Transcription

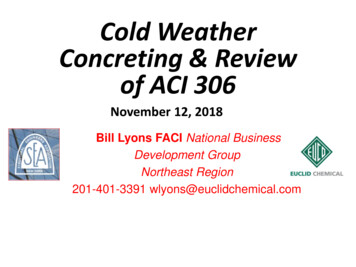

Cold WeatherConcreting & Reviewof ACI 306November 12, 2018Bill Lyons FACI National BusinessDevelopment GroupNortheast Region201-401-3391 wlyons@euclidchemical.com

Objectives/ Intent of ColdWeather Concreting1. Normalize set of concrete2. Limit rapid temperature change3. Prevent damage from freezing at early stages4. Provide protection consistent with serviceability ofstructure

Discussion Points:1. Risks2. Potential Problems3. Principles4. Objectives5. Goals6. Freeze Resistant Concrete7. Cold Weather Concrete Plan

Goal of ACI 306Concrete placed duringcold weather willdevelop sufficientstrength and durabilityto satisfy the intendedservice requirementswhen it is properlyproduced, placed, andprotected.The Key to Proper ColdWeather Concrete isManaging Risk

Risks of Cold Weather1.Neglecting protection against early freezing cancause immediate destruction or permanentlyweakened concrete.2.The durability of concrete can be significantlyreduced

Effect of Freezing1. Race Between the hydration of cement (Generatesheat as well as strength) and heat loss2. At a point after hydration, the concrete is strongenough to resist freezing3. Very little hydration takes place below 40 ºF

Bladed ice crystals cast in cementpaste- concrete froze while still plastic

Potential Problems forFreshly-Mixed Concrete in Cold Weather1. Delayed set times2. Frozen sub-grade3. Ice in bottom of forms4. Cold formwork5. Over/early finishing6. Plastic shrinkage cracking7. Crazing

Setting Time of Concrete atVarious Temperatures (Delay)TemperaturesApproximateSetting Time100 ºF (38 ºC)90 ºF (32 ºC )80 ºF (27 ºC )2 hours3 hours4 hours70 ºF (21 ºC)6 hours60 ºF (16 ºC)50 ºF (10 ºC)40 ºF ( 4 ºC )8 hours11 hours14 hours

ASTM C-1622 / C-1622M-05Standard Specification for ColdWeather Admixture Systems Determine the placement temperature ofconcrete according to ASTM C 1064/C1064M The more massive the concrete section, the lessrapidly it loses heat.

Potential Problems forFreshly-Mixed Concrete in Cold Weather1. Delayed set times2. Frozen sub-grade3. Ice in bottom of forms4. Cold formwork5. Over/early finishing6. Plastic shrinkage cracking7. Crazing

Frozen subgrade

Subgrade Has Previously BeenThawed With Hoses, Blankets & Tarps

Potential Problems forFreshly-Mixed Concrete in Cold Weather1. Delayed set times2. Frozen sub-grade3. Ice in bottom of forms4. Cold formwork5. Over/ early finishing6. Plastic shrinkage cracking7. Crazing

Ice/snow in forms

Potential Problems forFreshly-Mixed Concrete in Cold Weather1. Delayed set times2. Frozen sub-grade3. Ice in bottom of forms4. Cold formwork5. Over/ early finishing6. Plastic shrinkage cracking / Crazing

Over/ early finishing1. Because of drying conditions, concrete may appear to beready to finish or, require additional finishing effort2. Results:A. Detrained air in the top ¼”B. High potential for scaling

Over/ early finishing

Potential Problems forFreshly-Mixed Concrete in Cold Weather1. Delayed set times2. Frozen sub-grade3. Ice in bottom of forms4. Cold formwork5. Over/ early finishing6. Plastic shrinkage cracking / Crazing

Plastic Shrinkage Cracking1. Low relative humidity2. Wind3. Absorbent subgrade or formwork4. Prolonged set times5. Lack of early protection from drying

WHEN WATER EVAPORATES OFF THESURFACE TOO RAPIDLY, CRACKINGUSUALLY OCCURS.Plastic shrinkage occurs when the rate of evaporation ofsurface moisture exceeds the rate at which the risingbleed water can replace it.

Potential Problems forFreshly-Mixed Concrete in Cold Weather1.Delayed set times2.Frozen sub-grade3.Ice in bottom of forms4.Cold formwork5.Over/ early finishing6.Carbonation7.Plastic shrinkage cracking / Crazing

How to avoid plastic (or anyother kind of) shrinkage cracks:1. Accelerate the set (different from high-early concrete)2. Use micro-fibers3. Use temporary evaporation control1. Use evaporation retarder2. use poly/plastic sheeting4. Cut joint as soon as feasible- DO NOT WAIT!!5. Use a high quality curing compound, sooner ratherthan later6. Use curing/insulating covers7. Protect & Cure!!

Curing!

