Transcription

LEAN FOOD &BEVERAGE (F&B)www.fourprinciples.com

BACKGROUNDModern life is frenetic, more and more people grab a quick bite during their lunch break and are too tiredto cook at the end of a working day, preferring to order food from home delivery services or dining at arestaurant. Food & Beverage (F&B) industry produces more than 100 million meals per day across theworld, people from developed countries spend on average 4% to 7% of their income in Food & Beverage(F&B), representing an attractive market. However, competition is strong and companies need todifferentiate and/or follow the latest trends (e.g. organic food, vegan food, regional cuisine, “home made”cooking etc) while keeping the standards high both in terms of quality of products and speed of service atthe right price.The whole Food & Beverage (F&B) process, from conceptualisation to making and delivery, can benefit fromthe practices of Lean Management in order to build sustainable and profitable businesses. Lean Principlescan be applied to all sizes of business, from small stand-alone restaurants to big chains with integratedlogistics and central processes or industries supplying catered food.Copyright 2017 Four Principles Management Consulting FZ-LLC1

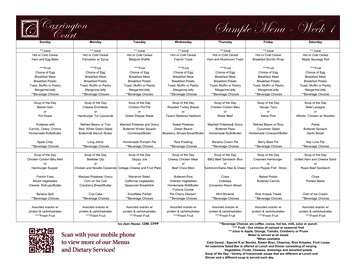

CHALLENGESTHE MAIN CHALLENGE IS TO ACHIEVE CUSTOMER SATISFACTION. THISREQUIRES FIRST UNDERSTANDING THE CUSTOMER’S NEEDS, SUCH AS:ECONOMICThe need for good value for the price paid.SOCIALFor example, a friendly atmosphere, a luxuriousenvironment or an ethnic experience.PHYSIOLOGICALThe need of special food items or to enhanceself-esteem and social status perception.CONVENIENCEThe desire for someone else to do the work.ONCE THE NEEDS OF THE TARGETED CUSTOMERS ARE CLEAR, THE NEXTCHALLENGE IS TO PROPOSE THE RIGHT TYPE OF SERVICE. THE SERVICE OFFOOD & BEVERAGE (F&B) MAY BE CARRIED OUT IN MANY WAYS DEPENDING ONA NUMBER OF FACTORS: Establishment type i.e. fast food, fine dining,cook-it-yourself, etc. Menu type i.e. set meals, a la carte, valuecombinations, etc. Customer type i.e. health conscious,income level, etc. Meal cost Meal time i.e. grab & go, three hour,six course dinner, etc. Establishment site i.e. stand-alone, mall foodcourt, etc. Expected customer turnover i.e. number ofseating per table, take-away orders, homedelivery orders, average catering order size,etc.Copyright 2017 Four Principles Management Consulting FZ-LLC2

CHALLENGES - CONTINUEDIn each case it is crucial to produce food and beverage products that conform to quality standards deliveredthrough excellent service. A nice environment or polite waiters are not enough to overcome the negativeeffects of poor quality meals or long waiting times.HENCE THE FOCUS ON PRODUCT QUALITY AND SERVICE LEVELS:PRODUCT QUALITYthe challenge for managers is to definequality standards for each product. Then theymust supervise and evaluate to ensure thatstandards are met. Personnel must be trainedto follow standard operating procedures. Qualitystandards must be incorporated into productionactivities through standard recipe cards,purchase specifications, and proper tools andequipment to ensure freshness and consistencyof flavour (in the same restaurant and amongbranches of the same chain).SERVICE LEVELThe challenge for managers is to ensurethe speed and consistency of service whilecontaining costs and ensuring qualitystandards. Standard procedures must bedeveloped and personnel trained on them whileproper planning of materials, equipment andheadcount is essential to get orders or partsof them ready at the right time while reducingwaste, inventory and cost for personnel.OTHER CHALLENGES FOR MANAGERS IN FOOD & BEVERAGE (F&B) INCLUDE: Standardisation and consistent utilisation ofstandard cost control tools (standard recipes,standard portion sizes, etc.) Definition and constant measurement of theright key performance indicators Periodic updating of the menu at the rightfrequency to follow the latest trends whilemaximising profitability (i.e. product portfolioreviews) Sales and production tracking to determine howmuch revenue each menu item is generating(also part of product portfolio reviews) Availability of tools and equipment Food waste minimisation while balancing theright stock to enable proper service Ensuring proper storage (i.e. FIFO, expiry datevisible, minimum time out of storage whenbeing used etc.) and prompt discarding ofnear expiry / damaged items Resolution of production bottlenecks Management of layout, equipment design,and utilities usage Recruiting, training, scheduling and retentionof good quality personnel Maintenance of high health & safetystandards Training of personnel to consistently complywith food production proceduresCopyright 2017 Four Principles Management Consulting FZ-LLC3

