Transcription

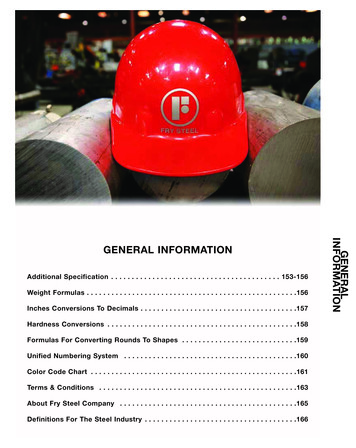

GENERAL INFORMATIONADHESIVESGENERAL INFORMATIONSECTION CONTENTSPURE50 General Information.1Reference Data (ASD).2Performance Data.3Strength Design (SD) .6Installation Instructions(Solid Base Materials) .14Reference Installation Tables .15Ordering Information .16Epoxy Injection Adhesive Anchoring SystemPRODUCT DESCRIPTIONThe Pure50 is a two-component adhesive anchoring system. The system includes injectionadhesive in plastic cartridges, mixing nozzles, dispensing tools and hole cleaning equipment. ThePure50 is designed for bonding threaded rod and reinforcing bar hardware into drilled holes in solidconcrete base materials.GENERAL APPLICATIONS AND USES Bonding threaded rod and reinforcing bar into hardened concrete Evaluated for installation and use in dry, wet, and water-filled holes Can be installed in a wide range of base material temperaturesFEATURES AND BENEFITS Designed for use with threaded rod and reinforcing bar hardware elementsEvaluated and recognized for freeze/thaw performanceCartridge design allows for multiple uses using extra mixing nozzlesMixing nozzles proportion adhesive and provide simple delivery method into drilled holesEvaluated and recognized for long term and short term loading(see performance tables for applicable temperature ranges)APPROVALS AND LISTINGS International Code Council, Evaluation Service (ICC-ES) ESR-3576 for cracked anduncracked concrete. Code Compliant with the 2015 IBC, 2015 IRC, 2012 IBC, 2012 IRC, 2009 IBC, and 2009 IRC. Conforms to requirements of ASTM C 881 and AASHTO M235, Types I, II, IV and V, Grade 3,Classes B & C(also meets Type III except for elongation) Department of Transportation listings - see www.DEWALT.com or contact transportation agency Tested in accordance with ACI 355.4 / ASTM E488, and ICC-ES AC308 for use in concrete(Design according to ACI 318-14 Chapter 17 and 318-11/08 Appendix D). Evaluated and qualified by an accredited independent testing laboratory for recognition in crackedand uncracked concrete including seismic and wind loading Compliant with NSF/ANSI Standard 61 for Drinking Water System Components - Health Effects;minimum requirements for material in contact with potable water and water treatmentGUIDE SPECIFICATIONSCSI Divisions: 03 16 00 - Concrete Anchors. and 05 05 19 - Post-Installed Concrete Anchors.Adhesive anchoring system shall be Pure50 as supplied by DEWALT, Towson, MD.Anchors shall be installed in accordance with published instructions and requirements ofthe Authority Having Jurisdiction.LIFIC ATISEIIC REGIEAONETQUCRTED CONCSMONKENEION ZOCRATECH MANUAL – ADHESIVES 2017 DEWALT – REV. B1NScode listedICC-ES ESR-3576CONCRETEwww.DEWALT.comPACKAGINGCoaxial Cartridge 9 fl. oz. (265ml) 1:1 mix ratioDual (side-by-side Cartridge)1:1 mix ratio 21 fl. oz. (620 ml) 1:1 mix ratio 51 fl. oz. (1400 ml) 1:1 mix ratioSTORAGE LIFE & CONDITIONSDual cartridge: Two yearsCoaxial cartridge: Eighteen monthsIn a dry, dark environment withtemperature ranging from41 F to 90 F (5 C to 32 C)ANCHOR SIZE RANGE (TYP.) 3/8” to 1-1/4” diameterthreaded rod No. 3 to No. 10 reinforcing bar (rebar)SUITABLE BASE MATERIALS Normal-weight Concrete Lightweight ConcretePERMISSIBLE INSTALLATIONCONDITIONS (ADHESIVE) Dry Concrete Water Saturated Concrete Water-Filled Holes

