Transcription

PRODUCTS CATALOGF O RM O R EManufacturerI N F O R M A T I O NandCall us at 775-246-5333Fax us at 775-246-5388E-Mail: info@helicalwire.comDistributorWebsite: www.helicalwire.comofPlease send inquiries to Helical Wire Inc.26 Cash Drive Carson City, Nevada 89706Screw Threadrevised 10-2014COPYRIGHT 2012 HELICAL WIRE INC.4242EHE2014AO FRS EVIESCYRW I R E , I N C.WE GLADLY ACCEPT VISA AND MASTERCARDI S O9001:2008CERTIFIEDH1972.C1972SinceAL WIREICINLInsertsI S OA S 9 0 01 CR E V .CCERTIFIEDP E N D I N GAN ALTERNATIVE SOURCEFORSCREW THREAD INSERTS AND RELATED TOOLING.

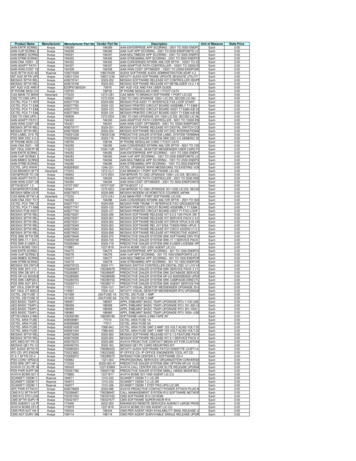

H E L I C A LW I R EI N CTABLEOFCONTENTS2Manufacturing4Standard Bulk Inserts, Non-Locking3Materials and Finishes10Standard Bulk Inserts, Locking17Te c h n i c a l I n f o r m a t i o n , M e t r i c23Metric Bulk, Locking28Ta p p i n g36I n s t a l l a t i o n To o l s38Captive Sleeve41P o w e r To o l s47Ta n g B r e a k - O f f To o l s50Repair Kits56Double-serts628-Pitch14Te c h n i c a l I n f o r m a t i o n , S t a n d a r d20Metric Bulk, Non-Locking26Drilling34Thread Gages37Bolt Type39Removable Sleeve46Strip Feed49E x t r a c t i o n To o l s54Oversize Inserts61Specials64Commercial GradeTABLEOFCONTENTS