FOCUS AREASLean always starts with focusing on your customers’ needs to effectively improve quality and leadtimes. Whether your business operates in catering or as a restaurant chain (either slow food or fastfood), customer satisfaction drives your sales and improves your production, which in turn leads toimproved quality, faster service, cost savings and more flexibility. We use a holistic approach that appliesLean principles to improve your entire production & logistic systems and not just individual processsteps. Involving all departments with a joint goal of reducing waste can produce and sustain long-termimprovements.AREAS OF WASTE OFTEN IDENTIFIED IN FOOD & BEVERAGE (F&B) ENVIRONMENT:RE-WORK / DEFECTSWrong cooking time / technique, poor qualityof materials used, lack of cleanliness drivedown product quality while poor applicationof standard recipes and poor training drive upinconsistency of taste. Both of which have theeffect of increasing returns from customers.WAITING TIMEKitchen operations might be delayed by alate delivery from the central food warehouse/ central kitchen or from suppliers therebyincreasing lead times to prepare meals andhence increasing customer waiting times.Kitchen operations may also delay one anotherwhen not synchronised, for example part of adish might be ready and losing freshness whilewaiting for other components of the same dish tobe ready and/or assembled. Lack of availabilityof seating space for dine-in customers results incustomers having to wait and eventually givingup and going somewhere else to eat, also homedelivery customers may have to wait due toinefficient central ordering systems or inefficientdelivery services due to poor delivery area/routeplanning or driver utilisation.INVENTORYFood related products are affected by a shortaverage shelf life, therefore it is important toset inventories at the right level to preservefreshness, optimise the utilisation of storage(cold, room temperature and heated) andreduce waste. While on the other handinventories should not be too low that thebranch is unable to fulfil orders early in the daywhere then customers cannot order their firstchoice item so they would either have to ordersomething else or, worse still, go somewhereelse to eat, resulting in a lost sale.SPACEAn inefficient utilisation of space in the kitchenincreases transportation, movement andrental cost. Dine-in table size and layout arenot aligned with average customers group sizethus limiting space utilisation and causingcustomers to leave due to lack of seatingavailability.Copyright 2017 Four Principles Management Consulting FZ-LLC4

FOCUS ARES - CONTINUEDTRANSPORTPoorly scheduled deliveries from centralkitchen to branches. Home delivery vanplanograms badly designed, if designed at all,providing inadequate separators between dry,heated and chilled areas.OVER-PRODUCTIONThis occurs when planning and forecasting arenot aligned with customer demand and whenlong lead times force kitchen staff to produceahead of customer demand (“push” production).Over-production drives up most of the abovetypes of waste.UNUSED SKILLSHigh specialisation of roles in modern kitchensdrives down efficiency by limiting flexibility ofkitchen staff to switch roles.MOVEMENTExcess movement slows down operators andincreases their fatigue driving down theirattention level and performances thus affectingservice to customers. Also, excess movement ina kitchen increases the chances for accidentsto happen, resulting in the need to washtools again in best case accident scenarios,to scrapping dropped food, to the worst-casesituations where staff get physically harmedthrough cuts or burns.Copyright 2017 Four Principles Management Consulting FZ-LLC5

