Transcription

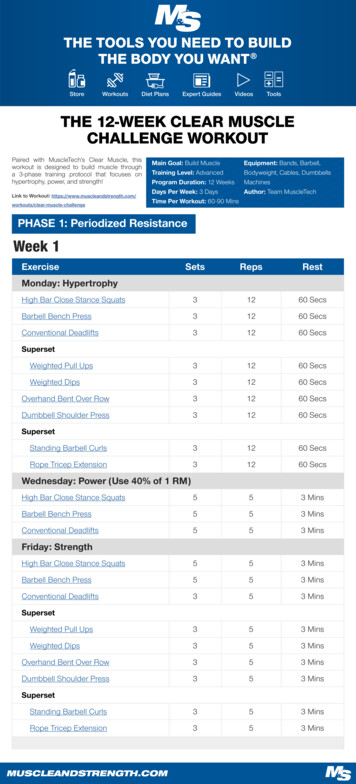

68RFE: Flexing Its MuscleLET'S PLAYBALL68RFE:Flexing Its Muscleby Lance Wigginsmembers.atra.comAfter-rebuild flexplateproblems are commonon these high-mileageDodge powerhouses.Here are some tips onhow to avoid them.The 68RFE transmission is starting to make its way into shops.Whether it’s a brand new 2013Dodge Ram that fell into a lake whenthe ice broke or the hauler with 240,000miles on it, if you haven’t seen one yet,you will. We’re going to talk about theDodge 3500 6.7L and some problemsyou might build in if you aren’t careful.Lately there’s been a plague offlywheel failures on these units and Iwanted to set the record straight: theinstallation isn’t causing the problem.When I say “problem,” I’m talking aboutflexplate failures, intermediate housingfailures, and all hell breaking loose.This problem could be caused byseveral things: Fatigue is the mostprominent, but there are other possibilities. There’s the converter, a new aftermarket flexplate, and a combinationof both. In this article we’ll cover thedo’s and don’ts, and how to eliminatefailures before they occur.Let’s start with the vehicle: a 2001Dodge Ram 3500 4x4 bad boy with156,000 miles on it. The vehicle is usedfor transporting other vehicles. It has allof the bells and whistles to make it govroom! Now imagine an owner that’salways in need of his vehicle. Time isof the essence, so there are two waysyou can help him: rebuild the transmission or install a remanufactured one.44lance-68rfe.indd 4Figure 1Figure 2GEARS March 20142/24/14 1:34 PM

CUT & CLIP THE DASHED LINE - AND SAVE THE HANDY VEHICLE APPLICATION CHART BELOW TO IDENTIFY WHICH KIT YOU NEEDsuperior314.indd 2STP HONDA Kits Chart Ad 2.indd 12/21/14 2:56 PM2/17/2014 5:04:26 PM

68RFE: Flexing Its MuscleIn this case the transmission wasreplaced with a remanufactured transmission and in less than 24 hours thetruck was back on the road. Here’swhere things get busy.Less than 2500 miles later, theflexplate blows up (figure 1), the intermediate housing is destroyed (figure2), the starter is hammered (figure 3),and the converter is badly damaged. Sowhat caused this? If you said installation error you’d be wrong. It’s fatigue.There are a couple of thingsthat can cause this, misalignment orfatigue. Misalignment can be causedby a missing dowel pin or the incorrectdowel pins installed. Fatigue, well that’shard to justify without signs of it, whichmakes this very difficult diagnose.A flexplate is similar to a spring(actually, it is a spring), in that itallows the torque converter to moveduring operation, preventing alignmentproblems between the converter andtransmission. Under load, the torqueconverter presses against the flexplate,bending it slightly toward the engine.So, as you’re driving, the converterand flexplate are moving back and forthas the load changes. Over time, thiscan weaken the flexplate; similar tobending a piece of wire back and forthuntil it breaks. You might also think ofit as a garage door spring: They’re gooduntil they break.It isn’t standard practice to replacethe flexplate during a transmissionrepair unless it’s cracked or damaged.The telltale of a cracked flexplate isa sharp scraping (tinny) sound as youaccelerate, particularly from a stop.Generally, this noise is enough to alertthe driver before a complete failuresuch as this one. That is, the noise isannoying enough that the flexplate isaddressed before it fails completely.Here’s what’s important to know aboutflexplate failure:1. It isn’t caused by an installationerror. However, we don’t knowif the installer missed signs offailure (hairline cracks) during thetransmission repair.2. It isn’t caused by the torqueconverter. It’s normal for thetorque converter to press andbend the flexplate. Its movementis limited; after a certain distancethe converter will bottom out on64lance-68rfe.indd 6Figure 3Figure 4the crankshaft.And it can’t be caused by converterballooning. Ballooning occurs whenthe converter is exposed to higherthan-normal pressure. This can causeit to expand like a balloon, as theterm implies. When this happens it’lldamage the converter or the pump, butnot the flexplate.Here’s why: The converter floatsback and forth in the transmission, so asa converter balloons, the converter hubsimply moves toward the transmission.At some point, excessive ballooningwill press the converter hub far enoughinto the transmission to break the pump.In this case the flexplate simplyfailed by natural causes, but there’smore. Let’s introduce the billet converter and flexplates:Installing an HD billet converter ina unit like this is normal; we do it all thetime. Could this be putting more strainon the flexplate?Most diesel owners will opt for abillet flywheel once they crack a stockflexplate so it never happens again.Especially if they do any searching onGEARS March 20142/21/14 2:33 PM

