Transcription

A Fiimy Material Selection Syst,em for McchariicalDesignJean-Luc KoningMay 28, 1994CML-R1-TR-94-22Robotics InstituteCarnegie Mellon University5000 Forbes AvenuePittsburgh, PA 15213-3890Copyfight @ I V Y 4 CMI! Robotics IrwlituteThis research was supported by INRIA, Domahe de \ 'ololnceau,h c q u c n c u u r t , B.P.10.5. 78153 Le Chesnay cedex, France.

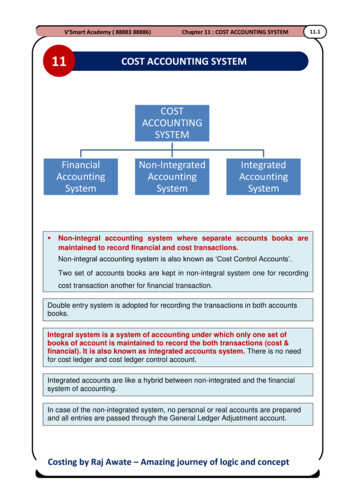

AbstractThis paper c.oncentratcs on two types of mat,erial-related reasoning that occursin engineering design: selection and substatution. Selection is based on criteriaset out by thc designer and is often associated with the process of designingnew art.ifact.s from scratch. Substitution, on the other hand, is done when newdesigns are created by adapting and re-using parts of previous designs. Thisinvolves re-evaluating the reasons for a particular material that was used in thcbase design: and determining whether the same, or new criteria are relevant inthe target design. Once the new criteria are established, appropriate materialsarc selected and substituted. The substitution step, hence, subsumes the selection task. tVe present a material selection/snbstilution system that is used aspart of a larger case-based design environment. The material selection syst,emhelps the designer adapt a previous designs by suggesting material substitutionst,liat better snit the target application. The system is intended t o provide support, right from the conceptual to the detailed stages of design, and can reasonabout material properties expressed in both numerical and qualitative terms.The system relies on the material selection charts developed by Prof. Aahbyof Cambridge University. To enable qualitative reasoning about the charts, wehave developed an cncoding based on fuzzy set theory. This allows access ofmaterials using specifications expressed in terms of fuzzy orders of magnitude.

Contents1 Introduction1.1 What. is this Report About? . . . . . . . . . . . . . . . . . . .1.2 Quick Survey of the Problem . . . . . . . . . . . . . . . . . .1.3 Illustrative Example . . . . . . . . . . . . . . . . . . . . . . .1.4 Select.ion and Substitutio lof Material . . . . . . . . . . .1.5 Outline of the Report . . . . . . . . . . . . . . . . . . . . . .6.6.6.1. . . . 8.102 The Material Selection Problem2.1 Overview of the Problem . . . . . . . . . . . . . . . . . . . . . . .2.2 Material Classes . . . . . . . . . . . . . . . . . . . . . . . . . . .2.3 Ashby’s Selection Charts . . . . . . . . . . . . . . . . . . . . . . .111112123 Rcpresentation of t h e Charts163.1 Four Possible Representations . . . . . . . . . . . . . . . . . . . .163.1.1 Continuous envelopes . . . . . . . . . . . . . . . . . . . .163.1.2 Discret envelopes . . . . . . . . . . . . . . . . . . . . . . .173.1.3 Rectangles . . . . . . . . . . . . . . . . . . . . . . . . . .173 . 1 . 4 Polygons . . . . . . . . . . . . . . . . . . . . . . . . . . .183.1.5 Fuzzy contours . . . . . . . . . . . . . . . . . . . . . . . .2U3.2 Polygons for Material Domains . . . . . . . . . . . . . . . . . . . 213.2.1 Specifying property boundaries . . . . . . . . . . . . . . . 223.2.2 Compiling the d a t a . . . . . . . . . . . . . . . . . . . . . .234 Description of t h e Materials Selection System4.1 Material Information Attached to a Case . . . . . . . . . . . . . .4.1.1 Justifications in the retrieved case . . . . . . . . . . . . .4.1.2 Inferencc of justifications for the adapted case . . . . . . .4.2 Fuzzy Orders of Magnitude . . . . . . . . . . . . . . . . . . . . .4.2.1 Definitions . . . . . . . . . . . . . . . . . . . . . . . . . .4.2.2 Partitioning a set of values . . . . . . . . . . . . . . . . .4.2.3 An int.erface for acquiring new orders of magnitude . . . .4.3 Combining Matching Degrees for Mat.erials Class Selection . . . .1252626272828293234

