Transcription

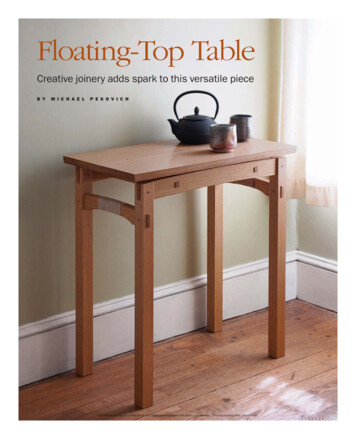

Floating-Top TableCreative joinery adds spark to this versatile pieceB yM i c h a e lP e k o v i c h28FINE woodworkINgCOPYRIGHT 2017 by The Taunton Press, Inc. Copying and distribution of this article is not permitted.W263PE.indd 28Fine Woodworking #263 - Sep/Oct 20176/27/17 3:53 PM

This is one of those projects that almost wasn’t.Rachel, my wife, had asked for a small, portable table for her sewing machine. My firstthought was to make something quick—just legs,aprons, and a top—so I could move on to something“more important.” Fortunately, I stopped and took aminute to think about how I could make this table alittle more interesting to build and a little more enjoyable to use. The result is a unique little table with aquiet personality that brightens our home every day.While Rachel puts it to use most often as a sewingtable, it serves very well as a side table, a small writing desk, or even a TV tray.Building the table is straightforward, though thejoinery is a little unusual. There are some bridle jointsand through-tenons, all of which are left proud of thesurface. Drawbore pins pull everything together for aclamp-free glue-up. If you’d like, you can leave out theQuick bridle joint at the bandsawStart with theslot. Scribe thebaseline of the slot,then cut the sidesat the bandsaw.Set the fence forone face, then flipthe stock to cut theopposite face.Drill out the wasteand square theend. Use a 1 2-in.Forstner bit to drill ahole at the baseline,which frees mostof the waste (right).Then square thebase of the slot witha chisel (far right).Chop halfway, thenrotate the stock tofinish squaring fromthe opposite face.glue altogether. Arched rails and a beveled tabletopadd lift, but the table remains a stout little thing.Begin with the baseI used white oak for the table, but I stayed away fromthe dramatic ray fleck of quartersawn oak on the base,instead turning to the quieter straight grain of riftsawnstock. It helps to reinforce the simple lines of the base.Start by milling the stock and cutting the parts tofinal length. Leave the curved rails square for now tomake cutting the joinery easier.The legs are connected to the front and back railswith a bridle joint and that’s a good place to start.I normally turn to the tablesaw and tenoning jig toslot the legs, but when making the original, I workedquickly and intuitively at the bandsaw. That’s the technique I’ll show you here. Set the fence to one faceof the slot, and make the first cut. Then flip the legfor the second cut to ensure a centered slot. For asmooth, accurate cut, make sure your blade is sharpSeptember/OctOber 2017Photo, opposite: Michael PekovichCOPYRIGHT 2017 by The Taunton Press, Inc. Copying and distribution of this article is not permitted.W263PE.indd 29Then cut thetenon to fit.Establish theshoulders at thetablesaw, then cutthe tenon cheeksat the bandsaw,using test piecesto set the fenceprecisely. A sharpblade and a slowfeed rate shouldyield a glue-qualitysurface right off themachine.29Fine Woodworking #263 - Sep/Oct 20176/27/17 3:54 PM

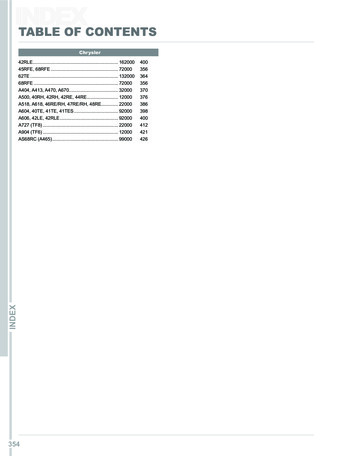

WHITE OAK SIDE TABLEDovetail slot, 3 4 in.wide by 3 16 in. deepby 51 2 in. longTop halves, 7 8 in.thick by 7 in. wideby 26 in. long5 bevelSpline, 1 4 in.thick by 11 2 in.wideFront and rear rails,7 8 in. thick by 29 16 in.wide by 235 8 in. longSupport, 7 8 in. thickby 211 16 in. wide by123 8 in. longGroove, 1 4 in. wideby 3 4 in. deepDovetail key, 5 32 in.thick by 3 4 in. wideby 10 in. longTenon,15 16 in. long1 8-in.-deeprecess for cordCove, 1 2-in.radiusSlot, 1 2 in. wideby 115 16 in. longAngle topof leg tomatch archof rail.Through-mortise, 16 in. square935 8 in.Pins, 4 in. dia.,centeredon tenons1Tenon,19 16 in. longLeg, 11 2 in.square by 26 in.long4 mm hemp rope,turkeyfootllc.comThrough-mortise,1 2 in. wide by11 2 in. long31 4 in.Tenon,1 2 in. thick by17 8 in. wide by113 16 in. long,end beveled 5 1 2 in.3011 2 in.13 4 in.1 8-in.shoulderFINE WOODWORKINGCOPYRIGHT 2017 by The Taunton Press, Inc. Copying and distribution of this article is not permitted.W263PE.indd 3026 in.273 8 in.3 8 in.97 8 in.14 in.Gap between railand top, 5 16 in. 16 in.41 4 in.To purchase expanded plans and acutlist for this Hall Table in WhiteOak and other projects, go toFineWoodworking.com/PlanStore.26 in.2 in.51 8-in.shoulderSide rail, 7 8 in.thick by 2 in.wide by 13 in.long20 in.97 8 in.23 in.127 8 in.Photos, except where noted: Rachel Barclay; drawings: John HartmanFine Woodworking #263 - Sep/Oct 20176/29/17 2:00 PM