A higher level.That’s what you get with Ford gas enginesand transmissions.A higher build level means you’re getting engine and transmission assemblies built to the exacting specifications ofFord Motor Company. So you not only get the quality build you expect in an assembly from Ford, but also one that’s built byusing parts that keep it specific to year, make and model as well as emissions calibrations.Introducing the all-new 3-Year Unlimited-Mile Warranty – No Commercial ExceptionsFord gasoline engines and transmissions are covered by a three-year/unlimited-mile warranty.* All warranties are backed byFord Motor Company. They’re also supported by more than 3,500 Ford and Lincoln Mercury Dealerships nationwide as wellas at their originating place of service.Plus, unlike some competitors, the warranty is good for fleet vehicles. That means you get the same advantagesand coverage for commercial use, no exceptions.For technical questions, contact the Powertrain Assistance Center at 1-800-392-7946 or visit FordParts.com.*See dealer for limited-warranty details. Remanufactured diesel engines are covered by a two-year/unlimited-mileage warranty.

68RFE: Flexing Its Musclethe internet and see it’s a fairly commonproblem for the stock converter to failafter high mileage, or after a programmer or chip has been added to a stocktransmission.Most converter companies sendnew, shorter converter bolts with theirnew converters, because there are threedifferent threaded rings used by themanufacturers: standard course thread,standard fine thread, and metric thread.The bolts are shorter because ofthe problem where the converter boltsare too long and they dimple the insidecover, damaging the TCC lining. Thesymptom would be a TCC shudder or aleak from the front that requires replacing the torque converter.So here you are, installing a billetconverter and flexplate, with the new,shorter bolts. The transmission is boltedup and you’re ready for the test drive.Next thing you know you’re dealingwith a noise. A quick examination confirms it’s coming from the bellhousingsplash pan.Further inspection reveals finemetal and aluminum shavings all overthe bellhousing area, so you pull thetransmission back out. Here’s the problem: You have a billet converter andflexplate with new converter bolts. Thebolt heads are touching the intermediate plate. If you don’t find this problemright away, imagine the damage thatcould have occurred.The clearances between the stockflexplate and billet flexplate on the 6.7Ldiesel are closer than the 5.9L, and it’smuch more likely to have this problemafter being worked on. Anytime youinstall a billet HD flexplate, you mustmake sure the bolts are long enoughthat there are plenty of threads holdingthe converter in place, but the bolt headsare shorter to leave adequate clearance.Here’s the fix: You can use thebolts provided or make your own; eitherway you must machine or shave the bolthead to fit the clearance. The 6.7L stockflex plate is 0.083” (2.11mm) thick. Thebillet flex plate is 0.165” (4.19mm);that’s a difference of 0.082” (2.08mm)(Figure 4).There are multiple bolt selectionsthat can get you into trouble. First youhave the Metric thread bolts (Figure5), then you have the Standard treadbolts (Figure 6), and finally the SAE84lance-68rfe.indd 8Figure 5Figure 6Figure 7Bolts (Figure 7). You can start with thestock bolt; it measures 0.380” x 0.600”(9.65mm x 15.24 mm). Shave the headof the bolt down to about 0.300” x0.600” (7.60mm x 15.24mm). Makesure that no matter what bolt you use thedepth is correct!Remember, before you put yourselfin a hole or find yourself looking at acomeback, make sure your flexplateto-converter combination is good andreplace the flexplate, for good measure especially if the vehicle has a lotof miles on it.Thanks to my friend, Jeff Funk, atSpecialty Transmission in Brighton, IL,for sharing this tip with the industry:Good Guys doing good things!GEARS March 20142/21/14 2:33 PM

ray314.indd 22/21/14 3:04 PM

transmission repair. 2. It isn’t caused by the torque converter. It’s normal for the torque converter to press and bend the flexplate. Its movement is limited; after a certain distance the converter will bottom out on the crankshaft. And it can’t be caused by converter ballooning. Ballooning occurs when