REFERENCE DATA (ASD)Installation Table for Pure50 (Solid Concrete Base Materials)NotationUnitsThreaded RodReinforcing BarDimension/Propertyd3/8#30.375(9.5)1/2-Nominal anchor diameterin.(mm)Carbide drill bit nominal sizedbitin.7/16ANSI9/16ANSIMinimum embedmenthnomMinimum spacing distancesminMinimum edge )1-7/8(48)ft.-lb.(N-m)ft.-lb.(N-m)Maximum torque1TmaxMaximum torque(low strength rods)1,2Nominal Anchor 0)2-1/2(62)2-1/2(62)5/8#50.625(15.9)11/16 79)-0.500(12.7)5/8ANSIADHESIVESREFERENCE DATA (ASD)1. Torque may not be applied to the anchors until the full cure time of the adhesive has been achieved.2. These torque values apply to ASTM A 36 / F 1554, Grade 36 carbon steel threaded rods; ASTM F1554 Grade 55 carbon steel threaded rods; and ASTM A193 Grade B8/B8M (Class 1)stainless steel threaded rods.Detail of Steel Hardware Elementsused with Injection Adhesive SystemThreaded Rod and Deformed Reinforcing Bar Material PropertiesSteelDescription(General)A 36 or F1554Grade 36TmaxThreaded Rodor RebarscdhnomNomenclatured Diameter of anchordbit Diameter of drilled holeh Base material thicknessThe greater of:[hnom 1-1/4"] and [hnom 2dbit]hnom Minimum embedment depthMinimumUltimateStrength,fu (ksi)36.058.055.075.0A 4493/8 through 11-1/492.081.0120.0105.0A 193, Grade B7 orF 1554, Grade 1053/8 through 1-1/4105.0125.0F 568M Class 5.83/4 through 1-1/458.072.5F 593,Condition CW3/8 through 5/83/4 through 1-1/465.045.0100.085.0A 193/A193M Grade 3/4 through 1-1/4B8/B8M2, Class 130.075.0A 193/A193M Grade 3/8 through 1-1/4B8/B8M2, Class 2B75.095.0hStainless SteelMinimumYield Strength,fy (ksi)3/8 through 1-1/4F 1554 Grade 55Carbon SteeldbitNominalAnchor Size(inch)Grade 40Reinforcing BarA 615, A 7673/8 through 3/4(#3 through #6)40.060.0Grade 60Reinforcing BarA 615, A 767A 706, A 7673/8 through 1-1/4(#3 through #10)60.060.090.080.0Grade 75Reinforcing BarA 615, A 7673/8 through 1-1/4(#3 through #10)75.0100.0TECH MANUAL – ADHESIVES 2017 DEWALT – REV. BcSteelSpecification(ASTM)www.DEWALT.com2

PERFORMANCE DATAADHESIVESPERFORMANCE DATAUltimate and Allowable Load Capacities for Pure50 Installed with Threaded Rodinto Normal-Weight Concrete (based on bond strength/concrete m Concrete Compressive Strength3,000 psi4,000 psiUltimate TensionLoad Capacity(lbs.)Allowable TensionLoad Capacity(lbs.)Ultimate TensionLoad Capacity(lbs.)Allowable TensionLoad ,2403,81017,7454,4355/811/16 or 251-1/41-3/811-1/476,98519,24588,89522,2251. Allowable load capacities listed are calculated using an applied safety factor of 4.0. Consideration of safety factors of 10 or higher may be necessary depending on the application, such as lifesafety or overhead.2. Linear interpolation may be used to determine allowable loads for intermediate embedments and compressive strengths.3. The tabulated load values are applicable to single anchors installed at critical edge and spacing distances and where the minimum member thickness is greater of [hnom 1-1/4"]and [hnom 2dbit].4. The tabulated load values are for applicable for dry concrete. Holes must be drilled with a hammer drill and an ANSI carbide drill bit. Installations in water saturated (wet) concrete or in waterfilled holes (flooded) require a 15% reduction in capacity. Contact DEWALT for more information concerning these installation conditions.5. Adhesives experience reductions in capacity at elevated temperatures. See the in-service temperature chart for allowable load capacity reduction factors.6. Allowable bond strength/concrete capacity must be checked against allowable steel strength in tension to determine the controlling allowable load.7. Allowable shear capacity is controlled by allowable steel strength for the given conditions.Ultimate and Allowable Load Capacities for Pure50 Installed with Reinforcing Barinto Normal-Weight Concrete (based on bond strength/concrete capacity)1,2,3,4,5,6,7TECH MANUAL – ADHESIVES 2017 DEWALT – REV. B3BarDiameterdin.Drill Minimum Concrete Compressive Strength3,000 psi4,000 psiUltimate TensionLoad Capacity(lbs.)Allowable TensionLoad Capacity(lbs.)Ultimate TensionLoad Capacity(lbs.)Allowable TensionLoad 42535,9308,985#81-1/8948,46512,11565,27016,3201. Allowable load capacities listed are calculated using an applied safety factor of 4.0. Consideration of safety factors of 10 or higher may be necessary depending on the application, such as lifesafety or overhead.2. Linear interpolation may be used to determine allowable loads for intermediate embedments and compressive strengths.3. The tabulated load values are applicable to single anchors installed at critical edge and spacing distances and where the minimum member thickness is greater of [hnom 1-1/4"]and [hnom 2dbit]4. The tabulated load values are for applicable for dry concrete. Holes must be drilled with a hammer drill and an ANSI carbide drill bit. Installations in water saturated (wet) concrete or in waterfilled holes (flooded) require a 15% reduction in capacity. Contact DEWALT for more information concerning these installation conditions.5. Adhesives experience reductions in capacity at elevated temperatures. See the in-service temperature chart for allowable load capacity reduction factors.6. Allowable bond strength/concrete capacity must be checked against allowable steel strength in tension to determine the controlling allowable load.7. Allowable shear capacity is controlled by allowable steel strength for the given conditions.www.DEWALT.com

