Transcription

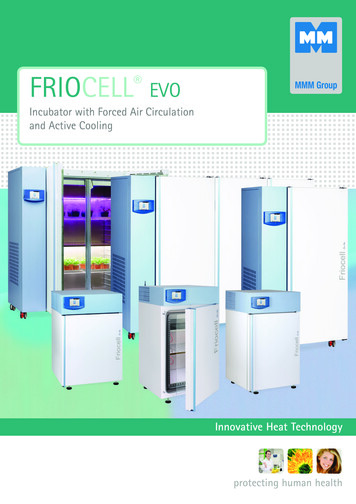

FRIOCELL EVOIncubator with Forced Air Circulationand Active CoolingInnovative Heat Technologyprotecting human health

Tradition, Quality,InnovationFRIOCELL EVOSince its establishment in 1921,BMT Medical Technology s.r.o., thetraditional manufacturer of medical andlaboratory technology, has been graduallytransformed from a small regionalcompany to an international corporation.Precise and Energy-Saving Incubator with Active CoolingIn 1992, it became a member of theEuropean MMM Group which has beenoperating on the world markets since 1954as an important supplier of systems for thehealth care industry, science and research.With its comprehensive offer of productsand services, sterilization and disinfectiondevices for hospitals, scientific institutes,laboratories and pharmaceutical industry,MMM Group has established itself asan outstanding quality and innovationsproducer on the global markets.The knowledge and experience gainedduring the implementations of individualsupplies for our customers all overthe world, and the technical innovationshave been permanently and positivelyinfluencing the development, constructionand production of our devices. High levelof our work has also been confirmedby the number of patents and industrialdesigns as well as an easy implementationof individual device adjustments.MMM Group- excellence in medicaland laboratory technology.The device FRIOCELL provides time and space-precision tempering of materials in the fieldof bio-technologies, botany, zoology, food processing, cosmetics, chemistry, etc. A uniquecooling system offers exact and economic simulation of selected natural processes;it reduces evaporation of samples and allows extremely low temperature conditionsregeneration times.In case of optional equipment buying, the device offers regulation of CO2 respectively othergases concentration or space-homogenous lighting in the field of visible or UV light withadjustable intensity and possibility of intensity measuring using special probes. Thanks tothe unique combination, the device offers a wide range of possible applications to users.Meeting the requirements of regulations2014/35/EU, 2014/30/EU, ICH 279/95 Option 2, FDA 21 Part 11, 2011/65/EU, 517/2014/EU.ApplicationsPharmaceutical IndustryWater ManagementTests of photo stability according toICH 279/95 Option 2, quality testsof pharmaceutical raw materialsTesting of water quality in municipalwater preparing plants (BSK5 at 5 C)Cosmetic IndustryAgricultureDurability testing, testing ofcosmetic products or primarymaterials stabilityEnzymatic reactions and microbiologicactivities in soilsPlastics IndustryZoologyTemperature stabilisation of referencesamplesSimulation of conditions for livingorganisms research – cultivationof fish eggs, cultivation of insectsdevelopment stagesGeneral and Applied Industry(research field)BotanyE.g. cultivation of tissue cultures– human or animal onesStudies of germination, green plantsgrowing for further researchBasic CharacteristicsVolume: 55, 111, 222, 404, 707, 1212 litresWorking temperature: 0 C up to 100 Crange up to 70 C for the volume of 1212 lFC EVO as optional equipment up to -20 CFC EVO as optional equipment of chamberdecontamination up to 160 C(except for the 1212 litres volume)Refrigerant: R134a without CFC(for -20 C R449a without CFC)CO2 concentration: 0,2% up to 20%(optional equipment)Inner glass doorInterior: stainless steel, mat. No. 1.4301(AISI 304)2Food IndustryPaper IndustryTests of food products expiration dateLong-term testing of paper qualityBeverage IndustryPaints and VarnishesIndustryRapid beer quality test(12h/5 C 12h/40 C)Paints stability testing – resistanceto UV radiation3

