Transcription

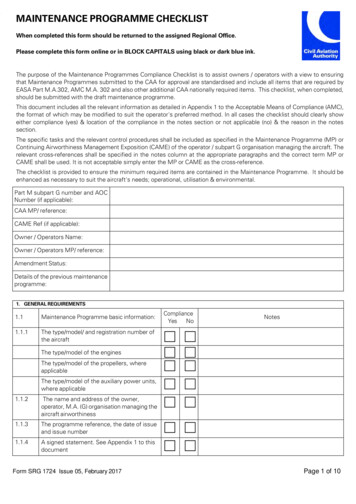

MAINTENANCE PROGRAMME CHECKLISTWhen completed this form should be returned to the assigned Regional Office.Please complete this form online or in BLOCK CAPITALS using black or dark blue ink.The purpose of the Maintenance Programmes Compliance Checklist is to assist owners / operators with a view to ensuringthat Maintenance Programmes submitted to the CAA for approval are standardised and include all items that are required byEASA Part M.A.302, AMC M.A. 302 and also other additional CAA nationally required items. This checklist, when completed,should be submitted with the draft maintenance programme.This document includes all the relevant information as detailed in Appendix 1 to the Acceptable Means of Compliance (AMC),the format of which may be modified to suit the operator's preferred method. In all cases the checklist should clearly showeither compliance (yes) & location of the compliance in the notes section or not applicable (no) & the reason in the notessection.The specific tasks and the relevant control procedures shall be included as specified in the Maintenance Programme (MP) orContinuing Airworthiness Management Exposition (CAME) of the operator / subpart G organisation managing the aircraft. Therelevant cross-references shall be specified in the notes column at the appropriate paragraphs and the correct term MP orCAME shall be used. It is not acceptable simply enter the MP or CAME as the cross-reference.The checklist is provided to ensure the minimum required items are contained in the Maintenance Programme. It should beenhanced as necessary to suit the aircraft's needs; operational, utilisation & environmental.Part M subpart G number and AOCNumber (if applicable):CAA MP/ reference:CAME Ref (if applicable):Owner / Operators Name:Owner / Operators MP/ reference:Amendment Status:Details of the previous maintenanceprogramme:1. GENERAL REQUIREMENTS1.1Maintenance Programme basic information:1.1.1The type/model/ and registration number ofthe aircraftComplianceYesNoNotesThe type/model of the enginesThe type/model of the propellers, whereapplicableThe type/model of the auxiliary power units,where applicable1.1.2The name and address of the owner,operator, M.A. (G) organisation managing theaircraft airworthiness1.1.3The programme reference, the date of issueand issue number1.1.4A signed statement. See Appendix 1 to thisdocumentForm SRG 1724 Issue 05, February 2017Page 1 of 10

1. GENERAL REQUIREMENTS (continued)1.1.5Contents listList of effective pagesRevision status of the document1.1.6Check periods for anticipated utilisation;include a utilisation tolerance of not more than25%. Where utilisation cannot be anticipated,calendar time limits should also be included1.1.7Procedures for escalation where applicable &acceptable to the CAADate and reference of approved amendments1.1.81.1.91.1.10Pre-flight maintenance tasks that areaccomplished by maintenance staffThe tasks and the periods (intervals / frequencies) at which inspections should be carried out, including the taskeffectivity and type and degree of inspection of the:a. Aircraftb. Engine(s)c. APUd. Propeller(s)e. Componentsf. Accessoriesg. Equipmenth. Instrumentsi. Electrical and radio apparatus1.1.11The periods at which components should be:a. Checkedb. Cleanedc. Lubricatedd. Replenishede. Adjustedf. Tested1.1.12Details of ageing aircraft systemrequirements with any specified samplingprogrammes, (if applicable)1.1.13Details of specific structural maintenance programmes, (if applicable), including but not limited to:a. Damage Tolerance and SupplementalStructural Inspection Programmes (SSID)b. SB review performed by the TC holderc. Corrosion prevention and controld. Repair Assessmente. Widespread Fatigue DamageForm SRG 1724 Issue 05, February 2017Page 2 of 10

