Transcription

1

SIZING AND PLANNING A LAUNDRYTABLE OF CONTENTSSECTION 1 BASIC INFORMATIONMachine nomenclatureCylinder volumeLoad factor"G" forces"G" forcesMoisture retentionWater pressureEstimated peak water flow ratesProper piping sizeConversion factorsWater hardnessHow to size a water softenerSizing drain troughsFuel-Unit of measureNatural gasCalculating natural gas required to heat waterSizing a water heaterLP gasButaneNo. 2 (diesel) oilNo. 6 (bunker) oilBoiler horsepowerSteam pressureSizing a boilerElectricityMotor full load currents chartsElectricityLinen cart capacity chart2

SECTION 2 SPACE ALLOCATIONLaundry space allocationSECTION 3 LINEN ARTICLES WEIGHTSTypical linen items and weightsWeight of textile rental itemsSECTION 4 LAUNDRY TASK INFORMATION FORMSHotel/MotelPrisonNursing HomeHospitalSECTION 5 SIZING WASHROOM EQUIPMENTGuidelines for sizing wash room equipmentDefining the taskHotel/MotelNursing HomeNursing HomeHospitalPrisonPrisonDivision of workSizing washroom equipment1-Washer-Extractors2-Batch washers3-Automatic batch dryer sizingSECTION 6 FUNDAMENTAL WASH CHEMISTRYWaterWashing chemicalsSurfactantsAlkaliesBleachesFinishing chemicalsAntichlorSours3

SECTION 6 FUNDAMENTAL WASH CHEMISTRYFabric softenersSizingWash stepsFlushesBreakBleach sudsRinsingTemperatureNumber of rinse bathsDilutionAntichlorsSour bathsExtractionSECTION 7 CONVERSION TABLESTablesSECTION 8 WATER CHARTSData Sheets by Model NumberSECTION 9 TERMINOLOGYGlossary of textile items used by LSAA4

PAGE INTENTIONALLY LEFT BLANK5

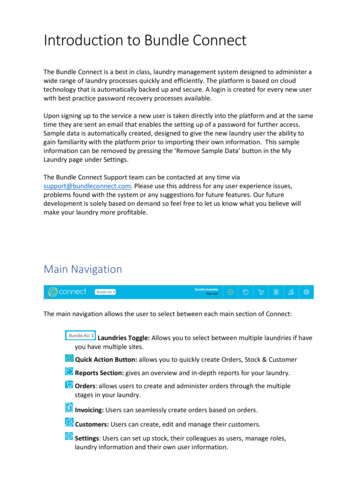

BASIC INFORMATIONNOMENCLATURE42044 Washer ExtractorFirst 2 digits (42) Cylinder Diameter (inches)Last 2 digits (44) Cylinder Depth (inches)Note: Other American Manufacturers use the same formatCYLINDER VOLUMEFormula:CDI Cylinder Diameter in inchesCd Cylinder depth in inchesCDI * CDI * cd CYLINDER VOLUME ( ft 3 )2,20042" Diameter * 42" Diameter * 44" Depth 35.28 ft 32,200LOAD FACTORFormula:CWGW Clean Weight of Goods in Washer (lbs)CV Cylinder Volume (ft3)CWGW Load FactorCVExample:42044WP2 Washer Extractor Load Size 200 lbs42044WP2 Washer Extractor Cylinder Volume 35.28 ft3.200 Pound Load 5.66 Pounds per Ft 3 .35.28 Cu FtNote:1.A generally accepted load factor (lbs of Linen/ft3 of CylinderVolume) is between 5.50 to 6.50 lbs.6

2.High bulk goods, like the new micro denier fabric for surgical items, require themachine to be under loaded to 65% of its capacity.3.Dense goods, like walk-on-mats permit the overloading of the machine by 30%."G" FORCESDEFINITION:A Measure of Extraction's Efficiency to Remove Water.Formula:CRPM Cylinder Revolutions per minuteCD Cylinder Diameter (Expressed in inches)CRPM * CRPM * CD " G" FORCES70,500Example:42044 WP2 with 700 RPM Final Extract Speed42" Cylinder Diameter700 RPM * 700 RPM * 42" Diameter 292 " G ' s"70,500Note:1.2.3.The higher the "G" force, the greater the centrifugal force exerted on the goods.One "G" equals 1 times the force of gravity.Other factors which may affect Extraction are:**Final bath temperature**Final bath chemicals**Length of extraction time**Type of goods (towels/sheets)**Ambient air humidity**% of cylinder open area to close area**Size of basket perforations**Type of material (cotton, 50/50)**Thickness of the load**Altitude of installationWATERMOISTURERETENTION:The amount of water contained in the linens after the final extraction. Expressed as a %of the dry weight of the goods being washed.7