ConnectivityData OutputsSD cardRS 232USB DeviceEthernet / Internet(optional equipment)WIFI (optional equipment)USB Host(optional equipment)BMSBMS remote alarm(optional equipment)Thanks to the most up-to-datecomponents of electronic, thedevice FRIOCELL EVO does not have anydata peripherals connection limit. The basicconfiguration contains traditional andreliable RS 232, USB Device and the SD cardas the data carrier. The device can be easilyextended with the Wifi 802.11b/g modulewith up to 100 meters reach, there is alsoavailable the USB Host for bi-directionalUSB communication and for remoteconnection there is the Ethernet (RJ 45)connection. Proper IP address allowseasy connection to PC or selected printer,respectively other usual data periphery(Smartphone, Netbook, etc.). Thanks to theopen platform and adjusted data formatit is also possible to configure remoteconnection and to work with on-line datain remote mode (internet).Connection of softwareWarmComm 4.0Integrated datalogger, SD cardCompatible thermoprinter via RS 232Specified desk-topprinter (USB/WiFi)SmartphonesCLC monitorlocalremote (internet)The New Control System Offers 5.7 inch (14.5 cm) touch screen display Data encryption and non-manipulability(corresponding to FDA 21 Part 11) S D memory card, USB Host and RS 232standardly included Microprocessor Fuzzy logic processcontrol Up to 100 programs and up to100 segments for each program Intuitive control via colour icons Yearly data logger in graphicand numeric form W IFI connection, USB device or Ethernetinterface with own IP address for remotedata transfer, control and diagnostics(optional equipment) Graphic configuration of a new program On-line or off-line data exportWarmComm 4.0Universal data administration for BMT/MMM heating technology devices P rogramming of ramps, real timeand cyclingInternet Fan setting 0–100% Transparent displaying of data courseat the cycle P repared service programs for fastdiagnostics of faults Protective thermostat class 3 E asy service diagnostics includingremote access Acoustic and visual alarm Multi-language communication M ulti-level users administration(corresponding to FDA 21 Part 11) Direct printing of protocols in PDFformat via Warmcomm 4.0 K eyboard lock against unauthorisedhandling Easy user configuration of the deviceGSM Main ON/OFF switch for security reasons Device state LED indicator4Messages Compatible with EVO line and ECO line devices Backward compatible with older heating technology series(Standard, Comfort - all except CO2CELL) Stable platform of the SQL library User-friendly environment Connection via Ethernet, RS 232 and USB Two-way communication – data monitoring and device control Client-Server architecture Three levels of the program depending on client’s requirements (Basic-Professional-FDA) In compliance with FDA CFR 21 Part 11 (version F) Web support, on-line updating Protected licence policy Compatible with MS Windows XP / 7/8/10 operating systems Validation documentation IQ/OQ5

FRIOCELL EVOComfort Machinewith Superior ParametersMMM Group offers traditionally fullyranged size of the cabinet, from personalsize 55 litres, up to new size 1212 litres,with the best ratio cost/performance.Patented vertical air flow with preheatingchamber and asymmetrically perforatedpanels ensure the well proven verticalspiralled air flow with the best spatialhomogeneity.Deep experience of the factory engineersand many years of careful developmenthelp with sophisticated Fuzzy logiccontrol system. By means of the Fuzzylogic are continually evaluated the currentprocess conditions as size of chamber, setparameters, quantity of the samples insideand herewith optimizing heating, coolingand steaming performance.Practical large and popular door handle,robust wheels with brakes and 220 (withexception of size 707, 1212) openable maindoor(s) contributes to high user friendlycharacter of the device. Light grey withlight blue device colours highlighted by darkblue smiley control panel cause a pleasantfeeling of harmony in the user everymorningSmart design with user friendlycontrol panelWiFi connectionfor wireless connection to PC/smartphone (optional equipment)Microprocessor control Fuzzy logicfor minimising the start-up andrecovery timesExtension of the device designedfor easy service accessEfficient LED diodes (up to 30 000 lx)– low temperature programmableexposition lighting (optionalequipment)Robust but easily permeable shelvesfor efficient air flow in the chamberStainless steel (AISI 304) chambermaking regular device cleaning easyMemory SD cardfor data transferService diagnosticsvia remote accessMain switch ON/OFF for reliableswitch off of the deviceTouch displaywith graphic interfaceIncreased maximal temperature – upto 160 C for chamber decontamination(optional equipment)Automatic defrosting system(optional equipment)Vertical device construction forsaving the space in your labEfficient chamber insulationfor long-term stability of parametersin the chamber and low operationcostsAdjusted dehumidification systemfor fast RH change in the chamberImproved cooling systemfor shorter recovery timesEasily removable inner panels foreasy chamber cleaningUnique vertical system of air flow inthe chamber for precise conditionsin the chamber and short recoverytimeHeating elements located betweenthe chamber shells ensure maximumsurface utilization for the mostefficient heat exchangeErgonomic handle for easy and safedoor closing (patent protected)Inner tight glass door made ofSecurity Izolas glass according toEN 12150-2Four-point adjustable door hangingfor perfect door sealingBraked castors for easy and safedevice handlingIncreased bottom slope for easiercondensate discharge67

