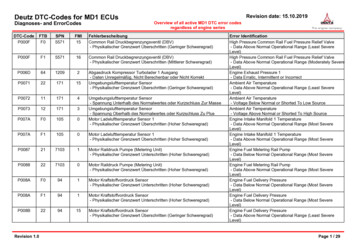

Transcription

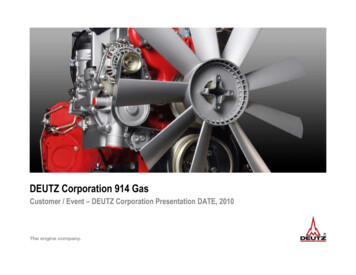

DEUTZ Corporation 914 GasCustomer / Event – DEUTZ Corporation Presentation DATE, 2010

914 GasContent Target Market General Product Features Performance Data Dimensions and Weight Emissions Gas Train and Ignition System Installation Operation Summary 914 Gas Features and BenefitsDEUTZ Corp. Guido Pesch DEUTZ AG. All rights reserved, also regarding any disposal, exploitation reproduction, editing, distribution, as well as in the event of applications for industrial property rights.2

914 GasTarget MarketThe further development of the 914-Series is intended for heavy duty and / or continuous operationssuch as:Pumps We offer continuous ratings for the irrigation pump market The demands of the oil industry are met by the 914 for pump jacks and gas compressionGenerating sets Fix speed applications at 1,500 and 1,800 rpm are available with zero speed droopDEUTZ Corp. Guido Pesch DEUTZ AG. All rights reserved, also regarding any disposal, exploitation reproduction, editing, distribution, as well as in the event of applications for industrial property rights.3

914 GasGeneral Product Features – Core EngineProduct Features of the Engine: Robust Air-Cooled Engine DesignDiesel Piston Modular Engine Concept with Single Cylinder Heads andPiston Liners High Quality Engine Components in an astonishingsimple engine design Maintenance-free Ignition System Well proven, state-of-the-art gas train Family of four natural, six natural and six turbo charged after-cooledengines EPA and CARB compliantDEUTZ Corp. Guido Pesch DEUTZ AG. All rights reserved, also regarding any disposal, exploitation reproduction, editing, distribution, as well as in the event of applications for industrial property rights.Gas Piston4

914 GasGeneral Product Features – Core EngineProduct Features of the Core Engine:The TC/G 914 is a derivative of the DEUTZ heavy duty 914 diesel engine series. The core engine ofthe 914 is based on the diesel versions, with the following exceptions: Piston Adjusted compression ratio of 9:1; the Diesel versions runs on 20 : 1 or 18 : 1 (turbo charged) Modified bowl shape Re-engineered piston rings Cylinder head Valves and valve seats are able to withstand the higher temperatures compared to the Diesel Insert for spark plugs, instead of accepting the fuel injector Fuel system components & drive parts (Gas Train & Ignition System) TurbochargerDEUTZ Corp. Guido Pesch DEUTZ AG. All rights reserved, also regarding any disposal, exploitation reproduction, editing, distribution, as well as in the event of applications for industrial property rights.5

914 GasGeneral Product Features – Basic Engine Data Air-cooled, four-stroke,, spark ignited, 4 and 6 cylinder in-line engines Natural aspirated engines G914L04 / G914L06 are running with a “stoichiometric “air-fuel ratio (λ : 1) The turbo charged version TCG 914L06 is designed as “lean-burn” engine (λ : 1.4 - 1.5) Integrated ignition and gas control system High rate of parts commonality between Diesel and Gas engine typesEngine TypeG914L04G914L06TCG914L06Boreinch / mm4.0 / 1024.0 / 1024.0 / pressionrationinch / mm5.2 / 1325.2 / 1325.2 / 132cu in / liter65.8 / 1.07865.8 / 1.07865.8 / 1.078cu in / liter263.2 / 4.314394.9 / 6.472394.9 / 6.472-9:19:19:1Aspiration-Naturally AspiratedDEUTZ Corp. Guido Pesch DEUTZ AG. All rights reserved, also regarding any disposal, exploitation reproduction, editing, distribution, as well as in the event of applications for industrial property rights.Turbo charged,Charge Air-Cooled6