NOTE:The DIN (German Industrial Norm, the equivalent of our American StandardAssociation) method adds 5% to the weight of dry textiles to account for the ambienthumidity. This method assumes that goods that have been dried will, when allowed tosit on a shelf, absorb 5% of their bone dry weight.MOISTURERETENTION:Formula:American Norm (Bone dry method)WGAX Weight of Goods after extractionDWG: Dry weight of goods((WGAX DWG ) * 100) % Moisture retentionDWGExample:42044 WP2 Washer Extractor310 lbs Weight of goods after extraction200 lbs dry weight of goods((310 200) * 100) 55% Moisture retention200Formula:European Norm (DIN Method)WGAX Weight of goods after extractionDWG5 Dry weight of goods plus 5% of its weight((WGAX DWG5) * 100) % Moisture retentionDWG5Example:42044 WP2 Washer Extractor310 lbs Weight of goods after extraction10 lbs 5% of 200 lbs of Dry Weight((310 (200 10)) * 100) 47.62% Moisture retention(200 10)200 lbs Dry weight of goodsWATERPRESSURE:The recommended water pressure is a range of 40 psi to 60 psi. Below 40, the washerextractor has to wait too long to fill. Above 60, there is the possibility of water hammer.8

Air operated water valves, on MILNOR large (standard) and small (optional) machines,have a closing adjustment which helps to minimize the water hammer problem.ESTIMATEDPEAK WATERFLOW RATES:In multiple machine installation, the maximum flow rate will occur when all inletvalves open simultaneously. But using this criteria would result in over design andcostly installation. Therefore, we use the following rule of thumb:1.2.The flow rate required by the largest machine in the installation, ORThe flow rate equivalent to one third of all machines filling simultaneously.We recommend the use of whichever results in the largest flow rate of the two options.The ideal flow rate will allow a machine to reach rinse level, which is usually thehighest level, in approximately 60 seconds. Filling in less than 60 seconds may resultin water hammer, particularly in the long runs of pipe.EXAMPLE:A laundry with 4 washer extractors, each requiring 40 gallons for the rinse level. Thetotal number of gallons if all machines filled simultaneously would be:40 gallons X 4 machines 160 gallonsApplying rule #1:Applying rule #240 gallons flow of largest machine160 gallons 3 53 gallonsTherefore, we would choose 53 gallons since it is the larger of the two values (40gallons and 53 gallons).PROPERPIPE SIZE:For multiple washer extractor installations, each water line should be sized according tothe following rules:A size larger than the largest water inlet valve in the installation, OR1.A size larger than the one third of the total area of all the water valves2.connected to the line.We recommend the use of whichever results in the largest flow rate.CONVERSIONFACTORS:1 gallon of water 8.33 lbs in weight1 cubic foot of water 7.48 gallons1 cubic foot of water 62.425 lbs in weight9

WATER HARDNESSHOW IT'SMEASURED:Grains of hardness OR parts per millionDegree HardnessSoftSlightly hardModerately hardHardVery hardNOTE:Grains per US GallonLess than 1.001.0 to 3.53.5 to 7.07.0 to 10.510.5 and overParts per MillionLess than 17.117.1 to 6060 to 120120 to 180180 and overWhat we call hardness is really calcium and magnesium salts in water. These minerals mayresult in deposit build-up on heat transfer surfaces and pipes thereby reducing efficiency. Asoftener is recommended when the degree of hardness exceeds 3.00 grains because chemicalcosts increase disproportionately as the water becomes harder.SIZING A WATERSOFTENER:1.Determine the hardness of the water supply. In most cases the municipal water workswill be glad to provide the information. Water softener companies will do freeanalysis. Call them for a sample bottle.2.Compute the amount of water required per day, the peak water flow rate (see estimatedpeak water flow rate") and the grain hardness that must be removed from the calculatedamount of water.3.A softener must be chosen with a capacity (gallons/regeneration) and a peak flow rateequal to or greater than the one required for the laundry. Ideally the regeneratingcapacity (number of grains of hardnessremoved in a given period of time) shouldpermit the softener to be regenerated once every day. If the regenerating capacity ofthe softener is not sufficient and requires more than one regeneration per day, then adual softener should be used.4.The salt requirement may be calculated using the formula below.FORMULA:THG Total hardness in grains(THG 1000) x 0.50 lbs of saltSIZING DRAIN10