Drawbore pins lock the jointsBy offsetting thetenon peg hole slightlytoward the shoulder,the mortised joint willbe drawn tight as thepeg is driven in.Tenon holeis offset. 1 32Locate the center. After drilling through theslots and mortises in the legs, dry-fit the jointand use a drill bit to mark the center of thehole on the tenons.in.Mark the offset. For the mortise-and-tenonjoints, offset the hole toward the shoulder of thejoint (left). This will pull the joint closed when thepin is driven in. Then drill the tenon using a scrapunderneath to prevent blowout (above).and aligned to the rip fence. Also, it helps to go slow.If it’s done correctly, you should end up with a surfacealmost as smooth as a cut from a tablesaw. Drill outmost of the waste using a 1 2-in.-dia. Forstner bit, whichmatches the slot width. Then square the slot with achisel, working in from each face. Undercutting thejoint in the center guarantees that there won’t be anymaterial to keep the tenon from fully seating in the slot.To make the tenons, first make the shoulder cuts atthe tablesaw. Then head back to the bandsaw to cutthe cheeks. Use a test piece to sneak up on a snug fit.When making fine adjustments to the bandsaw fence,be sure to cut off the end of the test piece to preventthe blade from wandering into the previous cut andgiving you a false reading.With the bridle joints complete, turn to the throughmortise-and-tenons that connect the side rails to thelegs. This completes the leg joinery and allows thebase to be dry-fitted, which is necessary to determineAngled approachfor the bridlejoints. This jointneeds to be pulledtogether in twodirections, so offsetthe holes slightly intoward the shoulderand up from thebottom edge of thetenon.SEPTEMBER/OCTOBER 2017nCOPYRIGHT 2017 by The Taunton Press, Inc. Copying and distribution of this article is not permitted.W263PE.indd 3131Fine Woodworking #263 - Sep/Oct 20176/27/17 3:55 PM

Add the tabletop supportsthe shoulder length of the tabletop supports. To do that, you’ll firsthave to drill for the drawbore pins that hold everything together.Drawbore pins pull it together; rails give it a liftMeasure for the supports. Dry-fit the base and measure between thefront and back rails to determine the shoulder-to-shoulder distance forthe supports. Then cut the tenon cheeks on the supports.The bridle joint is a difficult joint to clamp because it must bepulled together in two directions. The protruding ends of the partsonly complicate the situation. So I turn to drawbore pins, whichpull the joint together as they are driven in. I used the techniquefor the side rail mortise-and-tenons as well. The trick is to drillslightly offset holes through the parts. For the mortise-and-tenons,offset the mark roughly 1 32 in. toward the shoulder of the tenon.For the bridle joint, which needs to be clamped both across thejoint and down, offset the hole at a 45 angle. This way, the joint ispulled in both directions as the pin is driven in. I use a dowel plateto make the pins, starting with straight-grained stock to keep thepins from breaking under the stress of pulling the joint together.With the base dry-fitted, measure between the front and backrails to determine the shoulder-to-shoulder length of the support rails. Start by cutting the tenon cheeks, sneaking up on theLay out themortises andtenons at thesame time. Tapethe mortise areason the rails as wellas the tenon endson the supports.Then use a markinggauge to scribe thetop and bottomedges of themortises on bothfaces of the rails(right). Mark thetenons using thesame gauge settings(far right).Cut the joinery.Use a backsaw tocut the tenon sides.Remove the wasteby sawing along thebaseline and cleanup with a chisel.Drill out most ofthe waste from themortises and squarethe recesses witha chisel (bottom).Work in from eachface to avoid cuttingpast the scribe lines.32FINE woodworkINgCOPYRIGHT 2017 by The Taunton Press, Inc. Copying and distribution of this article is not permitted.W263PE.indd 32Photos:Fine Woodworking #263 - Sep/Oct 20176/27/17 3:56 PM

