Transcription

Food Fraud PreventionEconomically-motivated adulteration

Table of contents2344Introduction and purpose of this bookletWhat is food fraudWhy is it important to prevent food fraudGlossary of terms used in this booklet5610101011131416Food fraud prevention processVulnerability assessmentMitigation measures– Raw material specifications– Analytical surveillance– Supplier relationship– Supplier audit– Supply chain transparency and simplificationAlert system16Frequently asked questions19Useful resources & tools1

Introduction and purposeof this bookletThe food industry considers the safetyof its products as its main concern. Overthe years, industry and regulators havedeveloped food safety managementsystems, making major outbreaks offood poisoning now quite unusual inmany countries. These systems typicallyuse Hazard Analysis Critical ControlPoint (HACCP) principles, which areaccepted globally. HACCP has provento be effective against accidentalcontamination.What is food fraudNo process can guarantee that foodand food supply are not the target ofcriminal activity. The purpose of thisbooklet is to guide food operatorsthrough approaches and processes toimprove the resilience of supply chainsto food fraud. It provides guidance onhow to assure the authenticity of foodby minimising vulnerability to fraud andmitigating the consequences of foodfraud.However, HACCP principles havenot been routinely used to detect ormitigate deliberate, fraudulent actionson a system or process. These actionsinclude the deliberate contamination offood, or food fraud.This booklet Describes a process for food fraudprevention and the principles of thevulnerability assessment; Outlines measures that can deterfraudsters, or give early detectionof food fraud; Provides sources of informationand intelligence that may help toidentify emerging threats.2Food fraud commonly encompassesa wide range of deliberate fraudulentacts. The focus of this booklethowever, is on one type of food fraud– the intentional and economicallymotivated adulteration of foods. Thisis the fraudulent addition of nonauthentic substances, or the removal orreplacement of authentic substanceswithout the purchaser’s knowledge, foreconomic gain of the seller.The two main types of economically-motivated adulteration are: Sale of food which is unfit andpotentially harmful, such as:– recycling of animal by-productsback into the food chain;– packing and selling of meat withunknown origin;– knowingly selling goods past their‘use by’ date. Deliberate mislabelling of food,such as:– products substituted witha cheaper alternative,e. g. farmed salmon sold as wild,or Basmati rice adulteratedwith cheaper varieties;– false statements about the sourceof ingredients, i.e. their geographic,plant or animal origin.This booklet does not address theother types of food fraud such ascounterfeiting (fraudulently passingoff inferior goods as established andreputable brands), product tampering,theft, smuggling, document fraud, andproduct diversions. Neither does it coverfood adulteration intended to causepublic health harm, economic harm, orterror (i.e. food defense issues).Food Safety Management SystemFood safetyFood defenseFood fraudMitigation ofunintentional/accidentaladulteration –Science basedMitigation ofintentionaladulteration –IdeologicallymotivatedMitigation ofintentionaladulteration –Economicallymotivated3