TROUGHS:1.Determine the maximum amount of water to be dumped at one time. This isusually at the rinse operation which normally is the highest water level.2.Divide the total number of gallons by 7.48 to obtain the number of ft3 requiredto hold the given amount of water.3.Starting with a width of 14" and an initial depth of 12", find the lengthnecessary to obtain the required ft3 to hold the amount of water being dumped.4.The bottom of the trough should be sloped toward the drain, at 0.25 of an inchper linear foot. If the slope is too steep, the slope can be reduced to no less than0.12 of an inch per linear foot.5.The drain trough should be empty by the time the next large amount of water isdumped. The trough's drain must be sized properly to accomplish this.EXAMPLE:175 gallons are being dumped at one time.The width of the drain trough is 1.167 ft (14")The initial depth of the trough is 1.0 ft (12")The trough's drain is 4" diameter pipe175 Gallons 23.40 ft 37.48 Gallons per ft 323.40 Ft 3 20 ft 31.0 * 1.167@0.25" slope, the end of the trough would be 17" deep@0.12" slope, the end of the trough would be 14.50" deepFUEL11

UNIT OFMEASUREMENT:British Thermal Unit (Btu)- Amount of heat required to raise one pound ofwater one degree Fahrenheit.NATURALGAS:High heat (US Standard)1,000 Btu/ft3 (Approx.)Low Heat (European Standard)880 Btu/ft3 (Approx.)Therm 100,000 BtuMCF 1,000 ft3 10 Therms (Approx.)NOTE:Local natural gas supplier will provide actual Btu content of the natural gas itproduces. The Btu content of natural gas will vary over time, even from thesame source.CALCULATING NATURAL GAS REQUIRED TO HEAT WATER:FORMULA:HWT Hot water temperature (degrees Fahrenheit)IWT Incoming water temperature (degrees Fahrenheit)Gallons per hour * 8.33 ( Lbs per Gallon) * ( HWT IWT ) Btu per Hour (input )Water Heater Efficiency Factor (Typically 85% 95%)EXAMPLE:1,800 gallons of water required per hour70% of total water required to be heatedTemperature of hot water to be 180 FTemperature of incoming water is 45 FEfficiency factor of heating system is 85%(1,800 * 70) * 8.33 * ( 180 45) 1,666,980 Btu per Hour (input )85%Find number of Btu/Hour (input) required to heat water?FUEL12

Find number of Btu/Hour (input) required to heat water?1,666,980 Btu per Hour 16.67 Therms of Gas100,000 Btu per ThermSIZING A GASWATER HEATER:1.Match as close as possible the heater's Btu input to the calculatedBtu/Hour (input). Otherwise, the heater will not have the capacity tomeet the water heating requirements.2.The storage tank of the heater should have a minimum capacity equal toone half of the hourly requirement. The most desirable situation shouldbe for the storage tank to have 75% capacity of the hourly requirement.LP Gas:91,630 Btu per US gallon21,611 Btu per pound4.24 lbs per US gallonButane:1 cubic foot 3,200 BtuNo. 2Diesel Oil:1 US gallon 138,000 BtuNo. 6Bunker Oil:1 US gallon 142,000 BtuSTEAMBOILER HORSEPOWER (BHP):Work required to convert 34.50 lbs of water per hour from a liquid at 212 F tosteam at 212 F and 0 lbs gauge pressure.BHP 33,500 BtuBHP 34.50 lbs of steam1 Pound of steam 971.01 BtuSTEAM PRESSURE:Normal laundry steam pressure ranges between 100 to 125 PSI. Higherpressures may cause steam inlet valves to malfunction, because they are tryingto open against too high a pressure.FORMULA:13

HWT Hot Water Temperature (degrees Fahrenheit)IWT Incoming Water Temperature (degrees Fahrenheit)Gallons/Hour x 8.33 (lbs/Gallons) x (HWT-IWT) Btu/Hour (Output)EXAMPLE:1,800 gallon of water required per hour70% of total water required to be heatedTemperature of hot water to be 180 FTemperature of incoming water is 45 FFind number of Btu/Hour required to heat water?(1,800 x .70) x 8.33 x (180-45) 1,416,933 Btu per hourFind BHP/Hour required to heat water?1,416,933 Btu per hour (Output ) 42.29 BHP33,500 Btu per BHPSIZING ABOILER:EXAMPLE:1.Determine the total amount of the static steam requirements per hour. Convertthese requirements to boiler HP.2.Divide required BHP by 70% to get recommended boiler size. This allowsexcess capacity for plant start-up and plant expansion.3.Match as close as possible the hourly requirements to the manufacturer's ratingof the boiler. Make sure the boiler size exceeds the requirements divided by70%.The presses require 950 lbs of steam per hour950 Pounds of Steam per Hour 27.53 BHP34.50 Pounds of Steam27.53 BHP 70% 39.33 BHPA 40 HP boiler would be selected, because that is the closest standard manufactured sizeavailable.ELECTRICITYFORMULA:14