LEAN SOLUTIONSThe application of Lean in Food & Beverage (F&B) begins with looking at the operations from an industrialpoint of view in that cooking, delivering, purchasing, servicing dine-in etc. are all operations for processinga product or a service for a customer, be it internal - for example, a different function within the samecompany as in the case of a central kitchen - or external, as in the case of a restaurant customer. Theapplication of Lean principles to these processes provides faster service and better quality at a lower cost,thus driving up sales and increasing profit.LEAN FOOD & BEVERAGE (F&B) CAN BE APPLIED TO MANY AREAS, SUCH AS:KITCHENConnecting processes to increase speedof delivery improves product freshness.Introducing pull to efficiently produce only whatcustomers want and removing processes thatcan be centralised result in a faster serviceusually achieved with a reduced headcount.The combined effect of such improvementsincreases customer satisfaction and loyalty.DINE-INHospitality services leverage on the improvedkitchen services by leaning the process ofdelivering a ready meal to the customer’s tablethus reducing their waiting time while improvingproduct freshness. An increased service capacityenables the review of the seating configurationwhich can increase seating availability andtherefore reduce customers’ waiting time and inparallel increase sales.HOME DELIVERYDelivery services leverage on improvedkitchen services by reviewing delivery routesto optimise them and by triggering productionof products delivered through the same routeto be ready at the same time to improve theirfreshness. Delivery routes can be designedand scheduled according to customer Takt inorder to increase delivery van utilisation. Also,many reasons that tie up the delivery men atthe branch can be reduced so that the deliverymen can spend more time delivering (henceincreasing the capacity of deliveries using thesame number of delivery men).CENTRAL KITCHENSemi-finished goods and all products witha longer shelf life should be prepared in acentralised facility which operates like afactory. “Central kitchens” are managed withthe application of the Lean principles: volumesand types of products to be pulled by branches’orders, then production is scheduled “onepiece-flow” according to the branches’ Taktand delivered with zero defects. This results inincreased service levels to the branches andthe elimination of over production, waste andstock-outs.Copyright 2017 Four Principles Management Consulting FZ-LLC6

TANGIBLEIMPROVEMENTSLEAD TIMECOSTS Take away customers’ waiting time from anaverage of above 20 minutes to an average ofbelow 2 minutes (-90%) and peak waiting timefor take away customers dropped more than 80%by introducing “just-in-time” 15% to 20% headcount reduction per branch byimplementing a new vacation plan Dine in order distribution layout improvementsleveraged on kitchen improvements reducingdelivery to customer time by 63% Home delivery preparation time from 31 minutes to16 minutes (-48%) Dine-in layout optimised to accommodate for theright group size of customers, thereby increasingcapacity by 34.5% and consequently the sales bysquare metre ( 14%, measured 2 months afterimplementation) Up to 70% of the water used for rice washing savedwithin the process or recycled to other processesQUALITY Central kitchen delivery-to-branch vans re-scheduledto operate according to the value stream mappingmodel saving 15% of the vans Risk of cross contamination in the branches’ kitchenand in the Central Kitchen eliminated by separatingflow of raw and cooked products Work in progress inventory reduced by 60% byimplementing a Kanban pull system Freshness of products increased by implementingstorage standards, speeding up lead times andpulling materials from storage just in time Hygiene and safety improved thanks to theintroduction of sanitising stations and standardproceduresCopyright 2017 Four Principles Management Consulting FZ-LLC77

Should you be interested to know more about our Lean servicesregarding this topic, then please contact us:Tel 971 4 368 2124Emailinfo@fourprinciples.comDubai, UAE Office AddressDubai Media CityBuilding 8Office 212P.O. Box 502621Dubai, UAECopyright 2017 Four Principles Management Consulting FZ-LLC8

the practices of Lean Management in order to build sustainable and profitable businesses. Lean Principles can be applied to all sizes of business, from small stand-alone restaurants to big chains with integrated logistics an