914 GasGeneral Product Features – Scope of SupplyBasic Engine includes the following Features: Air-to-Air Charge-Air-Cooler heat exchanger for TurboModels, Lube Oil Pump, Lube Oil Filter, Lube Oil Cooler, Oil Pan, Crankcase Breather, Air IntakeManifold, Slate Grey finish Coating, Instruction and Spare Parts Manuals, and also comes with thefollowing Accessories: Basic Engine V-Belt driven Cooling Blower Lube Oil Pump, Oil Filter, Oil Cooler and Oil Pan Special Pistons and Cylinder Heads for Gas Applications Ignition System from GAC, Gas Train from other vendors SAE 3 Flywheel Housing and 10/11.5" Flywheel Alternator and Starter (12 V) Air Intake Manifold and Catalytic Converter (for EPA / CARB compliant Versions) Heavy Duty Dry Type Air Cleaner DEUTZ safety shut down control panel with integrated Engine Control Unit (ECU) Engine Mounts, Rigid (Four Cylinder Standard with Mass Balancer) Heavy Duty Skid BaseDEUTZ Corp. Guido Pesch DEUTZ AG. All rights reserved, also regarding any disposal, exploitation reproduction, editing, distribution, as well as in the event of applications for industrial property rights.7

914 GasPerformance Data – Open LoopEngine TypeSpeedOutputTorqueG914L03rpmhp / kWlb-ft / NmEngine TypeSpeedOutputTorqueG914L04rpmhp / kWlb-ft / Nm120037.5 / 28.0164.4 / 222.8150042.9 / 32.0180048.3 / 36.0200051.0 / 38.0Engine TypeSpeedOutputTorqueG914L06rpmhp / kWlb-ft / Nm120049.6 / 37.0216.7 / 294.0150063.7 / 47.5180073.8.0 / 55.0200080.5 / 60.0Engine TypeSpeedOutputTorqueTCG914L06rpmhp / kWlb-ft / Nm150095.2 / 71.0333.4 / 4521800110.0 / 82.01900114.0 / 85.0120029 / 21.6126.9 / 172.0150034.9 / 26.0180037.5 / 28.0DEUTZ Corp. Guido Pesch DEUTZ AG. All rights reserved, also regarding any disposal, exploitation reproduction, editing, distribution, as well as in the event of applications for industrial property rights.200038.9 / 29.08

914 GasPerformance Data – Closed LoopEngine TypeG914L04Speedrpm1,2001,5001,8001,900Outputhp / kW32.2 / 24.036.2 / 27.040.2 / 30.040.2 / 30.0Torquelb-ft / Nm140.9 / 191Engine TypeG914L06Speedrpm1,2001,5001,8001,900Outputhp / kW49.6 / 37.059.0 / 44.060.3 / 45.060.3 / 45.0Torquelb-ft / Nm216.7 / 294.0Engine TypeTCG914L06SpeedrpmN/A1,5001,800N/AOutputhp / kW-76.4 / 57.089.8 / 67.0-Torquelb-ft / Nm367.7 / 362.9DEUTZ Corp. Guido Pesch DEUTZ AG. All rights reserved, also regarding any disposal, exploitation reproduction, editing, distribution, as well as in the event of applications for industrial property rights.9

914 GasDimensions and WeightAll listed dimensions are based on DEUTZ Corporation providing the Skid Base.Engine TypeG914L04G914L06TCG914L06Lengthinch / mm41.0 / 1,04060.0 / 1,52060.0 / 1,520Widthinch / mm34.0 / 86034.0 / 86034.0 / 860Heightinch / mm51.0 / 1,30051.0 / 1,30046.5 / 1,180Weightlb / kg726 / 3301,012 / 4601,221 / 555DEUTZ Corp. Guido Pesch DEUTZ AG. All rights reserved, also regarding any disposal, exploitation reproduction, editing, distribution, as well as in the event of applications for industrial property rights.10