Issues that often arise inCold Weather1. Don’t skimp / forget curing2. Concrete Cylinders

Principles of ColdWeather Concreting

Principles of Cold WeatherConcreting:1. Concrete protected from freezing until it attains acompressive strength of at least 500 psi (3.5MPa)will not be damaged by exposure to a singlefreezing cycle (Powers 1962).2. Where a specified concrete strength should beattained in a few days or weeks, planning andprotection may be required to maintain theconcrete temperature

Principles of Cold Weather ConcretingUnder certain conditions, CaCl2 should not be used toaccelerate setting and hardening because of increasedchances of corrosion of metals embedded in concreteor other adverse effects

Required for DurabilityConcrete exposed to freeze/thaw while saturatedrequires lower w/cm than required for strength1. w/cm .50 (4,000 psi) moderate to severe freeze/thaw2. w/cm .45 (4,500psi) deicing salts3. w/cm .40 (5,000 psi reinforced concrete subject tobrackish water, sea water or deicing chemicals

Guide to Cold WeatherConcreting ACI 306R-16* The word “required”is now changed to“recommended.”

DEFINITION 306R-88

Cold Weather ConcretingACI 306R-10 Definition: “Cold weather exists when the airtemperature has fallen to, or is expected to fallbelow 40 F during the protection period. Theprotection period is defined as the timerequired to prevent concrete from beingaffected by exposure to cold weather.”

Guide to Cold Weather ConcretingACI 306R-16Balancing Risk in Producing Concretein Cold Weather

Chapter 3: Objectives,Principles and Economy 3.1 – Added – “The temperature of concrete is measured inaccordance with ASTM C1064.” 3.1.3 – Rewritten - “Maintain curing conditions that promotestrength development without exceeding the recommendedconcrete temperatures in Table 5.1 by more than 20 F andwithout using water curing, which may cause critical saturationat the end of the protection period, thus reducing resistance tofreezing and thawing when protection is removed (Section5.1).” 3.3 – Economy – “Cold weather concreting results in extra costsbecause of potentially lower worker productivity and additionalneeded products such as insulating blanket, tarping andheaters. But it may also allow a project to stay on schedule.”

Chapter 4: GeneralRecommendations Requirements4.3 Concrete TemperaturesDeleted – Concrete placed at lower temperatures (4055F), protected against freezing, and properly curedfor a sufficient length of time, has the potential todevelop higher ultimate strength and greaterdurability than concrete placed at highertemperatures. (Klieger 1958)

Chapter 4: 4.6 Finishing Air-EntrainedSlabs Slab Finishing1. Where hard troweled finish is specified, the addition of airentrainment may lead to In this case magnesium trowelsshould be used instead of steel tools.2. The water-cementitious materials ratio (w/cm) should notexceed the limits recommended in ACI 201.2R, and theconcrete should be protected from freezing and thawing forthe duration of the protection period. For steel-troweledfloor and slab construction, air-entrained concrete should notbe specified, and the concrete should be protected fromfreezing and thawing for the duration of the protectionperiod.

Chapter 4Slab Finishing4.6 Rewritten – Last sentence.New sidewalks and other flatworkexposed to melting snow and coldweather should be air-entrained andprotected from freezing and thawingfor the duration of the protectionperiod. Removed Until attaining atleast 3500 psi.

ConcreteTemperatureRequirementsAir temperature—Above 30 F(-1 C)0 to 30 F(-18 to –1 C)Below 0 F(-18 C)—Section size 12 in.(300 mm)minimum dimension, in. (mm)36-72 in.12-36 in.(900-1800(300-900 mm)mm) 72 in.(1800 mm)Minimum concrete temperature as placed and maintained50 F45 F40 F55 F(10 C)(7 C)(5 C)(13 C)Minimum concrete temperatureas mixed for indicated air temperature*60 F55 F50 F45 F(16 C)(13 C)(10 C)(7 C)65 F60 F55 F50 F(18 C)(16 C)(13 C)(10 C)70 F65 F60 F55 F(21 C)(18 C)(16 C)(13 C)Maximum allowable gradualtemperature drop in first 24 hrs after end of protection50 F40 F30 F20 F(28 C)(22 C)(17 C)(11 C)

Chapter 6Preparation Before Concreting6.2 Massive Metallic Embedments –Most embedments including bars, do not need to be heatedunless the air temperature is below 10 F (-12C). Embedmentswith a cross-sectional area greater than 4 in2 should be heatedto above 32deg F. Reinforcing bars smaller than No. 18 in size arenot considered massive embedments.