Why is it importantto prevent food fraudGlossary of termsused in this bookletFood fraud preventionprocessWhile it is not the intention of foodfraud to harm consumers, such actscan cause illness and even death. Thiswas the case in 2008 when melaminewas used as a nitrogen source tofraudulently increase the measuredprotein content of milk, resulting inmore than 50 000 babies hospitalisedand six deaths after having consumedcontaminated infant formula. Economically-motivatedadulteration (EMA): The intentionaladulteration of foods, motivated byeconomic gain. It is the type of fraudcovered in this booklet. Vulnerability assessment (orvulnerability characterisation):Within a food fraud managementsystem, the step aimed at reviewingand assessing various factors, whichcreate vulnerabilities in a supplychain (i.e. weak points where fraudhas greater chances to occur). Mitigation measure: Measuretaken to decrease vulnerability to acertain type of adulteration in a givensupply chain. Mitigation strategy: Selectedset of mitigation measures aimedat preventing food fraud in a givensupply chain. Food operator: Organisationcarrying out any of the activitiesrelated to processing, manufacture,packaging, storage, transportation,import, distribution of food, includingfood services and sale. Supplier: The party that is supplyingmaterials (raw or semi-finished), foodingredients or food products to otherparties (e.g. food operators) in thevalue chain. Buyer: The party that is buyingmaterials (raw or semi-finished), foodingredients or food products fromsuppliers.Like any management system, afood fraud management system is acontinuous process as depicted in thefigure below (from U.S. PharmacopeiaAppendix XVII: Food Fraud MitigationGuidance). It begins with an evaluationstep to characterise food fraudvulnerabilities, followed by the designand review of a mitigation strategy, andits tartVulnerabilitiescharacterizationDetermine ifdraft abilitiesor systemin placeleabptceacotNEconomically-motivated adulterationdeprives the consumers of the qualityproducts they intend to purchase. It canalso have serious implications on foodsafety and the health of consumers. Theprevention of food fraud is paramount toprotect the trust of our consumers andto maintain fair, sustainable businesspractices.Food Fraud Management SystemAcceThe common factor in many casesof food fraud, is that the adulterant isneither a food safety hazard, nor readilyidentified (as this would defeat the aimof the fraudster). Common adulterantsinclude water and sugar, or ingredientsthat may be legitimately used anddeclared, but whose improper useconstitutes fraud. Food fraud deceivesthe consumers by providing them withlower quality foodstuff, against theirknowledge and will.Periodically, or as changes occur thatmay impact the previously identifiedvulnerabilities (e.g. a newly identifiedadulterant for an ingredient is reported,changes in the supply chain for aningredient), the entire process must becarried out again to ensure its continuedeffectiveness.Draft ofmitigationstrategy5

Vulnerability assessmentA general approach to prevent foodfraud can be summarised as follows: Conduct vulnerability assessment,including:– Know your materials andrisks (history, economic factors,geographical origins, physicalstate, emerging issues);– Know your suppliers(manufacturer, broker, history);– Know your supply chain (length,complexity, supply & demandarrangements, ease of access);– Know your existing controlmeasures. Design mitigation strategy andimplement mitigation measures. Validate and verify mitigationmeasures, continually review foodfraud management system.To characterise the vulnerability of aningredient to food fraud, the following3 aspects must be assessed:Vulnerability driven by factorsinherent to the ingredientFactors such as the ingredient marketprice, its fraud history, composition,physical state and level of processingare entirely independent of the actionstaken by the buyer to mitigate the riskof fraud. This is defined as the inherentvulnerability of a food ingredient.Certain ingredients are by naturemore vulnerable to adulteration (e.g.apple juices or apple purees are morevulnerable than apple pieces).Fraud history (past cases of adulterationof specific raw materials) is a goodsource of information. It is anindicator of the raw material potentialvulnerability, and an important source ofpossible adulterants for which detectionand deterrence are needed.50/kg100/kgVulnerability driven by factorsimpacting the business (businesspressure)Factors such as the demand for aspecific ingredient (volume), the extentof its use (ingredient used in severalproducts and businesses), or the marketprice fluctuation may contribute to anincreased level of vulnerability to fraud.If the price of a valuable food is too good to be true, it probably is67

Any anomaly in the economics ofparticular raw material sources is anindicator of the raw material potentialvulnerability. Drastic increases in marketprice and scarce supplies of a rawmaterial (e.g. poor harvest following badweather, or caused by a new parasite)are good indicators of increasedraw material vulnerability based oneconomic anomalies.Geopolitical considerations are alsoimportant to characterise vulnerability tofood fraud. A country-specific low pricecompared with the rest of the marketmay indicate a lack of food controland/or regulatory/enforcementframework in the country of origin (orany other country through which theingredient may transit).Vulnerability driven by factorsunder the control of the buyerThis reflects the strength, or theweakness of a company’s mitigationstrategy (full traceability, adequatepurchasing specifications, availabilityof analytical methods, robustness ofsurveillance programmes).Adequate mitigation measures alleviate vulnerability to food fraudIn summary, assessing the risk offraud for a food ingredient requiresthe understanding of the inherent rawmaterial vulnerabilities, the businessvulnerabilities, and the existing controlsin place. This will allow to define whichpreventive actions are needed (andwhere) to mitigate the risk of foodadulteration.It is important to note that such avulnerability assessment is not a onetime activity but a dynamic process,which needs to be maintained withregards to new information and externalpressures (e.g. economic anomalies,bad harvest year).Self-assessmentRecent food fraud crises havehighlighted the need to reinforcecompanies’ ability to combat fraud– within their own organisation, andacross the entire food value chain.Companies are expected to workproactively towards mitigating the riskof food fraud.Guidance and self-assessment toolshave been developed by a number oforganisations (e.g. US Pharmacopeia,SSAFE, BRC) to help food companiesundertake their own vulnerabilityassessments and implementappropriate control plans (see sectionUseful resources & tools).Inherent vulnerabilitiesRaw materialPast and potentialcomposition andraw materialprocessingadulterationBusiness pressureMarket priceMarket pricefluctuationRaw material demand/business needYour control and mitigationmeasuresLevel ofverificationsTraceabilityAdequacy ofraw materialspecificationsAvailability ofmethodsVulnerability assessement89