1. GENERAL REQUIREMENTS (continued)1.1.14If applicable, details of Critical DesignConfiguration Control Limitations togetherwith appropriate procedures.1.1.15Statement of the limit of validity for thestructural programme in 1.1.13, if applicableThe periods at which overhauls should bemadeThe periods at which replacements should bemade1.1.161.1.17A cross-reference to other documents related to:a. Mandatory life limitationsb. Certification Maintenance Requirements(CMR's), (if applicable)c. Airworthiness Directives (AD)1.1.181.1.191.1.20Specific identification of the above itemsmandatory statusReliability programme or statistical methodsof continuous Surveillance (CMPA MA.302(f))A statement that practices and proceduresshould be the standards specified by the TCholderEach maintenance task (i.e. inspections detailed, scan, general) should be defined ina definition section2. PROGRAMME NoNotesIs the programme based upon the MRBreport, the TC holder's maintenance planningdocument or Chapter 5 of the maintenancemanual?For newly type-certificated aircraft /comprehensively appraise the manufacturer'srecommendations (and MRB report whereapplicable)For existing aircraft types, comparisons withmaintenance programmes previouslyapprovedIf CDCCL have been identified by theTC/STC holder, have maintenanceinstructions been developed3. AMENDMENTS3.1Amendments (revisions) to reflect changes: See Appendix 2a. In the TC holder's recommendationsb. Introduced by modificationsc. Discovered by service experienced. As required by the CAA e.g. ContinuingAirworthiness Tasks introduced by repairs.Form SRG 1724 Issue 05, February 2017Page 3 of 10

4. PERMITTED VARIATIONS TO MAINTENANCE PERIODS (with the exception of items identified in 1.1.16)ComplianceYesNo4.1NotesProcess in place to vary the periodsthrough a Procedure approved bythe CAA? (Refer to Appendix 3)Vary the periods with the approval by the CAA(temporary amendments to maintenanceprogramme)?5. PERIODIC REVIEW OF MAINTENANCE PROGRAMME CONTENTSCompliaceYesNo5.1NotesPeriodic review to ensure that the programme reflects current:a. TC holder's recommendationsb. Revisions to the MRB report (if applicable)c. Mandatory requirementsd. Maintenance needs of the aircraft5.2Annual review defined6. RELIABILITY loped in the following cases:Notesa. Programme is based upon MSG-3 logicb. Programme includes condition monitoredcomponentsc. Programme does not contain overhaultime periods for all significant systemcomponentsd. Specified by the Manufacturer's MPD orMRB6.1.2Need not be developed in the following cases:a. Programme is based upon the MSG-1 or2 logic (only hard times or on conditionitems)b. Not a complex motor poweredaircraft (CMPA)6.1.3c. Programme provides overhaul timeperiods for all significant systemcomponentsOperator may develop own reliabilitymonitoring programme6.2Applicability, small fleets6.2.1Less than 6 aircraft of the same type6.2.2Reliability programme is irrespective of thefleet size6.2.3Tailor reliability programmes to suit the sizeand complexity of operationForm SRG 1724 Issue 05, February 2017Page 4 of 10

6. RELIABILITY PROGRAMMES (continued)6.2.4Use of "Alert levels" should be used carefully6.2.5When establishing a reliability programme, consider the following:a. Focus on areas where a sufficient amountof data is likely to be processedb. How is engineering judgment applied?6.2.6Pool data and analysis (paragraph 6.6specifies conditions)6.2.7If unable to pool data / additional restrictionson the MRB/MPD tasks intervals specified6.3Engineering judgment.6.3.1Are there appropriately qualified personnel(with appropriate engineering experience andunderstanding of reliability concept) for thereliability programme?6.4Contracted maintenance.6.4.1Maintenance programme / may sub-contractcertain functions to the Part-145 organisation6.4.2These are:a. Developing the maintenance andreliability programmesb. Collection and analysis of the reliabilitydatac. Providing reliability reportsd. Proposing corrective actions6.4.3Approval to implement a corrective action /Subpart G prerogative and responsibility6.4.4Maintenance contract / CAME, and MOEprocedures6.5Reliability programme.6.5.1Objectives.6.5.1.1Statement summarising the prime objectivesof the programmea. Recognise the need for corrective actionb. Establish what corrective action is neededc. Determine the effectiveness of that action6.5.1.2The extent of the objectives should bedirectly related to the scope of theprogramme6.5.1.3All MSG-3 related tasks are effective andtheir periodicity is adequate6.5.2Identification of items.The items controlled by the programmeshould be statedForm SRG 1724 Issue 05, February 2017Page 5 of 10

6. RELIABILITY PROGRAMMES (continued)6.5.3Terms and definitions.Significant terms and definitions should beclearly identified6.5.4Information sources and collection.6.5.4.1Sources and procedures in the Exposition6.5.4.2Type of information to be collected should be related to the objectives, examples of the normal prime sources:a. Pilots Reportsb. Technical Logsc. Aircraft Access Terminal / On-boardreadoutsd. Maintenance Worksheetse. Workshop Reportsf. Reports on Functional Checksg. Reports on Special Inspectionsh. Stores Issues/Reportsi. Air Safety Reportsj. Reports on Delays and Incidentsk. Other sources: i.e. ETOPS, RVSM, CATII/III6.5.4.3Due account of Continuing Airworthinessinformation promulgated under Part-216.5.5Display of informationInformation displayed graphically or tabularor a combination6.5.5.1Provisions for "nil returns"6.5.5.2Where "standards" or "alert levels",information oriented accordingly6.5.6Examination, analysis and interpretation of the information.Method for examining, analysing andinterpreting the information should beexplained6.5.6.1Methods of examination may be varied content & quantity6.5.6.2The whole process should enable a critical assessment of the effectiveness of the programme as a total activity.May involve:a. Comparisons of operational reliability withestablished or allocated standardsb. Analysis and interpretation of trendsc. Evaluation of repetitive defectsd. Confidence testing of expected andachieved resultsForm SRG 1724 Issue 05, February 2017Page 6 of 10

