Transcription

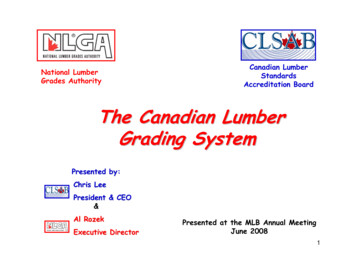

National LumberGrades AuthorityCanadian LumberStandardsAccreditation BoardThe Canadian LumberGrading SystemPresented by:Chris LeePresident & CEO&Al RozekExecutive DirectorPresented at the MLB Annual MeetingJune 20081

Objectives of Presentation1) Canadian Grading Systema) NLGA Backgroundb) Components of the Grade Stampc) CLSAB’s Role2

Canadian Lumber Quality SystemThe Canadian lumber grading system is atransparent regulatory system that providesongoing assurance to the designer, user andpublic that the lumber is of the quality asindicated on the product mark or grade-stamp.3

Structure of the Canadian Lumber Quality System4

Objectives of Presentation1) Canadian Grading Systema) NLGA Backgroundb) Components of the Grade Stampc) CLSAB’s Role5

NLGA BackgroundU Incorporated in January 1971 to amalgamate all Canadianlumber grading rules under one rule.U NLGA’s role is to: establish;publish & issue;interpret; andmaintain & amendLumber Grading Rules & Special Product Standards for allCanadian species of lumber.U And: establish;maintain & publishLumber design values for Canadian species for use in theUSA which are recognized in the AF&PA NDS .Note: Canadian design values are assigned to NLGA stress grades bythe Canadian wood design code committee (CSA O86)6

NLGA Organizational ChartBOARD OF DIRECTORS(13 Agency Representatives)EXECUTIVENLGA Staff(Executive Director)STANDARDS COMMITTEE(Consensus Group)GRADE COMMITTEE(Made up of Agency Chief Supervisors)Deals with Special Products StandardsMaintenance, Interpretations andDevelopmentDeals with Visual Grading Rule Maintenance,Interpretations and DevelopmentSPECIAL COMMITTEESTo deal with special subjects and to complete theirassignments in a specific time7

NLGA Background NLGA is governed by:NLGA Bylaws; &NLGA Technical Committee Procedures and Regulations(TCP&R). NLGA Standards and Rules were developed:þ by 'balanced consensus' committees (includes lumberproducers, consumers, users, academia, government andregulatory authorities.);þ following 'due process';þ through a 'transparent and accountable' voting process;þ with a rigorous procedure for resolving negatives.þ Approvals:þ There is a two-level NLGA approval process:a) Committee (ie, SC or GC)b) Boardþ Followed by CLSAB & ALS BoR approvals.8

NLGA Background NLGA Rules & Standards are: Referenced in the National Building Code of Canada (NBC) Recognized in the US through ALS whose authority isrecognized under the US Voluntary Softwood Standard PS 20. NLGA lumber design values for the USA are published &recognized in the AF&PA NDS .9

NLGA Background CWC provides engineering and technicalsupport to NLGA www.cwc.ca FP Innovations (Forintek) does researchand provides technical support to NLGA www.fpinnovations.ca10

NLGA PublicationsU NLGA Standard Grading Rules for Canadian Lumber (Softwood) &InterpretationsNote: All revisions to NLGA grade rules must be approved by both theCLSAB and the ALS Board of Review prior to implementation.U Canadian Lumber Grading Manual - is a lumber grader trainingmanual.11

NLGA PublicationsU Supplements to NLGA StandardGrading Rules for CanadianLumber(Softwood)&InterpretationsU Supplementsareissuedbetween printings to assure allNLGA Board, CLSAB Board andALS approvals are incorporatedin the rule in a timely fashion.U The latest supplement to theNLGA Grade Rule was issuedDec. 1, 2007 (Copy to theright)12

NLGA PublicationsU NLGA Special Product Standards– SPS 1-2003 - NLGA Special Products Standard For Finger-joinedStructural Lumber (Revised effective April 1, 2007)– SPS 2-2003 - NLGA Special Products Standard For Machine GradedLumber (Revised effective Dec. 1, 2006)– SPS 3-2003 - NLGA Special Products Standard For Finger-joined StudLumber “Vertical Stud Use Only" (Revised effective April 1, 20076)13

SPS 1 and 3 (Major Change)U A major change to SPS 1 and SPS 3 in 2007 was to introducecriteria to deal with Finger-joint adhesive heat–resistantperformance.U In order for fingerjoint (FJ) lumber to be used in fire-ratedassemblies, the adhesive must be a “Heat Resistant” Adhesive(HRA).U As of April 1, 2007, all SPS 1 and SPS 3 FJ products must begrade stamped with either an ‘HRA’ or ‘Non-HRA’.14

NLGA Publications–SPS 4-2003 - NLGA Special Products Standard For Finger-joined Flange StockLumber (Revised effective Dec. 1, 2006)–SPS 5-2003 - NLGA Special Products Standard For Face-Glued Lumber – VerticalUse Only (Revised effective Dec. 1, 2006)–SPS 6-2004 - NLGA Special Products Standard For Structural Face-Glued Lumber(New Standard Dec. 1, 2004) (Revised effective Dec. 1, 2006)Note: a. All Changes to all SPS’s must be approved by CLSAB prior to implementation.b. All NLGA Publications are available in both English and French15