Mitigation measuresRaw material specificationsAnalytical surveillanceSupplier relationshipAdequacy of raw material specificationsis an important preventive aspectagainst food fraud. Specificationsestablished for raw materials, which areused in the purchase of these materials,must include appropriate authenticitycriteria to mitigate – as much aspossible – the inherent vulnerabilitiesidentified in the self-assessment. Forexample, UV absorbance is specified todetect the potential adulteration of extravirgin olive oil with refined oils.Once the adulteration risks have beencharacterised for a given raw material,and a set of analytical control criteriadefined – a surveillance plan shouldbe established. The surveillance planallows to build confidence in thecompany’s suppliers, gain reassuranceon the company’s raw material supply,and confirm that the preventionmeasures in place are adequate orin contrast, the surveillance plan mayallow the detection of food fraud issues.As a starting point, processes mustbe in place to approve the suppliers’production sites, with requirements forapproval based on risk (e.g. raw materialrisk, location of food safety controlmeasures, supplier performance). Oncesuppliers have been qualified accordingto a robust approval process, therelationship between buyer and supplieris critical to support any adulterationprevention effort.Specification criteria linked to food fraudprevention must be thoroughly defined,in line with the level of complexityand variability of the ingredient’scomposition.Raw material monitoring shouldbe performed using appropriateanalytical methods for the verificationof authenticity. The methods must beselective, specific, and of appropriatesensitivity to verify that the foodauthenticity process is efficient. Thereare 2 approaches: Targeted analyses (linked toparameters specified in raw materialspecifications); Untargeted techniques (fingerprinting) that assess the raw materialintegrity against adulteration.When a specific parameter needs to bemeasured to control the raw materialauthenticity, particular attention mustbe given to using analytical methodsthat are fit-for-purpose (i.e. adaptedfor the natural variability in the rawmaterial).10The closer the relationship, the moreknowledge and confidence will beshared between each party. Askyourself: How well do you know yoursuppliers (e.g. how long have youbeen dealing with them and what istheir track record like, what is theirbusiness situation and are they underany financial stress)? How can you learnmore about them (e.g. partnerships,supplier schemes)?Confidence is increased with asupplier’s readiness to share informationon their supply chain and processes.This is why the development of trustedsuppliers (rather than continuousrotation) is important in mitigatingthe risk of food fraud. The closer therelationship, the lower the risk. Trusted supplier: Long-standingpartnership-type arrangement.High degree of confidenceestablished through long positivebusiness relationship, high degreeof transparency, and/or testingprogrammes. Sharing of keyinformation and expectations.Understanding of key needs andcontrols in both the buyer andsupplier processes. Trusted supplier, new ingredient:Similar to “Trusted Supplier”, exceptthe buyer only recently beganpurchasing a particular ingredientfrom the supplier. High degree ofconfidence established throughpurchase of other ingredients. Established supplier, somerelationship: Short history ofbusiness with the supplier, who iswell respected in their market witha solid reputation, and no significantissues reported. Established supplier,no relationship: Supplier respectedin their market with a solid reputation.A business relationship and historyhas not yet been established. Unestablished supplier,no relationship: Often a newsupplier, with whom the buyer hasno history or any general industryknowledge of the supplier. Thesupplier may be new to a givenindustry.11