914 GasEmissions, Certification Overview Certification is required on all stationary engines less than or equal to 25 hp regardless of fuelused. For engines greater than 25 hp: Certifications is required by engine manufacturer for Gasoline engines Rich-burn LPG enginesCertification is voluntary by engine manufacturer for Natural gas engines (lean or rich burn) Landfill/Digester gas engines Lean-burn LPG engines For non-certified engines supplied by engine manufacturer Owner/operator will be required to develop and follow a maintenance plan Emission testing must be performed to demonstrate compliance to the standard over the engine life Maintenance records must be kept to demonstrate complianceDEUTZ Corp. Guido Pesch DEUTZ AG. All rights reserved, also regarding any disposal, exploitation reproduction, editing, distribution, as well as in the event of applications for industrial property rights.11

914 GasEmissionsDEUTZ Certifiedto Natural GasEngine 0122013g/bhp-hrNOx :CO:VOC:NOx HC:3.05.01.02.05.01.026 - 99Natural Gas andLean Burn LPG100 - 500Landfill/DigesterGasEnergency NaturalGas and Lean BurnLPG 50026 - 129 130CO:NOx:CO:VOC:103872.04.01.0 26 – 99 hp category: DEUTZ TC / G 914 series 100 – 500 hp category: DEUTZ TCG 2015 seriesDEUTZ Corp. Guido Pesch DEUTZ AG. All rights reserved, also regarding any disposal, exploitation reproduction, editing, distribution, as well as in the event of applications for industrial property rights.12

914 GasBasic Design Concept G914EPA Compliant Version Naturally Aspirated Engines G914L04 G914L06 Rich burn engines with closed loop system and catalytic converter Turbo charged after cooled engine model TCG914L06 Lean burn engines with closed loop system and catalytic converterNone EPA Compliant Versions Naturally Aspirated Engines G914L03 G914L04 G914L06 Rich burn engines (open loop system, no exhaust gas after treatment) Turbo charged after cooled engine model TCG914L06 Lean burn engines (open loop system, no exhaust gas after treatment)DEUTZ Corp. Guido Pesch DEUTZ AG. All rights reserved, also regarding any disposal, exploitation reproduction, editing, distribution, as well as in the event of applications for industrial property rights.13

914 GasGas Train, OverviewShut off valveEngine Control ModuleNatural Gas InletThrottleJ1939HMICANBUSPressure RegulatorVenturi MixerFuel Stepper MotorEngine Sensors: MPU Magnetic Pick Up speedsensor MAP Manifold Absolute Pressure UEGO Pre Catalyst O2-Sensor HEGO Post Catalyst O2-Sensor OILT Oil Temperature LOP Lube Oil Pressure CYL Cylinder Head TemperatureDEUTZ Corp. Guido Pesch DEUTZ AG. All rights reserved, also regarding any disposal, exploitation reproduction, editing, distribution, as well as in the event of applications for industrial property rights.14

914 GasGas Train, Air-Fuel-Ratio (AFR)Pressure RegulatorSpeed MPUEngine ControllerAir IntakeTemperatureFuel Stepper MotorO2SensorsVenturi MixerMAP SensorDEUTZ Corp. Guido Pesch DEUTZ AG. All rights reserved, also regarding any disposal, exploitation reproduction, editing, distribution, as well as in the event of applications for industrial property rights.15

914 GasGas Train, Throttle SystemVenturi MixerSpeed MPUSpeedEngine ControllerATB ThrottleManifold pressureLoadPWMThrottlePositionSensor(TPS)Control PanelRaise / LowerTrimCylinder HeadDEUTZ Corp. Guido Pesch DEUTZ AG. All rights reserved, also regarding any disposal, exploitation reproduction, editing, distribution, as well as in the event of applications for industrial property rights.16