Side rails get a rope handle.,.se.k-:Get a handle on it. The side rails are wrapped with hemp cord,essentially transforming them into handles for lifting the table. Thehandle area of the rail is recessed for the cord at the tablesaw (top right).Pekovich mounts stop blocks on the crosscut sled fence and slides therail from side to side while slowly advancing the sled. The recesses onthe top and bottom are cut at the bandsaw.shoulder inset until the rail fits snugly in the dry-fitted base. Nowyou can continue with the rest of the joinery.The supports are wider than the rails, so register the layout fromthe bottom edges of the parts. Use a marking gauge to scribe thetop and bottom edges of the mortises as well as the tenons, usingthe same settings to ensure a gap-free fit. One thing to keep inmind when laying out those joints is that an arch will eventuallybe cut in the rails. So center the mortise on the finished profile,rather than on the square blank. Drill and chop the waste fromthe mortises and use a handsaw to cut the tenon ends.1Shaping brings the table to lifeOnce the joinery is complete, cut the parts to final shape. I cutthe arches in the rails using a steady hand at the bandsaw anda quick cleanup with a spokeshave.Trim the tops of the legs to match the arch, and cove the ends ofthe supports that extend above the rails. The last step is to anglethe ends of the front and rear rail tenons. This slight flair acts asa small corbel and complements the underbevel on the tabletop.It’s a subtle detail, but on a quiet piece like this, it has a big effect.I prefinish the parts with shellac before glue-up. I also take thetime to wrap the cord handles at this point. It’s much easier nowthan when everything is together.A unique tabletopOn the original table, I simply glued up a top and attached itwith screws to the supports. That’s a perfectly good solution, butI tried a little different approach this time around. I made the topin halves and joined them to the supports with a dovetailed cleat.Each half has a stopped dovetail slot that slides along the cleat.To keep the halves aligned, I grooved each half where they meetfor a full-length spline. Rather than glue the halves together, Ipinned them through the spline on both sides of the joint. A lightchamfer along the joint highlights the pair of boards.23Online ExtraTo see a simple way to addcord to a project, go OPYRIGHT 2017 by The Taunton Press, Inc. Copying and distribution of this article is not permitted.W263PE.indd 33Tie up looseends. Prefinishthe rail beforeadding the cord.Start by making afew wraps over theend of the cord tosecure it in place(1). Make sure theend is on the insideface of the rail, andtrim it after four orfive wraps. As younear the oppositeend, insert a loopof wire under thecord for the lastfew wraps (2). Trimthe end of the cord,leaving an extra2 in., and feed itthrough the wireloop. Use a pair ofpliers to pull theloop under thewraps to secure thecord (3). Trim offthe end betweenthe wraps with asharp knife.SEPTEMBER/OCTOBER 201733Fine Woodworking #263 - Sep/Oct 20176/30/17 1:22 PM

A two-part tabletopMake way for a spline and dovetail keys. Startby ripping a groove along the inside edge of eachhalf (above). Then clamp a half to the base andmark for the dovetail socket locations (right).Rout the dovetail sockets. Clampthe top halves together with themating edges facing out. Use atwo-sided edge guide and rout infrom each outside edge (above). Setthe depth of cut to leave enoughmaterial above the spline groove(right).After cutting the spline grooves, clamp thetop halves together and rout the dovetailslots at the same time to ensure that theyare aligned. With the mating edges facingout, use a two-sided fence to guide the router. This lets you rout safely in from eachend, stopping short of the center. Use thesame dovetail bit to make the keys at therouter table. Rout the profile along the edgeof a wide piece of stock. This keeps yourfingers away from the bit and makes for lessstressful routing. Dial in the width of thekey by moving the router fence. Once youget a nice, tight fit, rip the keys off the strip.To attach the keys, slide them into one ofthe tabletop halves, and clamp it in place.Then drill and screw the keys to the supports every 3 in. or so. Cut a slight underbevel on the edges of the top, and use ablock plane to run a light chamfer alongthe center joint. Rather than trying to hidethe fact that there are two boards, a smallshadowline highlights the joint and hidesany offset that may occur in the future.For final assembly, slide the halves ontothe cleats, inserting the spline betweenthem, and clamp them lightly together.Then drill through the top and spline oneither side of the joint near each end of thetop. Drive in pins to lock the top in placewithout glue. That’s one rather involvedway to avoid squeeze-out! Michael Pekovich is a furniture maker, instructor,and FWW’s executive art director.34FINE WOODWORKINGCOPYRIGHT 2017 by The Taunton Press, Inc. Copying and distribution of this article is not permitted.W263PE.indd 34Fine Woodworking #263 - Sep/Oct 20176/27/17 3:55 PM

Make the dovetail keys. Using the same dovetail bit, rout a dovetail profile on the edges of thekey stock (left). Dial in the fit by adjusting the router table fence until the key fits snugly in the slot(center). Finally rip the keys off the stock (right

Then flip the leg for the second cut to ensure a centered slot. For a smooth, accurate cut, make sure your blade is sharp W263PE.indd 29 6/27/17 3:54 PM COPYRIGHT 2017 by The Taunton Press, Inc. Copying and distribution of this article is not permitted. Fine Woodworking #263 - Sep/Oct 2017. 30 FINE WOODWORKING Photos, except where noted: Rachel Barclay; drawings: John Hartman Groove, 1 4