align theTransoms at 90 degrees.7. The larger openings are generally used forconnecting the diagonal braces.RINGLOCK ROSETTE12 Copyright 2017 Atlantic Pacific Equipment. All rights reserved.AP-UK-004-V1

RINGLOCKSAFETY MANUAL & USER GUIDESErection Guidelines—Step 2SCAFFOLDING ERECTION GUIDELINES STEP 21. Connect the Ledgers to the rosette on the Base Collar. Do not hammer in thewedges at this stage.2. Using a spirit level, adjustthe Jacks so that the Ledgersand Transoms are horizontal.Accuracy in leveling at thisstage eliminates the need forfurther leveling and plumbingas the scaffold is erected.PLANK CONFIGURATIONBAY WIDTH(m)NUMBEROF 0.32mPLANKSNUMBEROF 7713.079-BAY WIDTHDETAIL OF PLANK CONNECTIONAP-UK-004-V1Copyright 2017 Atlantic Pacific Equipment. All rights reserved. 13

RINGLOCKSAFETY MANUAL & USER GUIDESErection Guidelines—Step 33. Place Planks of the correctbay length into the end bay tofully deck out the bay. Adjustthe position of the Jacks andBase Collar by pushing oneJack sideways either in or outin order that the Planks areparallel with the Ledgers. Onlya small amount of movementmay be needed to ensure thebay is square enough to lockdown the Planks with DeckLocks. Once you are satisfiedthat the bay is square, fill allother bays with Planks so that aplatform is created from whichthe rest of the scaffold can be erected.4. When you are satisfied that the scaffold is fully squared and levelled, hammer inthe wedges.SCAFFOLDING NOTE:Irrespective of whether a platform is required on the lowest rosettes it isrecommended that the Planks are installed at this level. This ensures that the scaffoldis square and level prior to erection and it also provides plan stiffness. This is mostimportant, especially when the maximum height of the scaffold is above eight lifts.The installation of these Planks ensure that the out of alignment eccentricities are keptto a minimum in order for the scaffold to attain the maximum permissible height foreach recommended tie pattern (refer to Technical Manual).14 Copyright 2017 Atlantic Pacific Equipment. All rights reserved.AP-UK-004-V1

RINGLOCKSAFETY MANUAL & USER GUIDESSCAFFOLDING ERECTION GUIDELINES STEP 31. When the base lift iscompleted, the first RinglockStandards can be positionedinto the Base Collars. Thebottom of the Standards fitinto the socket tube at the topof the Base Collar.2. The Spigot on the Standardsalways point upwards.3. It is recommended that thejoints in inner and outerStan

Practice for System Scaff old. AT-PAC LTD. is a Non-Contracting Full Member of the National Access & Scaff olding Confederation INTRODUCTION TO AT-PAC ISO 9001 Registered ISO 14001 Registered OHSAS 18001 Registered For information on Ringlock system components not contained in this document please refer to the Ringlock Brochure. Introduction