Ultimate Load Capacities for Pure50 Installed with Threaded Rod into Normal-WeightConcrete, with 1-3/4" Edge Distance (Based on Bond Strength/Concrete Capacity)1,2,3,4Minimum Concrete Compressive Strength - f’c th(in.)2,500 psiUltimate TensionLoad Capacity(lbs.)3,000 psiUltimate ShearLoad Capacity(lbs.)Ultimate TensionLoad Capacity(lbs.)4,000 psiUltimate ShearLoad Capacity(lbs.)Ultimate TensionLoad Capacity(lbs.)Ultimate ShearLoad 5-ADHESIVESPERFORMANCE DATA1. The values listed above are ultimate load capacities which should be reduced by a minimum safety factor of 4.0 or greater to determine the allowable working load. Consideration of safetyfactors of 10 or higher may be necessary depending on the application, such as life safety.2. Allowable bond strength/concrete capacity must be checked against allowable steel strength to determine the controlling allowable load.3. The tabulated data is applicable to single anchors at critical edge distance in uncracked concrete, normal-weight concrete having a compressive strength as listed. Values are for dry concretein holes drilled with a hammer drill and an ANSI carbide drill bit.4. Linear interpolation may be used to determine ultimate loads for intermediate compressive strengths.Allowable Load Capacities for Pure50 Installed with Threaded Rod into Normal-WeightConcrete with 1-3/4" Edge Distance (Based on Bond Strength / Concrete Capacity)1,2,3,4,5,6Minimum Concrete Compressive Strength - f’c th(in.)3/83-3/82,500 psi3,000 psi4,000 psiAllowable TensionLoad Capacity(lbs.)Allowable ShearLoad Capacity(lbs.)Allowable TensionLoad Capacity(lbs.)Allowable ShearLoad Capacity(lbs.)Allowable TensionLoad Capacity(lbs.)Allowable ShearLoad Capacity(lbs.)1,6151,8001,6751,8001,7751,8001/24 ,4052,590193,100-3,215-3,405-TECH MANUAL – ADHESIVES 2017 DEWALT – REV. B1. Allowable load capacities listed are calculated using an applied safety factor of 4.0. Consideration of safety factors of 10 or higher may be necessary depending on the application, such as lifesafety or overhead.2. Linear interpolation may be used to determine allowable loads for intermediate embedments and compressive strengths.3. The tabulated load values are applicable to single anchors where the minimum member thickness is greater of [hnom 1-1/4"] and [hnom 2dbit]4. The tabulated load values are for applicable for dry concrete. Holes must be drilled with a hammer drill and an ANSI carbide drill bit. Installations in wet concrete or in water-filled holes mayrequire a reduction in capacity. Contact DEWALT for more information concerning these installation conditions.5. Adhesives experience reductions in capacity at elevated temperatures. See the in-service temperature chart for allowable load capacity reduction factors.6. Allowable bond strength/concrete capacity must be checked against allowable steel strength in tension to determine the controlling allowable load.www.DEWALT.com4

PERFORMANCE DATAADHESIVESAllowable Load Capacities for Pure50 Installed into Uncracked Normal-Weight Concretewith Threaded Rod and Reinforcing Bar (Based on Steel Strength)1,2,3Steel Elements - Threaded Rod and Reinforcing BarNominalRodDiameter orRebar Size(in. or #)A36 or F1554, Grade 36A 193, Grade B7 or F1554,Grade 105F 593, CW (SS)Grade 60 RebarGrade 40 ,170(18.5)6,520(29.0)9,390(41.8)12,780(56.8)

CSI Divisions: 03 16 00 - Concrete Anchors. and 05 05 19 - Post-Installed Concrete Anchors. Adhesive anchoring system shall be Pure50 as supplied by DEWALT, Towson, MD. Anchors shall be installed in accordance with published instructions and requirements of the Authority Having Jurisdiction. C R A C K E D C O N C R E T E T E N S I O N Z O N E Q U A LI FI C A T I O N S E I S M I C R E G I