H E L I C A LM A N U F A C T U R I N GHELICAL WIRE INC. inserts are precision manufactured screw thread inserts that play a critical role in engineeringapplications. Screw thread inserts are a reliable means of strengthening tapped holes in light weight materials and alloys.HELICAL WIRE INC. insert products are manufactured from 18-8 stainless steel diamond shaped wire per specificationsAS7245 and NASM8846 for the standard series and per MA1565 for the metric series. All inserts manufactured by HelicalMANUFACTURINGWire Inc. are engineered to meet and or exceed the Military and Aerospace standards and are inspected to meet therequirements of our ISO 9001-2008 quality system. Also inserts are manufactured from Inconel X-750 per AS7246,Phosphor Bronze per AMS 7247, Nitronic 60 per AMS5848B and Nimonic 90 per AMS 5829.Helical Wire inserts areavailable in thenon-locking or free runningscrew thread, or in thelocking or self-locking type.The self-locking style locksthe bolt or screw in placewhen installed due to aconfiguration of cords orflats on one or more of itsinterior convolutions.NON-LOCKINGLOCKINGHelical Wire utilizes a color coded system that identifies our insert’s materialsand finishes by color. This color system is used for easy identification in ourinternal house and for all customer shipment labels.LOCKING2NON-LOCKINGDRY FILM LUBEC ADMIUM PL ATEPRIMER FREESILVER PL ATEW I R EM A T E R I A L SA N DI N CF I N I S H E SHELICAL WIRE INC. screw thread inserts are manufactured of 18-8 stainless steel per AS7245, and other materials that areof the highest standard for strength and durability. Our inserts are also manufactured to meet the specific needs of certaintypes of mechanical applications. In various installation assemblyprocesses the need arises for material that will be non-magneticand in some applications heat resistant.Helical Wire can supply screw thread inserts made fromPhosphor Bronze and Inconel X-750 materials. Both of thesematerials meet the criterion mentioned above and conform toAMS 7247 and AS7246. We keep many of these Phosphor Bronzeand Inconel inserts in stock. All inserts that we make in theStandard Inch or Metric series are available in these materialsupon request.All of the wire that is used to make our coil thread inserts has a certain amount of oil that is a byproduct of manufacturing. Directly following the process of manufacturing, all of our inserts gothrough a process of cleaning to remove any residual oil that may be on the inserts in post-production.No matter what kind of material or finish, the process is the same.The Helical Wire standard inch free running, or non-locking series, will come in a clean finish. Thestandard inch self-locking series comes in a red colored finish. The Metric series is the same cleanfinish for both the locking series and the free-running series.Helical Wire inserts are available in various plated finishes. We offer all of ourinserts with plating upon request, regardless of the material or type of insert. Wesupply our screw thread inserts with Dry Film Lube per AS5272, Cadmium PlateOlive Drab per QQ-P-416 Type II, Cadmium plate without Olive Drab, and also PrimerFree per Xylan (R) 5251/840 Black or Xylan 5230/1131 Gray Black. We offer SilverPlating per AMS2411-D or QQ-S-365, and also Passivation upon request. We keepmany popular sizes in our stock with various plated finishes. We can usually shipplated inserts immediately upon request. If they aren’t quoted in stock, our leadtimes are faster than most,usually about two weeks. When plating is specified by acustomer’s part number and call out, we do whatever we can to meet their specific plating needs.PHOSPHOROUS BRONZEINCONEL X-750NITRONIC 60NIMONIC 90MATERIALSANDFINISHESTOOLING3

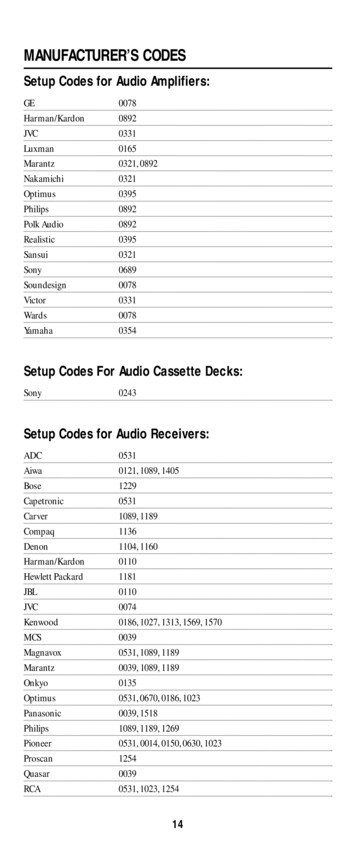

H E L I C A LN O N - L O C K I N 2412-244C O A R S EN O N - L O C K I N 1015202530W I R 1024N019002850380047505701/2-135/8-11C O A R S EI N CC O N T N062509381250156218755

H E L I C A LN O N - L O C K I N GINSERTSIZESTANDARD7/8-91-8BULK1 1/8-71 1/4-71 3/8-61 1/2-6C O A R S EC O N T .W I R EN O N - L O C K I N 00375045001/4-285/16-24When ordering Inconel per AS7246 add ‘X‘ at the end of the part number and before the plating letter. To specify Phosphor Bronze per AMS 7247material add ‘B‘ after the part number and before the plating letter and for Nitronic 60 per AMS 5848B add “N”.To order Dry Film Lube per AS5272 add an ‘L‘ at the end of the number. ‘W‘ appears after the ‘N‘ in the competitor’s part number. Example:c/r1185-24CNW1500, 1126N1500L. To request Cad Plate per QQ-P-416 Rev. F add an ‘P‘ at the end of the number. ‘Y‘ appears after the ‘N‘ in thecompetitor’s part number. Example: 1185-24CNY1500, 1126N1500P. For Primer Free per Xylan (R) 5251/840 Black add an ‘H‘ at the end of the number.‘PF‘ appears after the ‘N‘ in the competitor’s part number. Example: 1185-24CNPF1500, 1126N1500H. For Silver Plate per AMS 2411 or QQ-S-365 add‘V‘ at the end of the part number. Example: 1185-24CNV1500, 1126N1500V.6To request left hand thread add ‘LH‘ at the end of the part number and before plating letter.3/8-24I N CF I N 505620750093811257