Electric Motor HP * 0.7457 KWHMotor Efficiency Factor %EXAMPLE:Find the KWH of a 20HP motor with an efficiency factor of 85%.20.00 HP * 0.7457 17.55 KWH85% Efficiency FactorMOTOR FULL LOAD CURRENTS:3 Phase A.C. Induction Type-Squirrel Cage and Wound 8.3149.2150399.9346.6173.3200578.8501.6250.8NOTE: .740.048.659.073.795.0119.3138.6200.7Total AMPS for a piece of equipment with several motors equals the sum ofAMPS for each motor included in maximum number of motors which can runsimultaneously.Correction of AMPS for exact voltage-AMPS at chart voltage to AMPS atanother voltage.ELECTRICITYFORMULA:15

(CHART AMPS * CHART VOLTAGE ) New Full Load AMPSNew VoltageEXAMPLE:AMPS for 25 @ 415VSince we want to know the full load AMPS for a 25 HP motor at 415V,and this is not on the chart. We can pick any voltage (say 240V) for a25 HP motor and convert the amperage (65 AMPS in this case) for thechosen voltage to the AMPS for the desired voltage. The formula would be:65 * 240 37.59 AMPS415LINEN CARTSLinen Cart Capacity ChartSelect the proper cart size(s) to match your washer-extractors. Matching the carts to the washers makesit easy to get a full washer load of soiled goods without using a scale. Use this chart to find cart sizes.CART SIZEBushels681012141618202428CLEAN DRY WEIGHT (LBS)Ft37.510.012.414.917.419.922.424.929.934.8Dry Soiled374962758799112124149174Wet 917920923726829835841716

PAGE INTENTIONALLY LEFT BLANK17

SPACE ALLOCATIONLAUNDRY SPACE ALLOCATIONThe guidelines that follow are based on laundry located in a free standing totally self contained building.Further assumptions are that the laundry operates 5 days per week, 8 hours per day.Functional areas which are not required should be subtracted from the total estimated area.LAUNDRYFUNCTIONALAREASQ. FT. required perlbs. processedPer day% OFTOTALFt2.A.Administrative & officeTOTAL ADMINISTRATION0.01670.01672.78%2.78%B.Employee1. Restroom & lockers2. Lunch room & loungeTOTAL l Room:1. Maintenance2. Bulk salt storage3. Chemical storage4. Equipment areaTOTAL MECH. .84%13.19%Non-production:1. Soil cart processing2. Sewing & mending3. New linen inventoryTOTAL 26%Production:1. Dock and loading2. Soiled linen storage3. Processing4. Clean cart storageTOTAL %43.99%8.04%70.58%GRAND TOTAL.6000100%C.D.E.EXAMPLE: A freestanding laundry must process 4000 lbs of linen/hr. How largeshould the laundry be? The answer is 19,200 ft2 .4000 lbs / hr 8 hour day 32,000 lbs / 8 hour day32,000 lbs / 8 hour day .6 ft 2 / lbs processed / day 19,000 ft 218

PAGE INTENTIONALLY LEFT BLANK19

TYPICAL LINEN WEIGHTS*Weight lb per pieceDUST CONTROLDUST MOPS12"18"24"30"36"42"48"60"ENTRANCE MATS2' x 3'3' X 4'3' X 5'3' X 10'4' X 6'4' X 8'5' X 8'DUST CLOTHS18" x 24"SWEEP TOOL COVERS36" X 36"100% COTTON100% COTTON50% POLYESTER/50%100% COTTON50% POLYESTER/50%100% COTTON100% COTTON50% POLYESTER/50%100% COTTON100% COTTON50% POLYESTER/50%100% 25.645.811.411.217.3121313.317.813.9100% COTTONBLEND0.160.13100% COTTON0.27LINEN SUPPLY FLATWORKAPRONSAPRONS - BAR/WAISTBIB100% COTTON65% POLYESTER/35%50% POLYESTER/50%100% COTTON65% POLYESTER/35%50% .40.320.3320