CSA Standards & ISO 9000 NLGA SPS 1 thru 6 were formatted using CSA Standard requirementsoutlined in CSA Standard Z299.2-1979 (latest -1986).I.CSA StandardZ299.1 -1978Quality AssuranceProgram Requirements II.CSA StandardZ299.2 -1979Quality ControlProgram RequirementsIII.CSA StandardZ299.3 -1979Quality VerificationProgram RequirementsIV.CSA StandardZ299.4 -1979InspectionProgram RequirementsThe CSA Z299 series of standards set the basis for ISO 9000 Series ofStandards.16

Ratified Staff Responses The Ratified Staff Responses Document is a list of questions posed toNLGA staff and the staff response that has been ratified by theNLGA Standards Committee and/or the NLGA Grade Committee. NLGA has ratified response documents for: the NLGA Grade Rule; for FJ Lumber (SPS 1 & 3); & for MGL (SPS 2)17

NLGA WebsiteThe NLGA Website iswww.nlga.orgIt includes: Available NLGA publications & ordering info Member Agency Gradestamp Facsimiles &Contact Information Links to CLSAB, Forintek, ALSC & CWCwebsites18

Objectives of Presentation1) Canadian Grading Systema) NLGA Backgroundb) Components of the Grade Stampc) CLSAB’s Role19

Grade StampsTypical Grade Stamp Facsimile for Visually Graded Lumberc)a)d)e)f)b)a)b)c)d)Registered Symbol (logo) - of the grade stamping agency.Facility (mill) Identification - usually by number or mill name.Species Identification - indicates species individually or in comb.Grade Designation - grade name, abbreviation or number.e)Condition of Seasoning - at time of grade stamping:KD or S-DRY - Max. 19% moisture contentf)S-GRN- Over 19% moisture content (unseasoned)HT- Lumber heated in a kiln to a core temperature of 56O for 30 minutesGrade Rule- requirement of CLSAB (Para. 40 – NLGA Grade Rule)20

21

22

Objectives of Presentation1) Canadian Grading Systema) NLGA Backgroundb) Components of the Grade Stampc) CLSAB’s Role23

Organizational Chart24

The Role of CLSABU CLSAB’s role is to:1Establish policy for & control of;the identification and certification of lumber to be usedin Canada, exported from Canada, or manufactured inaccordance with standards approved in Canada2Review, advise upon and approve or disapprove gradingrules or other product standards for Canadautilized in accreditation of Agencies and the certificationof their manufacturers by CLSAB accredited Agencies.25

The Role of CLSAB (con’t)3Accredit Lumber Grading Agencies (13 in Canada):to supervise and certify lumber manufacturers to assigngrades to lumber (grade stamp or certify) by visual ormechanical means;to establish and monitor quality assurance methodsfor the manufacture of lumber;to apply identification marks (grade stamps) andcertificates attesting to the grade and quality of thelumber.4 Review, advise upon and approve or disapprove grading rules orother product standards for Canadautilized in accreditation of Agencies and the certification oftheir manufactures by accredited Agencies.26

Regulations Developed in accordance with the CLSAB By-laws andcriteria derived from CSA 0141 for Softwood Lumber, andinclude:Requirements for Approval ofGrading Rules and or ProductStandards;Requirements for SupervisingAgencies to monitor MachineGrade lumber (MGL) facilitiesAccreditation of AgenciesCLSAB Monitoring of Agencies CLSAB also has a policy for approving MGL Machines &residual MGL27

Levels of Supervision1. CLSAB - Monitors grading agency performance2. Accredited Grading AgenciesIssues grade stampsTrains and Certifies MGL & FJ lumber Operators & GradersMonitors mill lumber grading and grade stampingHas the ability to put a mill on probation, suspend or revokegrade stamps for non-conformance to standards3. Mill Quality Control SupervisorsRegularly inspects mill lumber graders & FJ & MGL operators4. Mill Lumber Graders & MGL OperatorsMGL & FJ Operators pass certification test & perform daily QCGraders must pass Agency’s lumber grading course & performhands-on piece-by-piece visual inspection of each piece of lumber28

New ProgramsSupervises - Treated Wood Program includinggrade stampingMonitors– CFIA Heat Treating ProgramOversees– CE Marking Program for Canada usingBM Trada as their Notification Body inEurope29

CLSAB WebsiteThe CLSAB Website is:www.clsab.ca30

NLGA / CLSAB Role Summary NLGA & CLSAB are autonomous organizations who work at arms length.NLGA Writes & Revises andLumber Grading Rulesmaintains Writes & Revises Special ProductsStandards Publishes and amendsRules and StandardsGrading Approves new lumberrevisions thereafterGradeRules&any Accredits Agencies to administer NLGA GradingRules & Special Products Standards (SPSs) Approves NLGA SPS’s including any revisions Establishes regulations and minimum inspection &reporting procedures for Agencies to follow whenmonitoring mills Oversees agencies who monitor facilities who use Interprets Grading Rules and SpecialProduct StandardsSPS 1, 2, 3, 4 &/or SPS 5 as well as the Grade Rules. Recognizes NLGA’s role to interpret NLGA GradeRules and Standards.31

NLGA / CLSAB Role SummaryU Simply put: NLGA writes, interprets and maintains the GradeRules & Special Product Standards; & CLSABaccreditsAgencies&policestheadministration these Grade Rules and Standardsgenerally through visits to Agency mills32

Parting Comments33

Thank You!!!Questions?34

Z299.1 -1978 Program Requirements II. CSA Standard Quality Control Z299.2 -1979 Program Requirements III. CSA Standard Quality Verification Z299.3 -1979 Program Requirements IV. CSA Standard Inspection Z299.4 -1979 Program Requirements The CSA Z299 series of standards set the basis for ISO 9000 Series of Standards.