6. RELIABILITY PROGRAMMES (continued)e. Studies of life-bands and survivalcharacteristicsf. Reliability predictions6.5.6.3Range and depth of analysis should be related to the particular programme:a. Flight defects and reductions in reliabilityb. Defects – line and main basec. Deterioration observed - routinemaintenanced. Workshop and overhaul findingse. Modification evaluationsf. Sampling programmesg. Adequacy of maintenance equipment andpublicationsh. Effectiveness of maintenance proceduresi. Staff trainingj. Service bulletins, technical instructions,etc.6.5.6.4Contracted maintenance - arrangementsestablished and details for information inputincluded6.5.7Corrective Actions6.5.7.1Procedures / time scales for implementing corrective actions / monitoring – should be fully described & couldinclude:a. Changes to maintenance, operationalprocedures or techniquesb. Changes requiring amendment of theapproved maintenance programme?c. Amendments to approved manualsd. Initiation of modificationse. Special inspections / fleet campaignsf. Spares provisioningg. Staff trainingh. Manpower and equipment planningForm SRG 1724 Issue 05, February 2017Page 7 of 10

6. RELIABILITY PROGRAMMES (continued)6.5.7.2Procedures for effecting changes should bedescribed6.5.8Organisational Responsibilities.Organisational structure – chains ofresponsibility should be defined6.5.9Presentation of information to the competent authority.Information submitted to the CAA for approval of the reliability programme:a. Format and content of routine reportsb. Time scales for reports / distributionc. Format and content of reports requestingamendments6.5.10Evaluation and review.Describe procedures and individualresponsibilities - continuous monitoring ofthe effectiveness of the programme6.5.10.1 Procedures for revising the "standards" or"alert levels".6.5.10.2 Criteria to be taken into account during the review includes:a. Utilisation (high / low / seasonal)b. Fleet commonalityc. Alert Level adjustment criteriad. Adequacy of datae. Reliability procedure auditf. Staff trainingg. Operational and maintenance procedures6.5.11Approval of organisation to implement maintenance programme changes arising from the reliability programmeresults:a. Does the reliability programme monitorthe content of the maintenanceprogramme in a comprehensive manner?b. Is appropriate control exercised by theowner / operator over the internalvalidation of such changes?6.6Pooling Arrangements.6.6.1Pooling information – must be substantially the same, including:a. Certification / modification / SBcomplianceb. Operational Factorsc. Maintenance factorsForm SRG 1724 Issue 05, February 2017Page 8 of 10

6. RELIABILITY PROGRAMMES (continued)6.6.2Is there a substantial amount of commonality/ has the CAA agreed?6.6.3Is the aircraft on short-term lease? CAA maygrant more flexibility6.6.4Changes to any M.A. (G) requiresassessment in order that the pooling benefitscan be maintained6.6.5Reliability programme managed by theaircraft manufacturer if agreed by the CAA7. CAA REQUIRED ITEMS (MA.302(d))ComplianceYesNo7.1Details of who may issue a CRS7.27.3Define which inspections/checksare considered to be basemaintenanceUK Maintenance Requirements, in theabsence of specific recommendations. SeeAppendix 47.3.1Aircraft battery capacity check/deep cycle?7.3.2Emergency equipment7.3.3Emergency escape provisions:Notesa. Portable valise type life-raftsb. Door & escape chutes/slidesc. Emergency exits / hatches7.3.4Flexible hoses7.3.5Fuel / oil system contamination checks7.3.6Pressure vessels7.3.7Seat belts and harnesses7.3.8CAAIPs (CAP 562) – applicability7.3.9Vital points and control systems7.3.10CAA Specifications. See Appendix 57.3.11Maintenance applicable to special operations approvals, if applicable:AWOPSMNPSRVSMETOPSForm SRG 1724 Issue 05, February 2017Page 9 of 10

7. CAA REQUIRED ITEMS (continued

The purposeof the MaintenanceProgrammes Compliance Checklist is to assist owners / operators with a view to ensuring that Maintenance Programmes submittedto the CAA for approval are standardisedand include allitems that are requiredby EASA PartM.A.302, AMC M.A. 302 and also other additional CAA nationally requireditems. This checklist, whencompleted,File Size: 2MBPage Count: 20