Supplier auditIn response to food fraud issuesreported in recent years, a numberof requirements have been added tofood safety schemes in order to minimisethe risk of operating sites purchasingfraudulent, or adulterated raw materials.One example (from BRC Issue 7, 2015):– Processes in place to accessinformation on historical and developingthreats to the supply chain, which maypresent a risk of adulteration or substitutionof raw materials. Such information maycome from trade associations, governmentsources, private resource centres.– Documented vulnerability assessmentcarried out on all food raw materials orgroups of raw materials to assess thepotential risk of adulteration or substitution(this assessment shall take into accounthistorical evidence of substitution oradulteration, economic factors which maymake adulteration or substitution moreattractive, ease of access to raw materialsthrough the supply chain, sophisticationof routine testing to identify adulterants,nature of the raw material). The vulnerabilityassessment shall be reviewed to reflectchanging economic circumstances andmarket intelligence, which may alter thepotential risk. It shall be formally reviewedannually.– Where products are labelled or claimsare made on finished packs which aredependent on the status of a raw material– including specific origin, breed/varietalclaims, assured status (e.g. GlobalGAP),genetically modified organism (GMO)status, identity preserved, specifictrademarked ingredients – the status ofeach batch of the raw material shall beverified.– The facility shall maintain purchasingrecords, traceability of raw materialusage and final product packingrecords to substantiate claims. The siteshall undertake documented mass balancetests (e.g. every 6 months in the absence ofa scheme-specific requirement).– Where claims are made about themethods of production (e.g. organic,Halal, Kosher) the site shall maintain thenecessary certification status in orderto make such a claim.– Where raw materials are identified asbeing at particular risk of adulterationor substitution, appropriate assurance and/or testing processes shall be in place toreduce the risk (e.g. auditor to review thehistorical test results of materials identifiedat risk of adulteration).The facility shall maintain purchasing records and the traceability of raw material usage1213

More targeted examination may becarried out by auditors during auditsat a specific raw material production/handling site. For example on a meatproduction site – auditors may detectthe presence of unapproved flavours,dyes or preservatives in the productionand/or storage areas. On a poultryproduction site – auditors may lookfor the presence of equipment used toinject brine.Supply chain transparencyand simplificationA streamlined upstream supply chainimproves transparency, traceability, andthe management of material safety andquality standards. It also gives feweropportunities for fraudsters to penetrateyour supply chain.The first step towards supply chaintransparency is to ask yourself: Do youhave full visibility of your supply chain?Who are your immediate suppliers?Who supplies them? Are you changinga supplier or process?Supply chain simplification will requirethat you:– Map your supply chain;– Gather information from suppliers toidentify those who are most at risk(e.g. via questionnaire and supplierassurance and audit processes), andusing expertise from both withinyour organisation and outside (e.g.your trade association) to gather therelevant information;– Simplify your supply chain as much aspossible to eliminate sources of risk.How well do you know your suppliers?1415