Programmable Exposure LightingConfiguration for typical applicationsNew generation of the FRIOCELL EVO device offers wide possibilities of selected lighting use. The variability of placement, selection of lightsources, user friendliness and possibility of fluent intensity control meet even the most demanding requirements towards applications withexposure lighting.Based on our experience we offer optimal configurations for selected applications, typical for FRIOCELL .Pharmaceutical IndustryBotanyStudies of germination, green plants growing for further researchFluorescent Tubes in DoorsGrowth Chamber - WhiteTraditional placement of the light case with new design and increasedintensity of lighting (up to 36 000 lx). Exposure of the whole cross-sectionof the chamber with the lowest purchase costs and minimal influence onconditions in the chamber. Program-controlled switching on and off ofthe lighting for FRIOCELL ECO. Program-controlled regulation of intensitywithin the range of 10-100% in increments of 1%, which can be completedwith intensity measuring for FRIOCELL EVO.Suitable for industrial simulation of materials ageing or undemandingprocesses of growth simulations. Simulation of day and night conditions.Available for FRIOCELL ECO FRIOCELL EVO.A vertical source of up to three light cases with direct lighting and variable height of lighting. Even lightingof the whole shelf and optimal use of the chamber volume for the area size lighting. Efficient balancing oftemperature emissions thanks to perforation of cases and precise regulation of conditions in the chambereven under full lighting. Maximal intensity 23 000 lx (12 cm below the source). Program-controlledswitching on and off of the lighting for FRIOCELL ECO. Program-controlled regulation of intensity within therange of 10-100% in increments of 1%, which can be completed with intensity measuring for FRIOCELL EVO. Typical for tests of photo-stability or basic growth simulations in botany. Simulation of day and nightconditions.Available for FRIOCELL ECO FRIOCELL EVO.Different colours of the light source.Luxline Plus- Day light - 860Black light blueGrowth Chamber - SpectralPhoto-stable ChamberGrowth chamber optimising high lightingintensity with optimal colour spectrum ofLED source for photosynthesis and low powerconsumption. Base used FRIOCELL EVO Chamber sizes 111, 222, 404, 707, 1212 Up to four floors with LED lighting Up to 3,4m2 of lighted surface Diversified blue-red-fared (2:2:1) LEDsource optimised for photosynthesiswith fluent regulation of individual lightcomponents Maximal intensity up to 311 µmol/m2/s* Maximal growth height up to 1300 mm Automatic defrosting CO2 regulation (option)Chamber with combined or separatedVIS-UV source of light with independentcontrol and automatic assessment of photostability test. Base used FRIOCELL EVO Chamber sizes 111, 222, 404, 707, 1212 Three combinable VIS-UV lighted shelvesor two VIS one UV lighted Shelf Automatic control of process duration Automatic assessment of exposure dose(with option VIS and UV measuring) High intensity of lighting – up to20,000 LUX and 3,0 mW/cm2/s-1* Short exposure times High light homogeneousness for equallighting of all the samples Printing of protocols for individualexposure doses with confirmation Automatic defrostingLuxline Plus - Cool white 840Fluorescent Tubes in ShelvesLuxline Plus- Cool white 840Tests of photo stability accordingto ICH 279/95 Option 2, quality testsof pharmaceutical raw materialsGro-Lux: increased blueand red share - supportof photobiological plantsprocessesFull spectrum light source:Activa (Not suitable forphotostability testing)Exact growth chamber with variablegrowth height and full-spectrum fluentlycontrollable LED lighting. Base used FRIOCELL EVO Chamber sizes 111, 222, 404, 707, 1212 Up to four floors with LED lighting Up to 3,4m2 of lighted surface Full-spectrum stable white LED lightingwith fluent intensity regulation (step 1%) Maximal intensity up to 330 µmol/m2/s* Maximal growth height up to 1300 mm Automatic defrosting CO2 regulation (option)DeepRedLED Lighting in the DoorEconomic solution of white exposure LED lighting with higher intensity (up to 21 000 lx).Exposure of the whole cross-section of the chamber with low temperature emissions. Program-controlledswitching on and off of the lighting for FRIOCELL ECO. Program-controlled regulation of intensity withinthe range of 10-100% in increments of 1%, which can be completed with intensity measuring forFRIOCELL EVO. Suitable for industrial testing with high demands towards intensity. Simulation of day andnight conditions. May be completed with intensity measuring.Available for FRIOCELL ECO FRIOCELL EVO.FarRedWhite LED Lighting in ShelvesPrecise horizontal lighting with white or colour LED lighting with maximal intensity (up to 30 000 lx),low temperature emissions of the light source, variability of enlightened cases placement. Programcontrolled switching on and off of the lighting for FRIOCELL ECO. Program-controlled regulation ofintensity within the range of 10-100% in increments of 1%, which can be completed with intensitymeasuring for FRIOCELL EVO. It is suitable for industrial use or use in botany. Maximal use of enlightenedsurface of shelves in relation to the chamber volume. Simulation of day and night conditions. May becompleted with intensity measuring.Available for FRIOCELL ECO FRIOCELL EVO.8Blue*) measured 12 cm below the Shelf9