H E L I C A LN O N - L O C K I N /4-167/8-141-121-148F I N EAEROSPACESTANDARDSC O N T .MSEQUIVALENTN O N - L O C K I N 208F141015202530MS21208F161015202530-W I R 250030001-3/8-12F I N 747787827MS124668708748788828MS124669709749789829I N CC O N T 15002250300037504500When ordering Inconel per AS7246 add ‘X‘ at the end of the part number and before the plating letter. To specify Phosphor Bronze per AMS7247 material add ‘B‘ after the part number and before the plating letter.To request Dry Film Lube per AS5272 add an ‘L‘ at the end of the number. ‘W‘ appears after the ‘N‘ in the competitor’s part number. Example:MS124669L, c/r1191-24CNW1500 or 11212N1500L.To request Cad Plate per QQ-P-416 Rev. F add an ‘P‘ at the end of the number. ‘Y‘ appears after the ‘N‘ in the competitor’s part number.Example: MS124669P, 1191-24CNY1500 or 11212N1500P.To request Silver Plate per QQ-S-365 add ‘V‘ at the end of the part number. Example: MS124669V or 11212N1500V.For Primer Free per Xylan (R) 5251/840 Black add an ‘H‘ at the end of the number. ‘PF‘ appears after the ‘N‘ in the competitor’s part number.Example: 1191-24CNPF1500, 11212N1500H.To request left hand thread add ‘LH‘ at the end of the part number and before plating letter.9

H E L I C A LL O C K I N 11201680224028003364-405-406-328-3210-2412-2410L O C K I N GTHREADSIZE3-48BULKC O A R S 05701224L02160324043205400648W I R 062509381250156218753410L07501125150018752250C O A R S EC O N T 09C141015202530789L087513121750218826251-81 1/8-71 1/4-71 3/8-61 02530I N 750343841251126L15002250300037504500When ordering Inconel per AS7246 add ‘X‘ at the end of the partnumber and before the plating letter. To specify Phosphor Bronze perAMS 7247 material add ‘B‘ after the part number and before theplating letter.To request Dry Film Lube per AS5272 add an ‘L‘ at the end of thenumber. ‘W‘ appears after the ‘N‘ in the competitor’s part number.Example: MS21209C1410L, c/r3585-14CNW0875 or 789L0875L.To request Cad Plate per QQ-P-416 Rev. F add an ‘P‘ at the end ofthe number. ‘Y‘ appears after the ‘N‘ in the competitor’s partnumber. Example: MS21209C1410P, c/r3585-14CNY0875 or789L0875P.To request Silver Plate per QQ-S-365 add ‘V‘ at the end of the partnumber. Example: MS21209C1410V or 789L0875V.For Primer Free per Xylan (R) 5251/840 Black add an ‘H‘ at theend of the number. ‘PF‘ appears after the ‘N‘ in the competitor’spart number. Example: 789L0875H/3585-24CNPF1500.To request left hand thread add ‘LH‘ at the end of the part numberand before plating letter.11

H E L I C A LL O C K I N GSTANDARDF I N 5202530MS21209F221015202530MS21209F241015202530I N CC O N T .AEROSPACESTANDARDS6-4012L O C K I N GTHREADSIZE4-48BULKF I N EW I R 05227503438412511212L150022503000375

9 helical wire inc 8 insert aerospace ms helical size standards equivalent wire ms124666 706 746 786 826 ms124667 707 747 787 827 ms124668 708 748 788 828 ms124669