Chapter 6 6.3 Subgrade Condition – In accordance with ACI302, slabs should not be placed on frozen base orsubgrade . 2nd paragraphLimit surface temperatures of supporting materialsbeneath slabs on ground and the concrete to atemperature differential of less than 20 F to avoidany inconsistent setting, rapid moisture loss,delaminations and plastic shrinkage cracking.Removed When the concrete temperature is morethan 10F cooler or 5F warmer than the subgrade,differential rates of setting between the top andbottom of the slab

Chapter 7: Protection againstfreezing for concrete not requiringconstruction supportsChapter 7. Concrete elements that do not use requiredconstruction supports are those elements that will notbe needed required for significant structuralperformance during the construction schedule thatwould otherwise be delayed by lack of design strengthdue to temperatures below 40F. To frozen conditions

Chapter 7 (Cont.) Added 7.3 Protection Period for Durability. Added this last paragraph: Concrete intended toprovide low permeability or high resistance tochloride ion ingress, identified in the contractdocuments as being exposure Class F3, C2, orP1 as defined by ACI 318, should be protectedfrom freezing until the mixture designcompressive strength has been achieved.

Chapter 8 Protection (Against Freezing) forStructural Concrete Requiring ConstructionSupports. (retitled)8.2 Field-Cured Cylinders intended to be cured with the structurewere once widely accepted to represent the lowest likely strengthof the concrete. Field cured cylinders can cause confusion andunnecessary delay in construction. The use of field curedcylinders is inappropriate and should not be allowed incold weather concreting. This is mainly related to the difficultyin maintaining the cylinders in any approximation of the conditionsof the structure. In-place testing, maturity testing, or both shouldbe used instead.

In-place testing & Maturity testing Photo

Concrete Cylindersat jobsite.Date: March 172011, 7:30 a.m.AmbientTemperature atthe time the photowas taken: 38º FCuring conditionsof deck: Heated &Covered, with fulljacketing.The deck is hotThe cylinders are not

Chapter 8: Protection (Against Freezing)for Structural Concrete Requiring Construction Supports. (retitled) 8.6 Increasing Early Strength added the following bullets Type, amount, and properties of cementitious materials w/cm Reducing the w/cm to increase the 28 day strength, thusincreasing the early strength Increase the volume of cement used in the mixture Increase the use of various supplementary cementitiousmaterials to increase early-age strength development. SCM’sMetakaolinSilicaFly ashfume(Class F)SlagFly ash(Class C)Calcinedshale

Chapter 10: Curing RequirementsRecommendations and Methods Measures should be taken to inhibit preventevaporation of moisture from concrete. Freshly placedconcrete is vulnerable to freezing when it is criticallysaturated. Therefore concrete should be allowed toundergo some drying before being exposed totemperatures below 32 F (0C) 10.2 3rd paragraph Added: If the relative humidity is less than 40 percentinside the enclosure, it is necessary to add moisture tothe air to maintain at least 40 percent relative humidity,and inhibit desiccation of the exposed surface.

Chapter 11: Acceleration of Settingand Strength Development 11.2.2 – rewritten - Calcium ChlorideThe amount of water soluble chloride ion shouldconsider all other sources of chlorides ions in theconcrete mixture. ACI 318 and ACI 332 provides themaximum water-soluble chloride ion content based onexposure class. All statements about calcium chlorideadded to concrete in permissible quantities To avoidmisplaced confidence in this practice, it is removed.

Chapter 11: Acceleration of Settingand Strength Development Removed from document 11.2.5 Non chloride accelerating admixtures for use in sub-freezing ambienttemperatures 11.2.6 Antifreeze Admixturesa) Backgroundb) Compositionc) Strengthd) Freezing & Thawing Resistancee) Reactive Aggregatesf) Corrosiong) Batchingh) Cost Benefitsi) Summary

Chapter 11: Acceleration of Settingand Strength Development11.3 Cold Weather Admixture Systems (CWASs)Follows ASTM C 1622/C1622M as an admixturesor group of admixtures that depresses thefreezing point of mixing water and increases thehydration rate of cement

Freeze Resistant ConcreteIS IT POSSIBLE?IS IT AFFORDABLE?

Bring the Outside Indoors

Why Should We Use FreezeResistant Concrete?1. Reduces initial set2. Concrete placing cycle is accelerated3. Improves early strength gain4. Allows same-day finishing5. Maintain Schedule6. Emergency Situations

Important Points1. Keep the design method simple2. Not all non-chlorides accelerators can makefreeze resistant concrete3. Can not be done with calcium chloride4. Many types of application5. Work very closely with your RM producer &admixture supplier

KEEP IT SIMPLE!1.2.3.4.600# TYPE 1 CEMENT minimum6% AIR60 oz. /cwt of freeze protection admixturePREVENT THE INGRESS OF MOISTURE– a. cover with visqueen or insulated blanketsor– b. apply solvent based cure and seal

Metal Deck PlacementsMost CommonApplication For FreezeResistant Concr

ASTM C-1622 / C-1622M-05 Standard Specification for Cold Weather Admixture Systems Determine the placement temperature of concrete according to ASTM C 1064/C1064M The more massive the concrete section, the less rapidly it loses heat. 1. Delayed set times 2. Frozen sub-grade 3. Ice in bottom of forms 4. Cold formwork 5. Over/early finishing 6. Plastic shrinkage cracking 7. Crazing .