Technical ParametersAccessories IncludedEach FRIOCELL EVOis supplied with standard equipment which does not have to be additionally ordered and it makes a standard part of delivery:FRIOCELL EVO (FC EVO)Technical dataInternal space - chamber,stainless steel DIN 1.4301(AISI 304)Touch screenCommunication ports RS 232and USB hostSealing inner glass door2 stainless steel traysSD cardMulti-conductor temperaturesensorOptional EquipmentThanks to modular construction of our devices even FRIOCELL EVO may be additionallyequipped according to your preferences with many additional options. FRIOCELL EVO may thenserve as a chamber for testing of photo-stability, light simulation of day and night, processeswith CO2 control, hot-air decontamination, etc. 1.2.3.4.5.6.7.Hot-air decontamination 160 CAdditional cooling 20 CFlexible temperature sensorsLED light shelvesExposure lighting in doorsLight sensors of exposureDefrosting system12CO2 controlSoftware WarmComm 4,0Data module USB device, Ethernet, wi-fiMechanic door lockElectromagnetic door lockTrays or shelvesAccess port Ø 25, 50, 100 mm8.9.10.11.12.13.14.3415.16.17.18.Programmable inner socketExternal printerMulti-point temp. / humidity measuringIQ/OQ . 30530Volume of the steam spaceApprox. l91167305530External dimensionswidthmm6407807801100(including door, Handle H andheightmm940H1187H1450H1890Ccaster C)depthmm755755885885Package – dimensionswidthApprox. mm99099211201332(three-layers carton)height (incl. palette)Approx. mm1300165017462200depthApprox. mm8309549521062Weightnettkg95/105** 110/120**143/153**240/250**brutt (carton)kg180/190** 220/230**263/273**390/400**Shelves of stainless steel *)shelvesmax. No.571019standard equipmentpcs. included2222min. distance between mm70707070shelvesStorage area (w d) mm380 335 520 335520 485520 485Maximal load *)per 1 traykg/screen20203030for a shelfkg/shelf20203030total inside of device kg/case505070100Number of outer metal doorspsc.1111Number of inner glass doorspsc.1111Electrical datamax. powerW700/850** 1000/1150** 1150/1300** 1700/1700**requirementmains 50/60 HzV115/230115/230115/230115/230IP CodeIP20IP20IP20IP20Temperature datafrom 0 Cto C100 (decontamination 160 C)Working temperaturefrom 20 Cto C100 (decontamination 160 C)Temperature accuracyin space at 10 CApprox. ( ) 0,5 0,5 0,5 1 Cin space at 37 CApprox. ( ) 0,5 0,5 0,5 1 Cin timeApprox. ( ) 0,2 0,2 0,2 0,3 CHeating/up time to 37 C from the ambient temperaturemin 11 11 11 13Cooling/down time from 22 C to 10 Cmin 21/ 11** 21/ 11** 17/ 14** 19/ 11**Recovery time after 30 s of door at 37 Cmin 5 5 2 2opening according to DIN 12 880 at 50 Cmin 6 6 3 4Heat emissionat 37 CApprox. W557063123Complete device noise leveldB45/50**46/52**50/56**56/58**%0,1-20CO2 concentrationbar/psi0,3-0,7/5-10**Required pressure 280/290**500/510**1927014083 540 839/865**3 19670920 4855020130222000/2050*****115/230IP20520 4853030300332500/3300** 1115/230IP207070 0,6 1 0,5 0,4 0,2 13 21/ 22**6614858/65**- 30 211010200600,1-200,3-0,7/5-10**Note: All technical data are related to 22 C ambient temperature.*)Approx. 50% of the tray area can be filled in a way a uniform air circulation is enabled inside the chamber.**) Value at cooling up to -20 C.789101112***) max. power requirement with decontamination 2500 WThe values may differ depending on specific charge and media parameters.Change in the design and make reserved.1310141516171811