4.3.14.3.24.3.3Queries for accessing materials classes . . . . . . . . . . . 34Combining matching degree . . . . . . . . . . . . . . . . 36Example of material selection . . . . . . . . . . . . . . . . 37539Description of the Program395 . 1 Data Structures . . . . . . . . . . . . . . . . . . . . . . . . . . . .5.1.1 Mechanical and engineering properties . . . . . . . . . . . 395.1.2 Materials classes . . . . . . . . . . . . . . . . . . . . . . .40415.1.3 Modes of loading . . . . . . . . . . . . . . . . . . . . . . .415.1.4 Compiled data . . . . . . . . . . . . . . . . . . . . . . . .425.2 Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5.2.1 Data coherence verification and knowledge base initializa42tion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5.2.2 Querying the data base . . . . . . . . . . . . . . . . . . . 436Conclusion44A Material Selection ChartsA.1 Materials Selection Chart for Light Stiff Components . . . . . . .A.2 Materials Selection Chart for Light Strong Components . . . . .A.3 Materials Selection Chart for Light Fracture-Resistant ComponentsA.4 Materials Selection Chart for Cheap, Stiff Components . . . . . .A.5 Materials Selection Chart for Cheap. Strong Components . . . .A . 6 Materials Selection Chart for Components Resistant t o Corrosion47B Materials Classes and PropertiesB.l Material Classes . . . . . . . . . . . . . . . . . . . . . . . . . . .B.2 Material Properties . . . . . . . . . . . . . . . . . . . . . . . . . .552474749194950-DJ56

List of Figures1.1 Sccsaw in a playground . . . . . . . . . . . . . . . . . . . . . . .concept . . . . . . . .1 2 Hot and cold water faucet using the -saw1 . 3 Sketch of a material selection chart . . . . . . . . . . . . . . . .#892 . 1 Ashby material selection chart for light stiff components (courtesy) . 13Discret representation of a region . . . . . . . . . . . . .Discret represent.ation of a region on a logarithmic grid .Representation by rectangles . . . . . . . . . . . . . . . .Representation by polygons . . . . . . . . . . . . . . . . .Representation by polygons of the worst case . . . . . . .3.6 Crisp set. of engineeriug polymers denuities . . . . . . . .3.7 Fuzzy set of engineering polymers densities . . . . . . . .3 . 8 Fuzzy representation of Ashby’s charts . . . . . . . . . .3.9 List of threshold values for property P . . . . . . . . . .3.13.23.33.43.5. . . . . . . . . . .1718181919202021231.1 Seesaw concept for a water faucet . . . . . . . . . . . . . . . .4.2 Example of non-fuzzy orders of magnitude . . . . . . . . . . .1.? Example of fuzzy orders of magnitude. . . . . . . . . . .1.4 Example of wrong fuzzy partition . . . . . . . . . . . . . . . . .4.5 Example of fuzzy orders of magnitude on a logarithmic scale . .4.6 Fuzzy compound orders of magnitude . . . . . . . . . . . . . . .4.7 ‘I’hree-clinicnsional representation of fuzzy orders of magnitude .4 . 8 User defined orders of magnitude . . . . . . . . . . . . . . . . . .4.9 Matching degree between a material class K and the order ofmagnitude A uf some property . . . . . . . . . . . . . . . . . . .4.10 Matching degree between a material class K and the order ofrriagnitude A of some other property . . . . . . . . . . . . . . . .35.5 .l Cbhcrence checking on fuzzy orders of magnitude.42-4.1 Material selection chart for light strong components (courtesy) .483252930303131323335

A.2 Matcrial selection chart for light fracture-resistant components(courtesy ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5I4 . 3 Material selection chart for cheap, stiff c0rnponent.s (courtesy). . 52-4.4 Material select,ion chart for cheap, strong components (courtesy). 53A.5 ?daterial select,ion chart for components resistant to corrosion(courtesy). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .544

List of Tables2.1 Sample of propertycombinations which determine performancein design (courtesy). . . . . . . . . . . . . . . . . . . . . . . . . .133.1 Kecesuary d a t a to be acquired . . . . . . . . . . . . . . . . . . . .2'23 2 Compiled data for a particular property P . . . . . . . . . . . . . 244.1 Materials satisfying the three behavioral properties . . . . . . . .538