914 GasGas TrainShut-Off ValvePressure RegulatorFuel Stepper MotorVenturi Mixer (Carb)ThrottleDEUTZ Corp. Guido Pesch DEUTZ AG. All rights reserved, also regarding any disposal, exploitation reproduction, editing, distribution, as well as in the event of applications for industrial property rights.17

914 GasGas Train, Shut-Off Valve and Pressure RegulatorShut-Off ValvePressure RegulatorFuel Stepper MotorVenturi Mixer (Carb)ThrottleDEUTZ Corp. Guido Pesch DEUTZ AG. All rights reserved, also regarding any disposal, exploitation reproduction, editing, distribution, as well as in the event of applications for industrial property rights.18

914 GasGas Train, Shut-Off Valve and Pressure RegulatorShut-Off ValveNatural Gas Inlet The shut off valve represents the first stage in the gas train. In addition to the ignition system, this device becomes the safety to shut down theengine by simply cutting off the fuel supply. The gas inlet port is ¾” for the G914L04 or 1” for the G914L06 and TCG914L06models.Pressure Regulator The “Zero” Pressure Regulator receives a gas pressure from 12” to 14” H2O andreduces the gas pressure level to 0” H2O. Outlet pressure to the fuel stepper motor is preset and sealed to 0” H2O(-0.25” to 0.25”) during the engine production and engine testing process. Inlet and outlet ports are 1.0” NPT thread.Stepper MotorDEUTZ Corp. Guido Pesch DEUTZ AG. All rights reserved, also regarding any disposal, exploitation reproduction, editing, distribution, as well as in the event of applications for industrial property rights.19

914 GasGas Train, Fuel Stepper Motor and Venturi Mixer (Carb)Shut-Off ValvePressure RegulatorFuel Stepper MotorVenturi Mixer (Carb)ThrottleDEUTZ Corp. Guido Pesch DEUTZ AG. All rights reserved, also regarding any disposal, exploitation reproduction, editing, distribution, as well as in the event of applications for industrial property rights.20

914 GasGas Train, Fuel Stepper Motor and Venturi Mixer (Carb)Fuel Stepper MotorPressure Regulator After the pressure regulator, the fuel stepper motor becomes the next componentof the fuel metering sub system. The stepper motor determines the mixture of theair-fuel ratio. The motor gets the signal out of the Engine Control Module (ECM) and varies theamount of gas mixed with air by the following venturi.Venturi Mixer (Carb) The venturi is the third and last subsystem of the fuel metering system. At this stage the gas gets mixed with the air and flows through the throttle into thecombustion area of the 914. In conjunction with the pressure regulator and the fuel stepper, the venturiprovides precise control of the desired fuel-air-ratio in response to the oxygensensor located in the exhaust system.ATB ThrottleDEUTZ Corp. Guido Pesch DEUTZ AG. All rights reserved, also regarding any disposal, exploitation reproduction, editing, distribution, as well as in the event of applications for industrial property rights.21

914 GasGas Train, ThrottleShut-Off ValvePressure RegulatorFuel Stepper MotorVenturi Mixer (Carb)ThrottleDEUTZ Corp. Guido Pesch DEUTZ AG. All rights reserved, also regarding any disposal, exploitation reproduction, editing, distribution, as well as in the event of applications for industrial property rights.22

914 GasGas Train, ThrottleThrottle SystemVenturi Mixer After the venturi, the air-to-fuel mixture passes through the throttle, whichcontrols the quantity of air-fuel-ratio according to the load and speed of theengine. The throttle has an effective diameter of 40 mm and is operated “fly-by-wire”. The needed position / angle of the thro

General Product Features –Core Engine Product Features of the Engine: . The TC/G 914 is a derivative of the DEUTZ heavy duty 914 diesel engine series. The core engine of the 914 is based on the diesel versions, with the following exceptions: Piston Adjusted compression ratio of 9:1; the Diesel versions runs on 20 : 1 or 18 : 1 (turbo charged) Modified bowl shape Re-engineered piston rings .