Alert systemFrequently asked questionsIt is essential to maintain a routine watchof official and industry publications,which give an early warning of changesthat may trigger new threats, or changethe priority of existing threats, includingmore local issues as they develop (e.g.climate impact on certain crop yield andsubsequent fraud).Question: What is economicallymotivated adulteration (EMA)?EMA is the intentional sale of substandard food products or ingredientsfor the purpose of economic gain.Common types of EMA includesubstitution or dilution of an authenticingredient with a cheaper product(such as replacing extra virgin olive oilwith a cheaper oil), flavour or colourenhancement using illicit or unapprovedsubstances (such as unapproved dyes),and substitution of one species withanother (such as fish species fraud).Conversely, it is of paramountimportance to trigger an alert when afraudulent material is detected. Alertyour business partners to prevent theadulterated material from reaching otherparts of the value chain. Report the caseto the competent local authorities and/or national food crime unit for furtherinvestigation.Is EMA the same as “food fraud”?EMA is often referred to as “foodfraud”. The two terms are usedinterchangeably.Is EMA the same as contamination?Whereas EMA is intentional andperpetrated for the sake of economicgain, contamination of a food productor ingredient can be accidental,environmental, or malicious (i.e. not foreconomic gain).What foods are affected by EMA?Many foods are susceptible to EMA.These include meat, fish and seafood,dairy products, fruit juices, oils, honey,spices and wine. EMA is not a newconcern, although there seems tohave been an increase in incidentsover the recent years. This is partlydue to increased media coverage and,perhaps, increased surveillance in16certain food products. The number ofdocumented incidents is most likely afraction of the true number of incidents,since the goal of EMA perpetrators is toavoid detection.What is Nestlé doing to preventfood fraud?Nestlé has established a process forprevention and mitigation of EMA, whichincludes a vulnerability assessment step(per raw material category), the definitionof mitigation measures, and thecontinual review of both the vulnerabilityassessment and the efficiency ofmitigation measures. Nestlé also driveslonger-term initiatives (e.g. developmentof non-targeted analytical methods,development of collaborative toolsacross the industry and with authoritiesto create transparency across the foodvalue chain).What should I do when I detect anadulterated material?Assess the impact of the deviation(food safety, regulatory, impactedproducts) with the support of expertswhenever needed. Take action basedon the outcome of the assessment(e.g. block raw material and/or finishedproduct stock, destroy stock, recallproducts). You should then conducta full traceability exercise to identifythe source of the adulterated material,and have an investigation initiated. Youshould alert your business partners(customers, distributors, companies– including competitors – operating inyour business) to prevent the fraudulentmaterial from reaching other parts of thevalue chain. Finally, you should reportthe case to competent authorities.What should I do when I identifya new adulteration risk?You should include this new risk inyour vulnerability assessment for theconcerned raw material category, thendefine measures that could mitigatethis particular risk, and continue tomonitor this risk (e.g. through analyticalsurveillance plans) to ensure that yourmitigation measures are effective toprevent occurrence of this issue in yoursupply chain.What should food operators andsuppliers do about food fraud?To prevent food fraud and better ensurefood safety and consumer protection,food operators, their suppliers andall partners along the food valuechain (including industry associationsand authorities) should consider thefollowing:– Conduct vulnerability assessments intheir supply chains;– Implement (and verify) mitigationmeasures accordingly;– Develop collaborative tools acrossthe industry and with authorities tocreate transparency across the foodvalue chain.17

