Transcription

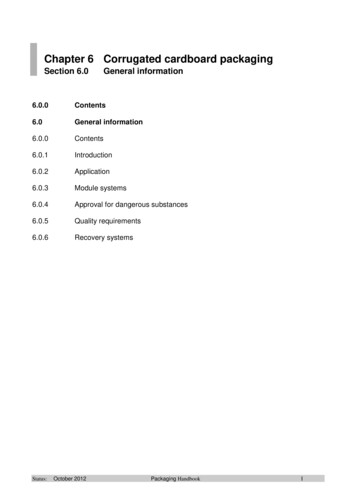

Working with Cardboardfor Packaging

There is no limit to the number of potential designs forcarton packaging and there always remains scope forimprovement, innovation and creativity.

Structural packaging design can often surpass thenumerous other methods of winning customer loyalty,such as advertising, marketing, graphic imagery and cansignificantly improve competitivenessin the marketplace.

A successful carton design can forge a company’simage in the public’s eye, convey a sense of quality andand deliver functional and environmental improvements.

There are many different types of cardboard and papersused for packaging, depending on the strength andamount of protection required. Coated and uncoatedstocks, pulps (for egg cartons and the like) andcorrugated boards each have a purpose in the arena ofcarton design and manufacturing.

Carton Board TypesDescriptionWhite back folding box boardFolding Box board reverse side creamSolid bleach boardRecycled solid white-lined chipboard(minimum 75% recycled content)Pulp BoardUnlined A Flute CorrugatedSingle faced A- Flute CorrugatedA-Flute Corrugated 33 flutes per footB-Flute Corrugated 47 flutes per footC-Flute Corrugated 3 flutes per footE-Flute Corrugated 90 flutes per footDouble walled Corrugated B & C FluteMulti layered solid bleached board(Waterproof lined)Typical usesNovelty & luxury packaging e.g. cosmetics, confectionery and high quality foodsFood Products including frozen,pharmaceuticals and cosmeticsHigh quality packaging used forcosmetics and the luxury tradeDisplay outers and non-food productsApprox Thickness0.3-0.58Used for low cost products, specialpromotions packsUsed for packs which need no strength,providing a layer of protection for theproductFMCG with good crush resistance andtactile qualitiesVery fragile goods great shockabsorbencyOptimal levels of crush absorbencyVery High shock absorbency (more thanB-Grade Corrugated)Thinnest Corrugated packaging used ininstances where a narrow gauge ofcorrugation is requiredUsed to protect fragile goods and toincrease the strength of cartonscontaining heavy objectsFood and drinks packaging0.3 -10.35 - 0.650.285 - 0.490.3 - 0.8544.24.5 - 4.72.1 - 2.93.5 - 3.71.1 - 1.25.6 - 6.60.8 - 1

The basic structure of the corrugtated boardconsists of a fluted sheet glued to one or moreUnlined Corrugated A FluteSingle Face Corrugated A FluteSingle Wall (double face) Corrugated A FluteDouble Wall (A and C Flute)

A number of flute structures are available,depending on packaging specificationsA Flute Corrugated33 flutes per linear footB Flute Corrugated47 flutes per linear footC Flute Corrugated39 flutes per linear footE Flute Corrugated90 flutes per linear footCorrugatedboard is usedin multicolouredshippers and pointof sale displays.It is one of thecheapest ofall packagingmaterials

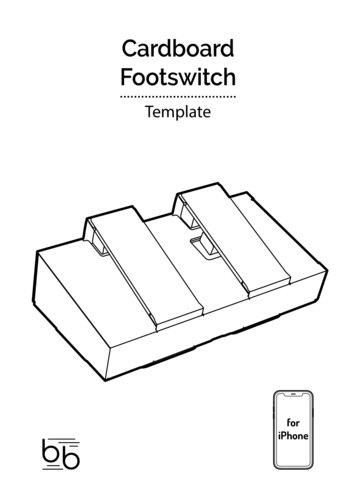

Before embarking on full production of a new packagingitem it is strongly recommended that you make a mockup using the final materials with the exact measurementsof the final work.

This can not only give the client a good tangible ideaof how the final pack will look and feel but will alsoavoid any costly mistakes. The design may requireperforations, die cutting or gluing. It may be designed tobe self locking or require a lot of intricate folding.