Make Acquaintance With Our Further Offers incubationdrying, tempering,sterilizationECOCELL drying oven5*–250/300DUROCELLdrying oven with protective layer ofinner space EPOLON5*–125VENTICELL drying oven10*–250/300STERICELL ***hot-air sterilizer10*–250VACUCELL drying oven with vacuum5*–250/300INCUCELL incubator / biological thermostat5–100INCUCELL Vincubator / biological thermostat10–100FRIOCELL incubator with cooling0-100(-20)CLIMACELL incubator with cooling and controlledhumidity0-100(-20)CO2CELL**incubator with CO2 atmosphere5*–60*above the exterior temperature** manufacturer MMM Medcenter Einrichtungen GmbH, Semmleweisstrasse 6, D-82152 Planegg / Munich,tel.: 49 89 89 92 26 20, e-mail: medcenter@mmmgroup.com***the STERICELL line also meets the Directive No. 93/42/EEC, the product is presented in a separate leafletMake acquaintance with our further offers Small steam sterilizers 15-25 lSteam sterilizers 140–2020lSteam sterilizers 70 lyoutube.com/bmtbrnoHot-air sterilizers 400-3900 lfacebook.com/bmt.czMMM Medcenter Einrichtungen GmbH, Semmelweisstrasse 6, D-82152 Planegg / MünchenTel.: 49 89 8992 2620, Fax.: 49 89 8992 2630, E-mail: medcenter@mmm-medcenter.de, www.mmm-medcenter.deFRIOCELL EVO 05/2020 EN/PRVolume 1212 (l)Volume 707 (l)Volume 404 (l)Volume 222 (l)Volume 190 (l)Volume 111 (l)Volume 55 (l)Volume 50 (l)Volume 22 (l)Temperature rangein C (Optionalequipment)Forced aircirculationNatural aircirculationLinie StandardLinie ComfortECO lineEVO lineLaboratory case typeType markingDesignationUnique Line Cell

Specified desk-top printer (USB/WiFi) Smartphones CLC monitor Connection of software WarmComm 4.0 remote (internet) local WarmComm 4.0 Universal data administration for BMT/MMM heating technology devices Compatible with EVO line and ECO line devices Backward compatible with older heating technology series (Standard, Comfort - all except .