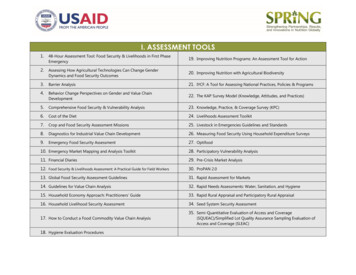

Useful resources & toolsWhat should consumers knowabout food fraud when purchasingfood?There are certain things consumerscan do to help protect themselves fromfood fraud. If the price of a valuablefood product is too good to be true, itprobably is. Whole, unprocessed foods(such as unground coffee and spices,or whole fruits instead of juice) aremore difficult to adulterate, thereforebuying these foods may offer somereassurance with regards to fraud. Asfor processed foods, it is a good idea tobuy from reputable sources and brandsthat have a vested interest in protectingtheir reputation. When fraud incidentsare discovered, they can result in largeprofit losses and reputation damagefor companies. Therefore, companieswith brand recognition will actively takesteps to protect their products. Sometrade associations also certify productsthrough quality and purity assurancetesting programmes, such as theNorth American Olive Oil AssociationSeal Program (http://www.naooa.org/sealprogram).Does EMA cause harm to health?The good news is that most incidentsof EMA do not result in public healthharm. Unfortunately, perpetratorssometimes make mistakes resultingin unintended health consequences.In 2008 for example, some companiesin China were found to be adulterating18milk supplies with a chemical calledmelamine, because it artificiallyincreased the apparent protein content.Melamine-adulterated milk was usedin the manufacture of infant formula,which led to the hospitalisation of morethan 50 000 Chinese infants, and thedeaths of at least six. In 1981, industrialgrade oil adulterated with multiplechemicals was sold as olive oil in Spain,and resulted in more than 300 deaths.Does EMA only affect humans?What about pets?Since the food supply chains for humans,pets and production animals areinterconnected, EMA in food productscan affect both humans and animals.In 2007, an EMA incident involvingadulterated wheat gluten used in petfood caused illnesses and death inthousands of dogs and cats in the USA.Are government regulatoryagencies concerned about EMA?In the USA, the US FDA (FDA.gov),USDA (USDA.gov), and DHS (DHS.gov)are working to protect the food supplyfrom EMA and other food safety risks. Inthe European Union, the food industryand regulators are working towardsan enhanced management frameworkto prevent food fraud, with guidanceavailable from e.g. the UK FoodStandards Agency. Other governmentagencies provide useful resources (seesection Useful resources & tools).Guidance documents– U.S. Pharmacopeia Appendix xvii:Food fraud mitigation guidancehttp://www.usp.org/sites/default/files/usp pdf/EN/fcc/food-fraud-mitigation-guidance.pdf– BRC Global Standard for Food Safety Issue 7Understanding Vulnerability � UK Food and Drink Federation (FDF)http://www.fdf.org.uk/corporate pubs/FoodAuthenticity-guide-2014.pdf– TACCP (Threat Assessment and CriticalControl Point): a practical guide 2014(Campden BRI) s.php?pubsID 4640Self-assessment tools– SSAFE Food Fraud Assessment Toolhttps://ffv.pwc.com; www.ssafe-food.org– US Food and Drug Administration (FDA)Vulnerability Assessment ducationalMaterials/ucm295900.htmAlerts & Databases– US Food and Drug Administration (FDA)Recalls and Enforcement tm– US Food and Drug Administration (FDA)Import Alerts and am/default.htmOnline tool compiling information on importrefusalshttp://www.imprex.us– US Food and Drug Administration (FDA)Enforcement and Criminal Investigationshttp://www.fda.gov/ICECI/– US Food and Drug Administration (FDA)Food Defensehttp://www.fda.gov/Food/FoodDefense– US Pharmacopeial ConventionFood fraud database; http://www.foodfraud.org/– Canada Recalls and t-rappel-avis/index-eng.php– European Union Rapid Alert /index en.htm– UK Food Standards Agency odfraud/– UK Serious Fraud Officehttp://www.sfo.gov.uk– Australia and New veillance/Pages/default.aspx– The Department of Food Safety, Govtof N.C.T of CompleteListFoodCategory.asp?SessNull 0– EMA Susceptibility Databasewww.FoodSHIELD.org (registration required)Standards– BS 10501, Guide to implementingprocurement fraud d 000000000030282473– BRC Global Standard Food Safety Issue ard-for-food-safety-issue-7-usfree-pdfSupply chain security– BS ISO 28000, Specification for securitymanagement systems for the supply chain– BS ISO 28002, Security management systemsfor the supply chain – Development ofresilience in the supply chain – Requirementswith guidance for use– PD CEN/TR 16412, Supply chain security(SCS) – Good practice guide for small andmedium sized operators19

Sources of informationand intelligence aboutemerging risks to food supply– Infosanhttp://www.who.int/foodsafety/areas work/infosan/en/– FAO Early Warning -warning-bulletin/en/– ther reading– Gfsi position on mitigating the public healthrisk of food fraud http://www.mygfsi.com/files/Technical Documents/Food FraudPosition Paper.pdf– Scottish Government and Food StandardsAgency Expert advisory group reportthe lessons to be learned from the 2013horsemeat incident; 7268.pdf– Centre for the Protection of NationalInfrastructure Holistic managementof employment risk (HoMER). London: CPNI,2012. homer/– US Michigan State Universityhttp://foodfraud.msu.edu/

2016, Nestec Ltd., Vevey (Switzerland)ConceptNestec Ltd., CO – Quality Management, Vevey (Switzerland)DesignNestec Ltd., Corporate Identity & Designwith Christian Stuker, 1097 Riex (Switzerland)Productionbrain’print GmbH (Switzerland)

use Hazard Analysis Critical Control Point (HACCP) principles, which are accepted globally. HACCP has proven to be effective against accidental contamination. However, HACCP principles have not been routinely used to detect or mitigate deliberate, fraudulent actions on a system or proce

![[] 9 IA NCLUDING R THE R OF F](/img/1/modern-auditing-chapter09.jpg)