FOUR-WAYMECHANICSSHOP, DENIMTEA, WAITRESS65% POLO50% POLYESTER/50% COTTON100% COTTON100% COTTON50% POLYESTER/50% COTTON100% COTTON0.30.310.480.520.550.19100% COTTON50% POLYESTER/50% COTTON100% COTTON0.350.380.5565% POLYESTER/35% COTTON0.91100% COTTON0.06100% COTTON100% COTTON100% COTTON50% POLYESTER/50% COTTON0.090.120.110.11100% COTTON100% YESTER0.730.791.091.232.1MISCELLANEOUS FLAT GOODSHAIR CLOTHSDIAPERSLAUNDRY BAGS30" X 45"TABLE LINENNAPKINS, CORDED18" X 18"NAPKINS, MOMIE18" X 18"20" X 20"22" X 22"NAPKINS, DAMASK20" X 20"TABLECLOTHES, MOMIE45" X 45"54" X 54"63" X 63"72" X 72"81" X 81"90" X 90"TABLECLOTHES, DAMASK54" X 54"63" X 63"72" X 72"81" X 81"BANQUET CLOTHS, MOMIE - 54" WIDTH6'8'10'100% COTTON100% COTTON100% COTTON1.071.361.6721

BEDDINGSHEETS, SINGLE63" X 100"66" X 115"SHEETS, TWIN72" X 100"SHEETS, DOUBLE81" X 100"81" X 104"81" X 108"SHEETS, QUEENPILLOWCASES42" X 33"42" X 36"BEDSPREAD, SINGLE50% POLYESTER/50% COTTON65% POLYESTER/35% COTTON50% POLYESTER/50% COTTON0.911.161.3465% POLYESTER/35% COTTON50% POLYESTER/50% 1.341.421.441.2750% POLYESTER/50% COTTON1.750% POLYESTER/50% COTTON100% COTTON65% POLYESTER/35% COTTON50% POLYESTER/50% COTTON0.240.260.230.25100% COTTON1.84100% OLYESTER/35%BLANKETS, SINGLETOWELSNONTERRY - BANK, CLUB, DOCTOR, OFFICE14" X 21"100% COTTON14" X 25"100% COTTONNONTERRY - BARBER/BEAUTY15" X 27"100% COTTONNONTERRY -DISH TOWELS36" X 24"100% COTTON36" x 30"100% COTTONNONTERRY - GLASS TOWELS15" X 27"100% COTTONNONTERRY - HAND TOWELS16" X 30"100% COTTON16" X 32"100% COTTONNONTERRY - KITCHEN TOWELS15" X 26"100% COTTON50% POLYESTER/50% COTTON0.090.140.160.190.140.110.180.150.110.122

BAR MOPS/SWIPES, RIBBED20" X 17"CONTINUOUS TOWELS40-50 YARDS100% COTTON0.13100% COTTON80% POLYESTER/20% COTTON71% POLYESTER/29% COTTON50% POLYESTER/50% COTTON4.363.994.363.75100% COTTON100% COTTON0.510.54100% COTTON100% COTTON100% COTTON0.40.490.54100% COTTON100% COTTON0.190.19100% COTTON0.06100% COTTON65% POLYESTER/35% 0.49TERRYBATH MATS18" X 24"20" X 30"BATH TOWELS20" X 40"20" X 44"22" X 44"MASSAGE/HAND15" X 25"16" X 26"WASHCLOTHS, FACE12" X 12"LINEN SUPPLY GARMENTSCAPS, CHEFCOATS, LONGFROCKS, LONG SLEEVEFROCKS, 3/4 SLEEVELUGGER, MEAT/BUTCHERSHOP COATWRAPAROUND, LONG SLEEVEWRAPAROUND, 3/4 SLEEVECOATS, SHORTCHEF, LONG SLEEVECHEF, SHORT SLEEVECOUNTER/WAITER, LONG SLEEVEDOCTOR (SIDE BUTTON), LONG SLEEVEDOCTOR (SIDE BUTTON), SHORT SLEEVEJACKETS, BARTENDER, LONG SLEEVEJACKETS, BUS BOY, LONG SLEEVEJACKETS, LAPEL, LONG SLEEVEVESTS, NO SLEEVE23

DRESSESBELTED, SHORT SLEEVEPRINCESS, LONG SLEEVEPRINCESS, SHORT SLEEVEGOWN, ARTIST'SNOT-FITTED, LONG SLEEVSEMI-FITTED, LONG SLEEVESEMI-FITTED, 3/4 SLEEVESHIRTSKITCHEN, SHORT SLEEVEPANTS SUITSTOP

Formula: CWGW Clean Weight of Goods in Washer (lbs) CV Cylinder Volume (ft3) Example: 42044WP2 Washer Extractor Load Size 200 lbs . BOILER HORSEPOWER (BHP): Work required to convert 34.50 lbs of water per hour from a liquid at 212 F to steam at 212 F and 0 lbs gauge pressure.