To make a mock up you always start with a knifelinedrawing or dieline of the intended carton or pack shape

A knifeline is a 2 dimensional drawing that acts as a‘pattern’ or template for a 3 dimensional object.A knifeline is drawn to the exact measurements of thefinal carton or pack with indicatiors for scoring, foldingcutting and ------------------------------------Cut and Crease. . . //////////////////////////////////////////////

Knifeline DrawingFinished Carton

FoldingA successful fold is determined in two ways;fold quality and fold strength.The quality of a fold refers to its appearance and thestrength is measured by how many times a piece ofpaper can be folded back and forth before breaking.There are several factors in achieving the highest qualityand strongest folds. These include the following:

Machine Folding for Mass Produced PackagingFor mass produced packaging, standard foldingmachines can make four separate folds in one go. Withadditional folding machine extensions the number offolds can be completed automatically is considerable.In addition there are folding machines that can score,perforate and glue at the same time as they fold.

Buckler Folding MachineThe paper travels through themachine.Hits the defector (A) andbegins to buckle (B)The paper is then caught in therollers and is pulled through,creating the foldThe knife comes down at aprecise moment, hits the paperand buckles itThe paper is then caught in therollers and is pulled through,creating the foldKnife Folding MachineThe paper travels through themachine.

Paper GrainWood pulp used in making paper and board containsfibres. At the beginning of the process the pulp is in aliquid state but as the paper goes from a liquid to a solidstate the fibres tend to align themselves in one particulardirection. This direction is referred to as the grain.

It is generally recommended that paper is folded with thegrain, meaning that the length of the fold lies parallel withthe grain. Folding against the grain can lead to crackingwhere the fibres wrapping around the fold break in two.Resulting in a rough, jagged edge along the fold.

Additionally booklets and folders tend to lie flatter whenthe paper stock is folded with the grain. Often, foldingagainst the grain is unavoidable.For e.g. folders with pockets, it is generallyrecommended that the main fold is made with the grainand the secondary fold against the grain.Main FoldSecondary Fold

Fibre ContentThe fibre content is a significant factor in fold strength.The greater the number of fibres, the stronger thefold. Coated papers generally contain less fibres andtherefore do not fold as well.Coated paper also tends to crack more easily as thecoated surface of the paper is less elasticthan the paper itself.

MoistureMoisture content of the paper is also an important factor.If paper is too dry and brittle it tends to crack whenfolded, if it is too moist it will pull and buckle and will nothold a crisp and accurate fold.

PrintingAllow time for ink to dry before attempting to fold paper.Printing dark inks over folds tends to accentuate thefold, especially if the paper has a tendency to crack, sodesign your piece accordingly.

ScoringTo reduce the stress that folding puts on paper, it maybe scored before being folded. Scoring also reduces therisks of cracking and for some types of board scoring isnecessary to create a clean, well-defined fold.

In packaging production, there are several types ofscoring devices, all working on the same principal; arounded rule pressing the paper into a channel.The width of the rule and the channel depend on thethickness of the paper.The rule should never be thinner than the paper.Surprisingly, the paper is actually folded away from thescore to create three stress points rather than one.

Principal of ScoringrulepaperchannelFolding After Scoringcorrectincorrect

Scoring should be considered in the following situations: Coated papers; fewer fibres and hard coating are prone to cracking High velocity printing uses hot air to dry inks.This makes inks brittle and susceptible to cracking Thick paper and all types of board as the weight of the stock increases so does the tendencyfor it to crack Folding against the grain Heavy ink coverage at the fold Whenever a job requires multiple folds.

ProductionFolding is one of the last operations in the printingprocess, so mistakes can be very costly.Therefore it is essential that you consult with your printer,bindery and paper supplier regarding the technicalaspects of producing your design.

Thankyou!Working with Cardboardfor Packagingwritten & prepared by Lisa MolloyMarch 2010for CD203 - Design Usability and the Communityimages from various sources including Googleistock, & The packaging Desugners book of Patters, George L. Wybenga

Working with Cardboard for Packaging. There is no limit to the number of potential designs for carton packaging and there always remains scope for improvement, innovation and creativity. Structural packaging design can often surpass the numerous other methods of winning customer loyalty, such as advertising, marketing, graphic imagery and can significantly improve competitiveness in the .