Chapter 1Introduction1.1What is this Report About?This report describes a general system for material selection. This system hasbecn developcd in the framework of the CADETproject. It is originally intendedfor material adaptation when old designs are to be reused in new contexts. Thepurpose of this system is to help designers pick up the right type of materialgiven some constraints on a mechanical artifact. This system is built on aknowledge base that makes use of materials selection charts from the mechanicalengineering field. Queries t o this d a t a base are embedded with imprecision.e'!!handle this aspect by relying on fuzzy set theory.1.2Quick Survey of the ProblemMechanical design is the act of devising an artifact t h a t satisfics a useful need,in other words, that performs some function. This requires, in part, a deepunderstanding of material propert,ies An engineer conceiving a new mechanicalartifact can choose from among 50,000 different materials [Ashby: 1989bj.This paper concentrates on twu t,ypes of material-related reasoning that occurs in engineering dmign: selection and substilation. A material is selectedbased on criteria set out, by the designer. At the early stages of the design process. criteria that define the properties of the required material are usually quitevague. For example! a designer might. know that the material for an artifactcomponent should be of high strength and very high fracture toughness, bult,he actual values for E (strength) or K (fracture toughness) may not be known.In addition, a designer may have certain g o d s that require t h e minimizationof weight and cost. Material selection is often associated with the designingof new artifacts horn scratch. As a designer proceeds from the conceptual design stage, through embodiment, and finally to detailed design. the criteria for6

material selecsion arc developed and refined. A large part o f cngineeririg design: however! is case-baTed. Yew designs are created by adapting and reusingp a r k of previous designs in a new context, or application. Part of the processof adapting a prior [base) design to a new (target) design is the subst,itntionof materials in the base, to suit the conditions of the target application. Thisinvolves re-evaluating the reaSons why a particular material was used in theha.e. and whether the same or new criteria are relevant in the target. Oncethe ncw criteria are established, appropriate materials are selected and suhstitilted. Thc snbslitution step, hcnce, subsumes the selection task. For examplc,if a honsohold Oven were being adapted for an aerospace application, one wouldhaw t,o reevaluate the material choices based on strict weight considerations,possibly replacing heavy steel components by ceramic coated aluminum o n e s1.3Illustrative Examplel,et, UY illustrate this problematic with a detailed example that we will refer t,olater 011 in lhis report. From that example, we willsee (in Chapter 4) how a basecase (a see-saw) is reused in a target problem (a faucet). Material justificationsin the base will be modified to suit the target context that will lead to theselection o f new materials.Consider the simple see-saw shown in Figure 1.1. The -saw'smain component is a beam, hinged a t its center. Material selection for the beam is basedon a variety o f criteria: since it is intended for children: it should not be tooheavy; since it is intended for outdoor use it should be water resistant; it shouldnot rnst; it shoiild not cost too much; and it's color should not fade in thesunlight,t-Figure 1.1: See-saw in a playground.The see-saw ca5e is represented in the database as a frame where the varionsattrihules (dimensions, material types, etc.) as well as their intrinsic reason(s)are stored (sce Section 4.1).Consider the target application for the see-saw: a hot and cold water faucet.Figure 1.2 depicts n faucet that utilizes the see-saw principle. The rotation7

in t,be vertical plane regulates t,he relative quantity of hot and cold water. Thevertical nroLionof its hinge increass or decreases the combined flow. The Caucctrepresents a target, application where the environmental conditions are quitedilTercnt from that of the see-saw in the playground.nFigure 1.2: Hot and cold water faucet using the see-saw concept.Although the (see-saw) principle is identical in both cases the material thefaucet, should be made of does not necessarily meet the same rcquirements. Onthe onc hand some requirements for rhe see-saw may no longer be valid: andon t,he other hand some new requirements may crop up. For example, sincethe heam is of a much smaller dimension its cost may become less important.Also, the material may have to be resistant to certain environments if used withchemical products.Clearly, thc problem is to come up with the material(s) that meet, the set ofrequirements. This calls for typical engineering knowledge and reasoning abilityon materials. Both types of informatlion are provided in the materials selectioncharts settled by M. Ashby.1.4Selection and Substitution of MaterialThe selection step is done using special ma,terial selection charts that werc developed by Prof. Ashby of Cambridge University [Ashby, 1989alTheses chast,s show the relative and absolute positions of various materialclasses wifh respect to a tradcoff between two different properties. For examplethe sketch in Figure 1.3 presents the positions of the material classes A, L1: C ,D based on their strengt,h and density.The oblique line L crases material classes with the same strength to denskytradeoff. The higher this line on the chart the better the ratio. Looking Curmaterials with a particular combined property (tradeoff between t v o properties)is a problem that, involves two kinds of imprecision. First. the malerial classesplorted o n the charts represent the smallest area containing all t.he materials ofsome class. This means that within a class

A Fiimy Material Selection Syst,em for Mcchariical Design Jean-Luc Koning May 28, 1994 CML-R1-TR-94-22 Robotics Institute Carnegie Mellon University 5000 Forbes Avenue Pittsburgh, PA 15213-3890 Copyfight @IVY4 CMI!Robotics Irwlitute This research was supported by INRIA, Domahe de \ 'ololnceau, hcqucncuurt, B.P. 10.5. 78153 Le Chesnay cedex, France.